- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Facility Layout презентация

Содержание

- 1. Facility Layout

- 2. Copyright 2006 John Wiley & Sons, Inc.

- 3. Copyright 2006 John Wiley & Sons, Inc.

- 4. Copyright 2006 John Wiley & Sons, Inc.

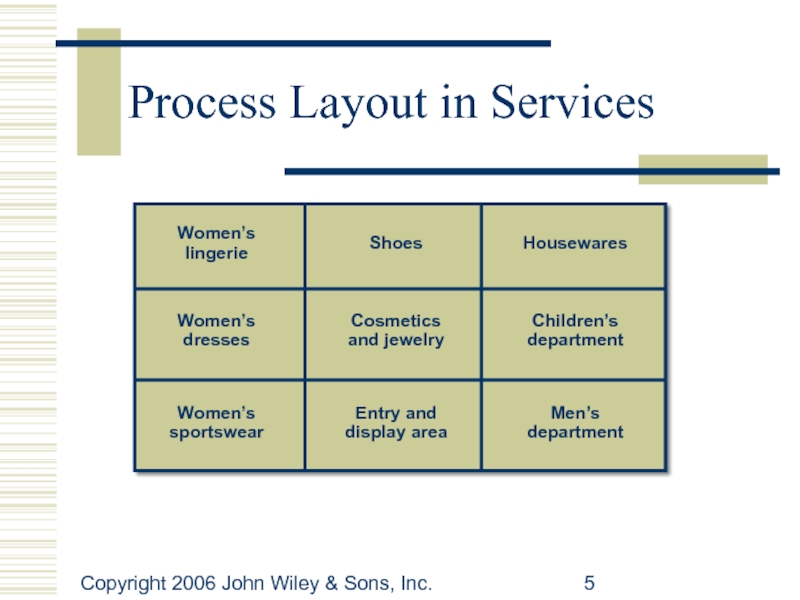

- 5. Copyright 2006 John Wiley & Sons, Inc. Process Layout in Services

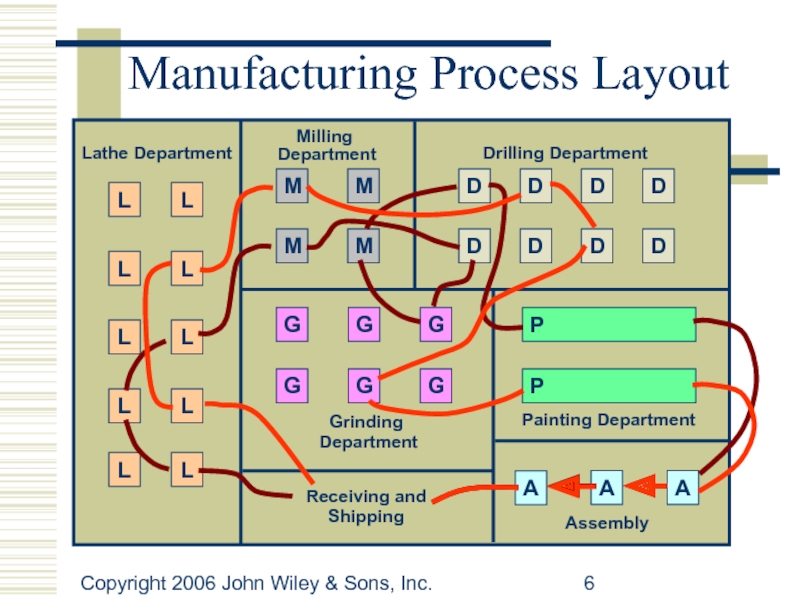

- 6. Copyright 2006 John Wiley & Sons, Inc.

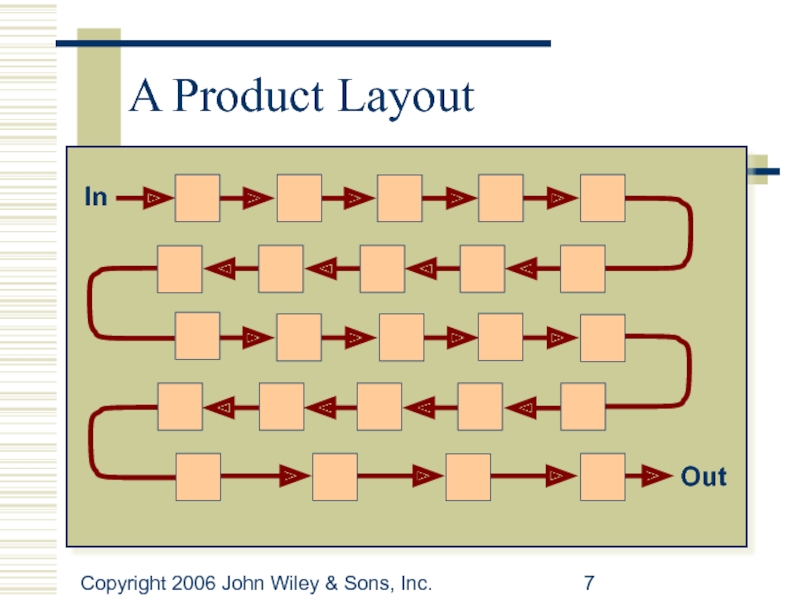

- 7. Copyright 2006 John Wiley & Sons, Inc. A Product Layout

- 8. Copyright 2006 John Wiley & Sons, Inc.

- 9. Copyright 2006 John Wiley & Sons, Inc.

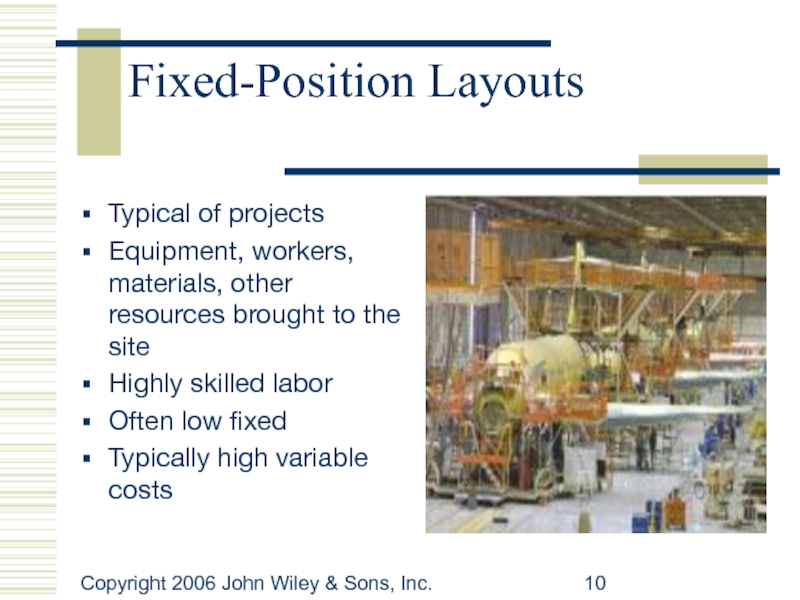

- 10. Copyright 2006 John Wiley & Sons, Inc.

- 11. Copyright 2006 John Wiley & Sons, Inc.

