- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Project Kick-Off. External Supervisory Interface for Process Automation презентация

Содержание

- 1. Project Kick-Off. External Supervisory Interface for Process Automation

- 2. Introduce project Project description Customer,

- 3. The project of External Supervisory Interface for

- 4. The customer: The Head of Automotive manufacturing

- 5. ID project team members Project Management:

- 6. The Project Scope includes: What: QC

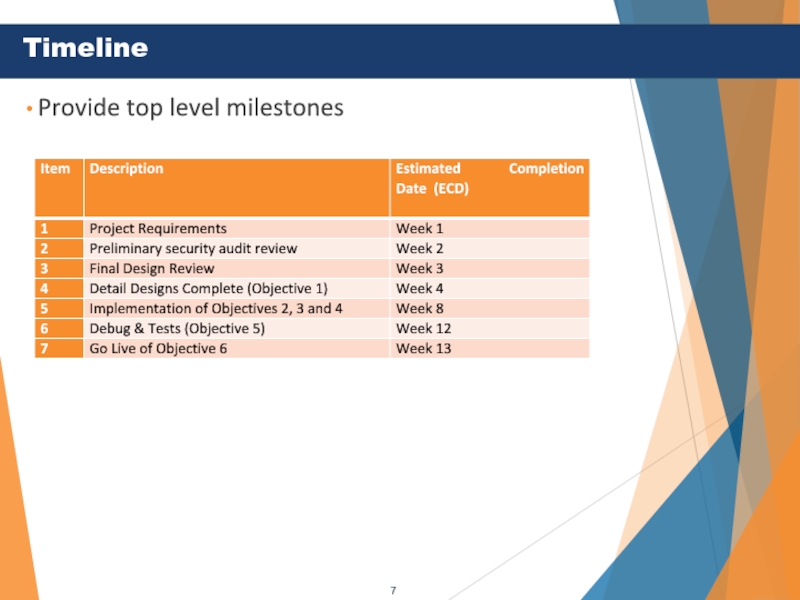

- 7. Provide top level milestones Timeline

- 8. Initial Cost estimated for system – 870,000

- 9. Additional extensive training of production team

- 10. Top level test and validation Security

- 11. Customer acceptance criteria Customer review and approvals

- 12. Assumptions The external interface will not control

- 13. ID challenges that may be associated with

- 14. Etiquette Communication – emails, phone, meetings, and

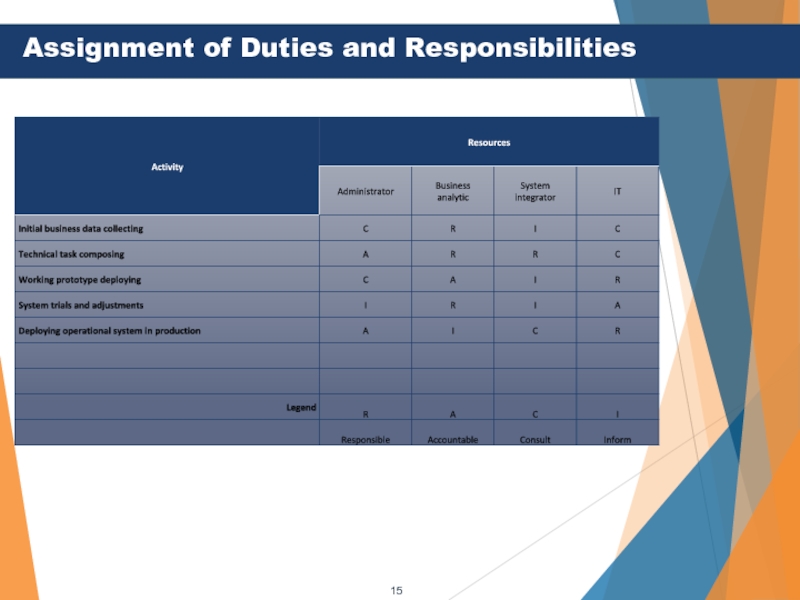

- 15. Assignment of Duties and Responsibilities

Слайд 2Introduce project

Project description

Customer, sponsor, stakeholders, and project team members

Scope,

Make-or-buy

Hardware and Software

Testing

Test articles, test stands, test documents, and test software

Agenda

Acceptance criteria

Assumptions, constraints, and challenges

Rules of engagement

Etiquette

Communication

Workflow

Assignment of duties and responsibilities

Слайд 3The project of External Supervisory Interface for Process Automation has the

The project execution will include software development, security audit and interface usability analysis

The possibility of remote supervising the manufacturing process will decrease quality issues reports by 5 times according to collected and analyzed statistical data.

