- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Quality Control TechniquesFor Food Safety презентация

Содержание

- 1. Quality Control TechniquesFor Food Safety

- 2. Quality Food quality is a sensory

- 3. Need For Quality Food Major challenge for

- 4. Techniques Ultrasound : Energy derived from sound

- 5. Ultrasound

- 6. What is Ultrasound? It

- 7. Physics of Ultrasound The sound waves

- 8. How can Ultrasound be applied in Food

- 9. Low Power Ultrasound: Low energy [low

- 10. Newton-Laplace Equation: The Newton-Laplace equation

- 11. Why Low Power ? Can

- 12. Applications of Low Power Ultrasound

- 13. High Power Ultrasound: High energy

- 14. The chemical and biochemical effects are effective

- 15. Why HPU ? Ultrasonic Inactivation of

- 16. High power ultrasound is known to damage

- 17. The advantages of ultrasound over heat pasteurization

- 18. Ultrasound in Food Industry

- 19. Food Irradiation

- 21. Process involved packaged food is passed through

- 22. How does Food Irradiation Works? Food is

- 23. The food irradiation process uses three types

- 24. Dose Effects Absorbed dose is measured

- 25. Parasites and insect pests, which have large

- 26. IMPACT !! It has been studied

- 27. Considering its potential role in the reduction

- 28. Advantages kill many

- 29. One of the most important advantages

- 31. Are irradiated foods still nutritious?

