- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Packaging Materials презентация

Содержание

- 1. Packaging Materials

- 2. Packaging Materials Cans Glass Containers Rigid plastic

- 3. Cans Advantages: Cheap & widely used in

- 4. Cans Aluminium Cans

- 5. Cans Steel Cans

- 6. Cans Cans that have bulges or dents

- 7. Glass Containers Characteristics: Chemically inert - wont

- 8. Glass Containers Uses: Semi-liquid, liquid & solid

- 9. Paper & Cardboard Paper: Used for a

- 10. Paper & Cardboard

- 11. Paper & Cardboard

- 12. Paper & cardboard

- 13. Rigid Plastic Packaging Advantages: Lightweight & strong

- 14. Rigid Plastic Packaging

- 15. Rigid Plastic Packaging Types of plastic used:

- 16. Rigid Plastic Packaging

- 17. Flexible Plastic Packaging Any plastic that is

- 18. Flexible Plastic Packaging Plastics are made by

- 19. Extrusion

- 20. Flexible Plastic Packaging

- 21. Flexible Plastic Packaging Laminations (composite plastics): Combining

- 22. Flexible Plastic Packaging

- 23. Flexible Plastic packaging

- 24. Aluminium Foils Most foils made from aluminium

- 25. Laminations Aluminium foil joined with other materials

- 26. Tetra Pak

- 27. Others Combination Packages: 2 or more separate

Packaging Materials Cans Glass Containers Rigid plastic containers Flexible plastic packaging Paper & board Aluminium foil & laminates Styrofoam

Слайд 2Packaging Materials

Cans

Glass Containers

Rigid plastic containers

Flexible plastic packaging

Paper & board

Aluminium foil

& laminates

Styrofoam

Styrofoam

Слайд 3Cans

Advantages:

Cheap & widely used in Australia

Provides good protection of the contents

Easy

to handle during manufacture (filling stacking & packing)

Stack easily on supermarket shelves

Store for long periods of time

Steel cans:

coated in tin which acts as a barrier and prevents the food reacting with the steel.

Cans containing acidic ingredients are coated with a plastic lacquer to prevent a reaction with the metal

Used for solid & semi-solid foods.

Aluminium cans:

used for soft drinks & beer

Stack easily on supermarket shelves

Store for long periods of time

Steel cans:

coated in tin which acts as a barrier and prevents the food reacting with the steel.

Cans containing acidic ingredients are coated with a plastic lacquer to prevent a reaction with the metal

Used for solid & semi-solid foods.

Aluminium cans:

used for soft drinks & beer

Слайд 6Cans

Cans that have bulges or dents

Air may have entered so there

is a risk of microbial contamination

Lacquer may be damaged & food may have reacted with the metal Canned food do not have a use-by date as they are required only on foods with a shelf life less than 2 years

Canned food do not have a use-by date as they are only required on foods that have a shelf life of less than 2 years

Lacquer may be damaged & food may have reacted with the metal Canned food do not have a use-by date as they are required only on foods with a shelf life less than 2 years

Canned food do not have a use-by date as they are only required on foods that have a shelf life of less than 2 years

Слайд 7Glass Containers

Characteristics:

Chemically inert - wont react with its contents

Non porous

Odourless &

hygienic

Contents can be seen as glass is transparent

Great strength (continually getting stronger & lighter)

Easy open & re-sealable

Variety of shapes & sizes

Long-term storage & extended shelf-life

Sustainable - can be recycled or re-used

Contents can be seen as glass is transparent

Great strength (continually getting stronger & lighter)

Easy open & re-sealable

Variety of shapes & sizes

Long-term storage & extended shelf-life

Sustainable - can be recycled or re-used

Слайд 8Glass Containers

Uses:

Semi-liquid, liquid & solid foods

Examples:

Preparation:

Air blowing, rinsing with warm water,

washing in detergent, sterilising (aseptic)

Слайд 9Paper & Cardboard

Paper:

Used for a wide variety of products

Versatile & cost

effective

Variety of shapes, textures & thickness' available

Greaseproof paper can be used when packaging products such as confectionary & butter. They act as a barrier to odours & moisture

Paperboard (thicker paper-based packaging)

Can be laminated with other materials to create strength & moisture resistance E.g. Tetra packs

Pulped Fibreboard

Offers protection for products such as eggs because of the airsplace between the particles

Refer to table 11.2 Pg 218

Variety of shapes, textures & thickness' available

Greaseproof paper can be used when packaging products such as confectionary & butter. They act as a barrier to odours & moisture

Paperboard (thicker paper-based packaging)

Can be laminated with other materials to create strength & moisture resistance E.g. Tetra packs

