- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Production planning презентация

Содержание

- 1. Production planning

- 2. Production planning is the planning of production and manufacturing modules

- 3. Single item manufacturing Batch

- 4. A production planning is made

- 5. The planning horizon is the amount of

- 6. material availability They can

- 8. Elements of production planning

- 9. Planning If you fail to plan, you are planning to fail! Benjamin Franklin

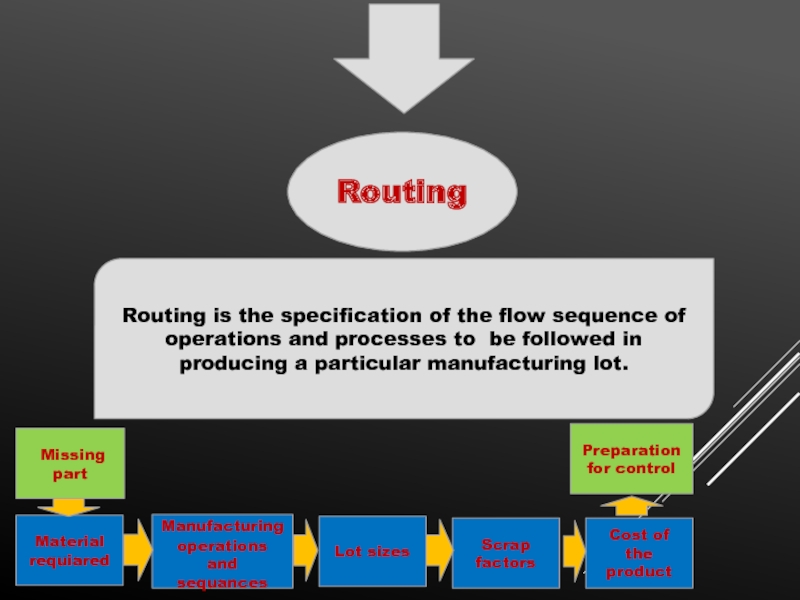

- 10. Routing Routing is the

- 11. Scheduling

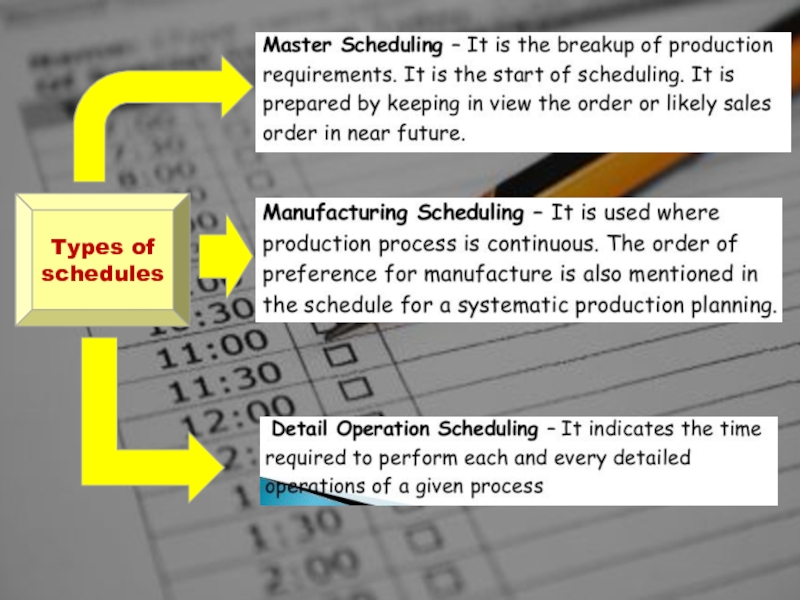

- 12. Types of schedules

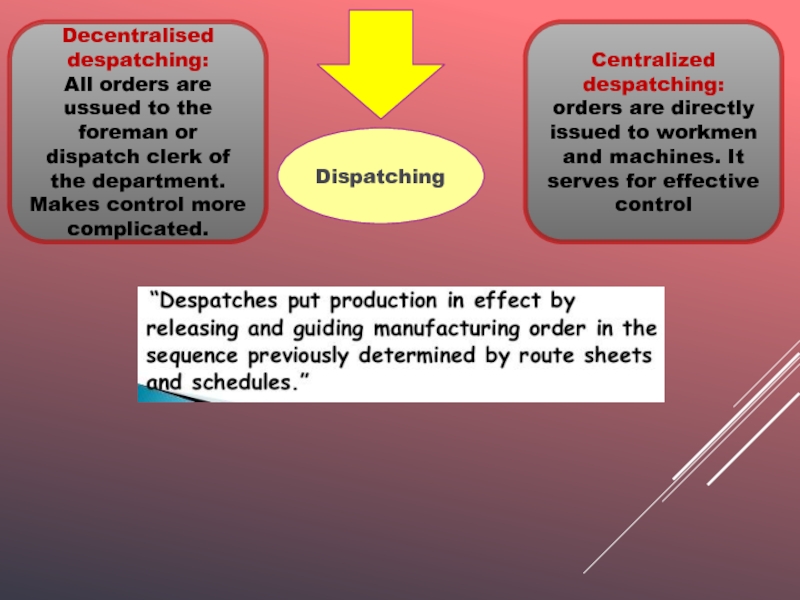

- 13. Dispatching Centralized despatching: orders are

- 14. Follow – up and expediting

- 15. Inspection Inspection is the process of

- 16. short term planning dealing with day

- 17. Combining Functions – It is desirable that

- 18. Factors Affecting Production Planning and

- 19. Crystal Pepsi > Company: PepsiCo > Year

- 22. Thank you for your attention

Слайд 2

Production planning is the planning of production and manufacturing modules in a company or industry.

It is a plan for the future production, in which the facilities needed are determined and arranged