- 32. Disadvantages Is used on

- 33. Prions, such as the one that causes

- 35. Cold Plasma Technology

- 36. Current Scenario Preferences of the

- 37. What is Cold Plasma Technology ? Cold

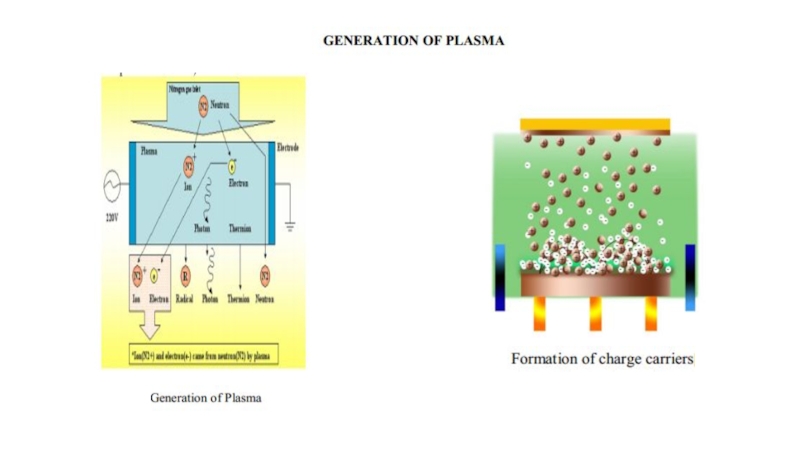

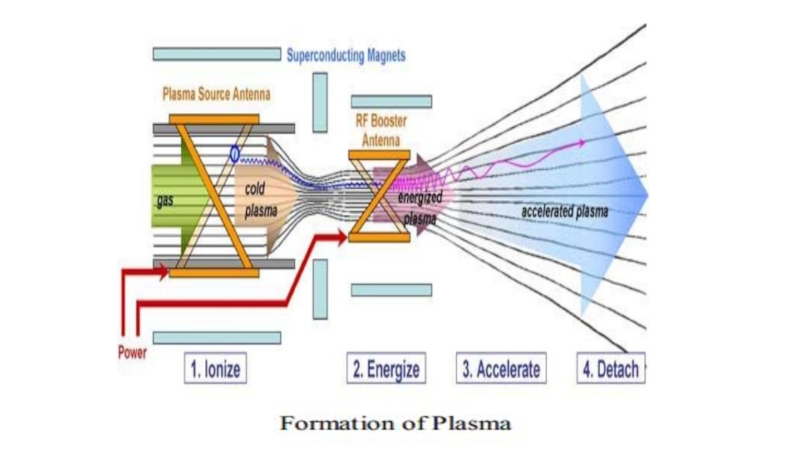

- 38. Generation of Plasma Man-made plasma can

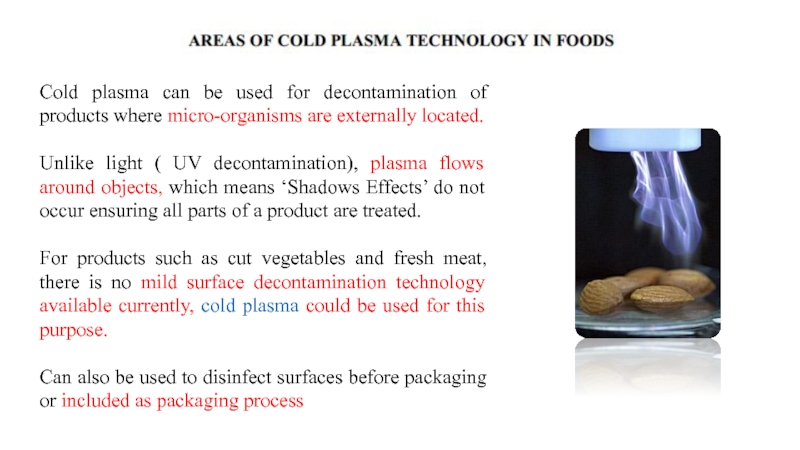

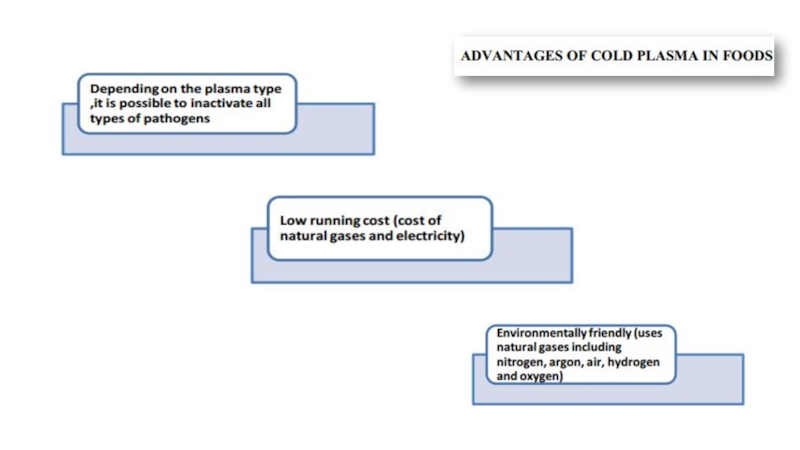

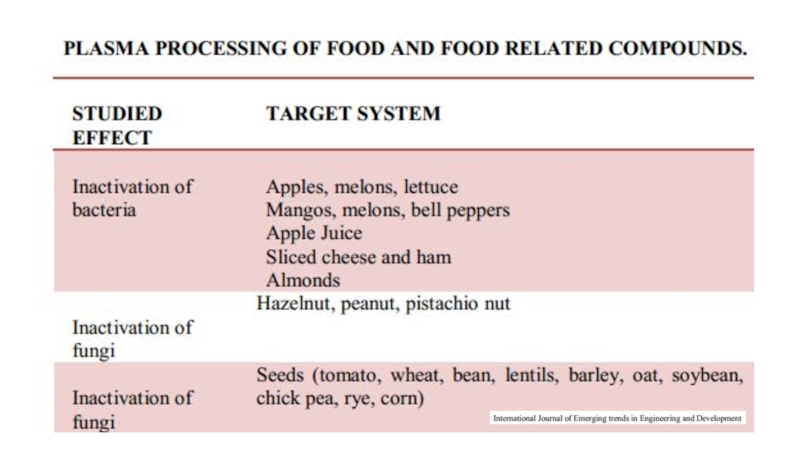

- 41. Cold Plasma Technology in Foods Cold

- 42. A second cleaning action is carried out

- 43. Cold plasma can be used for

- 44. https://www.youtube.com/watch?v=AC2q4TsDHrY

- 47. Illustration – Sterilization capability of Cold

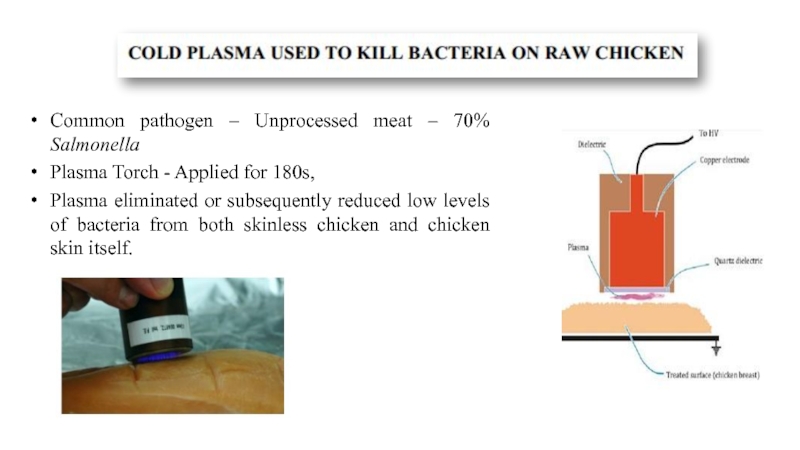

- 49. Common pathogen – Unprocessed meat – 70%

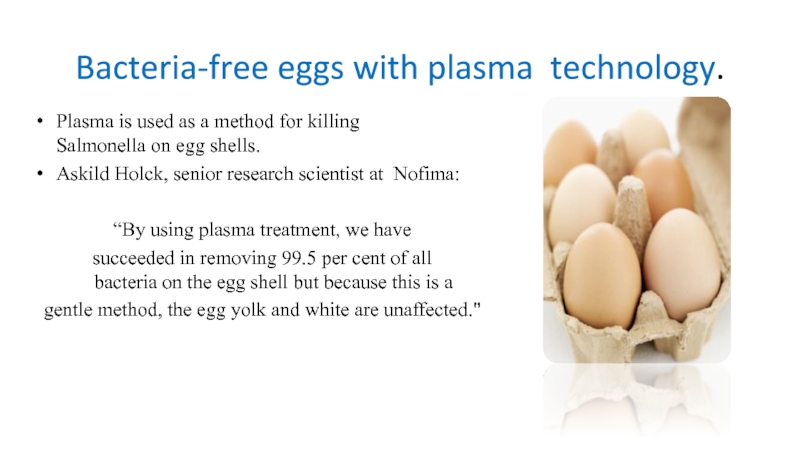

- 50. Plasma is used as a method for killing Salmonella on egg shells. Askild Holck, senior research scientist at Nofima: “By using plasma treatment, we have succeeded in removing 99.5 per cent of all bacteria on the egg shell but because this is a gentle method, the egg yolk and white are unaffected." Bacteria‐free eggs with plasma technology.

- 52. Concerns !! Important aspects of this

- 53. What's Next ??

- 54. References T.J. Mason, L. Paniwnyk, J.P.

- 55. References http://rspublication.com/ijeted/may-12/89.pdf http://ccr.ucdavis.edu/irr/how_food_irr.shtml http://www.stockandland.com.au/news/agriculture/horticulture/generalnews/irradiation-pros-and-cons/2665981.aspx

- 57. Presented by Naveen Cheema [300774182] Navdeep

Слайд 2Quality

Food quality is a sensory property that includes appearance, taste, nutritional

It includes those attributes which affect consumer’s choice for a product.

Слайд 3Need For Quality Food

Major challenge for food industry is to maintain

For this reason food industry has to adopt certain techniques in order to meet the growing need of maintaining food quality; this is known as food quality control.

