- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

WLS Definitions Training. Machine terminology, bucket sizing and selection презентация

Содержание

- 1. WLS Definitions Training. Machine terminology, bucket sizing and selection

- 2. Objective: to understand machine terminology to understand

- 3. Bucket Capacities - Heaped vs. Struck

- 4. Heaped Struck Machine terminology, bucket sizing and selection

- 5. Tipping Loads - Straight vs. Full Turn

- 6. Straight tipping load Machine terminology, bucket sizing and selection

- 7. Full Turn tipping load Machine terminology, bucket sizing and selection

- 8. Tipping Loads - Straight vs. Full Turn

- 9. Rated Operating Load (Payload) - Bucket vs.

- 10. Dump Clearance vs. Hinge-pin height Dump Clearance

- 11. Basic Requirements Primarily we are interested in

- 12. For the below listed models, calculate your

- 13. For the below listed models, calculate your

- 14. Worked Example – Bucket sizing Calculate the

Слайд 2Objective:

to understand machine terminology

to understand how to match bucket and density

Machine terminology, bucket sizing and selection

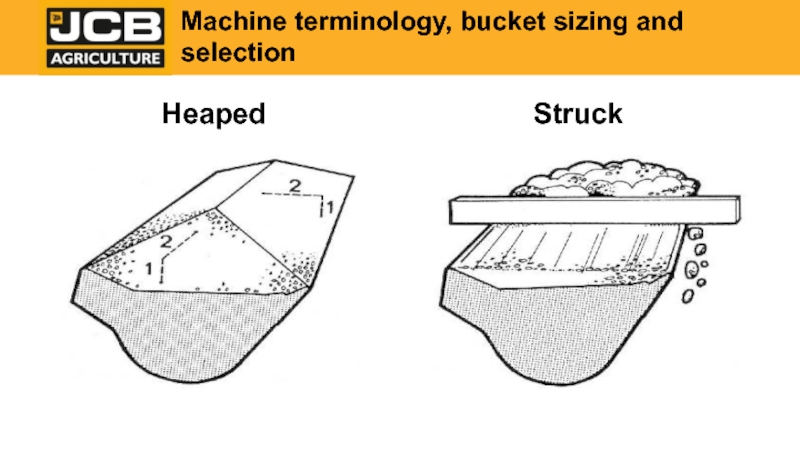

Слайд 3Bucket Capacities - Heaped vs. Struck

Heaped Capacity - The volume of

Struck Capacity - The volume of material held in a bucket when a straight edge is slid across the top and bottom edge of a bucket, no material outside dimension of bucket.

Machine terminology, bucket sizing and selection

Слайд 5Tipping Loads - Straight vs. Full Turn

Straight tipping load - The

Full Turn tipping load - The weight of material loaded into the specified bucket which will raise any tire from the ground when the machine is fully articulated. - This amount is always lower as the counterweight moves nearer the pivot point. It is this reason which makes articulated loaders harder to drive than they at first appear.

Machine terminology, bucket sizing and selection

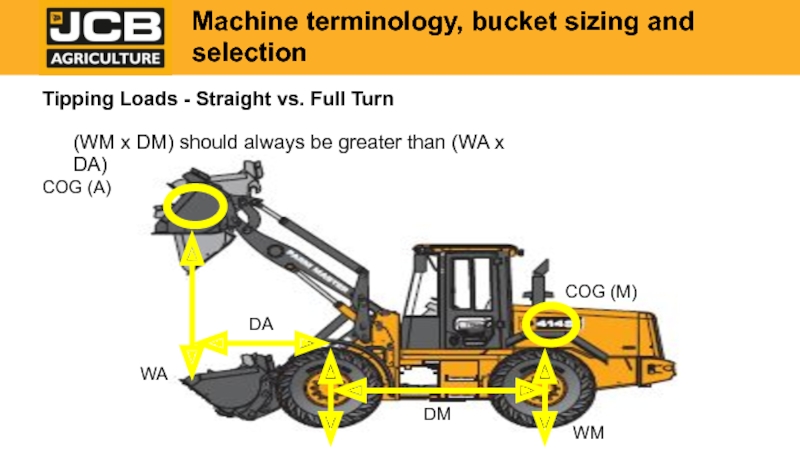

Слайд 8Tipping Loads - Straight vs. Full Turn

(WM x DM) should always

COG (M)

