- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Reliability of bearing knots презентация

Содержание

- 1. Reliability of bearing knots

- 2. FUNCTION OF A BEARING The main function

- 3. Bearings are classified under two main categories:

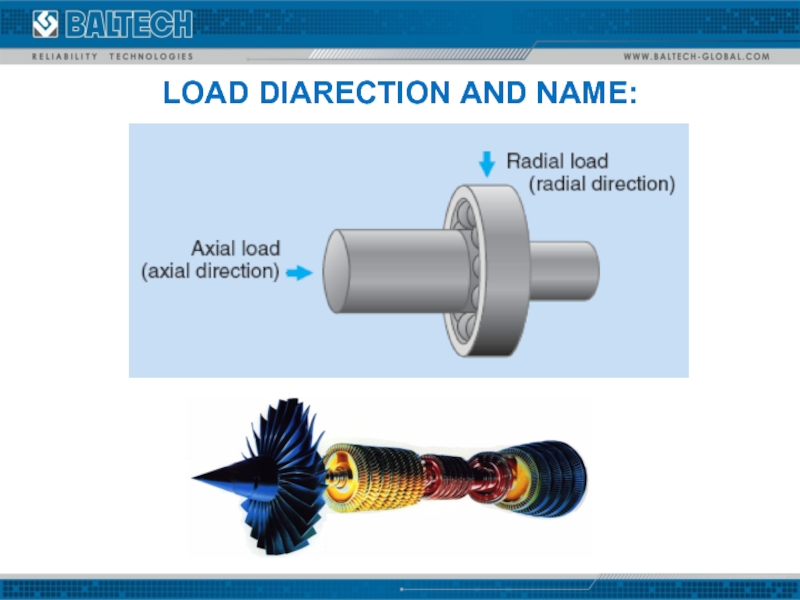

- 4. LOAD DIARECTION AND NAME:

- 5. Sleeve Bearing

- 6. Description: Bearing used to constrain, guide, or

- 7. Sleeve Bearing Materials Relative softness (to absorb

- 8. Materials Whitemetal - usually used as a

- 9. Materials Sintered bronze - Sintered bronze is

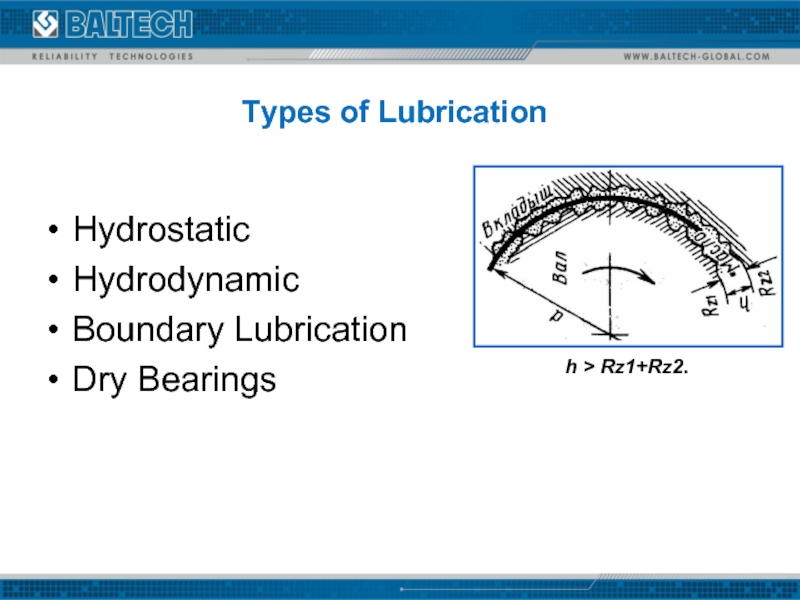

- 10. Types of Lubrication Hydrostatic Hydrodynamic Boundary Lubrication Dry Bearings h > Rz1+Rz2.