The main issue which is considered while quality control process is to deteriorate the level of microbes and other contaminants in food.

Слайд 4Techniques

Ultrasound : Energy derived from sound waves

Irradiation: Energy derived from ionising

Cold Plasma Technique: Energy derived from plasma

Слайд 6

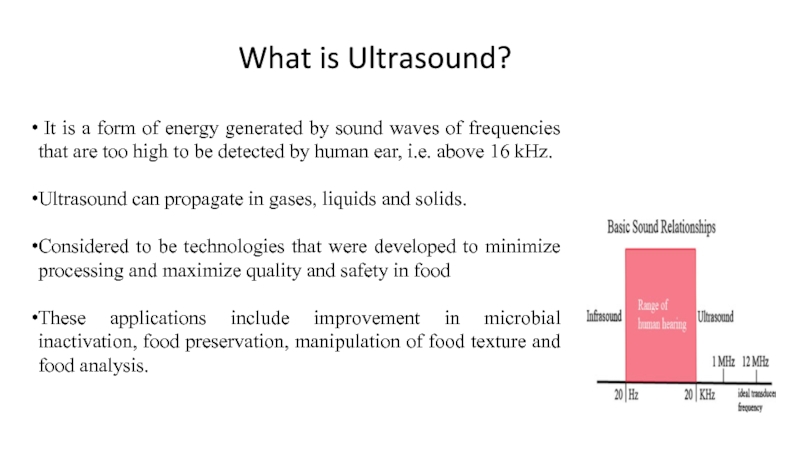

What is Ultrasound?

It is a form of energy generated by

Ultrasound can propagate in gases, liquids and solids.

Considered to be technologies that were developed to minimize processing and maximize quality and safety in food

These applications include improvement in microbial inactivation, food preservation, manipulation of food texture and food analysis.

Слайд 7Physics of Ultrasound

The sound waves travel effectively through liquids which are

Sound is transmitted as sequential sine waves whose height represents amplitude or loudness.

A single full cycle is measured from peak to peak, and the number of these cycles per one second represents the frequency. The frequency is described in Hertz [Hz] which by convention is in honor of the German physicist Heinrich Hertz for his work on electromagnetic transmission.

Слайд 8How can Ultrasound be applied in Food ?

Ultrasound when propagated through

In food industry, the application of ultrasound can be divided based on range of frequency:

low power ultrasound

high power ultrasound

Слайд 9Low Power Ultrasound:

Low energy [low power, low intensity] ultrasound

Principles of

It uses a small power level that the waves cause no physical and chemical alteration in the properties of the material through which it passes.

This property is been utilized for non-invasive analysis and monitoring of various food materials during processing and storage to ensure quality and safety.

Ultrasonic velocity (v) is determined by density (ρ) and elasticity (E) of the medium, according to the Newton-Laplace equation (Blitz, 1963).

Слайд 10

Newton-Laplace Equation:

The Newton-Laplace equation is the starting point for the determination

This equation implies that the ultrasound velocity of the solid form of a material is larger than that of its liquid form.

In food industry, the sensitivity of ultrasound velocity to molecular organizations and intermolecular interactions makes UVM – Ultrasound Velocity Measurements suitable for determining composition, structure, and physical state of different food materials.

It also helps in detection of foreign bodies and defects in processed and packaged food.

Слайд 11Why Low Power ?

Can provide information about the physiochemical properties

The major advantage of this technique over other traditional techniques is that the measurement is so rapid and non-destructive.

Слайд 12

Applications of Low Power Ultrasound

In Meat Technology

In Fruits and Vegetables

In

Ultrasonic monitoring for food freezing

Слайд 13High Power Ultrasound:

High energy [high power, high intensity] ultrasound

20 and

Disruptive and enforce effect on the physical, mechanical, or biochemical properties of foods. These effects are promising in food processing, preservation and safety.

Слайд 14The chemical and biochemical effects are effective tools for sterilizing equipments,

Principle of HPU

Factors that affect power ultrasound are energy, intensity, pressure, velocity and temperature.

