- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

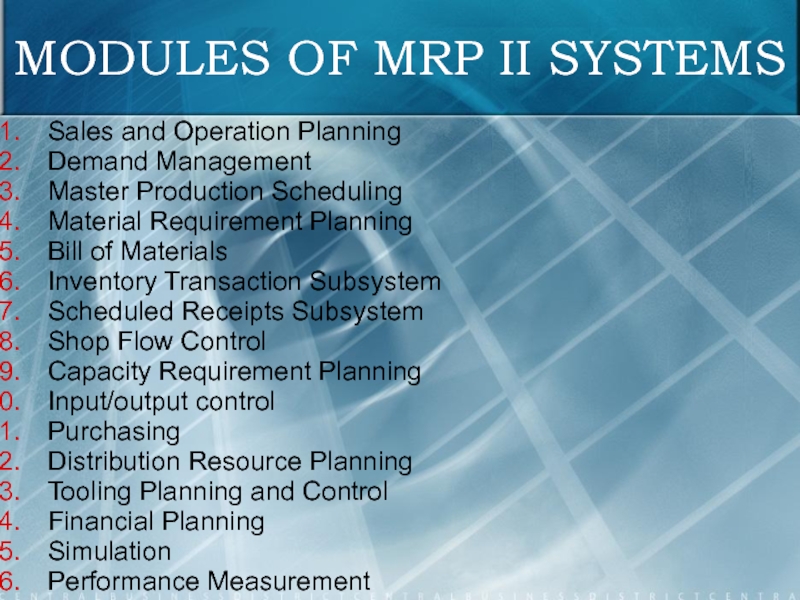

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Evolution of management and enterprise systems презентация