- 11. Advantages and disadvantages of the plain bearing

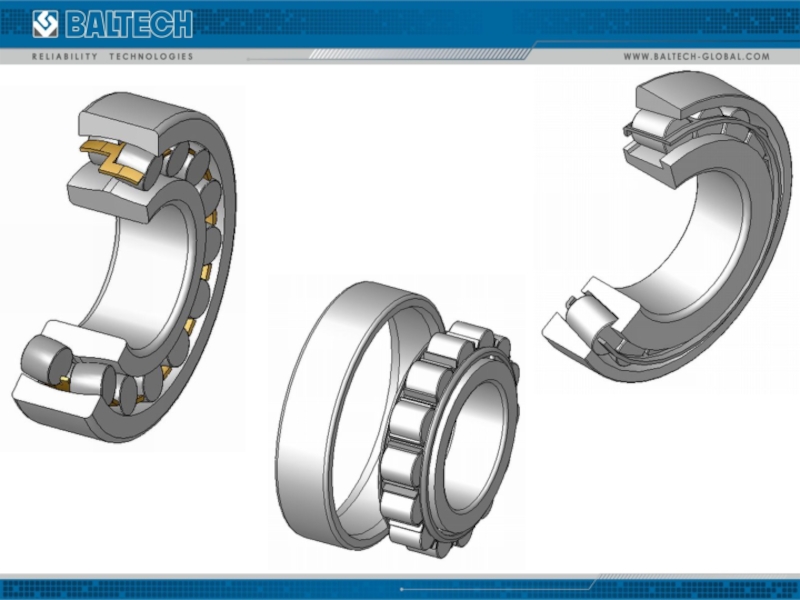

- 12. Ball and roller bearings

- 13. Races and balls are high carbon chrome

- 14. Inner ring or race which fits on

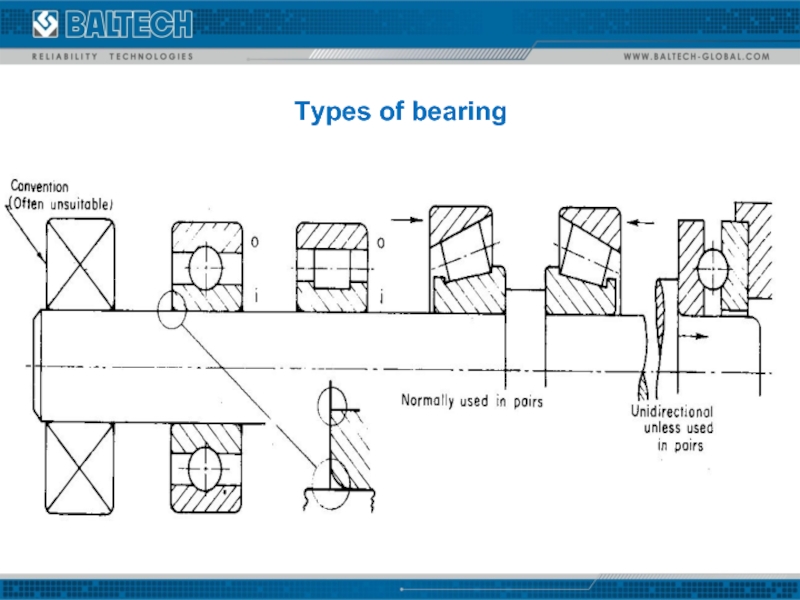

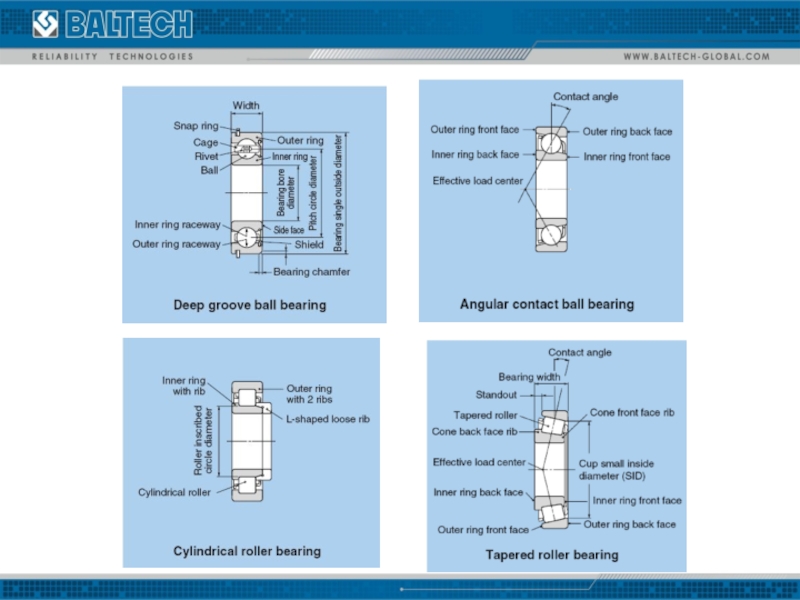

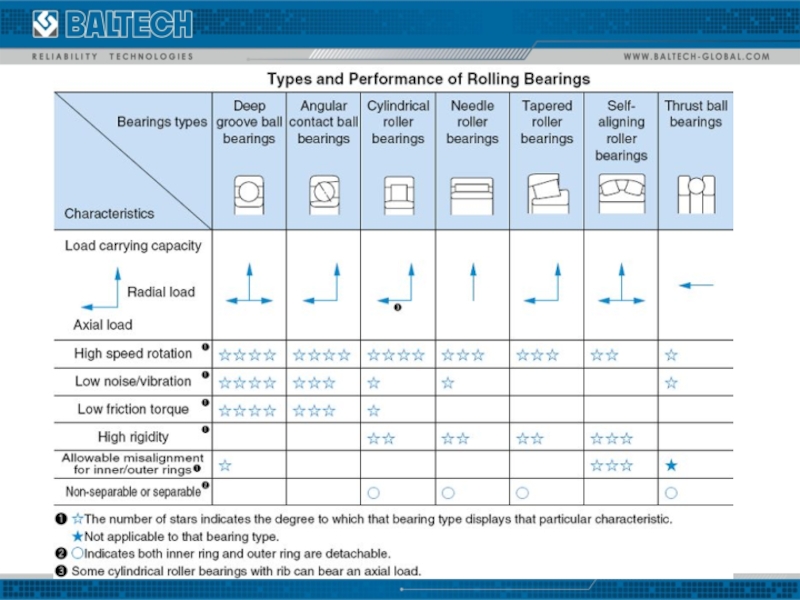

- 15. Types of bearing

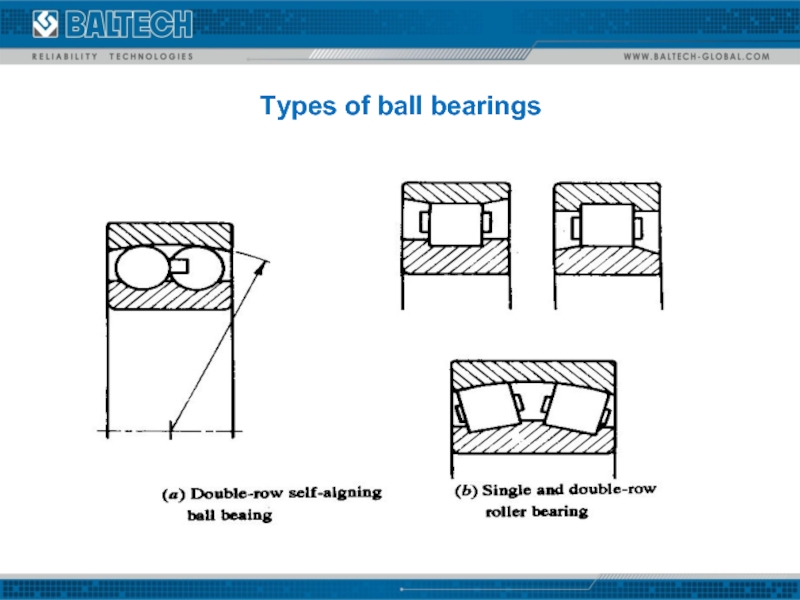

- 17. Types of ball bearings

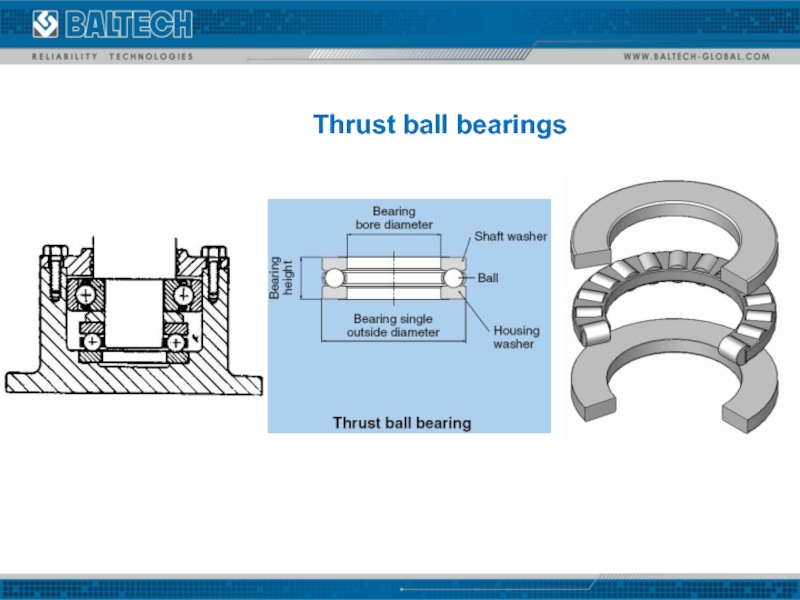

- 20. Thrust ball bearings

- 22. Tapered roller bearing (TRB): TRB can take

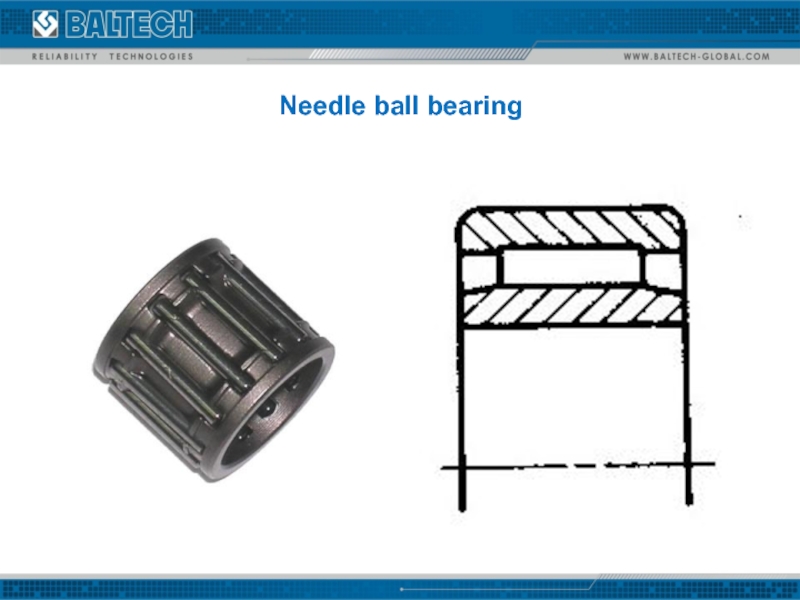

- 23. Needle ball bearing

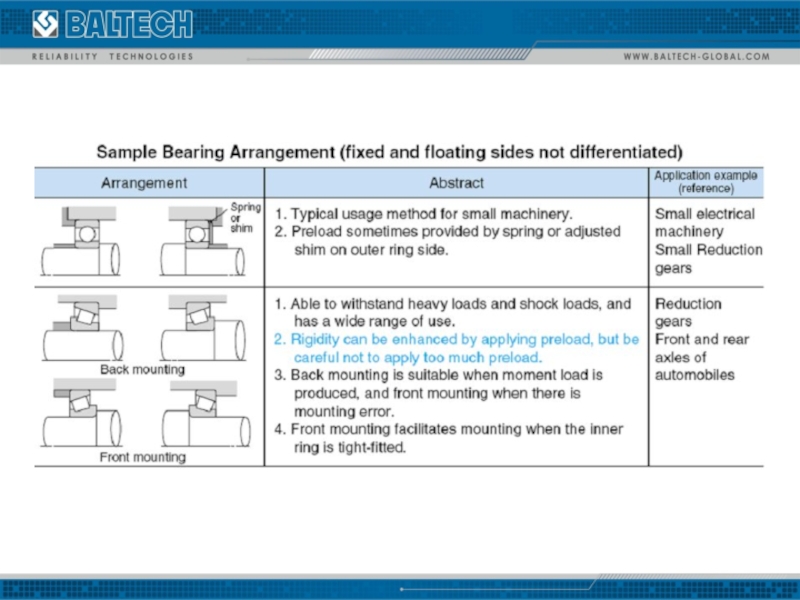

- 29. Bearing stock conditions

- 33. During the work with rotation bearings lack

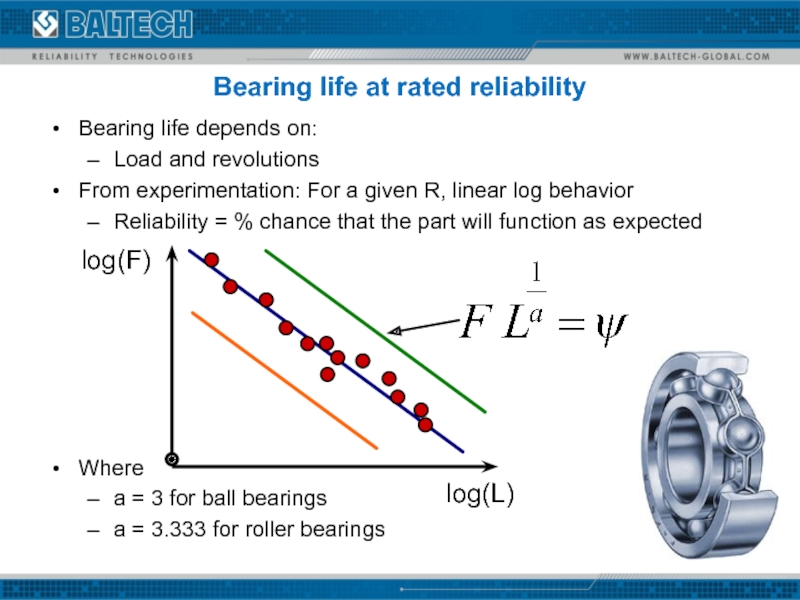

- 34. Bearing life depends on: Load and revolutions