Where, Pa is the acoustic pressure (a sinusoidal wave), which is dependent on time (t), frequency (f) and the maximum pressure amplitude of the wave.

Pa max is related to the power input or intensity (I) of the transducer:

I = Pa max/ 2ρv , where ρ is the density of the medium and v is the sound velocity in the medium.

Mechanical Chemical and Biological Effects:

Слайд 15Why HPU ?

Ultrasonic Inactivation of Microorganism

The most common techniques currently used

Thermal processing does kill vegetative microorganisms and some spores; however, its effectiveness is dependent on the treatment temperature and time.

The magnitude of treatment, time and process temperature is also proportional to the amount of nutrient loss, development of undesirable flavors and deterioration of functional properties of food products.

Слайд 16High power ultrasound is known to damage or disrupt biological cell

Unfortunately very high intensities are needed if ultrasound alone is to be used for permanent sterilization. However, the use of ultrasound coupled with other decontamination techniques, such as pressure, heat or extremes of pH is highly applicable.

Thermosonic (heat plus sonication),

manosonic (pressure plus sonication),

and manothermosonic (heat plus pressure plus sonication) treatments are likely the best methods to inactivate microbes, as they are more energy – efficient and effective in killing microorganisms.

Слайд 17The advantages of ultrasound over heat pasteurization include:

The effectiveness of an ultrasound treatment is dependent on the type of bacteria being tested, amplitude of the ultrasonic waves, exposure time, volume of food being processed, the composition of food and the treatment temperature.

Слайд 18

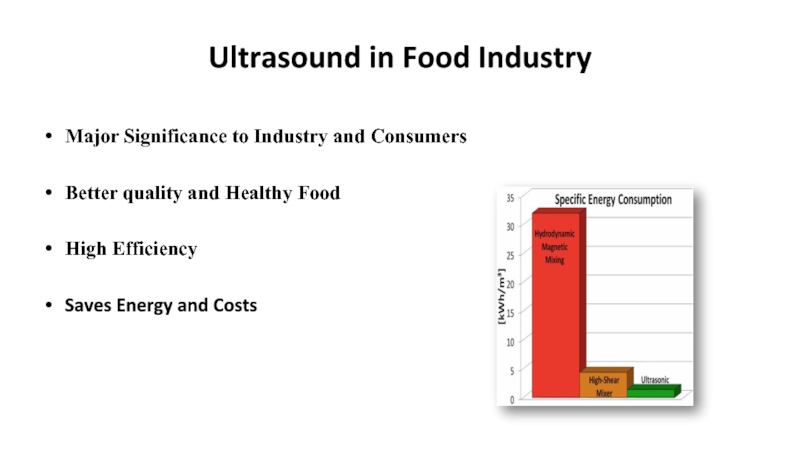

Ultrasound in Food Industry

Major Significance to Industry and Consumers

Better

High Efficiency

Saves Energy and Costs

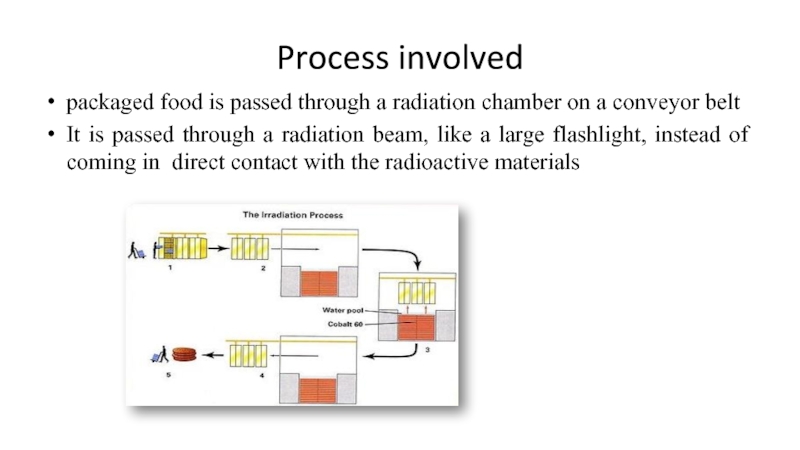

Слайд 21Process involved

packaged food is passed through a radiation chamber on a

It is passed through a radiation beam, like a large flashlight, instead of coming in direct contact with the radioactive materials