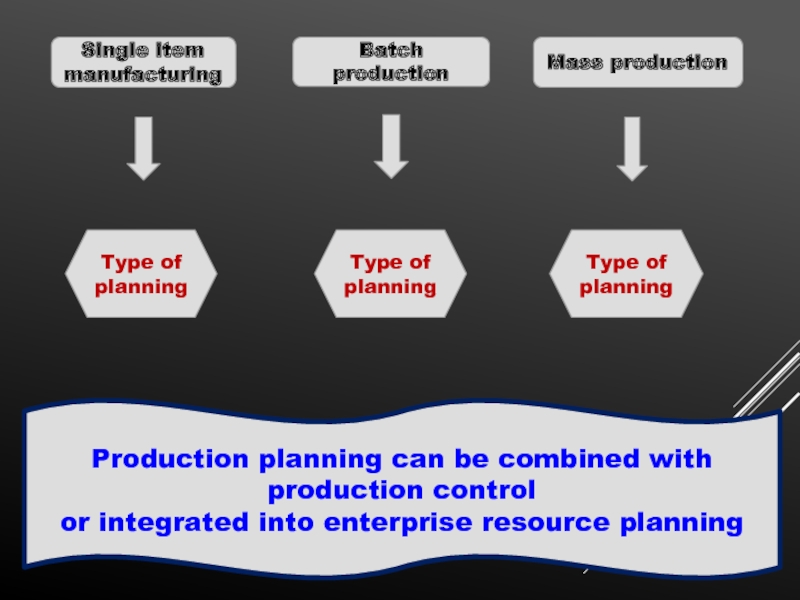

Слайд 3

Single item manufacturing

Batch production

Mass production

Type of planning

Type of planning

Type of planning

Production

or integrated into enterprise resource planning

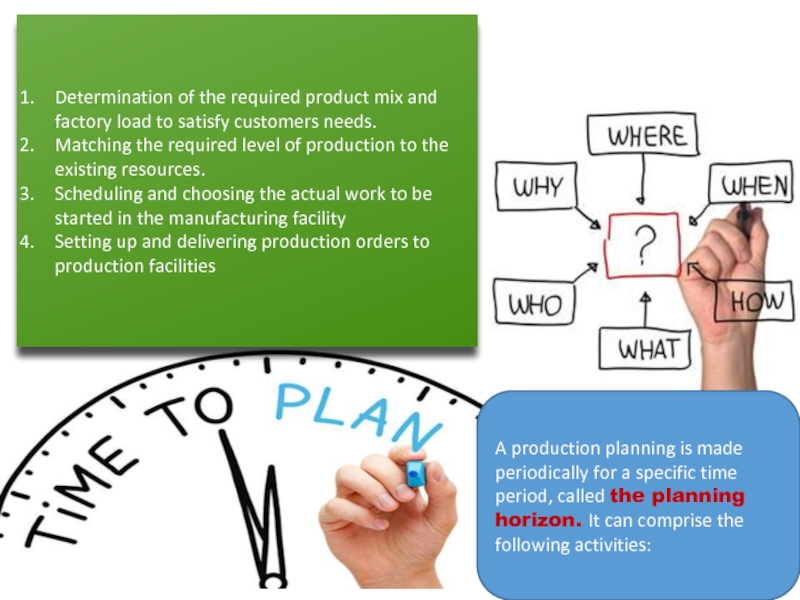

Слайд 4

A production planning is made periodically for a specific time period,

Determination of the required product mix and factory load to satisfy customers needs.

Matching the required level of production to the existing resources.

Scheduling and choosing the actual work to be started in the manufacturing facility

Setting up and delivering production orders to production facilities

Слайд 5

The planning horizon is the amount of time an organization will look into

In manufacturing, a planning horizon is a future time period during which departments that support production will plan production work and determine material requirements