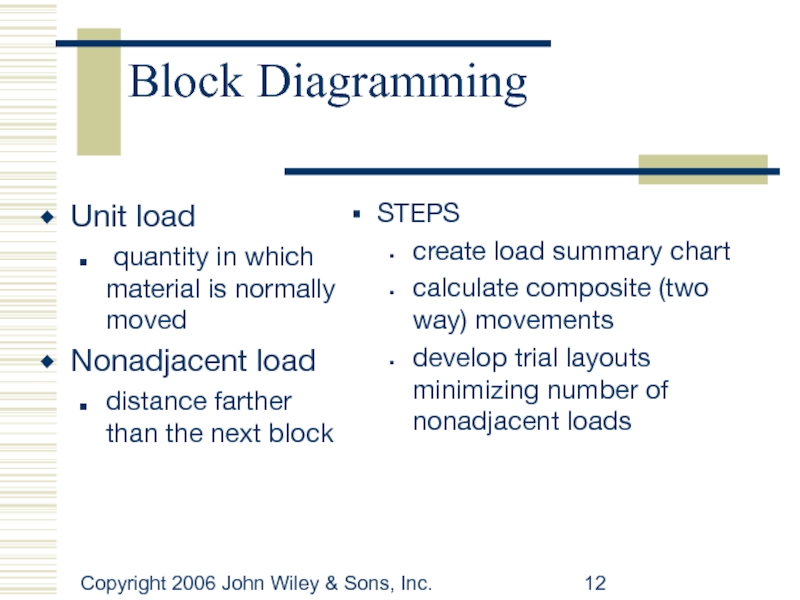

- 12. Copyright 2006 John Wiley & Sons, Inc.

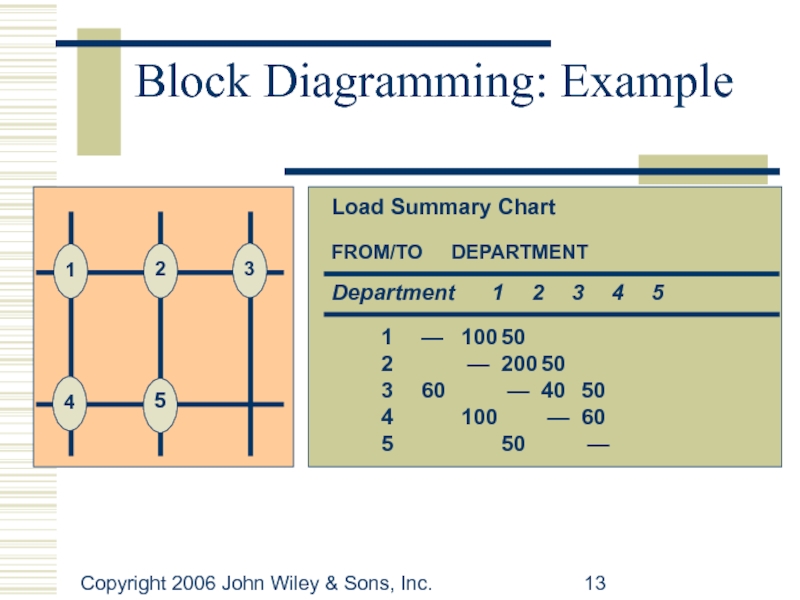

- 13. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming: Example

- 14. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming: Example (cont.)

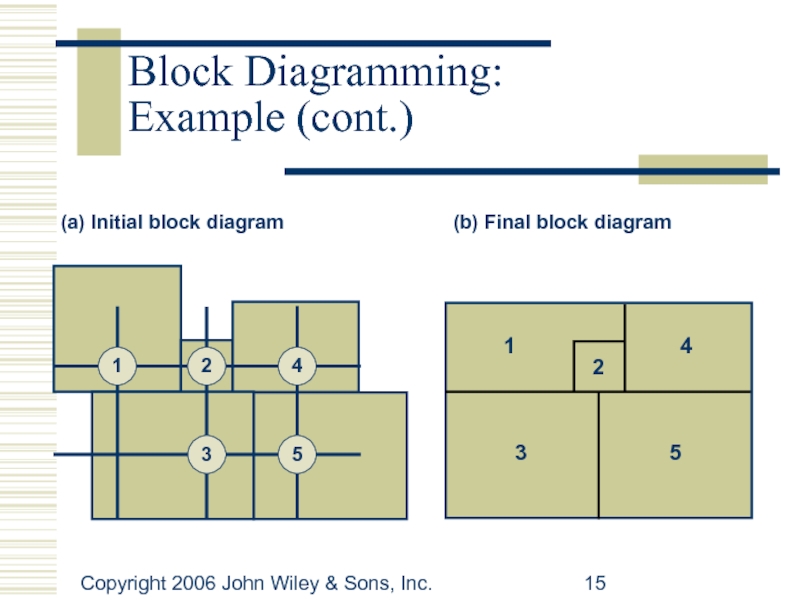

- 15. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming: Example (cont.)

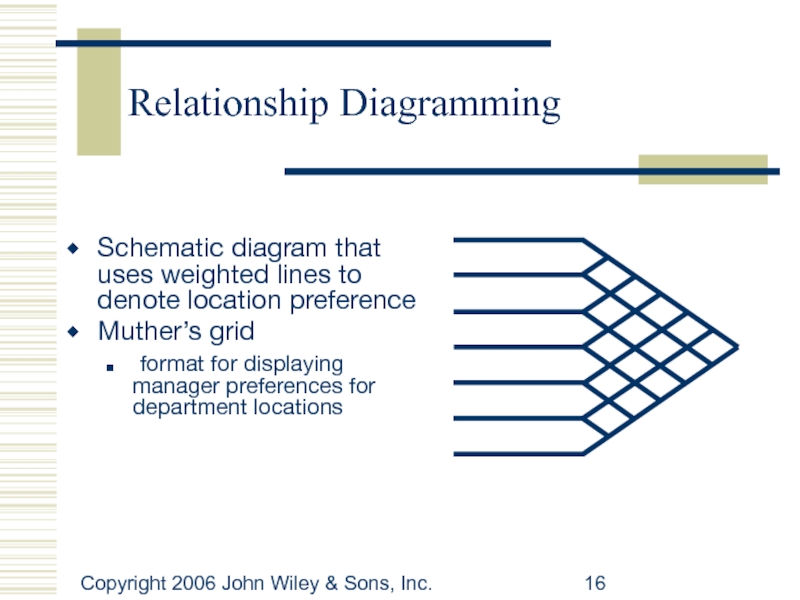

- 16. Copyright 2006 John Wiley & Sons, Inc.