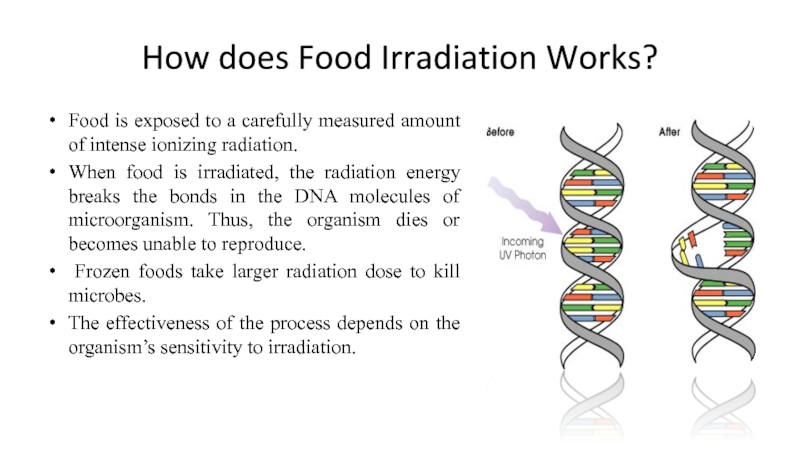

Слайд 22How does Food Irradiation Works?

Food is exposed to a carefully measured

When food is irradiated, the radiation energy breaks the bonds in the DNA molecules of microorganism. Thus, the organism dies or becomes unable to reproduce.

Frozen foods take larger radiation dose to kill microbes.

The effectiveness of the process depends on the organism’s sensitivity to irradiation.

Слайд 23The food irradiation process uses three types of ionizing radiation sources:

cobalt-60

electron beam generators

x-ray accelerators

gamma rays

Слайд 24Dose Effects

Absorbed dose is measured as the quantity of radiation imparted

The unit of absorbed dose is the gray (Gy) where 1 gray is equivalent to 1 joule per kilogram.

Low doses (up to 1 kGy) inhibit sprouting in tuber, bulb and root vegetables, inhibit the growth of asparagus and mushrooms, and delay physiological processes (ripening, etc.) in fruits

Medium doses (1 to 10 kGy) extend the shelf life, eliminate spoilage and pathogenic microorganisms

High doses (10 to 50 kGy) can be used for industrial sterilization and decontamination of certain additives or ingredients

Слайд 25Parasites and insect pests, which have large amounts of DNA, are

It takes more irradiation to kill bacteria, because they have less DNA.

Viruses are the smallest pathogens that have nucleic acid, and they are, in general, resistant to irradiation at doses approved for foods.

Another useful effect: it can be used to prolong the shelf life of fruits and vegetables because it inhibits sprouting and delays ripening.

Слайд 26IMPACT !!

It has been studied that when irradiation is used as

Disease-causing microorganisms are reduced or eliminated

The nutritional value is essentially unchanged

The food does not become radioactive

Irradiation is a safe and effective technology that can prevent many food borne diseases.

Слайд 27Considering its potential role in the reduction of post-harvest losses, providing

There is also a trend towards increased commercialization of irradiated food.

Currently, there are 47 irradiation facilities in some 23 countries being used for treating foods for commercial purposes.

Current Scenario

Слайд 28

Advantages

kill many insects and pests that infest foods like grains,

kill or considerably reduce the level of dangerous micro organisms in foods such as salmonella and campylobacter in raw meat and poultry.

