- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

3D Printing презентация

Содержание

- 1. 3D Printing

- 2. Printing process Printing is a process for

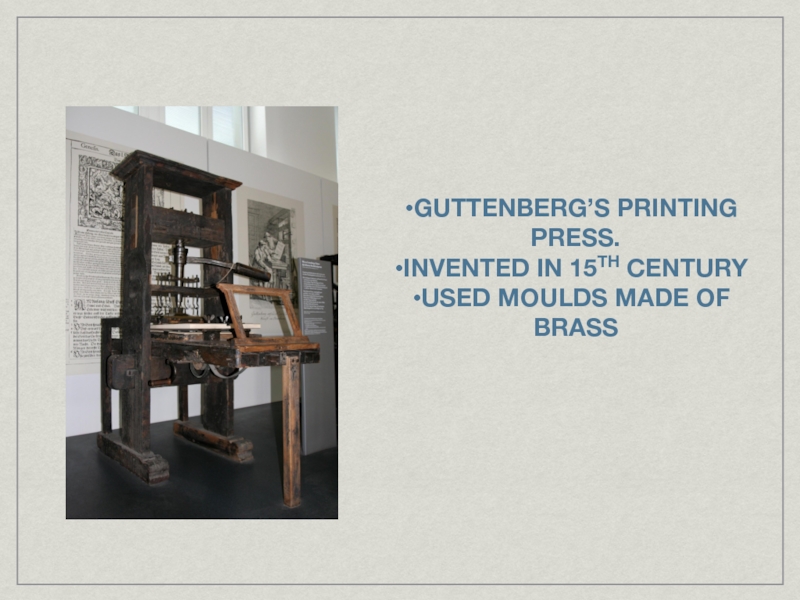

- 3. GUTTENBERG’S PRINTING PRESS. INVENTED IN 15TH CENTURY USED MOULDS MADE OF BRASS

- 4. Invention of first printing machine FIRST PRINTING

- 5. Subtractive

- 6. Computerized Numerical Control (CNC) Machining A method

- 7. Additive Manufacturing Creates a product through adding

- 8. 3D Printing

- 9. 3D printing Imagine a near future

- 10. Different methods Selective laser sintering (SLS) Stereolithography Fused deposition modeling (FDM) Laminated object manufacturing

- 11. SLS method Selective laser sintering (SLS)

- 12. STEREOLITHOGRAPHY Stereolithography is an additive manufacturing process

- 13. STEREOLITHOGRAPHY

- 14. FDM Fused deposition modeling (FDM) is an

- 15. Laminated object

- 16. Equipment types Dimension 3D printer

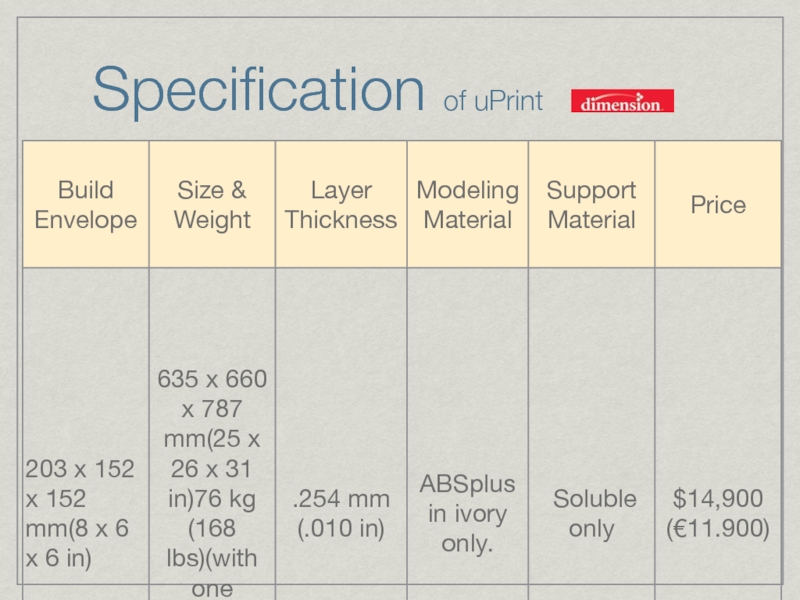

- 17. Specification of uPrint

- 18. What is ABSplus? ABSplus is a production-grade

- 19. Technique

- 21. The PRINTING CYCLE Preparation : Once

- 22. The PRINTING CYCLE b) Printing

- 23. The PRINTING CYCLE The binder solidifies the

- 24. The PRINTING CYCLE c) Depowdering/Recycling :

