- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Fundamentals of quality. (Chapter 2) презентация

Содержание

- 1. Fundamentals of quality. (Chapter 2)

- 2. Process Basics Definition of a process

- 3. Definition of a process It is

- 4. Definition of a Process Processes exist in

- 5. Definition of a process An organization is

- 6. Variation in a Process The outputs

- 7. Variation in a process Special causes of

- 8. Variation in a process Common causes of

- 9. Variation in a process Employees cannot control

- 10. Process Basics

- 11. More About the Feedback Loop A feedback

- 12. More About the Feedback Loop There

- 13. The Quality Environment The pursuit (follow up)

- 14. Employees are the most critical stakeholders of

- 15. Types of Quality There are three types

- 16. Quality of design Quality of

- 17. Quality of design / redesign Quality

- 18. Quality of conformance Quality of conformance is

- 19. Quality-of-performance Quality of performance studies focus on

- 20. Relationship between Quality and Cost Features

- 21. Generally, products or services with more features

- 23. Dependability and Uniformity: Accreditation and standards

- 24. Conclusion Managers must balance the cost

- 25. Stressing productivity often has the opposite effect

- 26. Benefits of Improving Quality Several benefits result

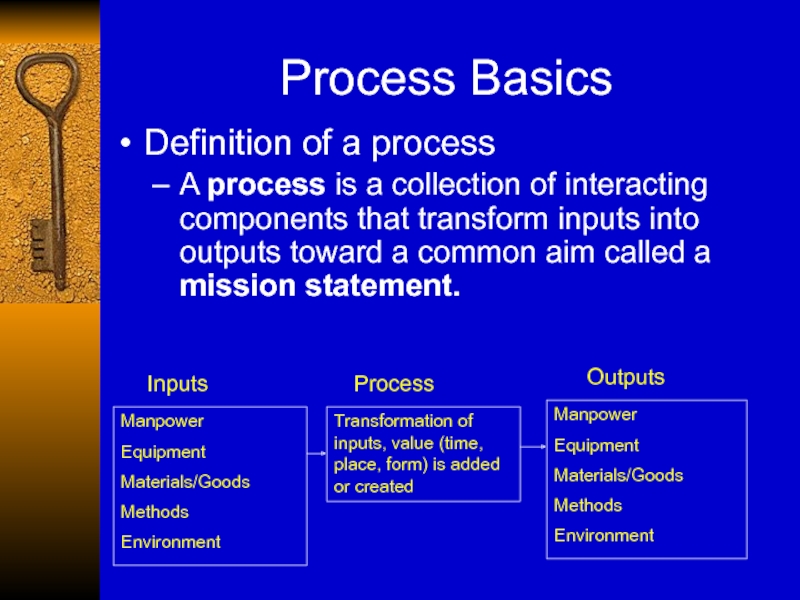

Слайд 2Process Basics

Definition of a process

A process is a collection of

Manpower

Equipment

Materials/Goods

Methods

Environment

Inputs

Transformation of inputs, value (time, place, form) is added or created

Process

Manpower

Equipment

Materials/Goods

Methods

Environment

Outputs

Слайд 3Definition of a process

It is management’s job to optimize (improve) the

This may require the sub-optimization of selected components of the process.

Слайд 4Definition of a Process

Processes exist in all facets of organizations and

Administration

Sales and service

Human resources

Maintenance

Communication

Production

Relationships between people are processes

All processes can be studied, documented, defined, improved, and innovated.

Слайд 5Definition of a process

An organization is a multiplicity (great number) of

All processes have customers and suppliers; these customers and suppliers can be internal or external to the organization.

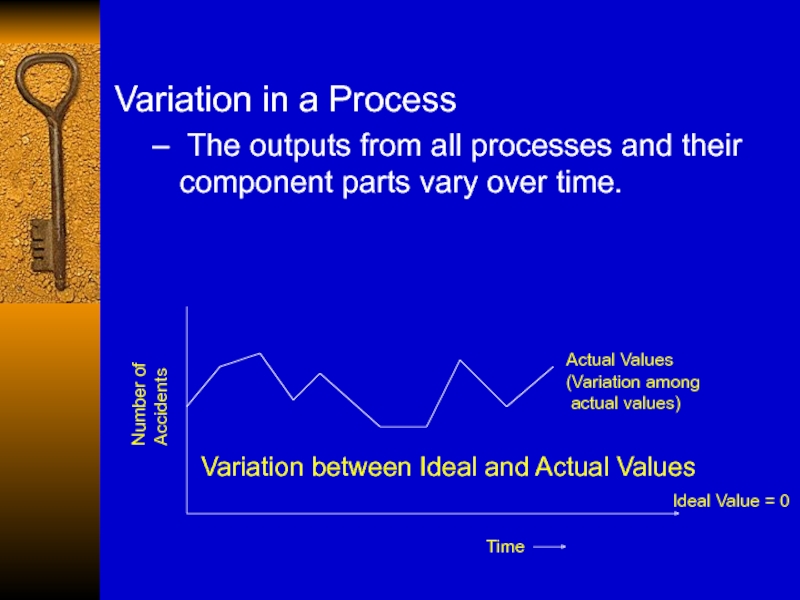

Слайд 6Variation in a Process

The outputs from all processes and their

Time

Number of

Accidents

Actual Values

(Variation among

actual values)