Listeria in ready to eat foods like hot dogs

Delay or stop normal ripening and decay processes so that foods can be stored for longer

Irradiation can successfully replace the fumigation treatment of cocoa beans and coffee beans and disinfest dried fish, dates, dried fruits, etc.

Слайд 29

One of the most important advantages of food irradiation processing is

It can be applied to food after its final packaging

Слайд 31Are irradiated foods still nutritious?

Their nutritional value doesn’t change

levels of

no significant changes in the amino acid, fatty acid, or vitamin content of food.

the changes induced by irradiation are so minimal that it is not easy to determine whether or not a food has been irradiated.

A big advantage of irradiated food, is that it is a cold process: the food is still essentially “raw”, because it hasn’t undergone any thermal process.

Слайд 32

Disadvantages

Is used on a very limited range of foods as it

Affects some important constituents of foods, for example, vitamin E levels can be reduced by 25% after irradiation and vitamin C by 5-10%

Radiation doses at the levels recommended will not kill all micro organisms, 90% may be destroyed so need to handle with care otherwise remaining organisms can reproduce rapidly

Ineffective against viruses - as they are the smallest pathogens that have DNA or RNA, and they are relatively resistant to irradiation at the levels approved for foods.

Слайд 33Prions, such as the one that causes “mad cow” disease (bovine

Can create new substances called Radiolytic products. While this does not mean that the food is radioactive, there is considerable controversy over whether these products are unique and if so whether they are dangerous.

Слайд 36Current Scenario

Preferences of the consumers have shifted towards healthy, tasty

Challenge to Food Industries – providing such foods in a form suitable for distribution and mass production without affecting texture, flavour, and color, is technically complex and expensive.

Слайд 37What is Cold Plasma Technology ?

Cold Plasma Technology is a novel,

Plasma is a mixture of positive and negative charges as well as neutral particles and photon. Plasma exist over a massive range in temperatures and densities.

It is estimated that 99% of the known universe is in a plasma state. The sun and stars are examples of natural plasmas

Слайд 38Generation of Plasma

Man-made plasma can be generated at low temperatures

Accelerated electrons collide with gas atoms to excite or ionise them. Ionisation of gas atoms releases more electrons; this cascaded reaction can generate a rich abundance of highly reactive chemical species which are capable of inactivating a wide range of microorganisms including food borne pathogens and spoilage organisms.

Слайд 41Cold Plasma Technology in Foods

Cold Plasma Technology in food Industry relies

The vacuum ultraviolet (VUV) energy is very effective in the breaking most organic bonds (i.e., C-H, C-C, C=C, C-O, and C-N) of surface contaminants. This helps to break apart high molecular weight contaminants.

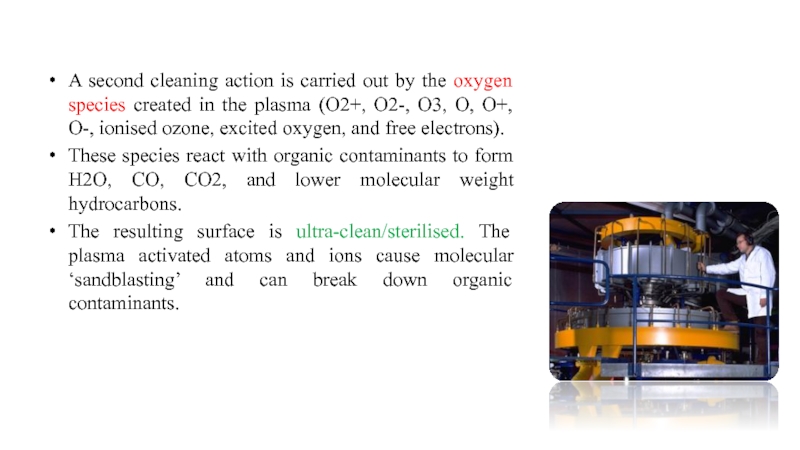

Слайд 42A second cleaning action is carried out by the oxygen species

These species react with organic contaminants to form H2O, CO, CO2, and lower molecular weight hydrocarbons.