Содержание

- 1. Evolution of management and enterprise systems

- 2. 1776 Adam Smith published “The Wealth of

- 3. 1820s The railroad companies introduced bureaucracies to

- 4. EARLY XX CENTURY Taylor was a mechanical

- 5. SCIENTIFIC MANAGEMENT The main elements of the

- 6. SCIENTIFIC MANAGEMENT Taylor called these elements “merely

- 7. EARLY XX CENTURY Henry Gantt's legacy to production

- 8. EARLY XX CENTURY The Task And Bonus

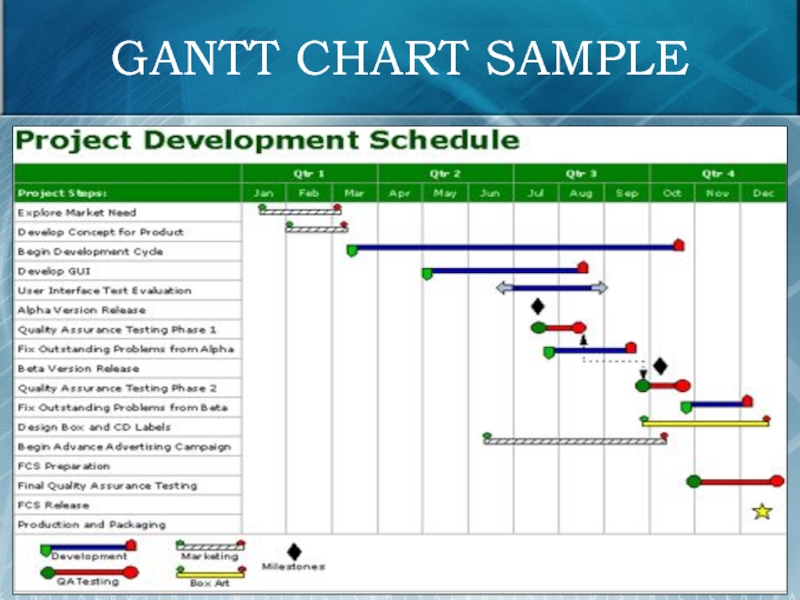

- 9. GANTT CHART SAMPLE

- 10. EARLY XX CENTURY Henry Ford introduced the

- 11. MIDDLE OF XX CENTURY Industrial engineering is a