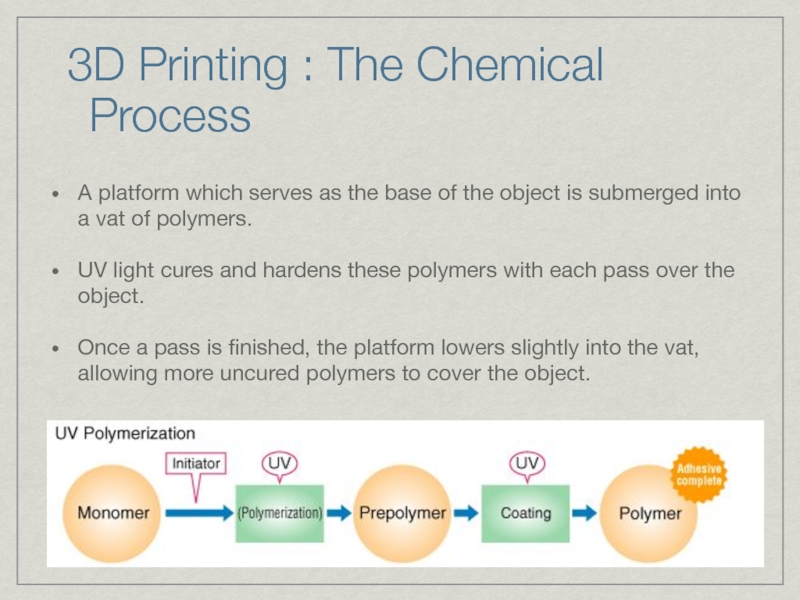

- 25. 3D Printing : The Chemical Process A

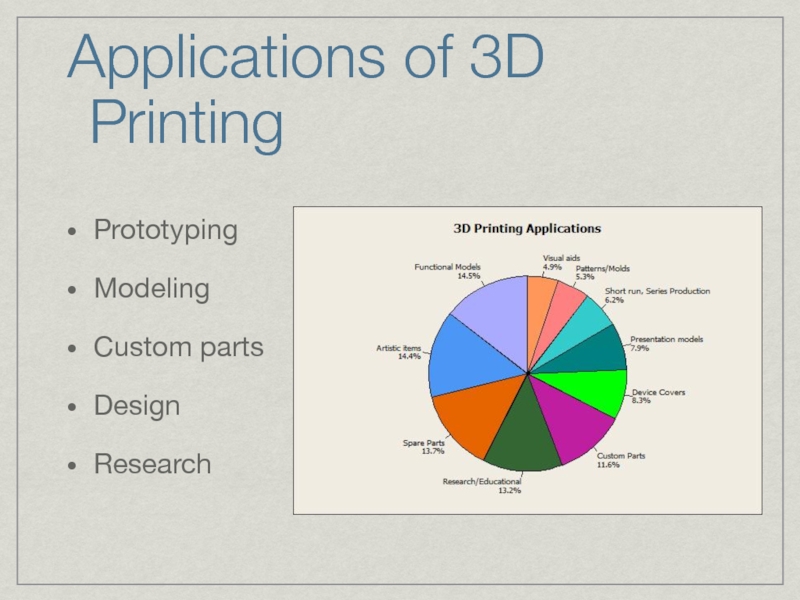

- 26. Applications of 3D Printing Prototyping Modeling Custom parts Design Research