Project Overview

Слайд 4The customer: The Head of Automotive manufacturing unit has pointed out

Sponsor: Automotive Business Unit with corporation as the most sensitive to deviations in process in terms of final product quality.

Stakeholders (all are internal):

Head of procurement EMEA region

Head of Automotive EMEA region

Head of Manufacturing site in Russia

Head of IT EMEA region

Customer, Sponsor, and Stakeholders

Слайд 5ID project team members

Project Management: Denys Ivanov

Designer: Head of QC

Engineering: IT architecture manager

Purchasing, Contracts: head of procurement Russia

Quality: Head of IT Russia, Head of QC lab

Operations: CS solutions (outsourcing), IT team, QC engineers, Manufacturing team engineers

Human resources: HR engineer

The Project Team

Слайд 6The Project Scope includes:

What: QC will be improved with the

Where: Manufacturing site in Russia

How: To implement secure and usable interface to supervise all steps of manufacturing process

Who: The team will include internal resources, outsourcing. End users: QC engineers.

Why: The purpose of the project is to reduce issues with quality and thus to increase production capacity of installed equipment.

Project Scope

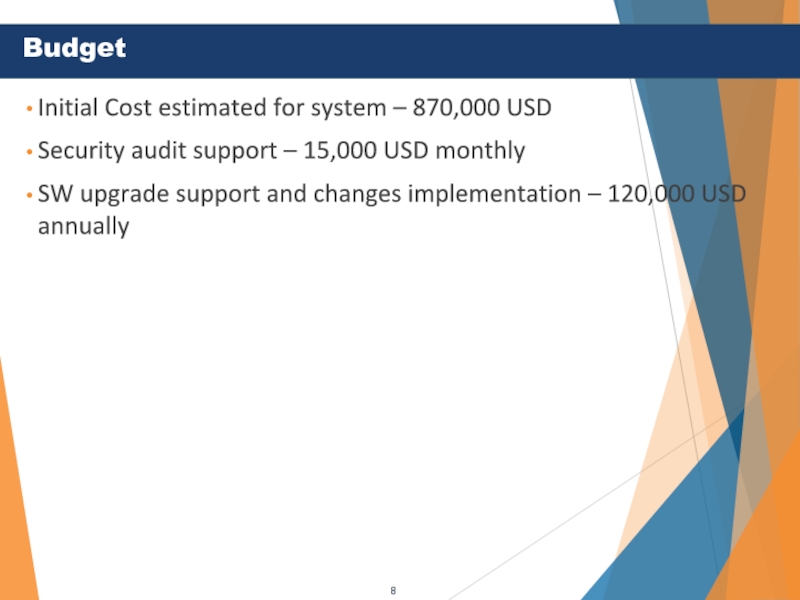

Слайд 8Initial Cost estimated for system – 870,000 USD

Security audit support –

SW upgrade support and changes implementation – 120,000 USD annually

Budget

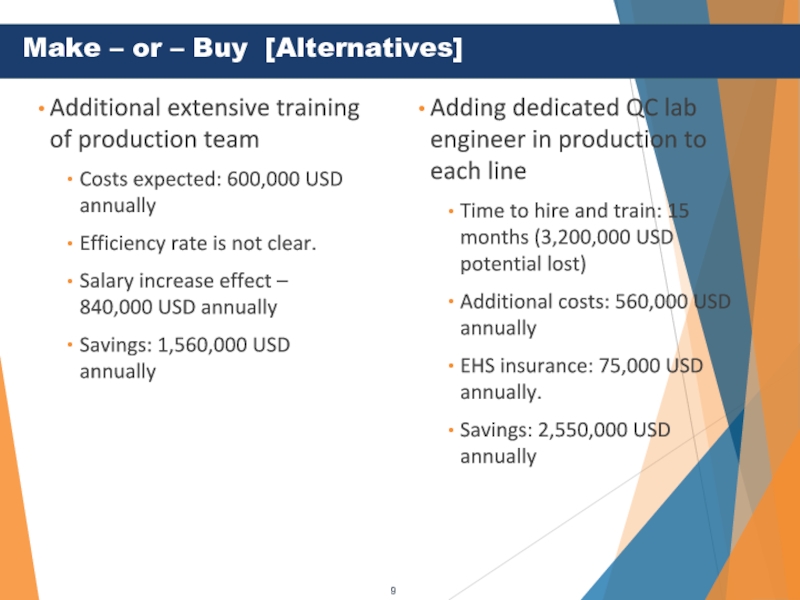

Слайд 9Additional extensive training of production team

Costs expected: 600,000 USD annually

Efficiency

Salary increase effect – 840,000 USD annually

Savings: 1,560,000 USD annually

Make – or – Buy [Alternatives]

Adding dedicated QC lab engineer in production to each line

Time to hire and train: 15 months (3,200,000 USD potential lost)

Additional costs: 560,000 USD annually

EHS insurance: 75,000 USD annually.