- 12. MIDDLE OF XX CENTURY Operational research encompasses

- 13. 60S OF XX CENTURY

- 14. MAINFRAME OF 1960s

- 15. 1960s MATERIAL REQUIREMENTS PLANNING Material Requirements Planning

- 16. MATERIAL REQUIREMENTS PLANNING MRP systems provide answers

- 17. TRADITIONAL COMPONENTS OF MRP SYSTEMS the master

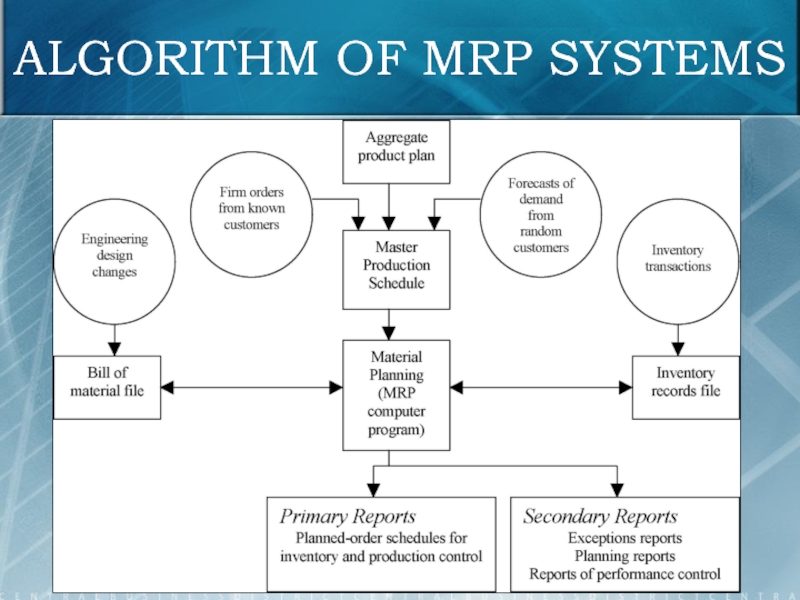

- 18. ALGORITHM OF MRP SYSTEMS

- 19. APPLYING OF MRP SYSTEMS MRP is being

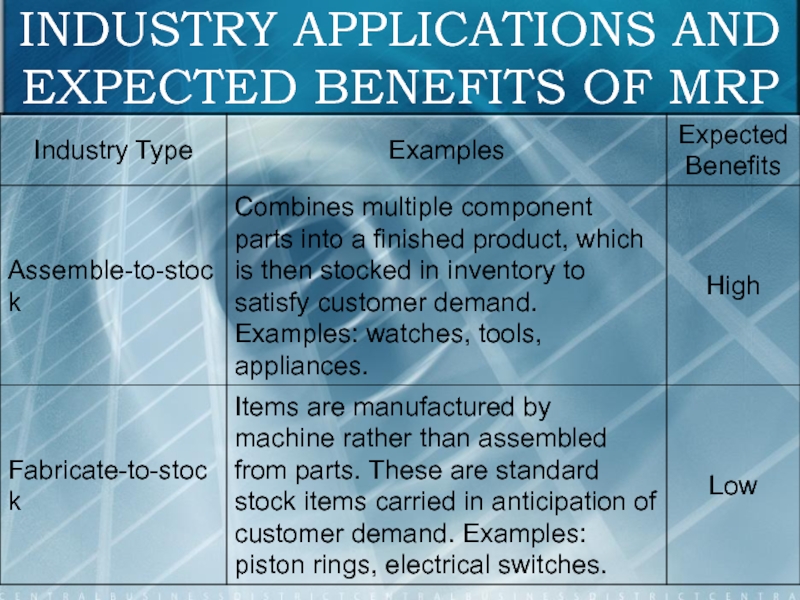

- 20. INDUSTRY APPLICATIONS AND EXPECTED BENEFITS OF MRP

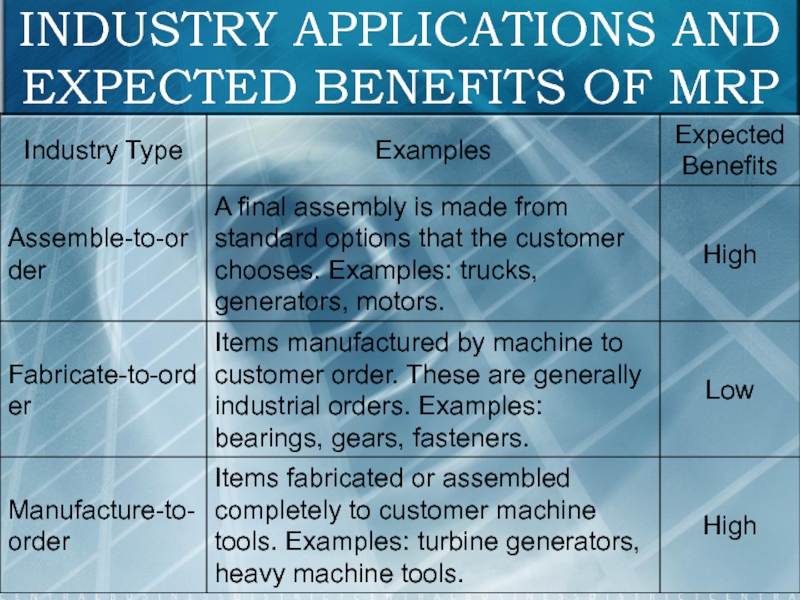

- 21. INDUSTRY APPLICATIONS AND EXPECTED BENEFITS OF MRP