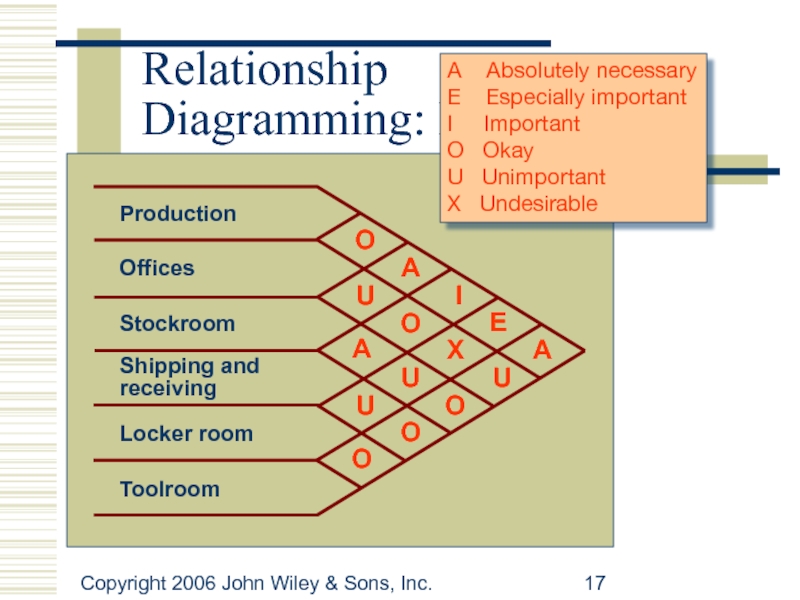

- 17. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagramming: Example

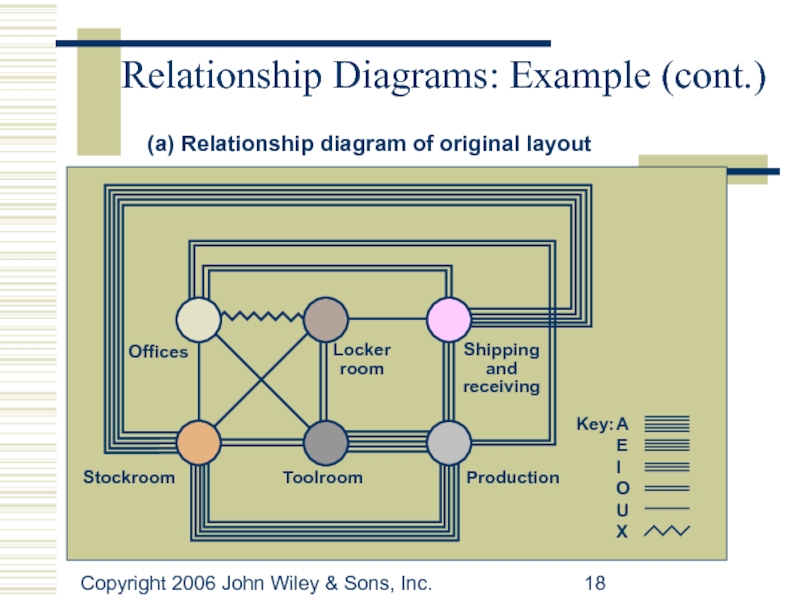

- 18. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagrams: Example (cont.)

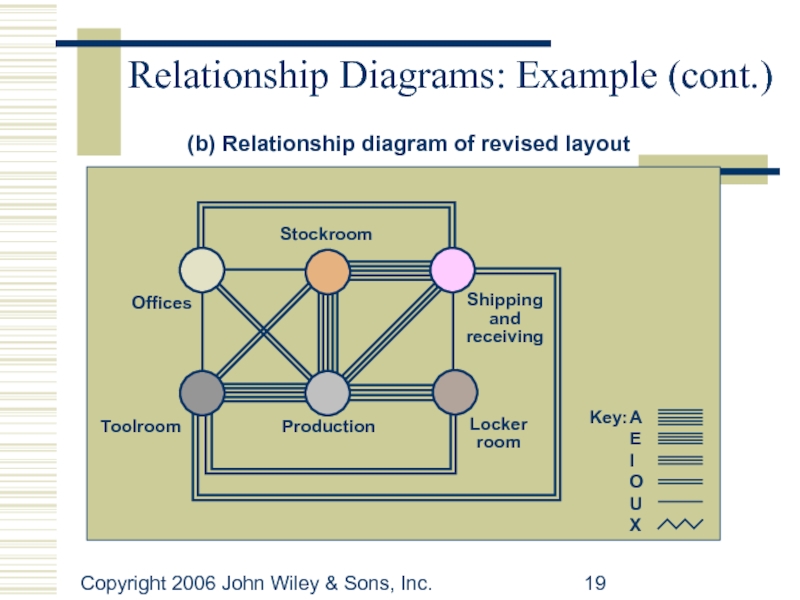

- 19. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagrams: Example (cont.)

- 20. Copyright 2006 John Wiley & Sons, Inc.

- 21. Copyright 2006 John Wiley & Sons, Inc.

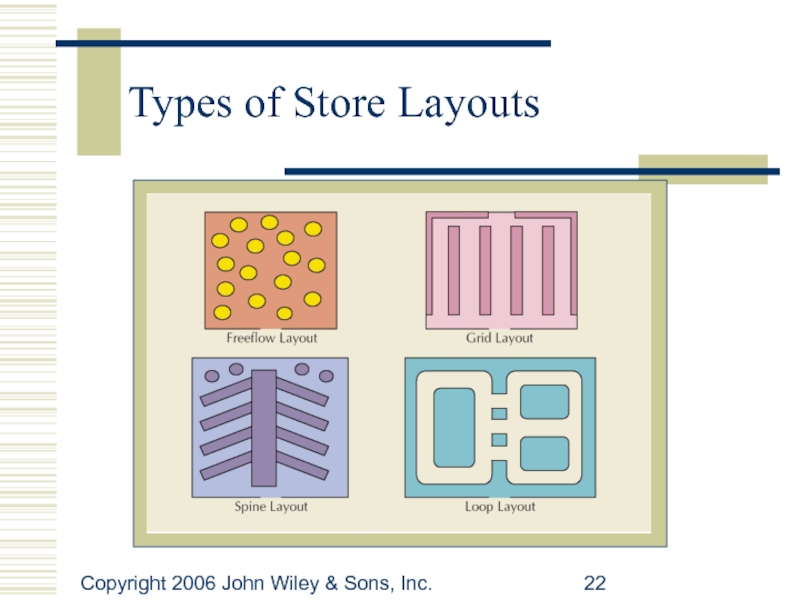

- 22. Copyright 2006 John Wiley & Sons, Inc. Types of Store Layouts

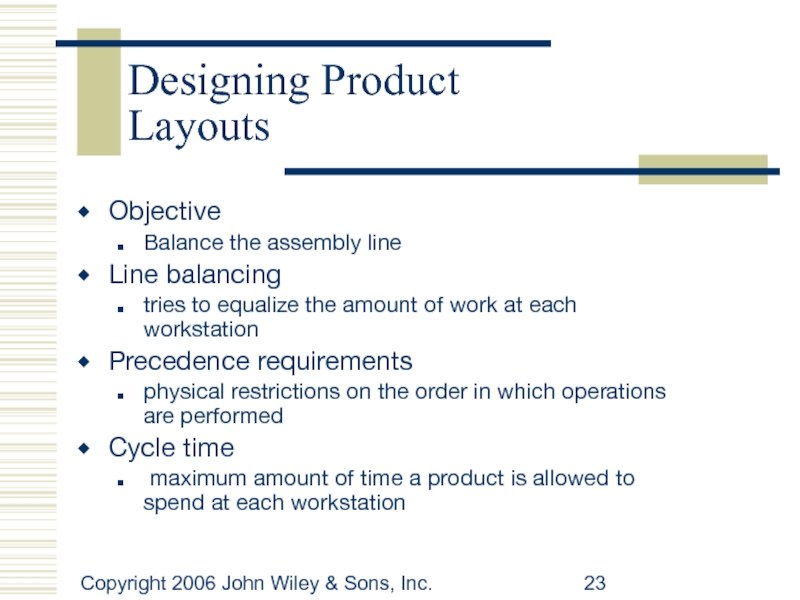

- 23. Copyright 2006 John Wiley & Sons, Inc.