- 27. 3D Printing and Sustainability 3D printing with

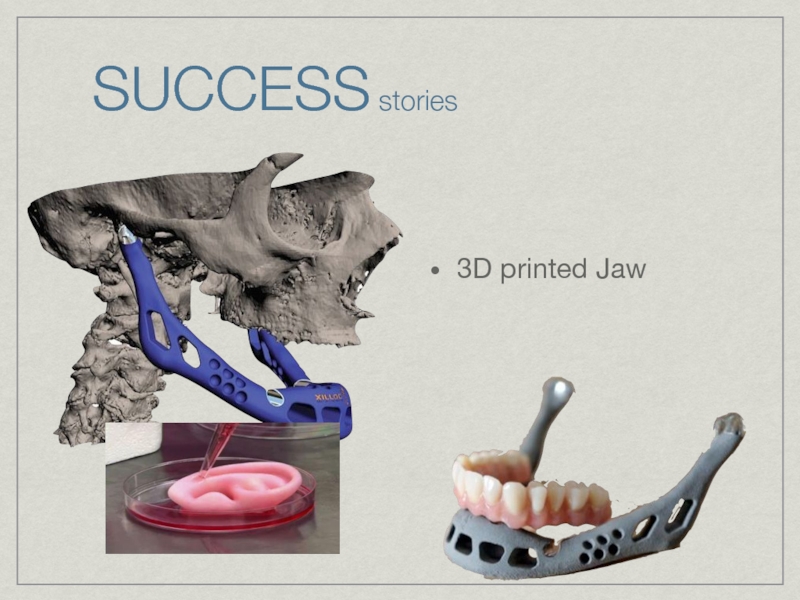

- 28. SUCCESS stories 3D printed Jaw

- 29. Challenges Facing 3D Printing Intellectual property rights

- 30. In Conclusion 3D printing is an expanding

- 31. References http://en.wikipedia.org/wiki/3D_computer_graphics

Слайд 2Printing process

Printing is a process for reproducing text and images, typically

Слайд 4Invention of first printing machine

FIRST PRINTING MACHINE WAS INVENTED BY JOHANNES

THIS SUPERSEDED THE COST AND SLOW PRODUCTION.

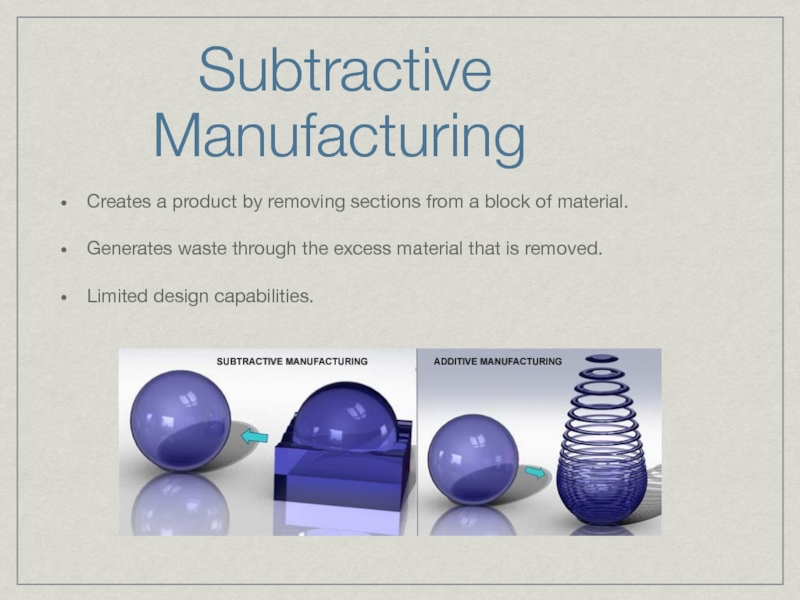

Слайд 5 Subtractive

Creates a product by removing sections from a block of material.

Generates waste through the excess material that is removed.

Limited design capabilities.