- 22. INDUSTRY APPLICATIONS AND EXPECTED BENEFITS OF MRP

- 23. REQUARIMENTS FOR IMPLEMENTATION OF A MRP SYSTEM

- 24. REQUARIMENTS FOR IMPLEMENTATION OF A MRP SYSTEM

- 25. 1970s MANUFACTURING RESOURCE PLANNING Manufacturing Resource Planning

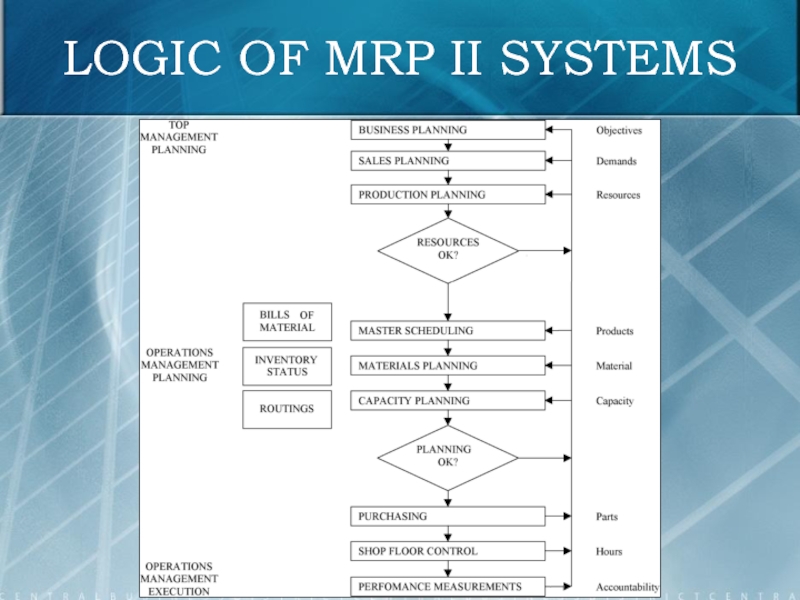

- 26. LOGIC OF MRP II SYSTEMS

- 27. Sales and Operation Planning Demand Management Master

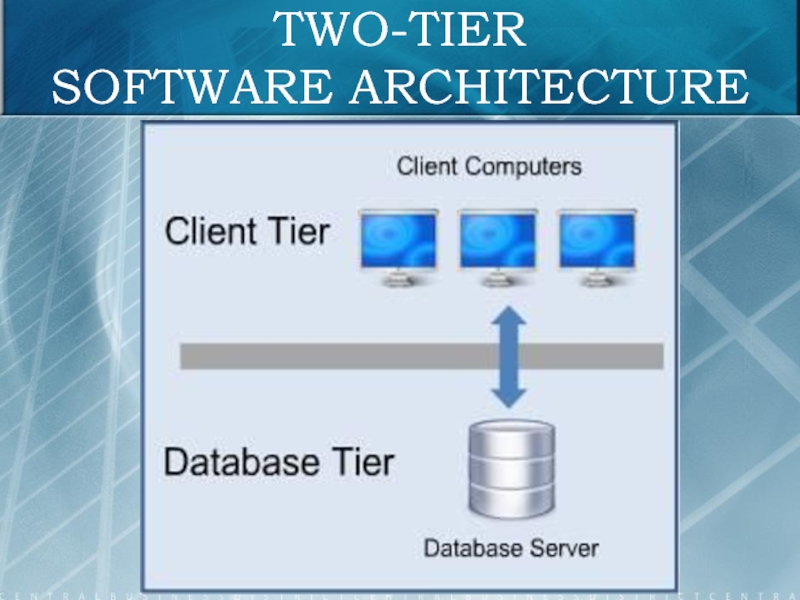

- 28. TWO-TIER SOFTWARE ARCHITECTURE

- 29. TERMINAL OF 1980s

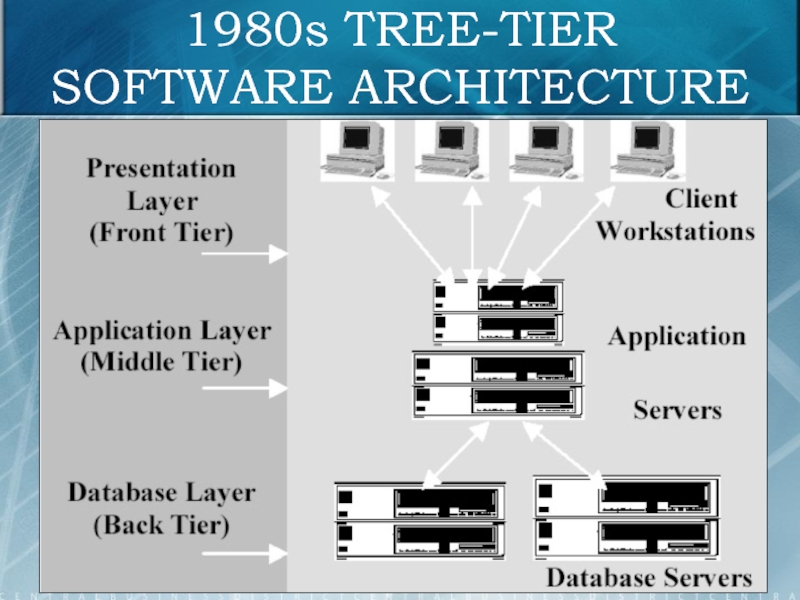

- 30. 1980s TREE-TIER SOFTWARE ARCHITECTURE

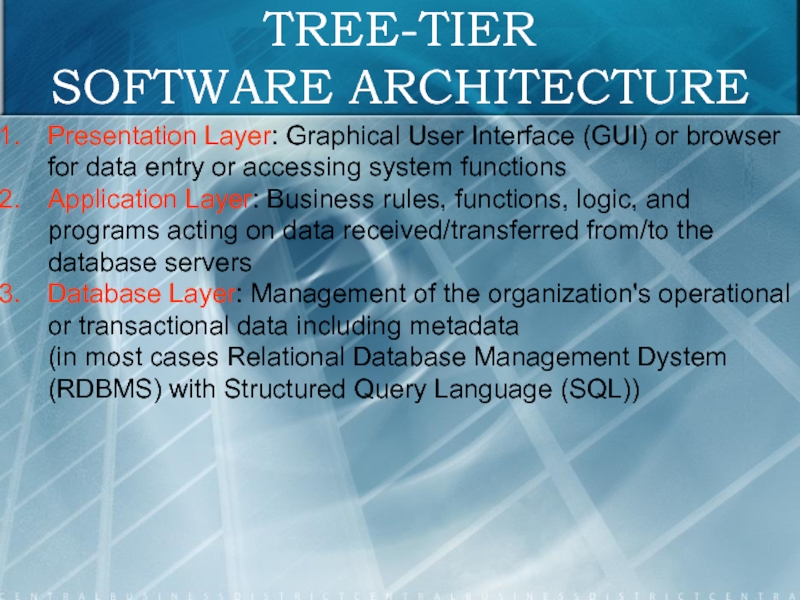