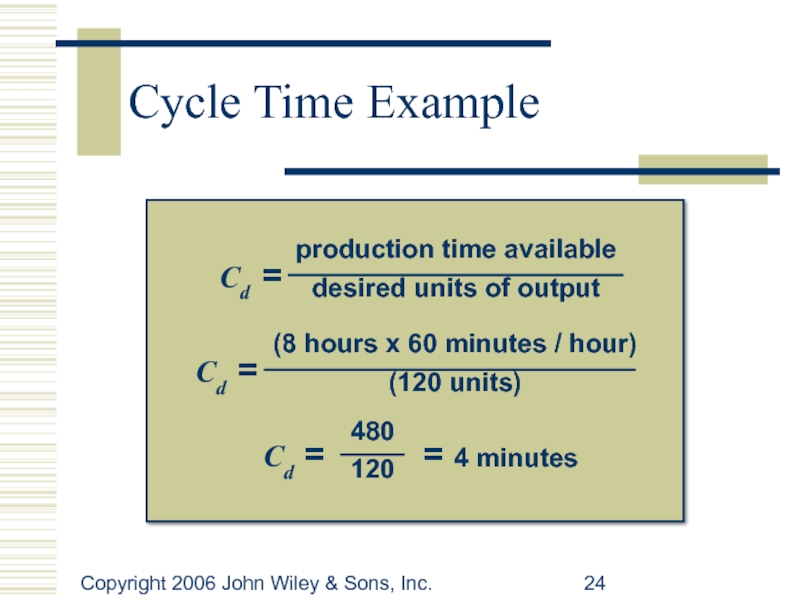

- 24. Copyright 2006 John Wiley & Sons, Inc. Cycle Time Example

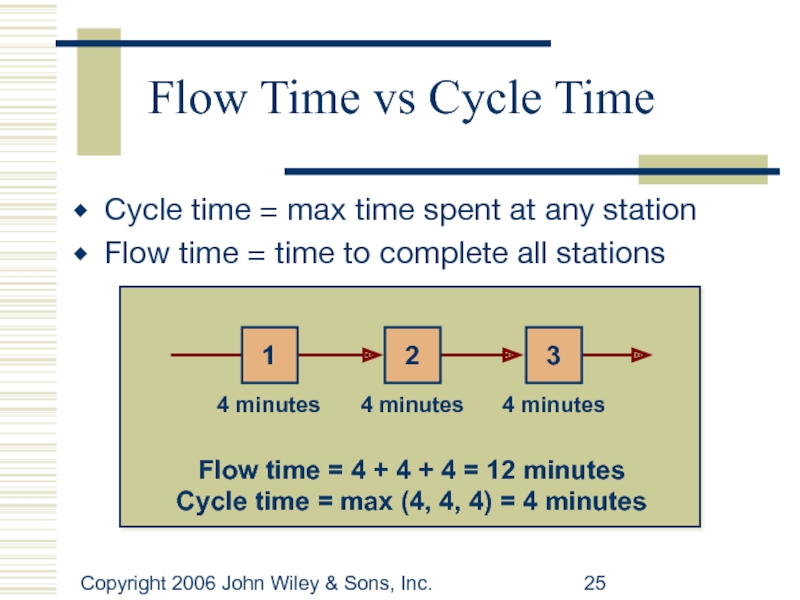

- 25. Copyright 2006 John Wiley & Sons, Inc.

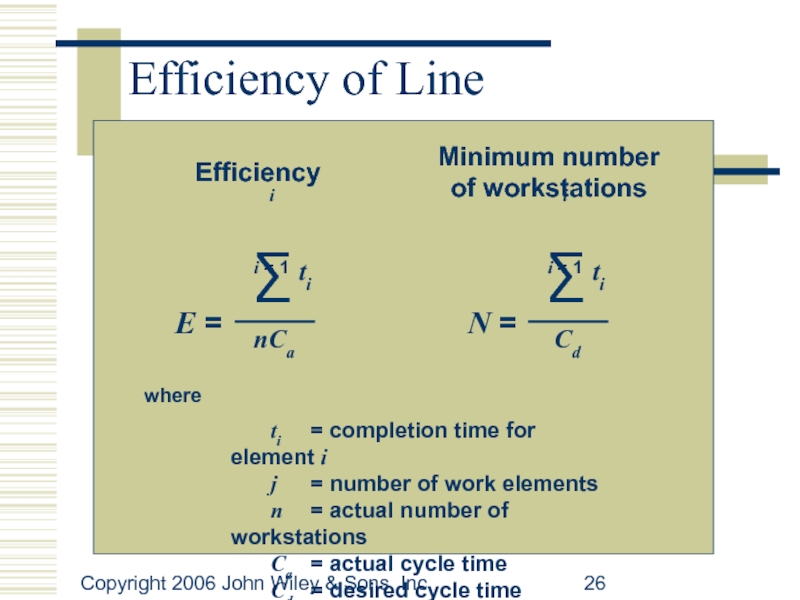

- 26. Copyright 2006 John Wiley & Sons, Inc. Efficiency of Line

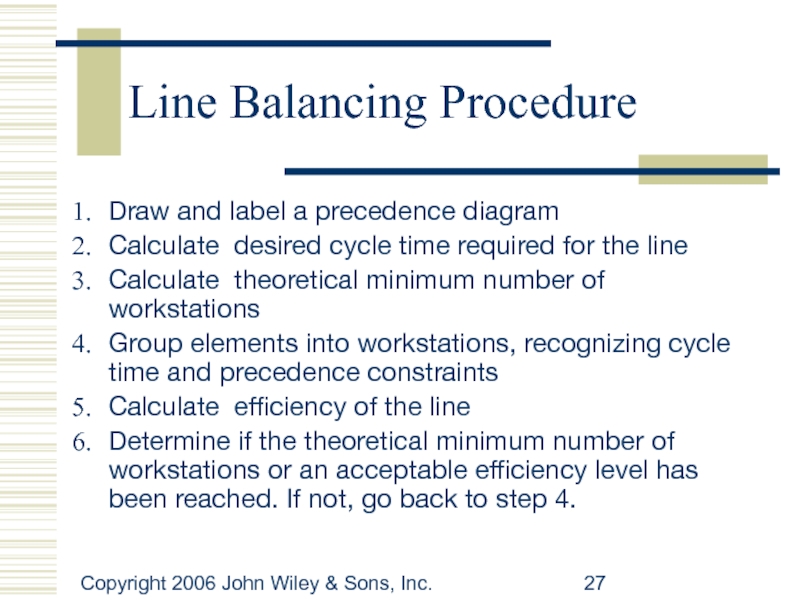

- 27. Copyright 2006 John Wiley & Sons, Inc.

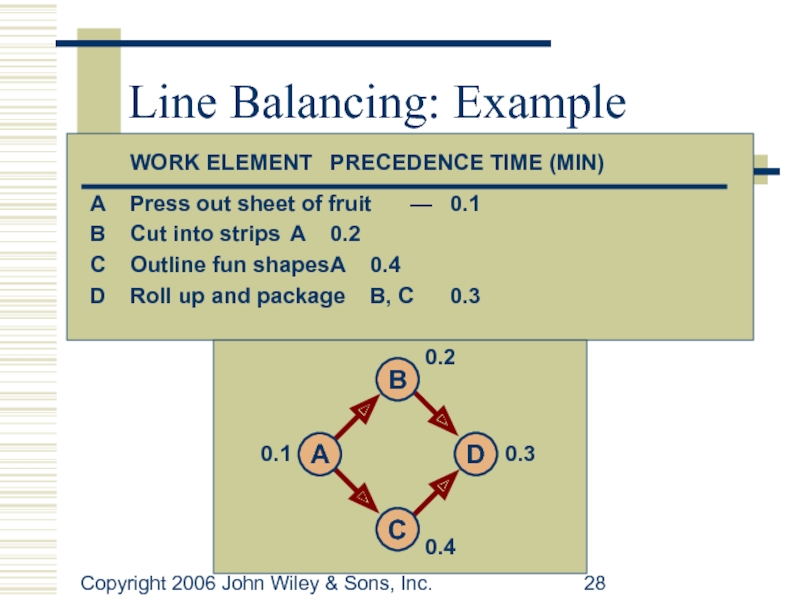

- 28. Copyright 2006 John Wiley & Sons, Inc. Line Balancing: Example

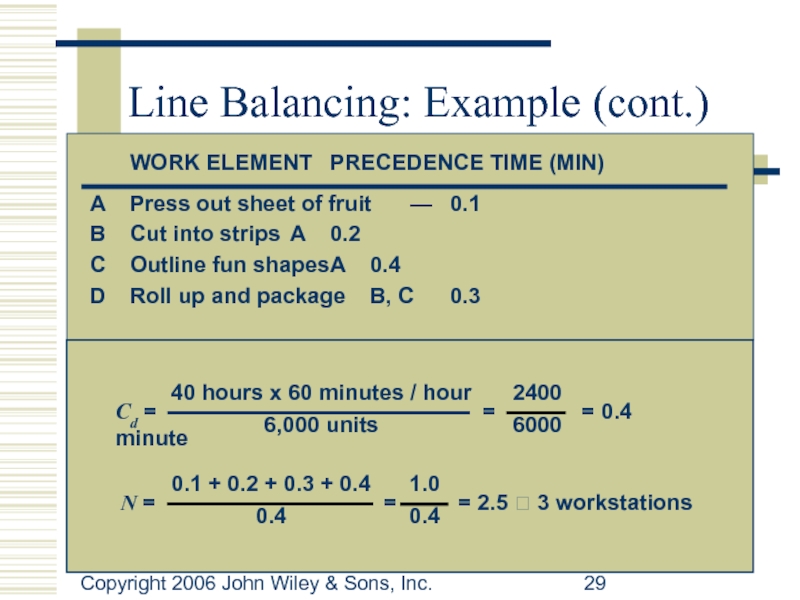

- 29. Copyright 2006 John Wiley & Sons, Inc. Line Balancing: Example (cont.)

