- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Welcome to Technical Training Induction презентация

Содержание

- 1. Welcome to Technical Training Induction

- 2. OBJECTIVE By the end of this course

- 3. Basic Xerography

- 4. Course Objective The Xerographic Process Charging

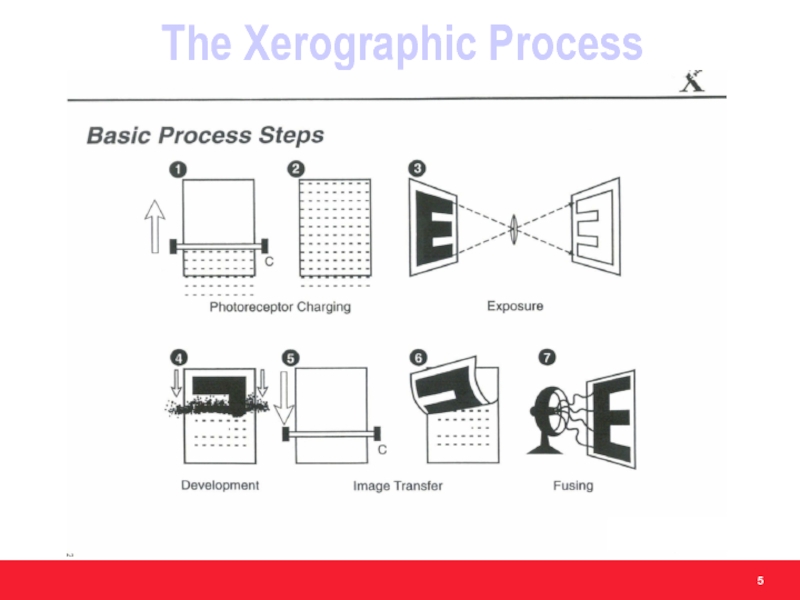

- 5. The Xerographic Process

- 6. Charging Preparing the photoreceptor for accepting the image