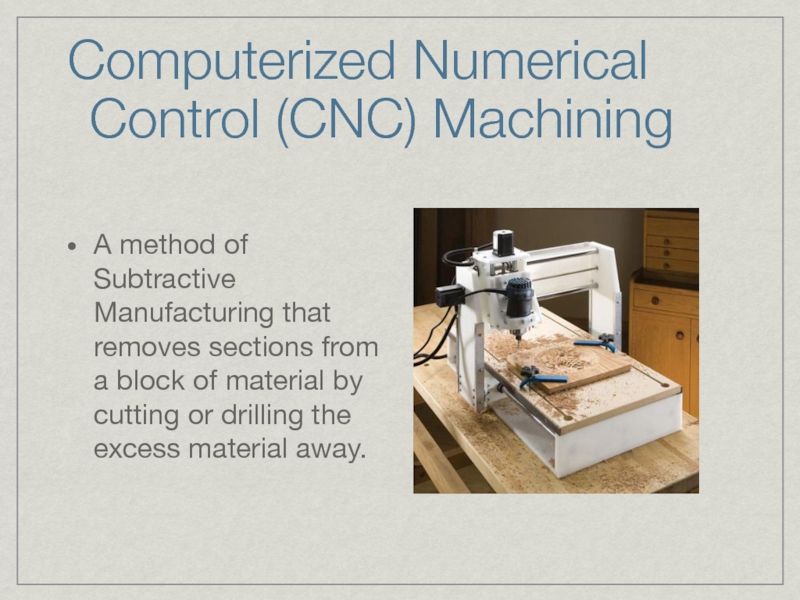

Слайд 6Computerized Numerical Control (CNC) Machining

A method of Subtractive Manufacturing that removes

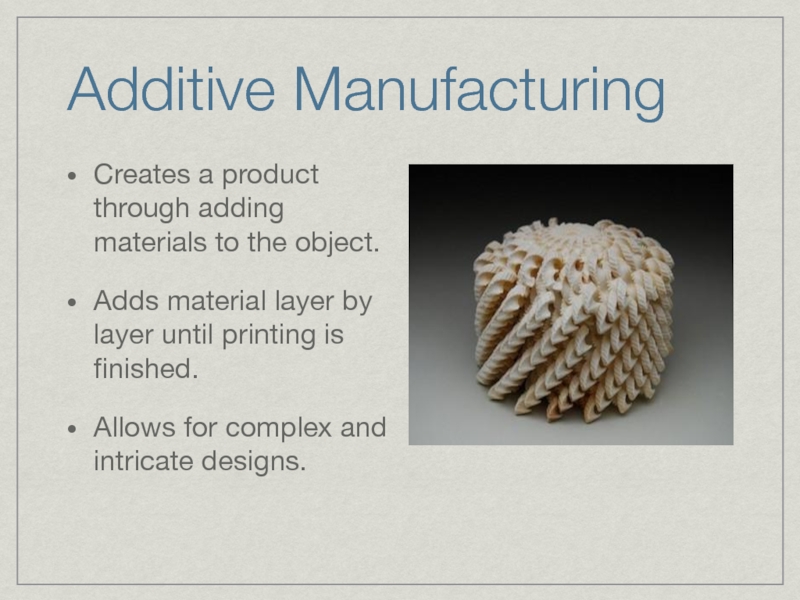

Слайд 7Additive Manufacturing

Creates a product through adding materials to the object.

Adds material

Allows for complex and intricate designs.

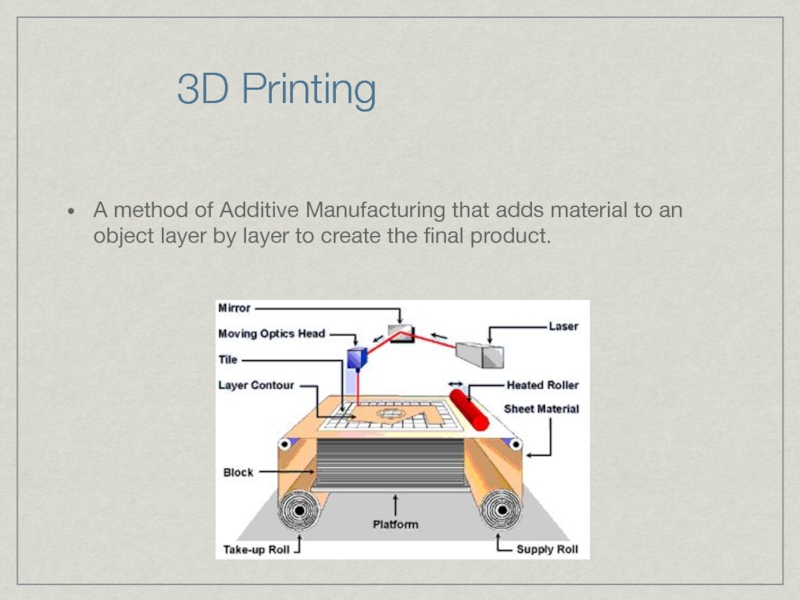

Слайд 8 3D Printing

A method of Additive

Слайд 9 3D printing

Imagine a near future in which a device connected

We can have tangible goods and intangible services delivered over the INTERNET.