- 30. Copyright 2006 John Wiley & Sons, Inc.

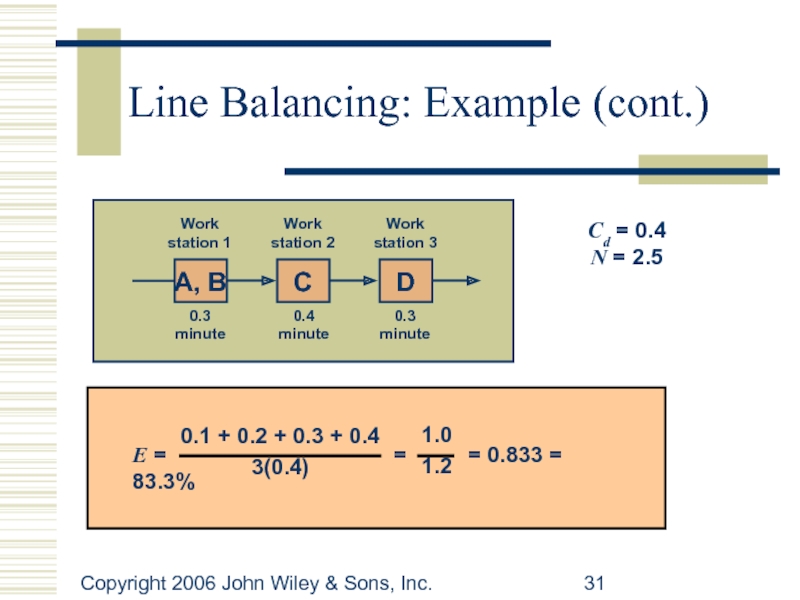

- 31. Copyright 2006 John Wiley & Sons, Inc.

- 32. Copyright 2006 John Wiley & Sons, Inc.

- 33. Copyright 2006 John Wiley & Sons, Inc.

- 34. Copyright 2006 John Wiley & Sons, Inc.