- 8. Configurations of Photoreceptors Drum: Smaller size No

- 9. Corona Charging Devices

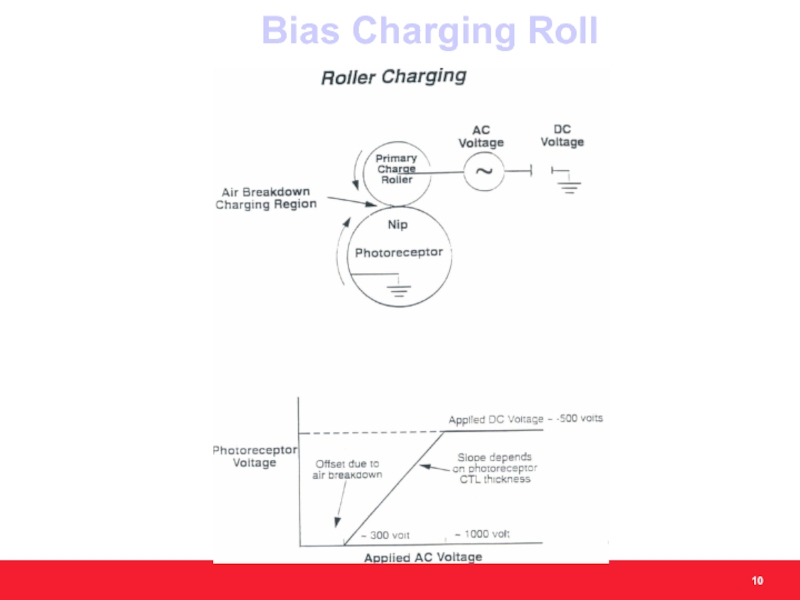

- 10. Bias Charging Roll

- 11. Bias Charging Roll – Pros & cons

- 12. Exposing Capturing the latent image on the photoreceptor

- 13. Imaging Devices

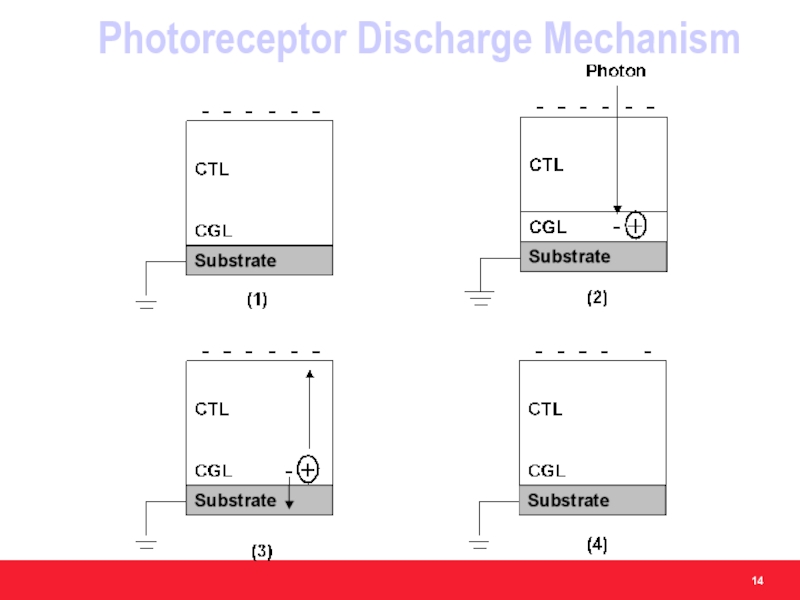

- 14. Photoreceptor Discharge Mechanism

- 15. Development Toning the latent image

- 16. Development Two Main Schemes: Single Component Development