Ideal Value = 0

Variation between Ideal and Actual Values

Слайд 7Variation in a process

Special causes of variation are due to events

Examples could include (if they are not part of the system):

New raw materials

New employee

A new operator

Слайд 8Variation in a process

Common causes of variation are due to the

Process capability is determined by inherent (deeply come) common causes of variation.

Examples of common causes of variation include:

Hiring, training and supervisory practices

Lighting

Stress

Management style

Policies and procedures

Design of products or services

Слайд 9Variation in a process

Employees cannot control a common cause of variation.

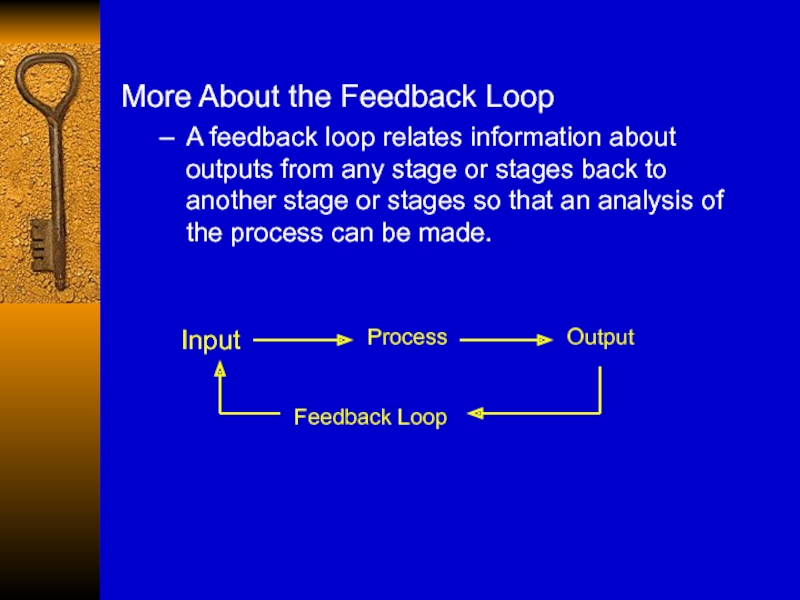

Слайд 11More About the Feedback Loop

A feedback loop relates information about outputs

Input

Process

Output

Feedback Loop

Слайд 12More About the Feedback Loop

There are three feedback loop situations

no

special cause only feedback loop

special and common cause feedback loop

Слайд 13The Quality Environment

The pursuit (follow up) of quality requires that organizations

This system includes employees, customers, investors, suppliers and subcontractors, regulators, the environment, and the community.

Слайд 14Employees are the most critical stakeholders of an organization.

According to

Слайд 15Types of Quality

There are three types of quality:

Quality of design /

Quality of conformance

Quality of performance

The above types of quality create the never ending spiral (cycle) of continuous improvement of products, services or processes

Слайд 16Quality of design

Quality of design / redesign focuses on determining

Слайд 17Quality of design / redesign

Quality of design studies begin with consumer

Next, specifications are prepared for the product concept.

Слайд 18Quality of conformance

Quality of conformance is the extent to which a

The ultimate (main) goal of process improvement and innovation efforts is to create products and services whose quality is so high that consumers (both external and internal) extol (celebrate, achieve) them.

Слайд 19Quality-of-performance

Quality of performance studies focus on determining how the quality characteristics

The major tools of quality-of-performance studies are consumer research and sales/service call analysis.

These tools are used to study after-sales service, maintenance, reliability, and logistical support, as well as to determine why consumers do not purchase the company’s products.

Слайд 20Relationship between

Quality and Cost

Features and Price

Features and price determine whether

Dependability (confidence) and uniformity (organizing) determine a product’s success, and therefore its market share, within a market segment.

Слайд 21Generally, products or services with more features have higher costs to

Слайд 23Dependability and Uniformity:

Accreditation and standards

Uniformity and dependability create an inverse

Слайд 24Conclusion

Managers must balance the cost of having many market segments

Слайд 25Stressing productivity often has the opposite effect of what management desires

Management’s

Слайд 26Benefits of Improving Quality

Several benefits result from improving a process:

rework

productivity rises

quality improves

cost per good unit is decreased

price can be cut

workers’ morale goes up because they are not seen as the problem. This last aspect leads to further benefits:

less employee absenteeism

less burnout,

more interest in the job

increased motivation to improve work.

This is called the chain reaction of quality