- 31. Presentation Layer: Graphical User Interface (GUI) or

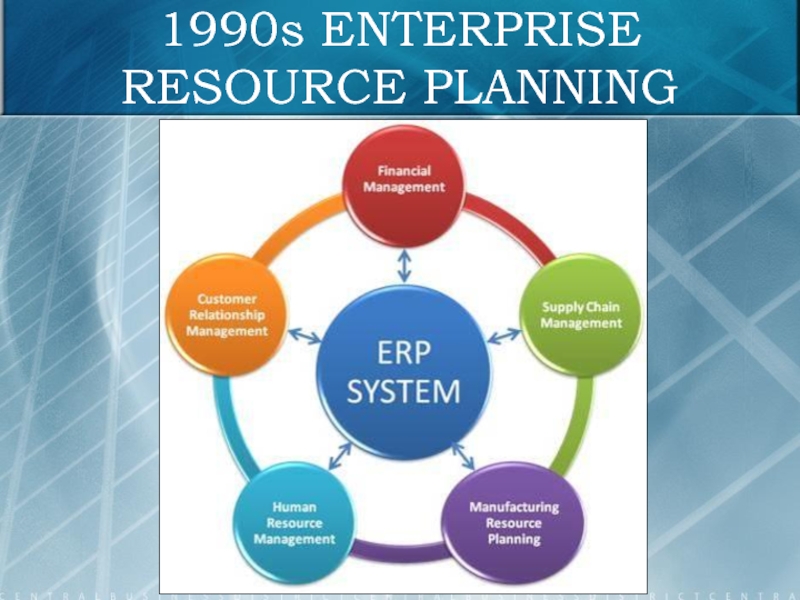

- 32. 1990s ENTERPRISE RESOURCE PLANNING

- 33. WEB BASED SOFTWARE ARCHITECTURE Enterprise resource planning

- 34. WEB-ENABLED EXTENDED ERP SYSTEM

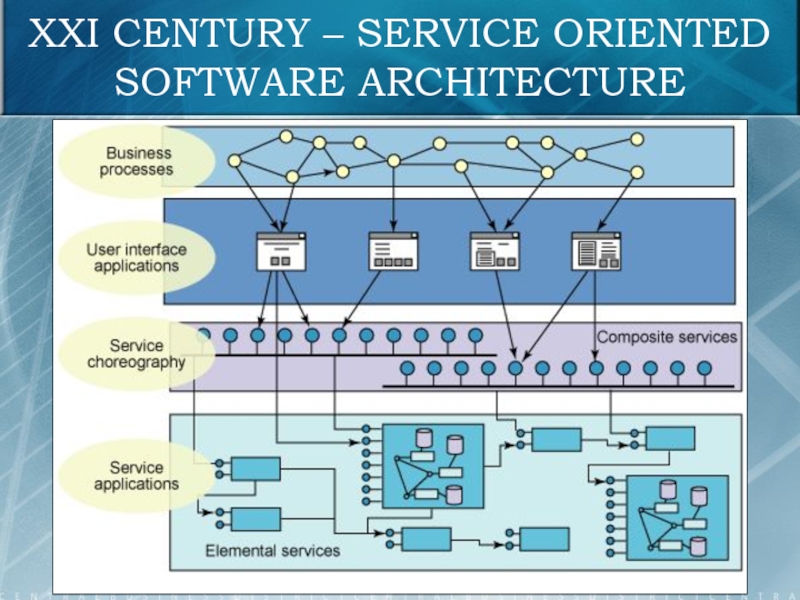

- 35. XXI CENTURY – SERVICE ORIENTED SOFTWARE ARCHITECTURE

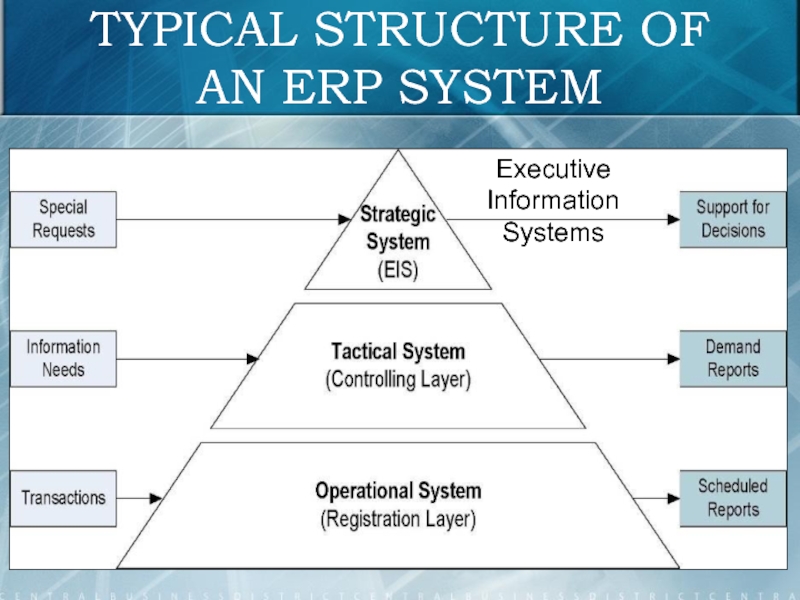

- 36. TYPICAL STRUCTURE OF AN ERP SYSTEM Executive Information Systems

- 37. THE WAYS OF SUPPORTING AN ORGANIZATION BY

- 38. THE WAYS OF SUPPORTING AN ORGANIZATION BY

Слайд 21776

Adam Smith published

“The Wealth of Nations”.