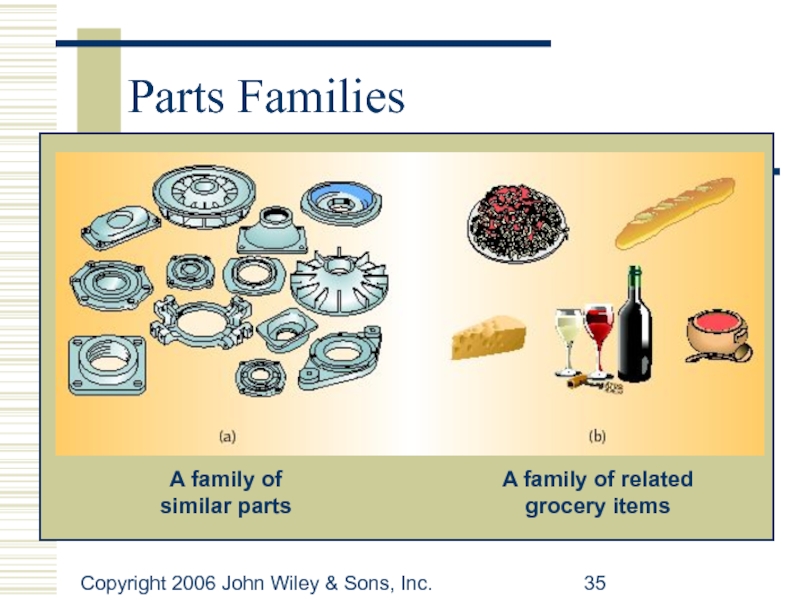

- 35. Copyright 2006 John Wiley & Sons, Inc. Parts Families

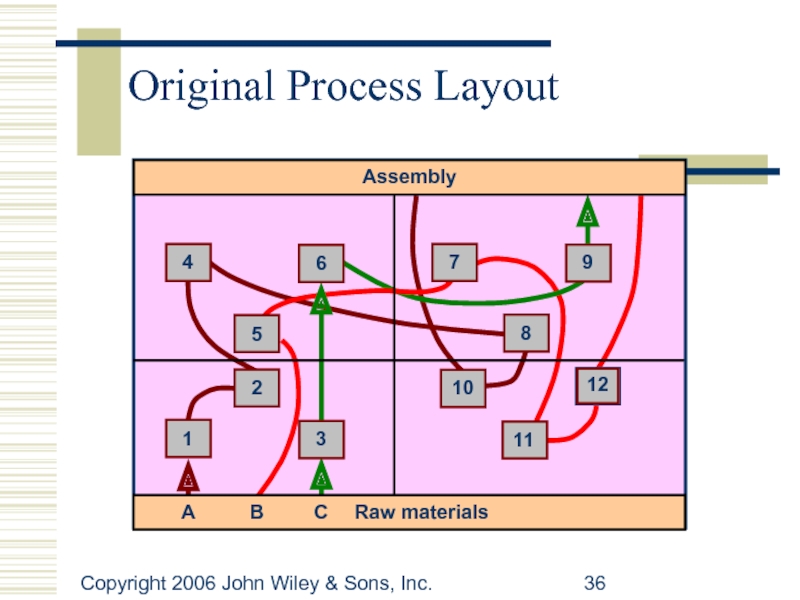

- 36. Copyright 2006 John Wiley & Sons, Inc. Original Process Layout

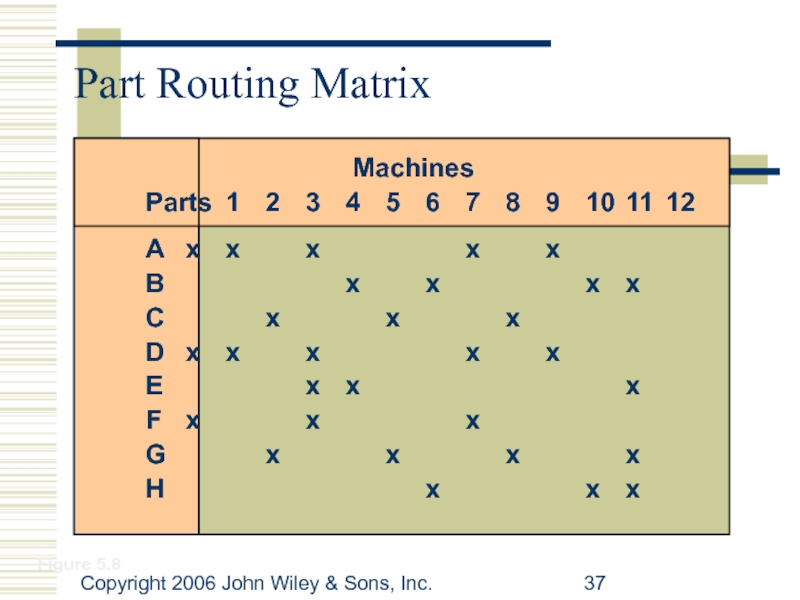

- 37. Copyright 2006 John Wiley & Sons, Inc. Part Routing Matrix Figure 5.8

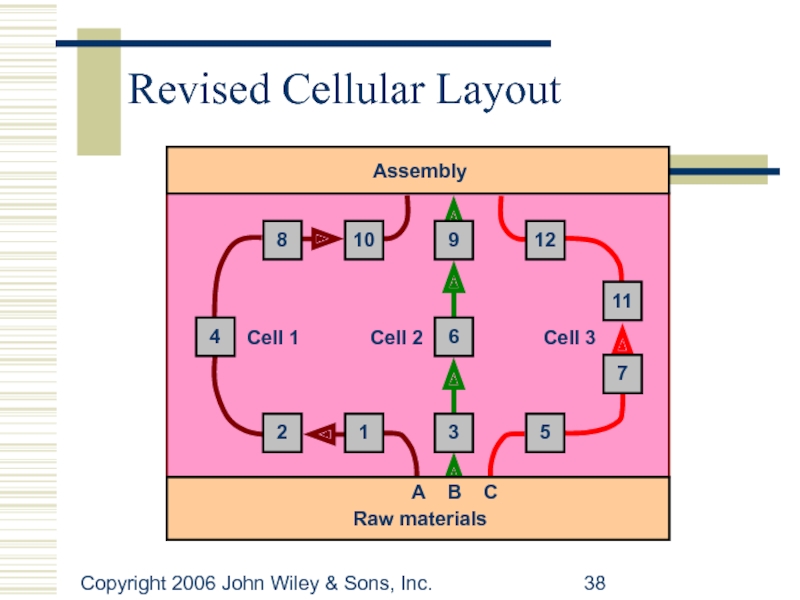

- 38. Copyright 2006 John Wiley & Sons, Inc. Revised Cellular Layout

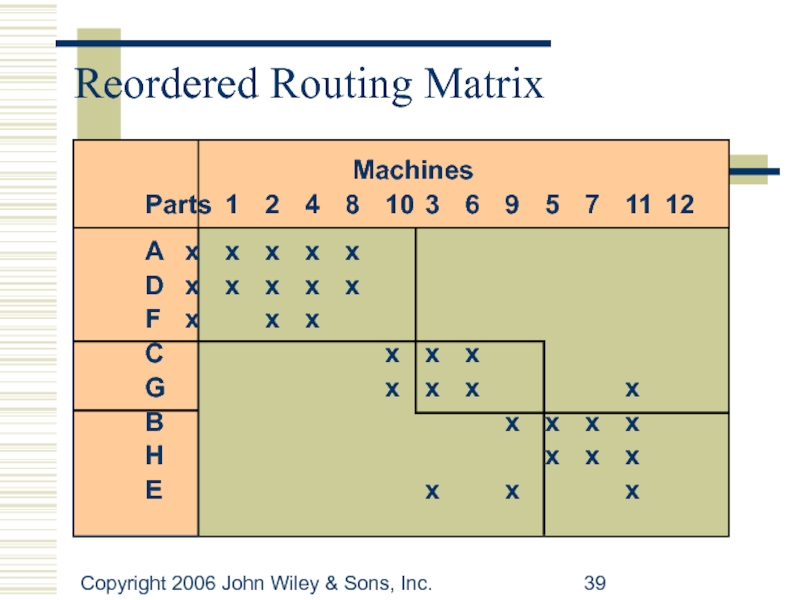

- 39. Copyright 2006 John Wiley & Sons, Inc. Reordered Routing Matrix

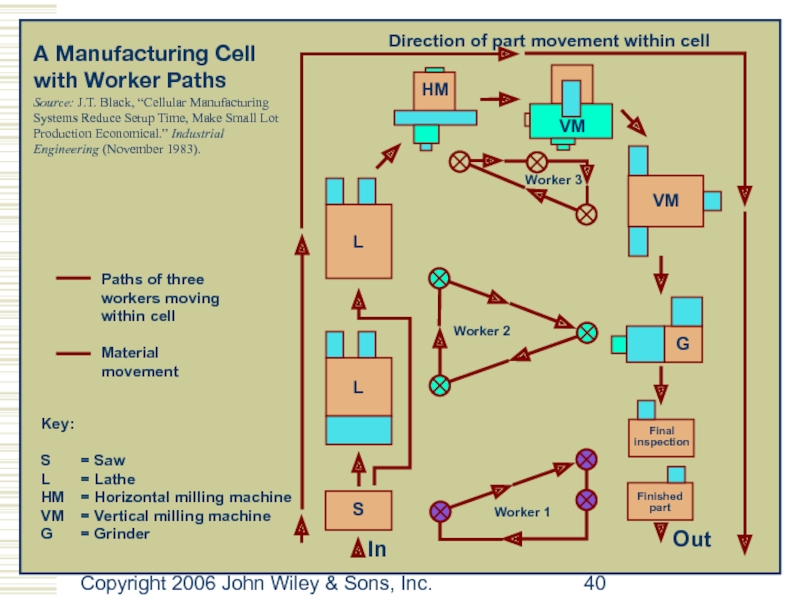

- 40. Copyright 2006 John Wiley & Sons, Inc.

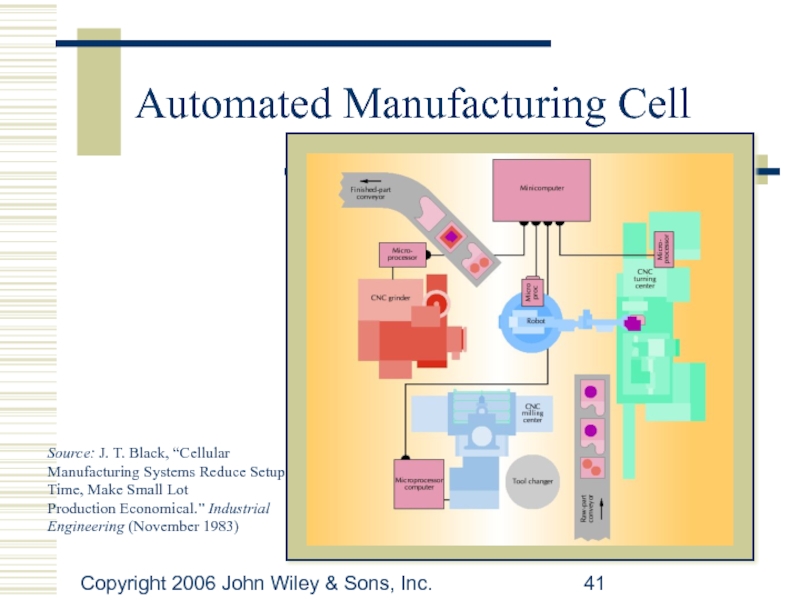

- 41. Copyright 2006 John Wiley & Sons, Inc. Automated Manufacturing Cell

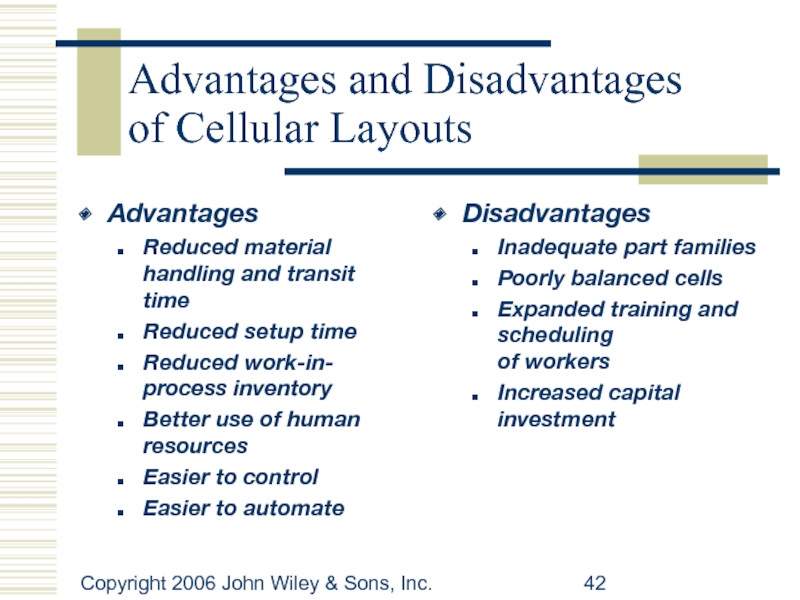

- 42. Copyright 2006 John Wiley & Sons, Inc.