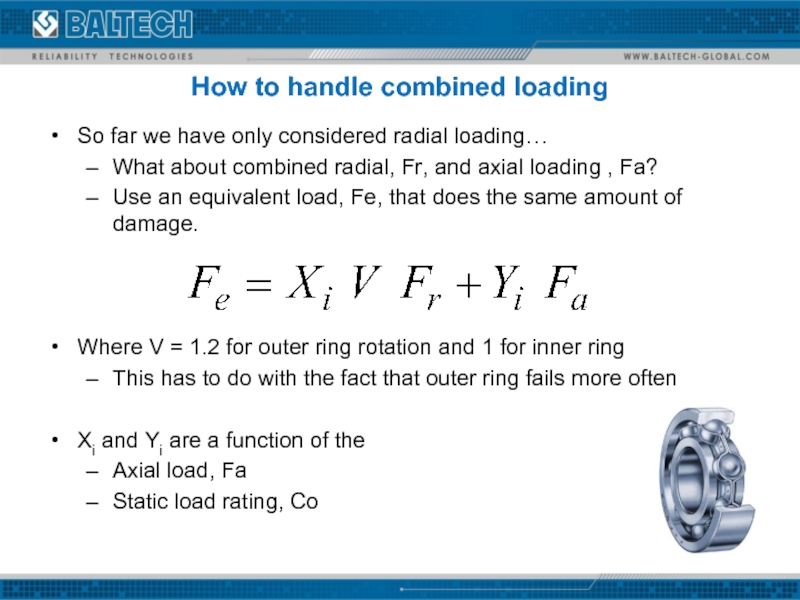

- 35. How to handle combined loading So far

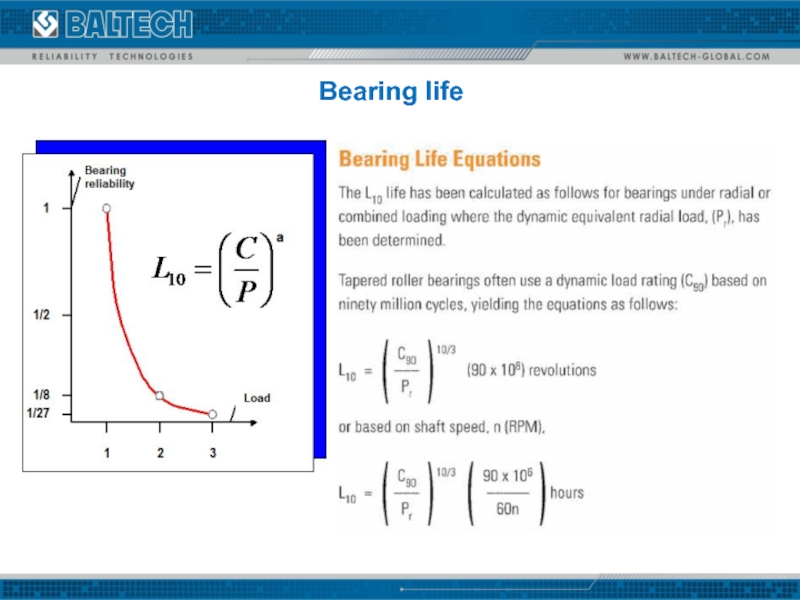

- 36. Bearing life

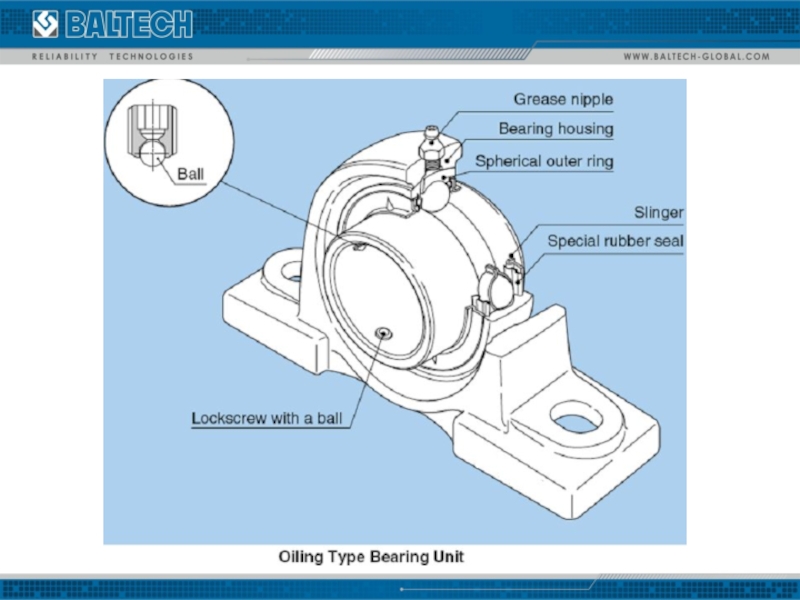

- 37. Bearing Mounting For instrument bearings, certain

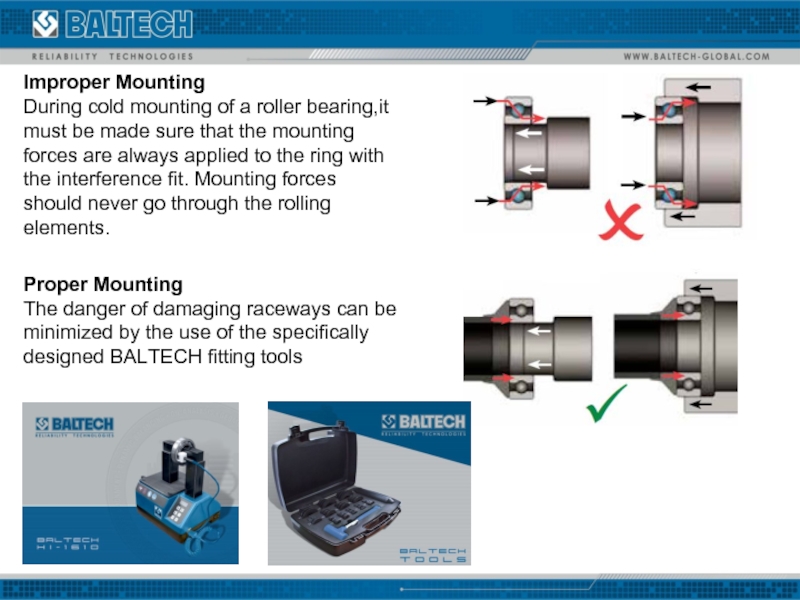

- 38. Improper Mounting During cold mounting of a

- 39. INDUCTION HEATERS BALTECH HI SERIES The

- 48. BALTECH Germany Kronsforder Allee 45, 23560,

Слайд 2FUNCTION OF A BEARING

The main function of a rotating shaft is

It needs a good support to ensure stability and frictionless rotation. The support for the shaft is known as “bearing”.

The shaft has a “running fit” in a bearing. All bearing are provided some lubrication arrangement to reduced friction between shaft and bearing.