Pulped Fibreboard

Offers protection for products such as eggs because of the airsplace between the particles

Refer to table 11.2 Pg 218

Слайд 13Rigid Plastic Packaging

Advantages:

Lightweight & strong

High resistance to breakage

Available in a wide

variety of colours, shapes, sizes & textures

Can add to the sale appeal of the product

Cheap and easy to produce compared to other packaging materials

Can add to the sale appeal of the product

Cheap and easy to produce compared to other packaging materials

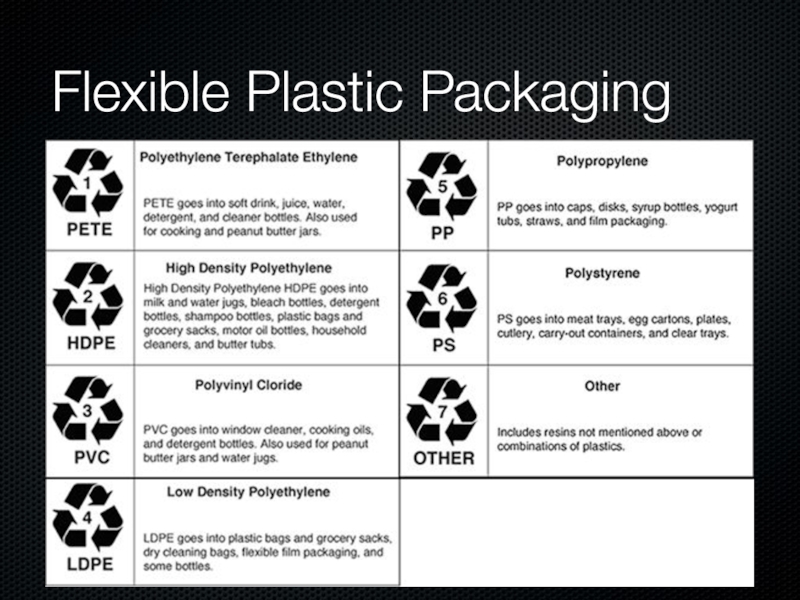

Слайд 15Rigid Plastic Packaging

Types of plastic used:

polyethylene terephalate (PET) - used clear

as colouring has an impact on the strength. E.g. soft drink, water & oil

high density polyethylene (HDPE) - stronger when colour is added. Used for products with a shorter shelf life E.g. milk

Polypropylene (PP) - high melting point so is useful for hot fill products such as soups & fruits in syrup. Can be moulded easily E.g. yoghurt & ice cream

Polystyrene (PS) - Aerated texture allows package to protect the product from physical damage. Also provide thermal retention E.g. trays & cups

high density polyethylene (HDPE) - stronger when colour is added. Used for products with a shorter shelf life E.g. milk

Polypropylene (PP) - high melting point so is useful for hot fill products such as soups & fruits in syrup. Can be moulded easily E.g. yoghurt & ice cream

Polystyrene (PS) - Aerated texture allows package to protect the product from physical damage. Also provide thermal retention E.g. trays & cups

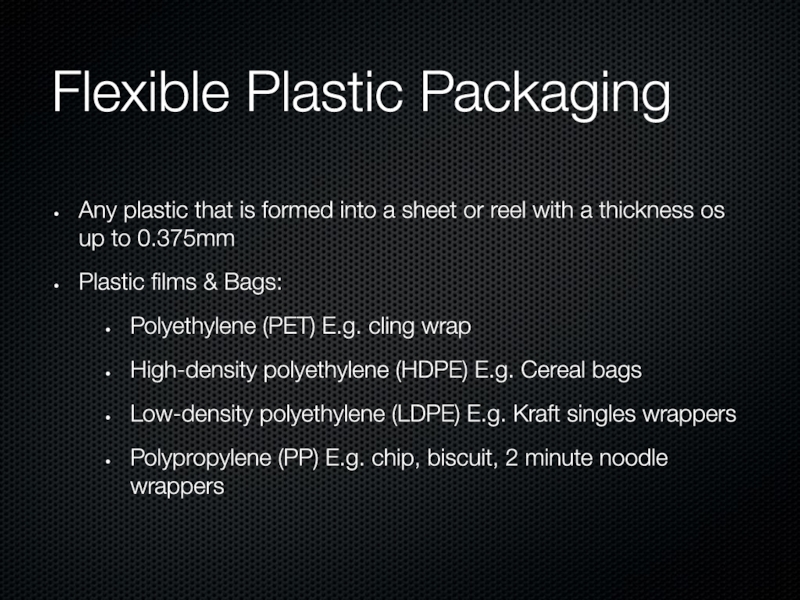

Слайд 17Flexible Plastic Packaging

Any plastic that is formed into a sheet or

reel with a thickness os up to 0.375mm

Plastic films & Bags:

Polyethylene (PET) E.g. cling wrap

High-density polyethylene (HDPE) E.g. Cereal bags

Low-density polyethylene (LDPE) E.g. Kraft singles wrappers

Polypropylene (PP) E.g. chip, biscuit, 2 minute noodle wrappers

Plastic films & Bags:

Polyethylene (PET) E.g. cling wrap

High-density polyethylene (HDPE) E.g. Cereal bags

Low-density polyethylene (LDPE) E.g. Kraft singles wrappers

Polypropylene (PP) E.g. chip, biscuit, 2 minute noodle wrappers

Слайд 18Flexible Plastic Packaging

Plastics are made by melting a pellet and forcing

it out into the desired shape. This process is known as EXTRUSION

Слайд 21Flexible Plastic Packaging

Laminations (composite plastics):

Combining 2 or more plastic materials from

separate reels that are glued together with adhesive

Plastics are extruded and glued together at the same time

MAP packaged and vacuum packages can use 3-11 layers

Plastics are extruded and glued together at the same time

MAP packaged and vacuum packages can use 3-11 layers

Слайд 24Aluminium Foils

Most foils made from aluminium

Advantages:

light

flexible

strong

Able to withstand moderate heat

Examples:

Tubes -

condensed milk

Trays - frozen foods

Product seals - sour cream, butter & yoghurt

Wrappers - Cadbury chocolate block

Trays - frozen foods

Product seals - sour cream, butter & yoghurt

Wrappers - Cadbury chocolate block

Слайд 25Laminations

Aluminium foil joined with other materials such as plastic and paper

to create a stronger packaging material.

Example:

Muesli bar wrapper (paper, foil & plastic)

Tetra Packs:

Multi-layered laminations known as composite packages

Each layer provides a different purpose

Metallising:

Plastic coated in a fine layer of metal. E.g. Twisties chip packets

Example:

Muesli bar wrapper (paper, foil & plastic)

Tetra Packs:

Multi-layered laminations known as composite packages

Each layer provides a different purpose

Metallising:

Plastic coated in a fine layer of metal. E.g. Twisties chip packets

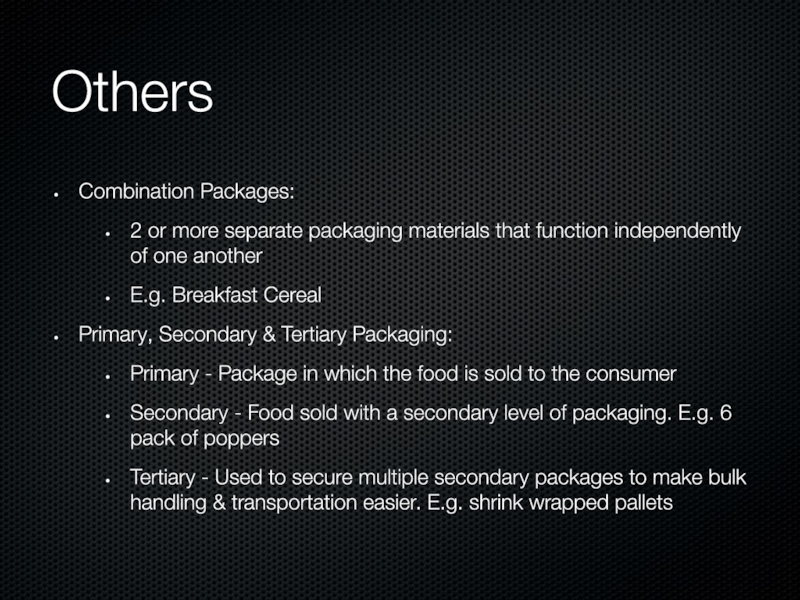

Слайд 27Others

Combination Packages:

2 or more separate packaging materials that function independently of

one another

E.g. Breakfast Cereal

Primary, Secondary & Tertiary Packaging:

Primary - Package in which the food is sold to the consumer

Secondary - Food sold with a secondary level of packaging. E.g. 6 pack of poppers

Tertiary - Used to secure multiple secondary packages to make bulk handling & transportation easier. E.g. shrink wrapped pallets

E.g. Breakfast Cereal

Primary, Secondary & Tertiary Packaging:

Primary - Package in which the food is sold to the consumer

Secondary - Food sold with a secondary level of packaging. E.g. 6 pack of poppers

Tertiary - Used to secure multiple secondary packages to make bulk handling & transportation easier. E.g. shrink wrapped pallets