In this, he suggested the specialization

Adam Smith

(1723 – 1790)

Слайд 31820s

The railroad companies introduced bureaucracies to avoid collisions on single-track lines

This was the forerunner of the command-and-control system still in use today – where there are workers and supervisors to keep things organized.

Слайд 4EARLY XX CENTURY

Taylor was a mechanical engineer who sought to improve industrial

“It is only through enforced standardization of methods, enforced adoption of the best implements and working conditions, and enforced cooperation that this faster work can be assured. And the duty of enforcing the adoption of standards and enforcing this cooperation rests with management alone”

Frederick Winslow Taylor

(1856 – 1915)

Слайд 5SCIENTIFIC MANAGEMENT

The main elements of the Scientific Management are:

Time studies

Functional or

Standardization of tools and implements

Standardization of work methods

Separate

Planning function

Management by exception principle

The use of “slide-rules and similar time-saving devices”

Instruction cards for workmen

Task allocation and large bonus for successful performance

The use of the “differential rate”

Mnemonic systems for classifying products and implements

A routing system

A modern costing system

Слайд 6SCIENTIFIC MANAGEMENT

Taylor called these elements “merely the elements or details of

The development of a true science

The scientific selection of the workman

The scientific education and development of the workman

Intimate and friendly cooperation between the management and the men

Слайд 7EARLY XX CENTURY

Henry Gantt's legacy to production management:

The Gantt chart still accepted as

Industrial efficiency can only be produced by the application of scientific analysis to all aspects of the work in progress. The industrial management role is to improve the system by eliminating chance of accidents.

Henry Laurence Gantt

(1861 – 1919)

Слайд 8EARLY XX CENTURY

The Task And Bonus System – he linked the

The social responsibility of business – he believed that businesses have obligations to the welfare of the society in which they operate.

Henry Laurence Gantt

(1861 – 1919)

Слайд 10EARLY XX CENTURY

Henry Ford introduced the assembly line – workers performed

Слайд 11MIDDLE OF XX CENTURY

Industrial engineering is a branch of engineering dealing with the optimization

Its underlying concepts overlap considerably with certain business-oriented disciplines such as operations management.

Слайд 12MIDDLE OF XX CENTURY

Operational research encompasses a wide range of problem-solving

Слайд 151960s

MATERIAL REQUIREMENTS PLANNING

Material Requirements Planning (MRP) is a time phased priority-planning

MRP techniques focus on optimizing inventory.

MRP techniques are used to explode bills of material, to calculate net material requirements and plan future production.

Information Technology plays a major role in designing and implementing MRP systems and processes as it provides information about manufacturing needs (linked with customer demand) as well as information about inventory levels.

Слайд 16MATERIAL REQUIREMENTS PLANNING

MRP systems provide answers for several questions:

What items are

How many are required?

When are they required?

The main theme of MRP is “getting the right materials to the right place at the right time”.

Слайд 17TRADITIONAL COMPONENTS OF MRP SYSTEMS

the master production schedule, which describes when

bill of materials, which lists exactly the parts or materials required to make each product

production cycle times and material needs at each stage of the production cycle time

supplier lead times

Слайд 19APPLYING OF MRP SYSTEMS

MRP is being used in a variety of

MRP is most valuable to companies involved in assembly operations and least valuable to those in fabrication.

MRP does not work well in companies that produce a low number of units annually. Especially for companies producing complex expensive products requiring advanced research and design. Experience has shown that lead times tend to be too long and too uncertain, and the product configuration too complex for MRP to handle. Such companies need the control features that network-scheduling techniques offer.