Слайд 10Different methods

Selective laser sintering (SLS)

Stereolithography

Fused deposition modeling (FDM)

Laminated object manufacturing

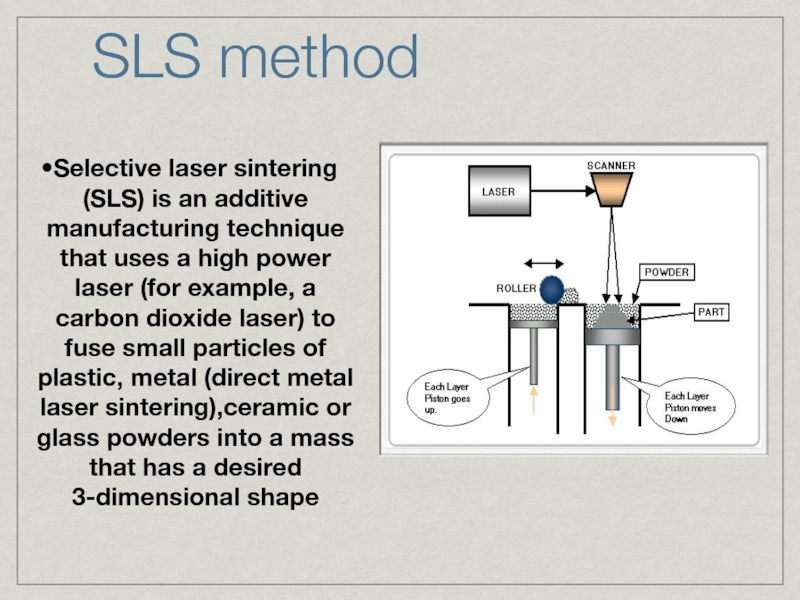

Слайд 11SLS method

Selective laser sintering (SLS) is an additive manufacturing technique that

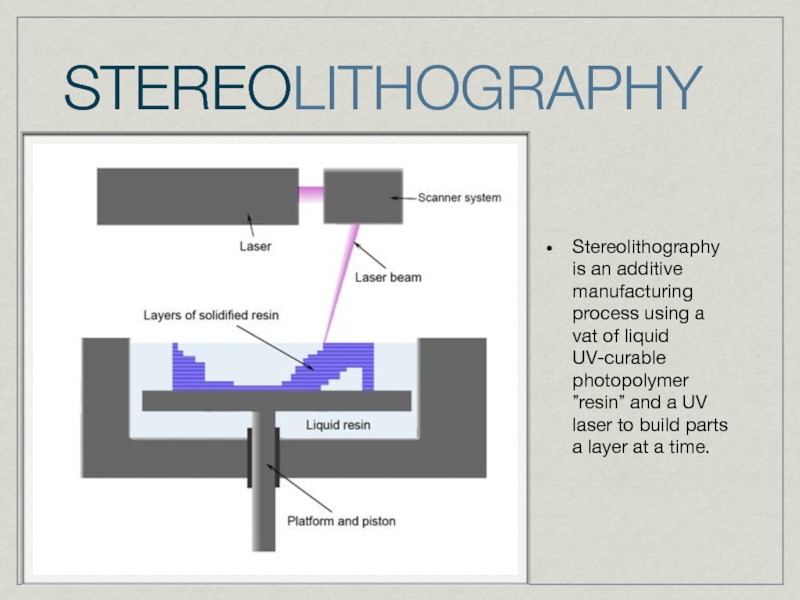

Слайд 12STEREOLITHOGRAPHY

Stereolithography is an additive manufacturing process using a vat of liquid

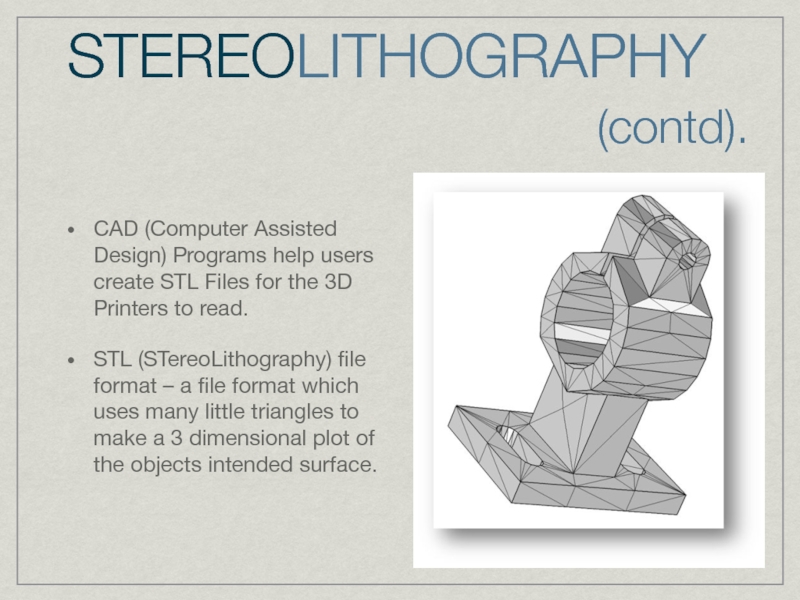