Слайд 3Bearings are classified under two main categories:

Plain or slider bearing :

In which the rotating shaft has a sliding contact with the bearing which is held stationary . Due to large contact area friction between mating parts is high requiring greater lubrication.

Rolling or anti-friction bearing : -

Due to less contact area rolling friction is much lesser than the sliding friction , hence these bearings are also known as antifriction bearing.

Слайд 6Description:

Bearing used to constrain, guide, or reduce friction in rotary applications.

Work

Proper lubrication is required to reduce wear and friction.

Слайд 7Sleeve Bearing Materials

Relative softness (to absorb foreign particles), reasonable strength, machinability

A bearing element should be less than one-third as hard as the material running against it in order to provide embedability of abrasive particles.

Слайд 8Materials

Whitemetal - usually used as a lining bonded to bronze, steel

Copper Based alloys - most common alloys are copper tin, copper lead, phosphor bronze: harder and stronger than whitemetal: can be used un-backed as a solid bearing.

Aluminium based alloys - running properties not as good as copper based alloys but cheaper.

Слайд 9Materials

Sintered bronze - Sintered bronze is a porous material which can

Nylon - used only in very light applications.

Слайд 11Advantages and disadvantages of the plain bearing

Plain bearing are cheap to

Disadvantages are they require large supply of lubricating oil, they are suitable only for relative low temperature and speed; and starting resistance is much greater than running resistance due to slow build up of lubricant film around the bearing surface.

Слайд 12Ball and roller bearings due to low rolling friction

Frictional resistance considerably less than in plain bearings

Rotating – non-rotating pairs separated by balls or rollers

Ball or rollers has rolling contact and sliding friction is eliminated and replaced by much lower rolling friction.

In plain bearing the starting resistance is much larger than the running resistance due to absence of oil film.

In ball and rolling bearings the initial resistance to motion is only slightly more than their resistance to continuous running.

Hence ball and rolling bearing are more suitable to drives subject to frequent starting and stopping as they save power.

Owing to the low starting torque, a low power motor can be used for a line shaft running in ball bearing.