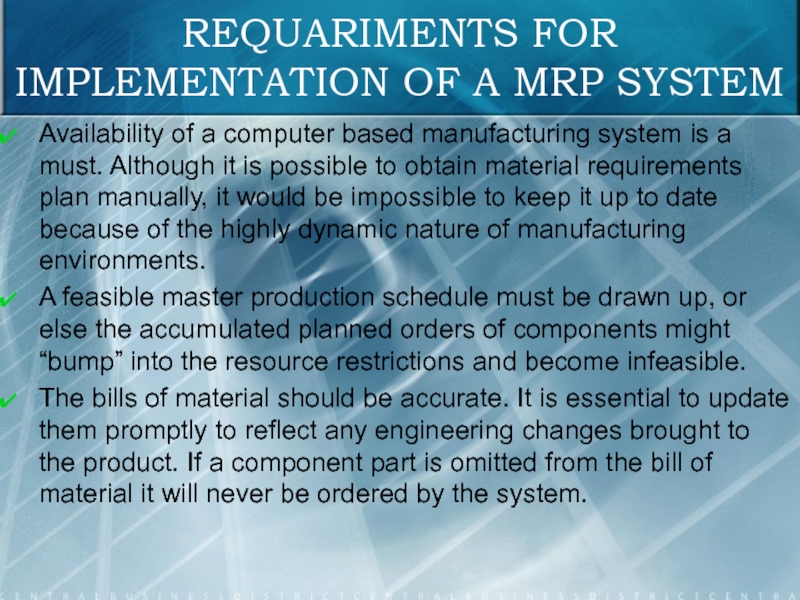

Слайд 23REQUARIMENTS FOR IMPLEMENTATION OF A MRP SYSTEM

Availability of a computer based

A feasible master production schedule must be drawn up, or else the accumulated planned orders of components might “bump” into the resource restrictions and become infeasible.

The bills of material should be accurate. It is essential to update them promptly to reflect any engineering changes brought to the product. If a component part is omitted from the bill of material it will never be ordered by the system.

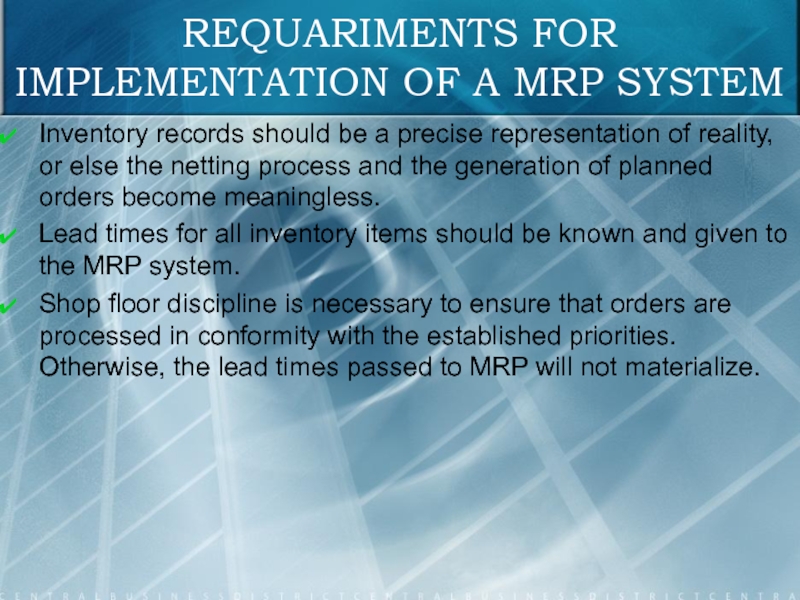

Слайд 24REQUARIMENTS FOR IMPLEMENTATION OF A MRP SYSTEM

Inventory records should be a

Lead times for all inventory items should be known and given to the MRP system.

Shop floor discipline is necessary to ensure that orders are processed in conformity with the established priorities. Otherwise, the lead times passed to MRP will not materialize.

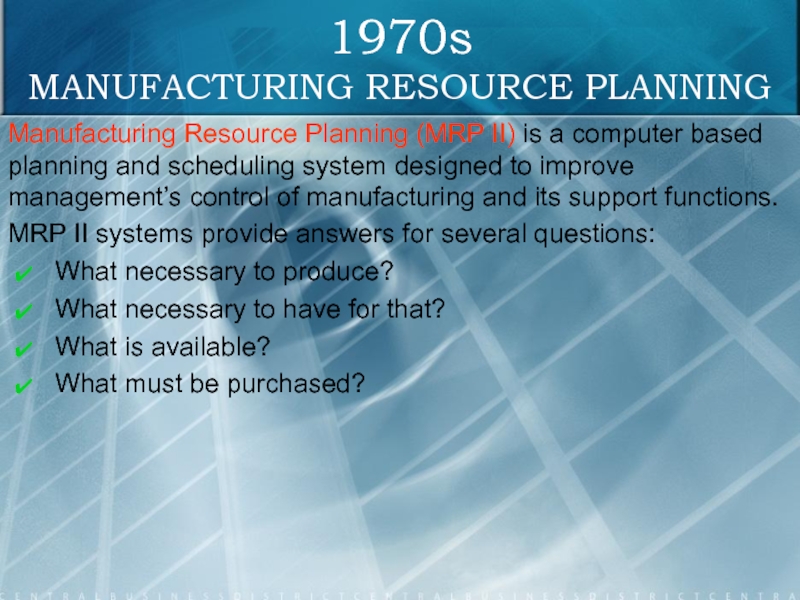

Слайд 251970s

MANUFACTURING RESOURCE PLANNING

Manufacturing Resource Planning (MRP II) is a computer based

MRP II systems provide answers for several questions:

What necessary to produce?