Слайд 13STEREOLITHOGRAPHY

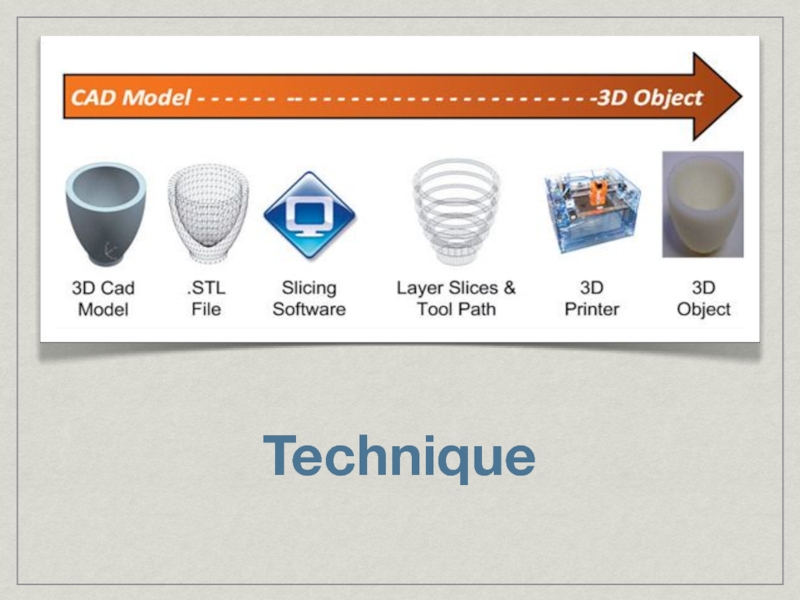

CAD (Computer Assisted Design) Programs help users create STL Files for the 3D Printers to read.

STL (STereoLithography) file format – a file format which uses many little triangles to make a 3 dimensional plot of the objects intended surface.

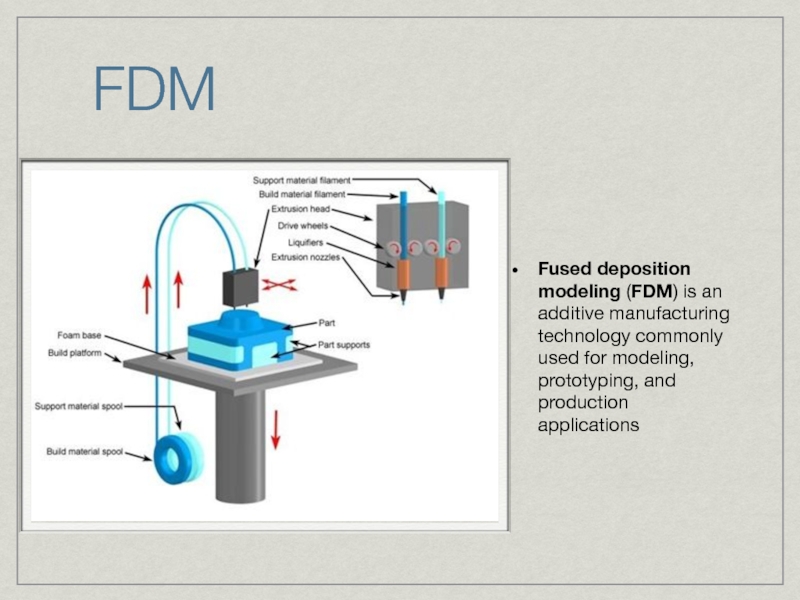

Слайд 14FDM

Fused deposition modeling (FDM) is an additive manufacturing technology commonly used