The resulting surface is ultra-clean/sterilised. The plasma activated atoms and ions cause molecular ‘sandblasting’ and can break down organic contaminants.

Слайд 43

Cold plasma can be used for decontamination of products where micro-organisms

Unlike light ( UV decontamination), plasma flows around objects, which means ‘Shadows Effects’ do not occur ensuring all parts of a product are treated.

For products such as cut vegetables and fresh meat, there is no mild surface decontamination technology available currently, cold plasma could be used for this purpose.

Can also be used to disinfect surfaces before packaging or included as packaging process

Слайд 47

Illustration – Sterilization capability of Cold plasma

E.coli – inoculated in

One dish was left as a control with no plasma exposure, another was exposed for 30s of plasma treatment, and a third was exposed for 120 seconds.

The bacterial kill zone was progressively higher with longer plasma exposure

Слайд 49Common pathogen – Unprocessed meat – 70% Salmonella

Plasma Torch -

Plasma eliminated or subsequently reduced low levels of bacteria from both skinless chicken and chicken skin itself.

Слайд 50

Plasma is used as a method for killing Salmonella on egg shells.

Askild Holck, senior research scientist at Nofima:

“By using plasma treatment, we have

succeeded in removing 99.5 per cent of all bacteria on the egg shell but because this is a

gentle method, the egg yolk and white are unaffected."

Bacteria‐free eggs with plasma technology.

Слайд 52Concerns !!

Important aspects of this technology are still immature, particularly with

We do not know how cold plasma inactivates spores or how the cold plasma – specifically the electronically excited molecules – interact with the food or packaging materials, or the stability of the plasma for large-scale commercial operation.

Need to determine optimum operating conditions for a given application - Safety of treated products.

Слайд 54References

T.J. Mason, L. Paniwnyk, J.P. Lorimer. Ultrasonics Sonochemistry 3 (1996),

Retrieved from http://www.vscht.cz/ktk/www_324/studium/konzervace/pdf/ultrazvuk.pdf

Hao Feng, Gustavo V.Barbosa-Canovas, Jochen Weiss. Ultrasound technologies for Food and Bioprocessing. Food engineering series, pages 1-10

Retrieved from http://books.google.ca/books?id=jHRczaYL18C&printsec=frontcover&source=gbs_ge_summary_r&cad=0#v=onepage&q&f=false

Erika Kress-Rogers and Christopher J.B. Brimelow, Woodhead publishing in food science and technology, Instrumentation and sensors for the food industry-second edition. Pages 361-390

Zbigniew J. Dolatowski, Joanna Stadnik, Dariusz Stasiak ,Application of ultrasound in food technology, Acta Sci. Pol., Technol. Aliment. 6(3) 2007, 89-99

Слайд 55References

http://rspublication.com/ijeted/may-12/89.pdf

http://ccr.ucdavis.edu/irr/how_food_irr.shtml

http://www.stockandland.com.au/news/agriculture/horticulture/generalnews/irradiation-pros-and-cons/2665981.aspx

Слайд 57Presented by

Naveen Cheema [300774182]

Navdeep Bains [300769430]

Basani Prashanth Reddy [300778111]

Romil Patel

Bharath Battina [300776818]

Jithin M J [300778750]

![Low Power Ultrasound: Low energy [low power, low intensity] ultrasound Principles of LPU for Food](/img/tmb/3/277302/e64e6505b79355440b10c8c98611aaa8-800x.jpg)

![High Power Ultrasound: High energy [high power, high intensity] ultrasound 20 and 500 kHzDisruptive and](/img/tmb/3/277302/5479baea4d59064a45224db3ff4421d5-800x.jpg)

![Presented by Naveen Cheema [300774182]Navdeep Bains [300769430]Basani Prashanth Reddy [300778111]Romil Patel [300779128]Bharath Battina [300776818]Jithin M](/img/tmb/3/277302/77fd3bf599d9f06051ead9e5c13e0293-800x.jpg)