DM

COG (A)

DA

WM

WA

Machine terminology, bucket sizing and selection

Слайд 9Rated Operating Load (Payload) - Bucket vs. Forks

Rated Operating Load is

Bucket Operating Load is 50% of the machines full turn tipping load with specified bucket

Fork Operating Load is 60% of the machine full turn tipping load with specified fork attachment. (This can be raised to 80% if the machine is used solely on flat level surfaces)

Machine terminology, bucket sizing and selection

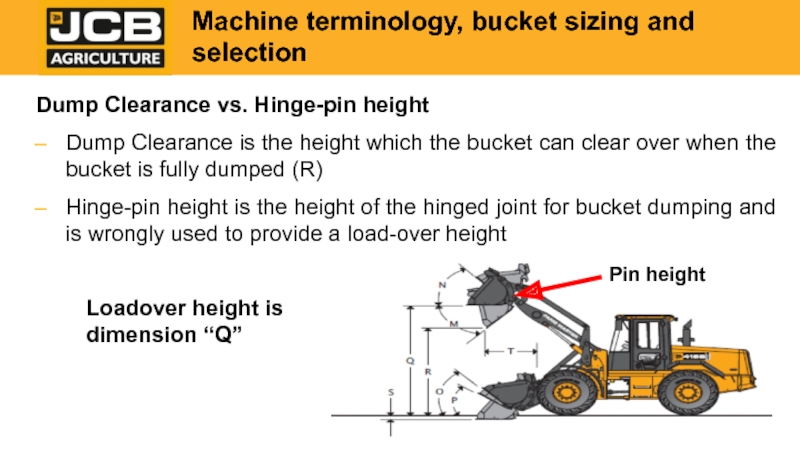

Слайд 10Dump Clearance vs. Hinge-pin height

Dump Clearance is the height which the

Hinge-pin height is the height of the hinged joint for bucket dumping and is wrongly used to provide a load-over height

Loadover height is dimension “Q”

Pin height

Machine terminology, bucket sizing and selection

Слайд 11Basic Requirements

Primarily we are interested in throughput, tonnage, m³ etc, whatever

Variables to consider:

Site conditions

Material to be handled

Loadover height & reach

Required production rates and throughput

Truck/trailer loading rates and availability

Machine terminology, bucket sizing and selection

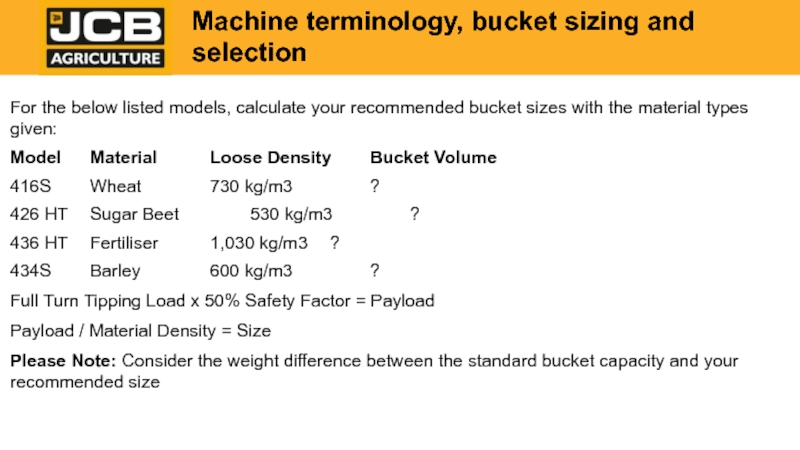

Слайд 12For the below listed models, calculate your recommended bucket sizes with

Model Material Loose Density Bucket Volume

416S Wheat 730 kg/m3 ?