What necessary to have for that?

What is available?

What must be purchased?

Слайд 27Sales and Operation Planning

Demand Management

Master Production Scheduling

Material Requirement Planning

Bill of Materials

Inventory

Scheduled Receipts Subsystem

Shop Flow Control

Capacity Requirement Planning

Input/output control

Purchasing

Distribution Resource Planning

Tooling Planning and Control

Financial Planning

Simulation

Performance Measurement

MODULES OF MRP II SYSTEMS

Слайд 31Presentation Layer: Graphical User Interface (GUI) or browser for data entry

Application Layer: Business rules, functions, logic, and programs acting on data received/transferred from/to the database servers

Database Layer: Management of the organization's operational or transactional data including metadata (in most cases Relational Database Management Dystem (RDBMS) with Structured Query Language (SQL))

TREE-TIER

SOFTWARE ARCHITECTURE

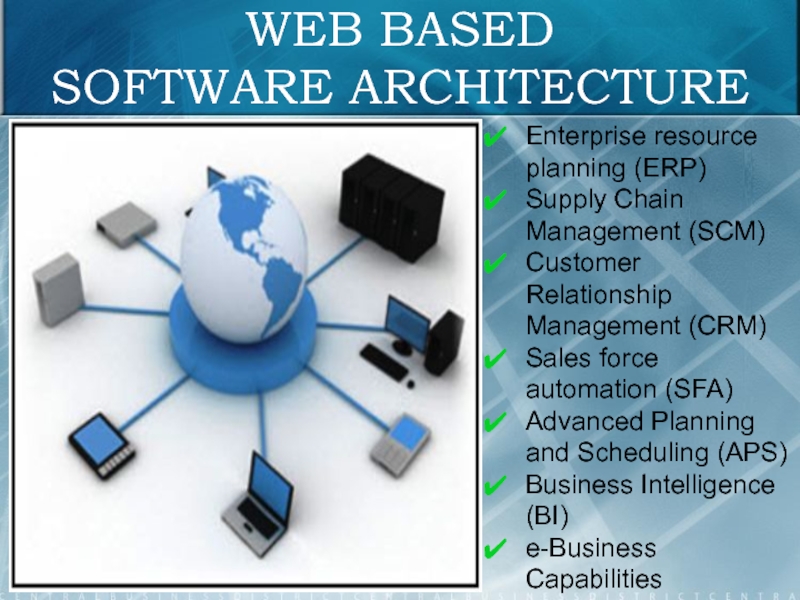

Слайд 33WEB BASED

SOFTWARE ARCHITECTURE

Enterprise resource planning (ERP)

Supply Chain Management (SCM)

Customer Relationship Management

Sales force automation (SFA)

Advanced Planning and Scheduling (APS)

Business Intelligence (BI)

e-Business Capabilities

Слайд 37THE WAYS OF SUPPORTING AN ORGANIZATION BY ERP SYSTEMS

support organizations by

integrate diverse primary business activities, functions, processes, tasks, and work flows (such as accounting, finance, and procurement) as well as secondary activities with primary activities (such as inventory management)

server as a common data repository (master data) for organizations (a data repository for an organization is that it may define the format of the data, which makes communication and interpretation of easier)

specify how organizations should conduct their business based on a best business practice reference model

Слайд 38THE WAYS OF SUPPORTING AN ORGANIZATION BY ERP SYSTEMS

reduce the number

deliver functionality per se – the core business processes (such as sales and marketing, procurement, and production) and support processes (such as controlling, human resource, and finance) of an enterprise.

To achieve these benefits from an ERP implementation, organizational changes are required, which are prompted by business process reengineering, organizational transition to an ERP system, retraining of entire departments, job redefinition, and transformation of core processes.

ERP systems are often thereby assumed to be a technology, since organizations have to align their business process to the embedded business processes representing best practice, which are assumed to generate organizational change.