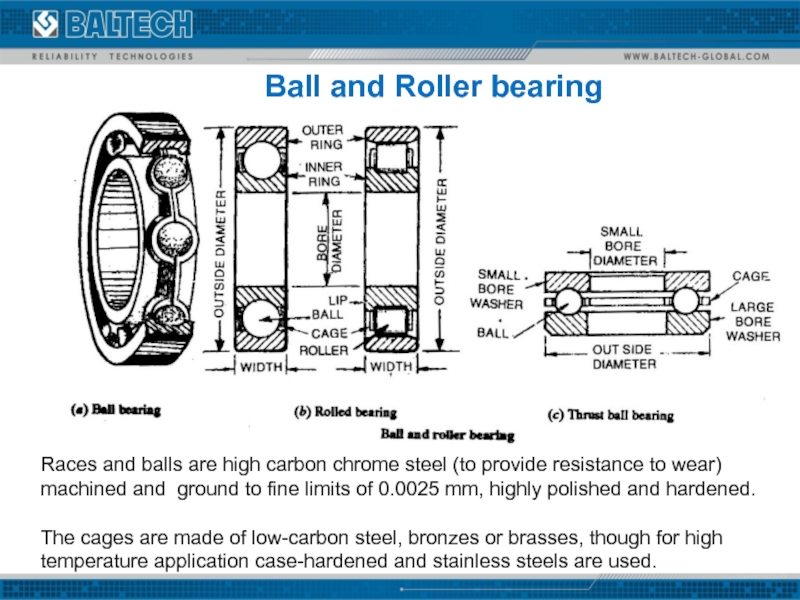

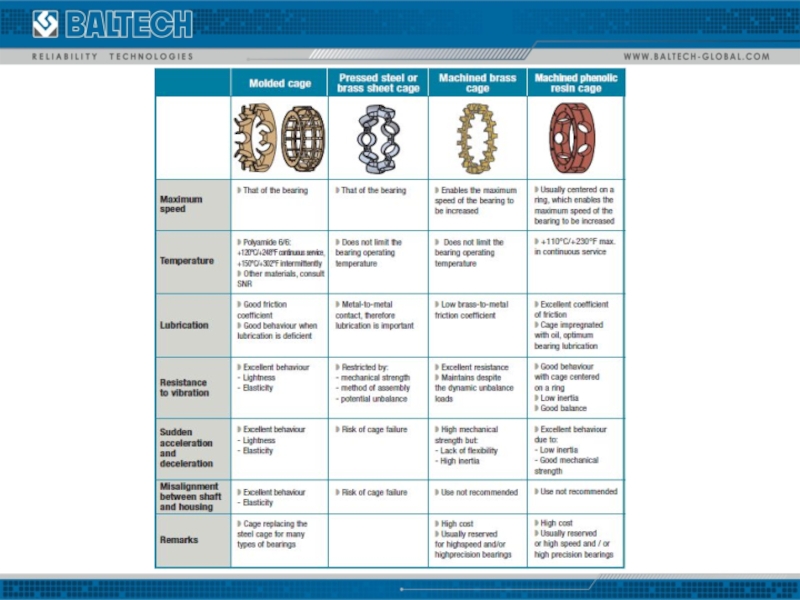

Слайд 13Races and balls are high carbon chrome steel (to provide resistance

The cages are made of low-carbon steel, bronzes or brasses, though for high temperature application case-hardened and stainless steels are used.

Ball and Roller bearing

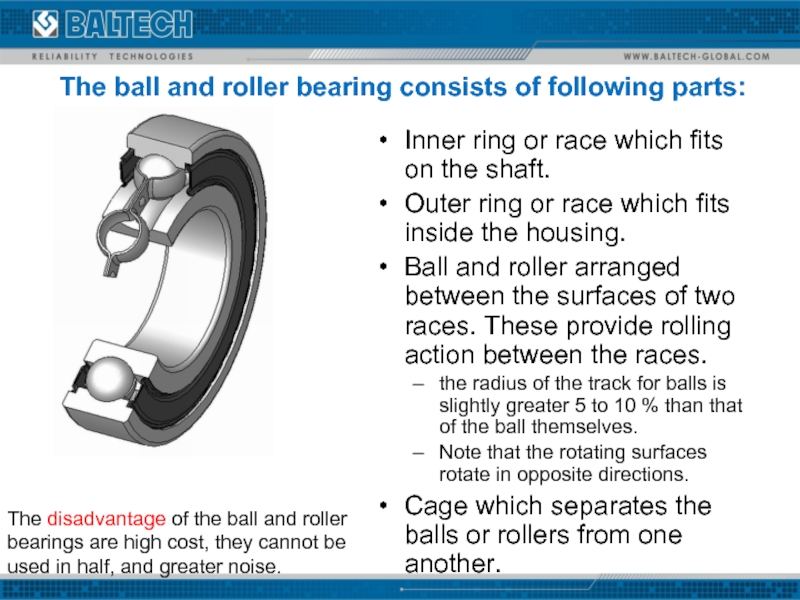

Слайд 14Inner ring or race which fits on the shaft.

Outer ring or

Ball and roller arranged between the surfaces of two races. These provide rolling action between the races.

the radius of the track for balls is slightly greater 5 to 10 % than that of the ball themselves.

Note that the rotating surfaces rotate in opposite directions.

Cage which separates the balls or rollers from one another.

The disadvantage of the ball and roller bearings are high cost, they cannot be used in half, and greater noise.

The ball and roller bearing consists of following parts:

Слайд 22Tapered roller bearing (TRB):

TRB can take both radial and axial loads

Thrust ball bearing:

It can take only thrust loads.

Thrust ball bearing are used for heavy axial loads and low speeds.

Needle roller bearing:

It use small diameter of rollers. They are used for radial load at slow speed and oscillating motion.

They have the advantage of light weight and occupy small space.

They are used in aircraft industry, live tail stock centers, bench-drill spindles, etc.