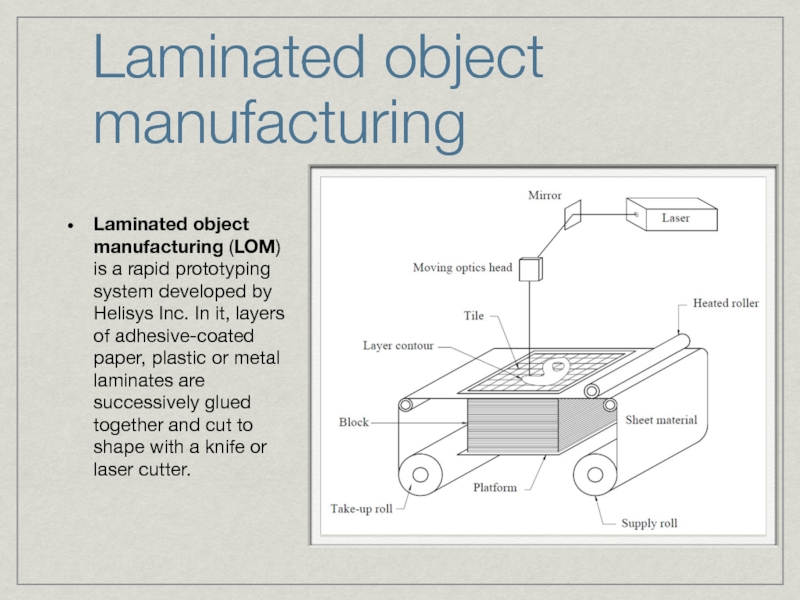

Слайд 15Laminated object manufacturing

Laminated

Слайд 18What is ABSplus?

ABSplus is a production-grade thermoplastic that gives models the

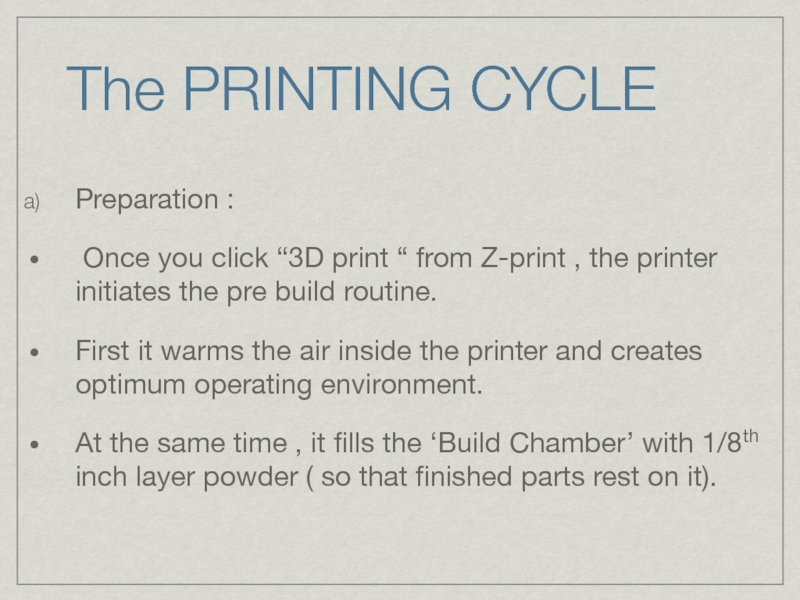

Слайд 21The PRINTING CYCLE

Preparation :

Once you click “3D print “ from

First it warms the air inside the printer and creates optimum operating environment.

At the same time , it fills the ‘Build Chamber’ with 1/8th inch layer powder ( so that finished parts rest on it).

Слайд 22The PRINTING CYCLE

b) Printing :

Once the pre-build is complete

The machine deposits 0.1mm thick layer of powder from the ‘Hopper”.

The ‘Print Carriage’ then moves across this layer depositing the binder.

Слайд 23The PRINTING CYCLE

The binder solidifies the powder in that cross section

The piston below the ’Build Carriage ’ lowers the powdered bed by 0.1mm , preparing the next layer.

The process repeats until the model is complete

Слайд 24The PRINTING CYCLE

c) Depowdering/Recycling :

When finished the model, it is

At the end of curing time , the machine then automatically removes most of the powder around the model by vaccum pressure.

The loose powder is pneumatically conveyed through the system for reuse.

Слайд 253D Printing : The Chemical Process

A platform which serves as the

UV light cures and hardens these polymers with each pass over the object.

Once a pass is finished, the platform lowers slightly into the vat, allowing more uncured polymers to cover the object.

Слайд 273D Printing and Sustainability

3D printing with non harmful chemicals.

3D printing generates

3D Printing can be used to create replacement parts.

Слайд 29Challenges Facing 3D Printing

Intellectual property rights of the 3D Printer users.

Nearly

Слайд 30In Conclusion

3D printing is an expanding technology which may soon start

3D printing has a lot of possible benefits to society, although the products created must be regulated.