- 43. Copyright 2006 John Wiley & Sons, Inc.

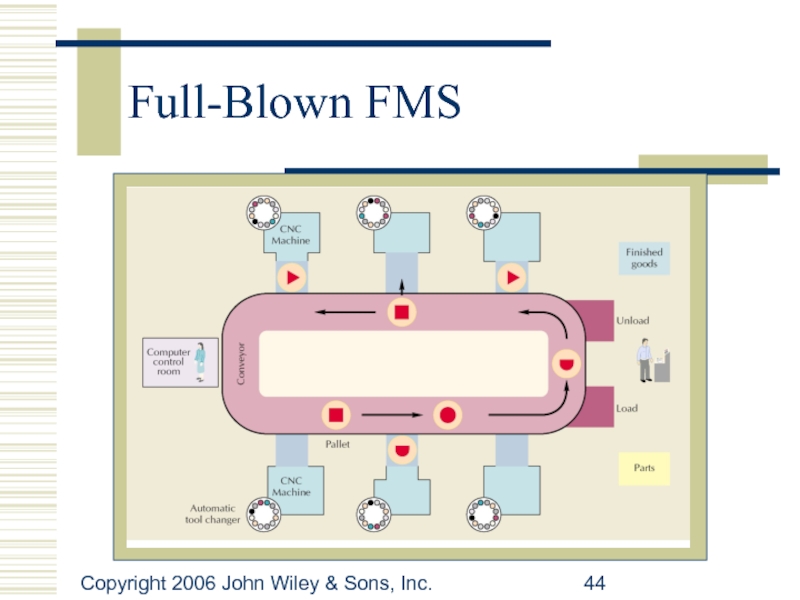

- 44. Copyright 2006 John Wiley & Sons, Inc. Full-Blown FMS

- 45. Copyright 2006 John Wiley & Sons, Inc.

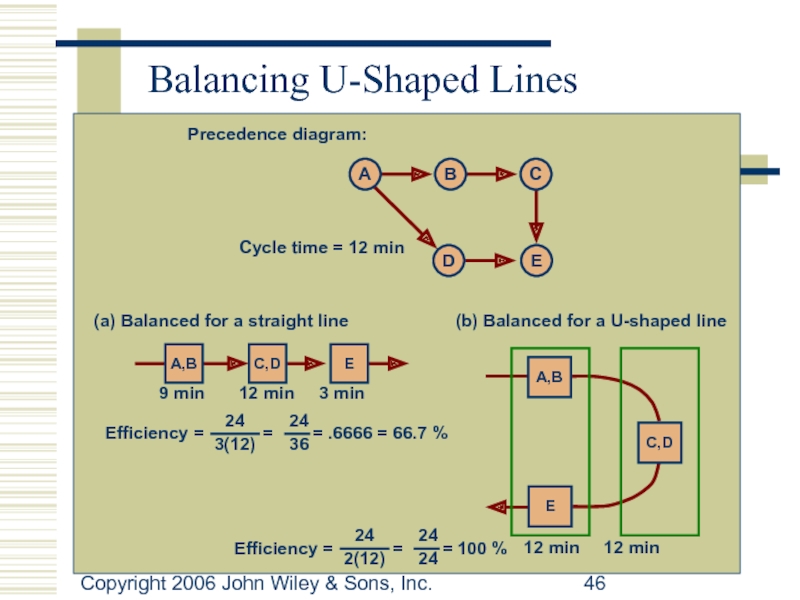

- 46. Copyright 2006 John Wiley & Sons, Inc. Balancing U-Shaped Lines

- 47. Copyright 2006 John Wiley & Sons, Inc.

Слайд 1Beni Asllani

University of Tennessee at Chattanooga

Facilities

Operations Management - 5th Edition

Chapter 7

Roberta

Слайд 2Copyright 2006 John Wiley & Sons, Inc.

Lecture Outline

Basic Layouts

Designing Process Layouts

Designing

Designing Product Layouts

Hybrid Layouts

Слайд 3Copyright 2006 John Wiley & Sons, Inc.

Facility Layout

Minimize material-handling costs

Utilize space

Utilize labor efficiently

Eliminate bottlenecks

Facilitate communication and interaction

Reduce manufacturing cycle time

Reduce customer service time

Eliminate wasted or redundant movement

Increase capacity

Facilitate entry, exit, and placement of material, products, and people

Incorporate safety and security measures

Promote product and service quality

Encourage proper maintenance activities

Provide a visual control of activities

Provide flexibility to adapt to changing conditions

Arrangement of areas within a facility to:

Слайд 4Copyright 2006 John Wiley & Sons, Inc.

BASIC LAYOUTS

Process layouts

group similar activities

Product layouts

arrange activities in line according to sequence of operations for a particular product or service

Fixed-position layouts

are used for projects in which product cannot be moved

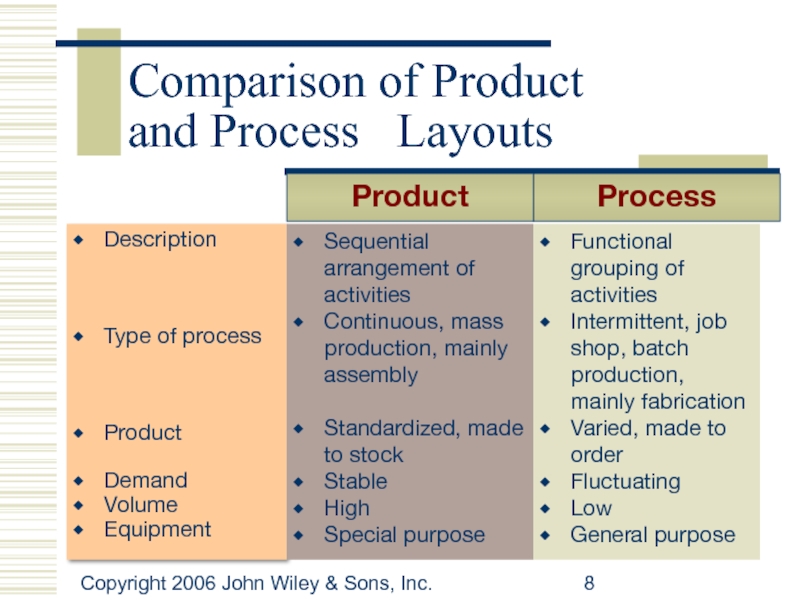

Слайд 8Copyright 2006 John Wiley & Sons, Inc.