APPLICATIONS OF ROLLER BEARINGS

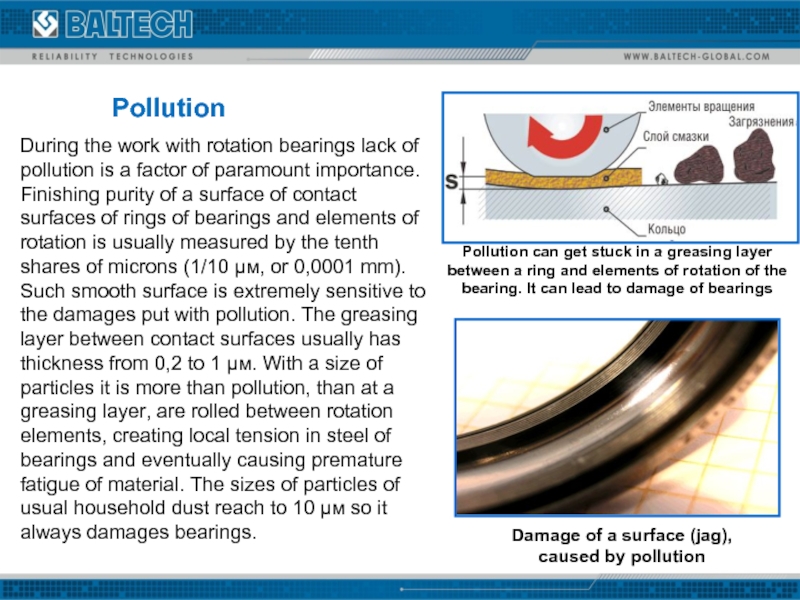

Слайд 33During the work with rotation bearings lack of pollution is a

Pollution

Pollution can get stuck in a greasing layer between a ring and elements of rotation of the bearing. It can lead to damage of bearings

Damage of a surface (jag),

caused by pollution

Слайд 34Bearing life depends on:

Load and revolutions

From experimentation: For a given R,

Reliability = % chance that the part will function as expected

Where

a = 3 for ball bearings

a = 3.333 for roller bearings

Bearing life at rated reliability

log(F)

log(L)

Слайд 35How to handle combined loading

So far we have only considered radial

What about combined radial, Fr, and axial loading , Fa?

Use an equivalent load, Fe, that does the same amount of damage.

Where V = 1.2 for outer ring rotation and 1 for inner ring

This has to do with the fact that outer ring fails more often

Xi and Yi are a function of the

Axial load, Fa

Static load rating, Co

Слайд 37Bearing Mounting

For instrument bearings, certain special considerations should be emphasized:

Heavy press fits should be avoided.

Accuracy of mounting surfaces should be equal to accuracy of mating bearing surface.

Misalignment for low torque and running accuracy should not exceed 1/4°. Loading across the bearing during assembly should be avoided.

Слайд 38Improper Mounting

During cold mounting of a roller bearing,it must be made

Proper Mounting

The danger of damaging raceways can be

minimized by the use of the specifically

designed BALTECH fitting tools

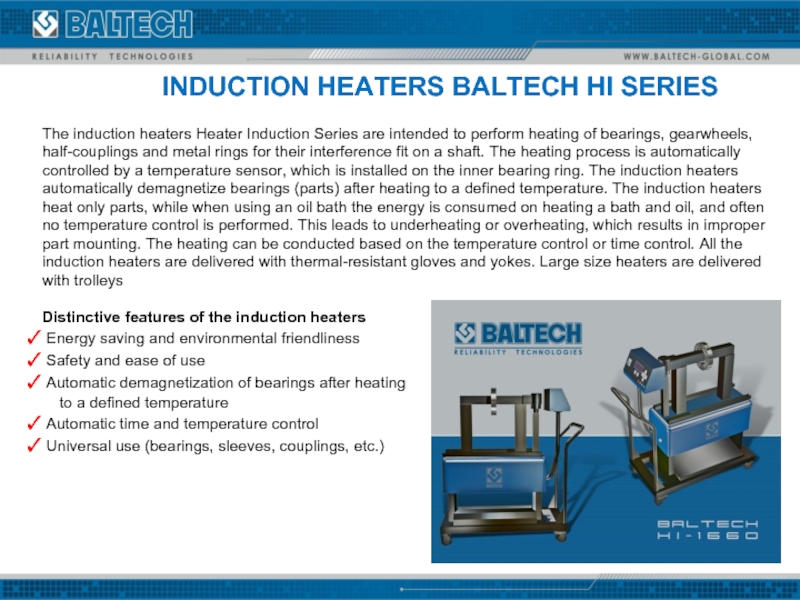

Слайд 39INDUCTION HEATERS BALTECH HI SERIES

The induction heaters Heater Induction Series are

Distinctive features of the induction heaters

Energy saving and environmental friendliness

Safety and ease of use

Automatic demagnetization of bearings after heating to a defined temperature

Automatic time and temperature control

Universal use (bearings, sleeves, couplings, etc.)

Слайд 48BALTECH

Germany

Kronsforder Allee 45, 23560, Lübeck

Tel: +49 (0) 451-370-87-700,

Fax: +49 (0)

Internet: www.baltech.biz, E-Mail: info@baltech.biz

Russia

St. Petersburg, 194044, Chugunnaya, 40

Tel/fax: +7 (812) 335-00-85,

Internet: www.baltech.ru, E-mail: info@baltech.ru

Kazakhstan

Astana city, Pobeda Avenue (Avenue Jenis) 79B, office number 408

Tel/fax: +7 (7172) 52-29-42, 52-29-43, 52-29-66,

Internet: www.baltech.kz, E-mail: info@baltech.kz