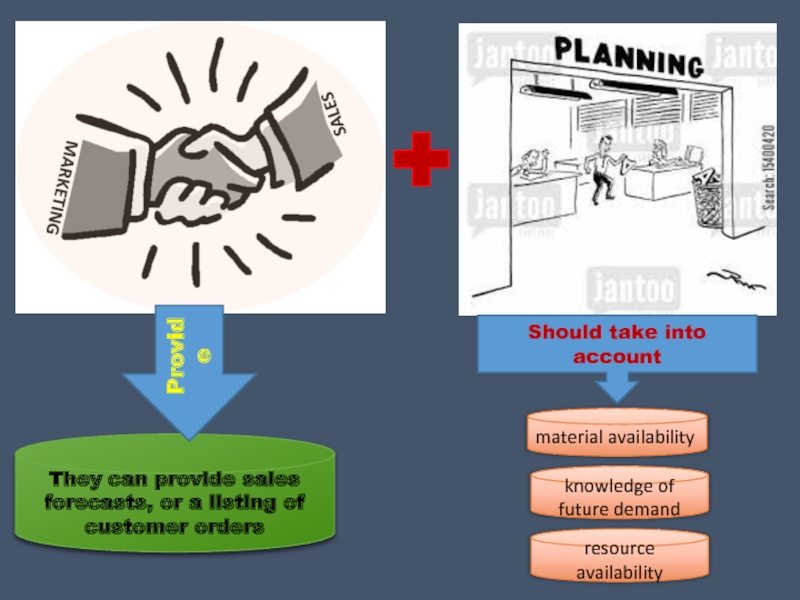

Слайд 6

material availability

They can provide sales forecasts, or a listing of customer

Provide

Should take into account

resource availability

knowledge of future demand

Слайд 8

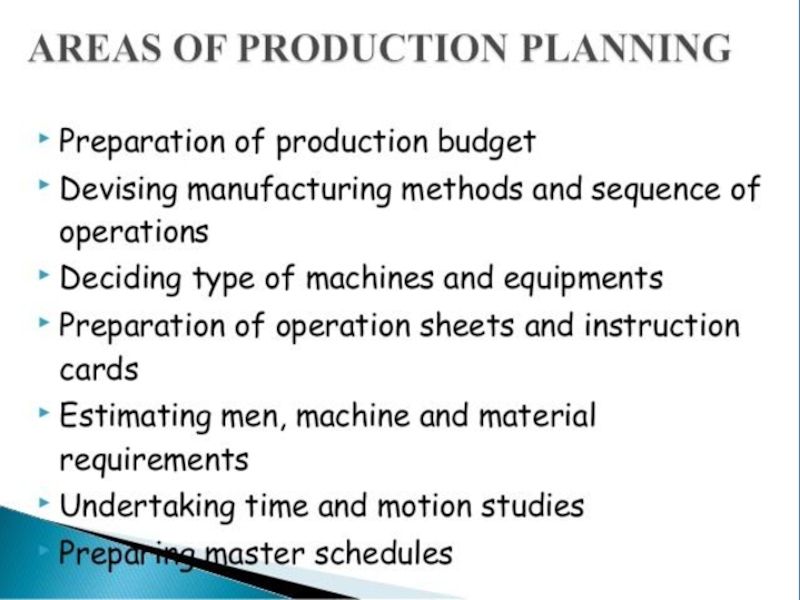

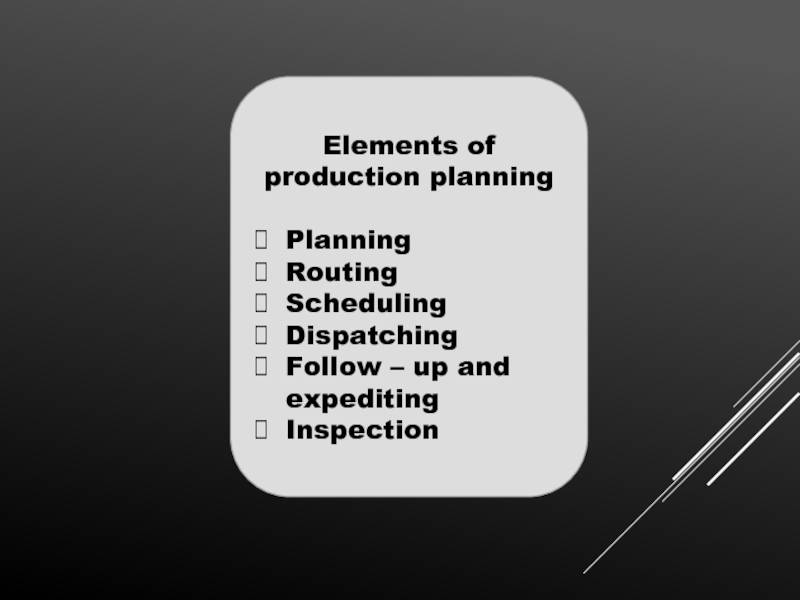

Elements of production planning

Planning

Routing

Scheduling

Dispatching

Follow – up and expediting

Inspection

Слайд 10

Routing

Routing is the specification of the flow sequence of operations and

Missing part

Material requiared

Manufacturing operations and sequances

Preparation for control

Cost of the product

Scrap factors

Lot sizes

Слайд 13

Dispatching

Centralized despatching:

orders are directly issued to workmen and machines. It serves

Decentralised despatching:

All orders are ussued to the foreman or dispatch clerk of the department. Makes control more complicated.

Слайд 14

Follow – up and expediting

Follow up or expediting is that branch

Слайд 15

Inspection

Inspection is the process of ensuring whether the products manufactured are

Слайд 16

short term planning dealing with day to day operations

Medium – range

Deamnd forecast and capacity planning

Long – range planning:

Facility planning, capital investment, location planning

Production planning is done at three different time dependent levels

Слайд 17

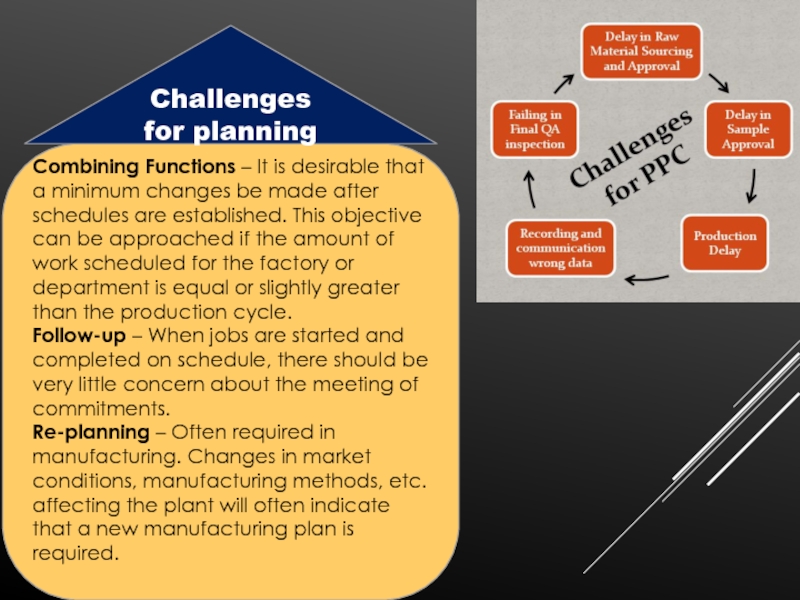

Combining Functions – It is desirable that a minimum changes be made

Follow-up – When jobs are started and completed on schedule, there should be very little concern about the meeting of commitments.

Re-planning – Often required in manufacturing. Changes in market conditions, manufacturing methods, etc. affecting the plant will often indicate that a new manufacturing plan is required.

Challenges for planning

Слайд 18

Factors Affecting Production Planning and Control

Market Forecast – It will indicate future

Sales Order – It is a rewrite of the customer order specifying what has been purchased (product, quantity and authorizing shipment of the goods to the customer).

Standard Process Sheet – It is prepared by process engineering group or process owner and it is the source of basic data which may include type of machine to be used, time required for processing, etc. (keep an eye on preventive maintenance and breakdowns)

Load Charts – These charts are prepared for each workstation or machine in the plant or may be for groups of machines or departments.

Project Planning Method – The product to be produced are manufactured in quantities and their total processing time can be measured.

Слайд 19

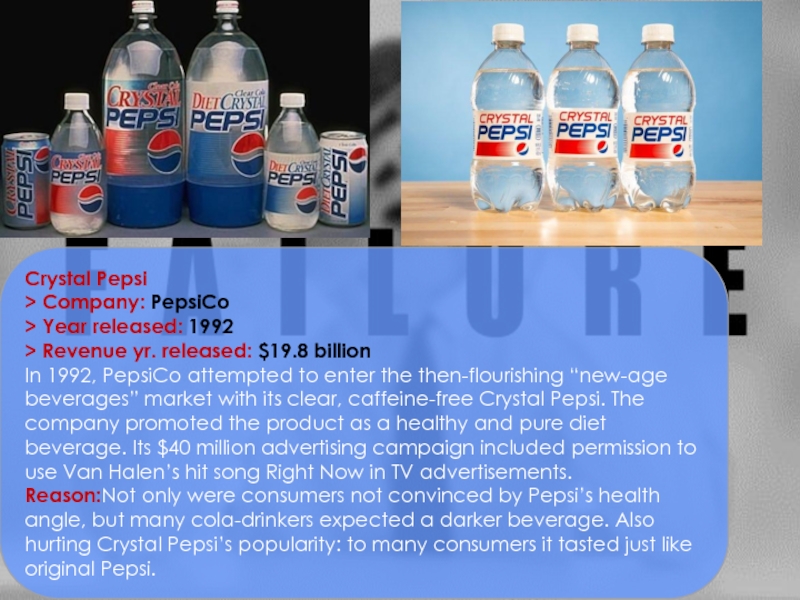

Crystal Pepsi

> Company: PepsiCo

> Year released: 1992

> Revenue yr. released: $19.8 billion

In 1992, PepsiCo

Reason:Not only were consumers not convinced by Pepsi’s health angle, but many cola-drinkers expected a darker beverage. Also hurting Crystal Pepsi’s popularity: to many consumers it tasted just like original Pepsi.