Description

Type of process

Product

Demand

Volume

Equipment

Sequential arrangement of

Continuous, mass production, mainly assembly

Standardized, made to stock

Stable

High

Special purpose

Process

Comparison of Product

and Process Layouts

Functional grouping of activities

Intermittent, job shop, batch production, mainly fabrication

Varied, made to order

Fluctuating

Low

General purpose

Product

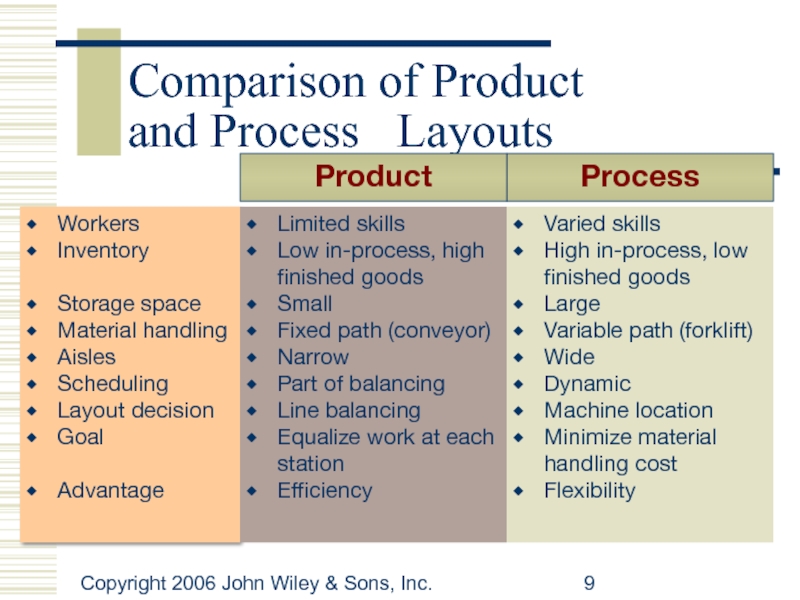

Слайд 9Copyright 2006 John Wiley & Sons, Inc.

Workers

Inventory

Storage space

Material handling

Aisles

Scheduling

Layout decision

Goal

Advantage

Limited skills

Low

Small

Fixed path (conveyor)

Narrow

Part of balancing

Line balancing

Equalize work at each station

Efficiency

Process

Comparison of Product

and Process Layouts

Varied skills

High in-process, low finished goods

Large

Variable path (forklift)

Wide

Dynamic

Machine location

Minimize material handling cost

Flexibility

Product

Слайд 10Copyright 2006 John Wiley & Sons, Inc.

Fixed-Position Layouts

Typical of projects

Equipment, workers,

Highly skilled labor

Often low fixed

Typically high variable costs

Слайд 11Copyright 2006 John Wiley & Sons, Inc.

Designing Process Layouts

Goal: minimize material

Block Diagramming

minimize nonadjacent loads

use when quantitative data is available

Relationship Diagramming

based on location preference between areas

use when quantitative data is not available

Слайд 12Copyright 2006 John Wiley & Sons, Inc.

Block Diagramming

Unit load

quantity in

Nonadjacent load

distance farther than the next block

STEPS

create load summary chart

calculate composite (two way) movements

develop trial layouts minimizing number of nonadjacent loads

Слайд 16Copyright 2006 John Wiley & Sons, Inc.

Relationship Diagramming

Schematic diagram that uses

Muther’s grid

format for displaying manager preferences for department locations

Слайд 20Copyright 2006 John Wiley & Sons, Inc.

Computerized layout Solutions

CRAFT

Computerized Relative Allocation

CORELAP

Computerized Relationship Layout Planning

PROMODEL and EXTEND

visual feedback

allow user to quickly test a variety of scenarios

Three-D modeling and CAD

integrated layout analysis

available in VisFactory and similar software

Слайд 21Copyright 2006 John Wiley & Sons, Inc.

Designing Service Layouts

Must be both

Types

Free flow layouts

encourage browsing, increase impulse purchasing, are flexible and visually appealing

Grid layouts

encourage customer familiarity, are low cost, easy to clean and secure, and good for repeat customers

Loop and Spine layouts

both increase customer sightlines and exposure to products, while encouraging customer to circulate through the entire store

Слайд 23Copyright 2006 John Wiley & Sons, Inc.

Designing Product Layouts

Objective

Balance the assembly

Line balancing

tries to equalize the amount of work at each workstation

Precedence requirements

physical restrictions on the order in which operations are performed

Cycle time

maximum amount of time a product is allowed to spend at each workstation

Слайд 25Copyright 2006 John Wiley & Sons, Inc.

Flow Time vs Cycle Time

Cycle

Flow time = time to complete all stations

Слайд 27Copyright 2006 John Wiley & Sons, Inc.

Line Balancing Procedure

Draw and label

Calculate desired cycle time required for the line

Calculate theoretical minimum number of workstations

Group elements into workstations, recognizing cycle time and precedence constraints

Calculate efficiency of the line

Determine if the theoretical minimum number of workstations or an acceptable efficiency level has been reached. If not, go back to step 4.

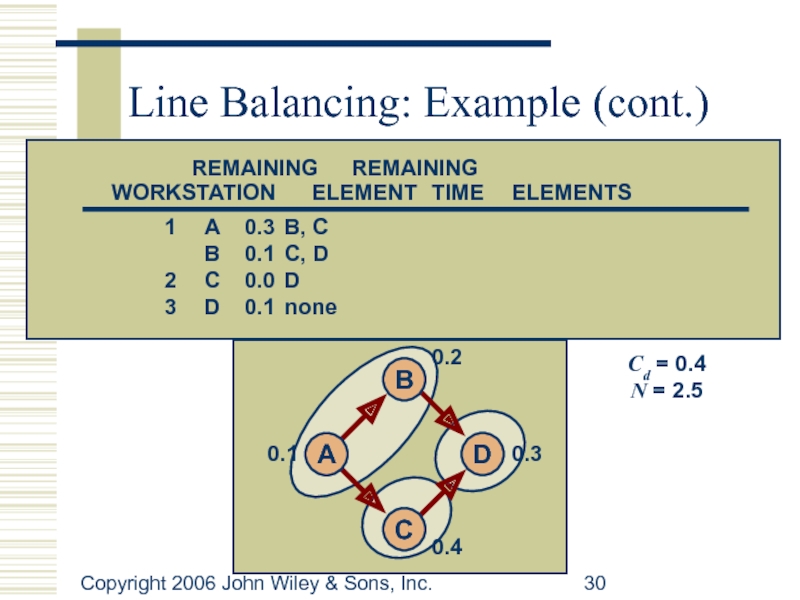

Слайд 30Copyright 2006 John Wiley & Sons, Inc.

Line Balancing: Example (cont.)

Cd =

N = 2.5

REMAINING REMAINING

WORKSTATION ELEMENT TIME ELEMENTS

1 A 0.3 B, C

B 0.1 C, D

2 C 0.0 D

3 D 0.1 none

Слайд 32Copyright 2006 John Wiley & Sons, Inc.

Computerized Line Balancing

Use heuristics to

Longest operation time

Shortest operation time

Most number of following tasks

Least number of following tasks

Ranked positional weight

Слайд 33Copyright 2006 John Wiley & Sons, Inc.

Hybrids Layouts

Cellular layouts

group dissimilar machines

Flexible manufacturing system

automated machining and material handling systems which can produce an enormous variety of items

Mixed-model assembly line

processes more than one product model in one line

Слайд 34Copyright 2006 John Wiley & Sons, Inc.

Cellular Layouts

Identify families of parts

Group machines into cells based on part families

Arrange cells so material movement is minimized

Locate large shared machines at point of use

Слайд 42Copyright 2006 John Wiley & Sons, Inc.

Advantages and Disadvantages

of Cellular

Advantages

Reduced material handling and transit time

Reduced setup time

Reduced work-in- process inventory

Better use of human resources

Easier to control

Easier to automate

Disadvantages

Inadequate part families

Poorly balanced cells

Expanded training and scheduling

of workers

Increased capital investment

Слайд 43Copyright 2006 John Wiley & Sons, Inc.

Flexible Manufacturing Systems (FMS)

FMS consists

FMS combines flexibility with efficiency

FMS layouts differ based on

variety of parts that the system can process

size of parts processed

average processing time required for part completion

Слайд 45Copyright 2006 John Wiley & Sons, Inc.

Mixed Model

Assembly Lines

Produce multiple

Issues in mixed model lines

Line balancing

U-shaped line

Flexible workforce

Model sequencing