426 HT Sugar Beet 530 kg/m3 ?

436 HT Fertiliser 1,030 kg/m3 ?

434S Barley 600 kg/m3 ?

Full Turn Tipping Load x 50% Safety Factor = Payload

Payload / Material Density = Size

Please Note: Consider the weight difference between the standard bucket capacity and your recommended size

Machine terminology, bucket sizing and selection

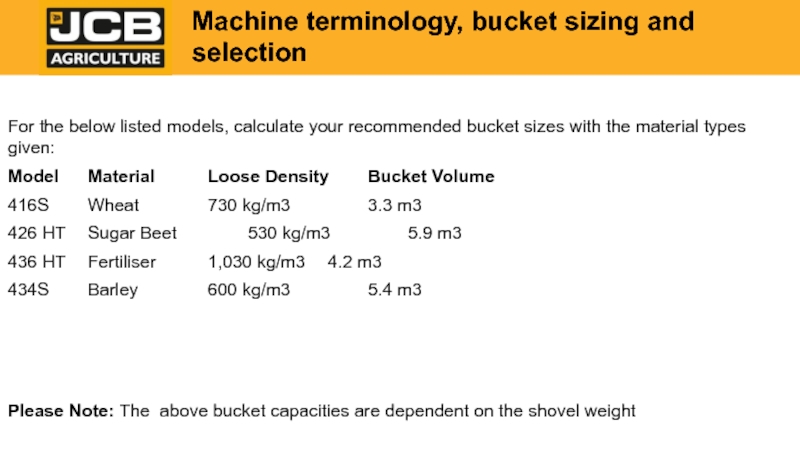

Слайд 13For the below listed models, calculate your recommended bucket sizes with

Model Material Loose Density Bucket Volume

416S Wheat 730 kg/m3 3.3 m3

426 HT Sugar Beet 530 kg/m3 5.9 m3

436 HT Fertiliser 1,030 kg/m3 4.2 m3

434S Barley 600 kg/m3 5.4 m3

Please Note: The above bucket capacities are dependent on the shovel weight

Machine terminology, bucket sizing and selection

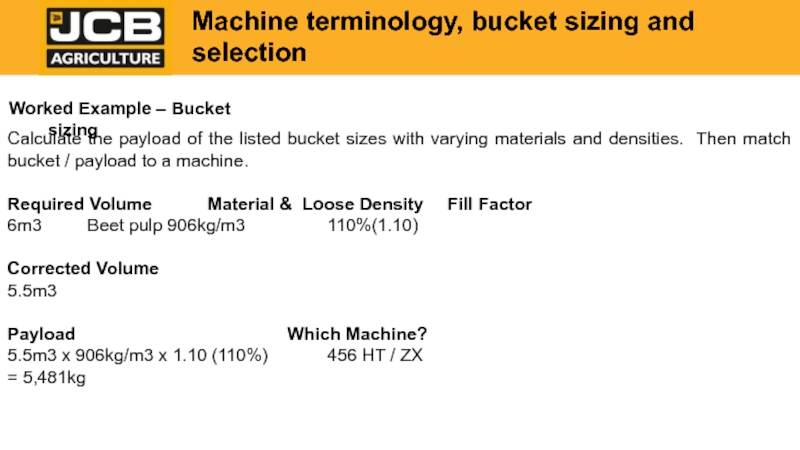

Слайд 14Worked Example – Bucket sizing

Calculate the payload of the listed bucket

Required Volume Material & Loose Density Fill Factor

6m3 Beet pulp 906kg/m3 110%(1.10)

Corrected Volume

5.5m3

Payload Which Machine?

5.5m3 x 906kg/m3 x 1.10 (110%) 456 HT / ZX

= 5,481kg

Machine terminology, bucket sizing and selection