Savings: 2,550,000 USD annually

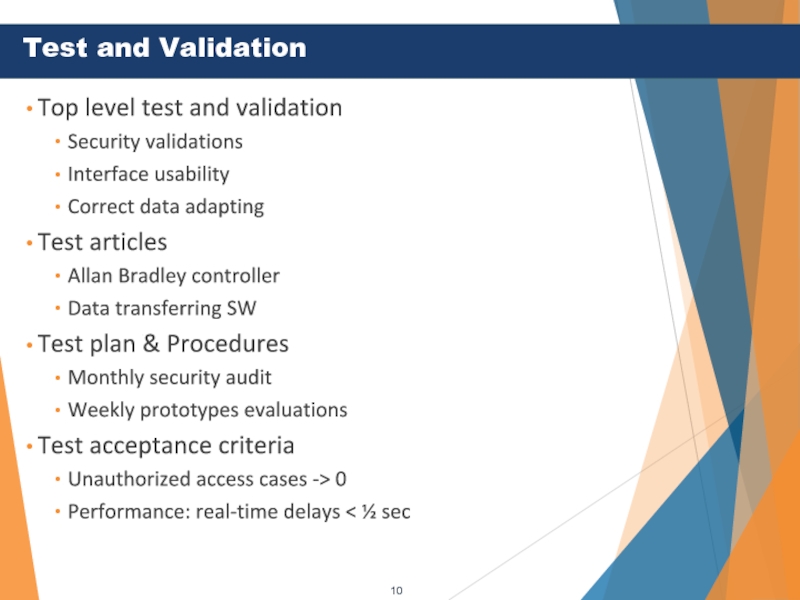

Слайд 10Top level test and validation

Security validations

Interface usability

Correct data adapting

Test

Allan Bradley controller

Data transferring SW

Test plan & Procedures

Monthly security audit

Weekly prototypes evaluations

Test acceptance criteria

Unauthorized access cases -> 0

Performance: real-time delays < ½ sec

Test and Validation

Слайд 11Customer acceptance criteria

Customer review and approvals

Prototype approval

User interface usability approval

Performance

Final adjustments and deploying in production environment

Customer Acceptance Criteria

Слайд 12Assumptions

The external interface will not control the production and can be

No dedicated employee will be needed to watch the dashboard. QC lab has enough resources.

User Interface will resemble control panels interface in production in read-only mode.

Assumptions and Constraints

Constraints

Due to extended demands to security, the module development will require expensive resources.

Even after most thorough tests and debug process, we still reserve some time for problems solving in production within 6 weeks of operations.

Слайд 13ID challenges that may be associated with the project

Internal challenges

Properly

External challenges

To exclude any possibility of unauthorized access to the system

Challenges

Слайд 14Etiquette

Communication – emails, phone, meetings, and others

Communication

Updates – on weekly

Status reports – after each milestone

Actions – actions plan submitted to heads of departments on weekly basis

Meetings

Kick Off meeting, by PM

Prototype review and acceptance meetings by IT

Status reports meetings by PM

Workflow

9-00 a.m. short meeting

Weekly: each Wednesday, 10-00 a.m. – 11-00 a.m.: progress review

By milestones completion – status review

Rules of Engagement