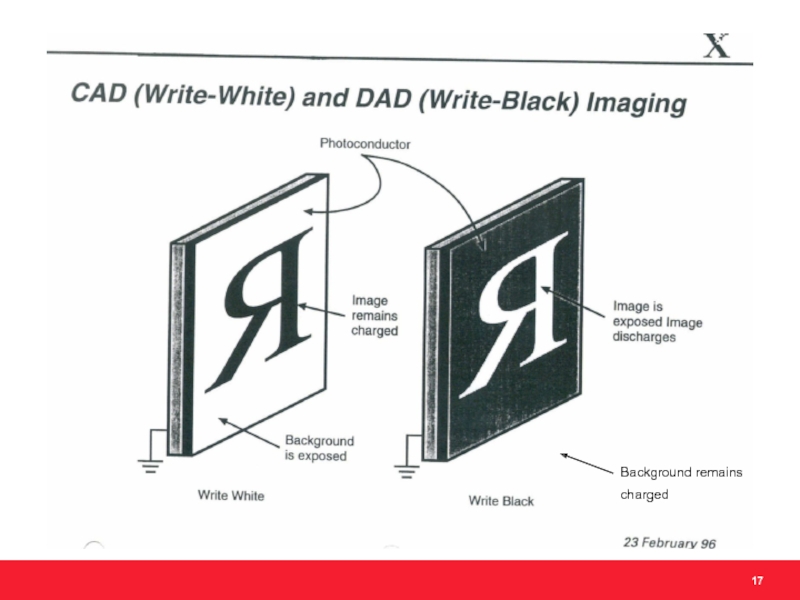

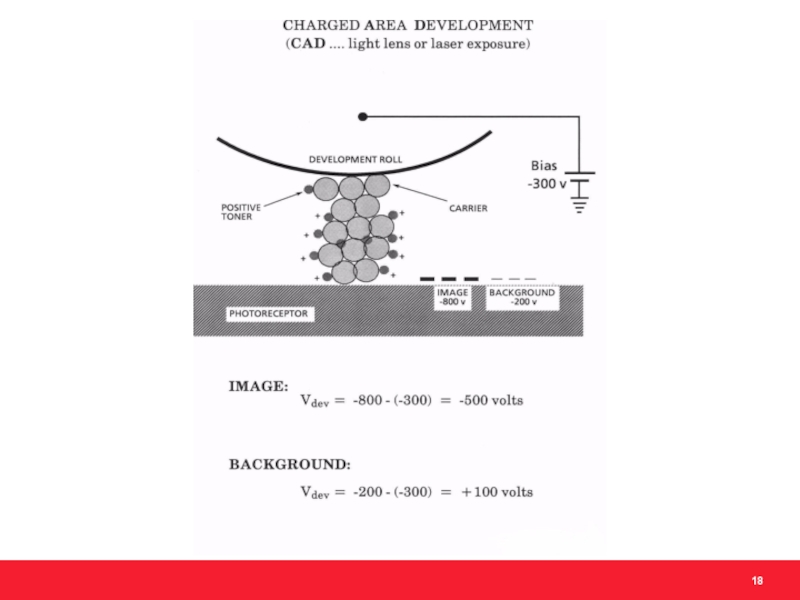

- 17. Background remains charged

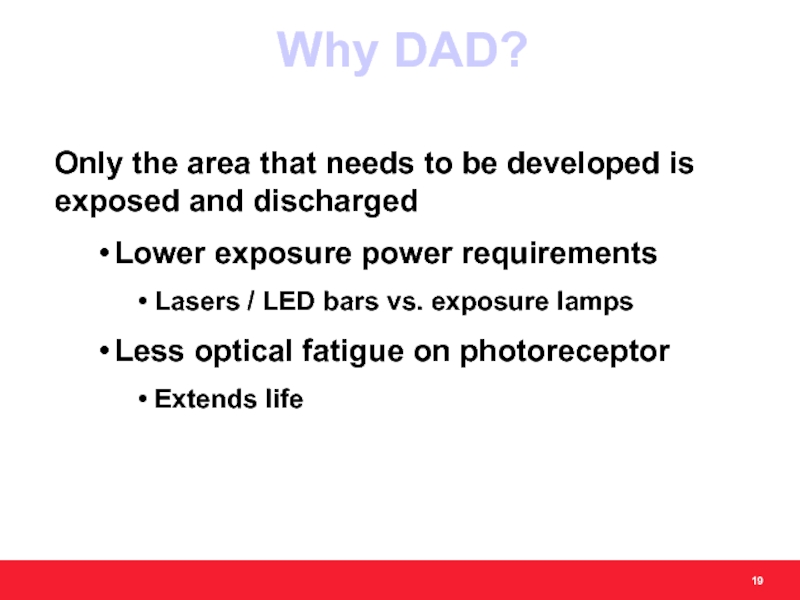

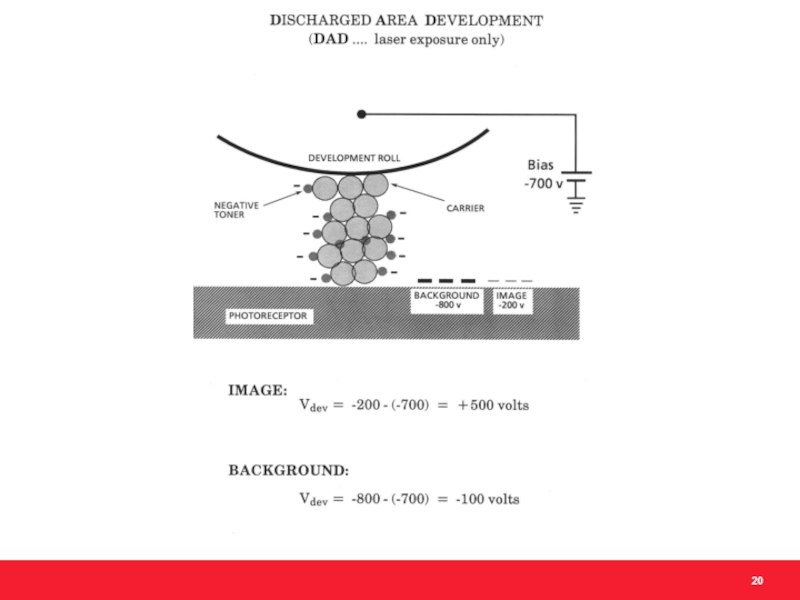

- 19. Why DAD? Only the area that needs

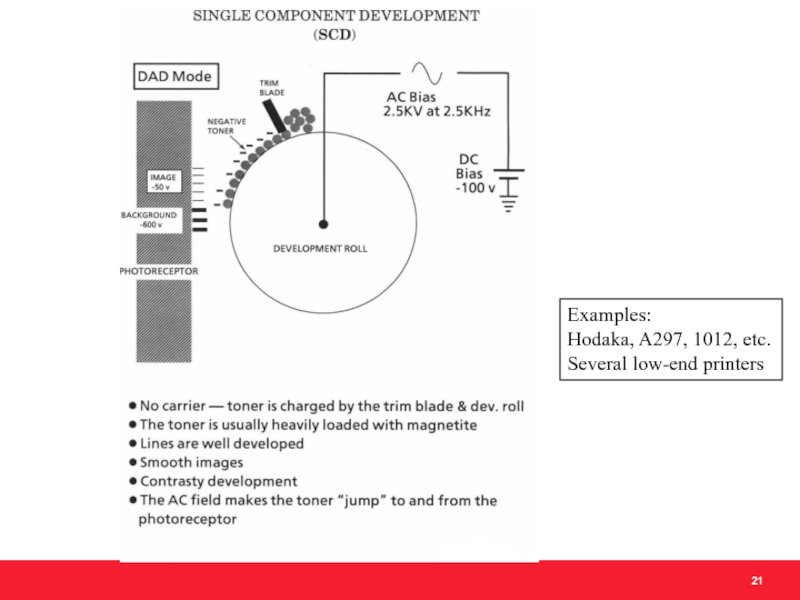

- 21. Examples: Hodaka, A297, 1012, etc. Several low-end printers

- 22. Common Two Component Development Techniques

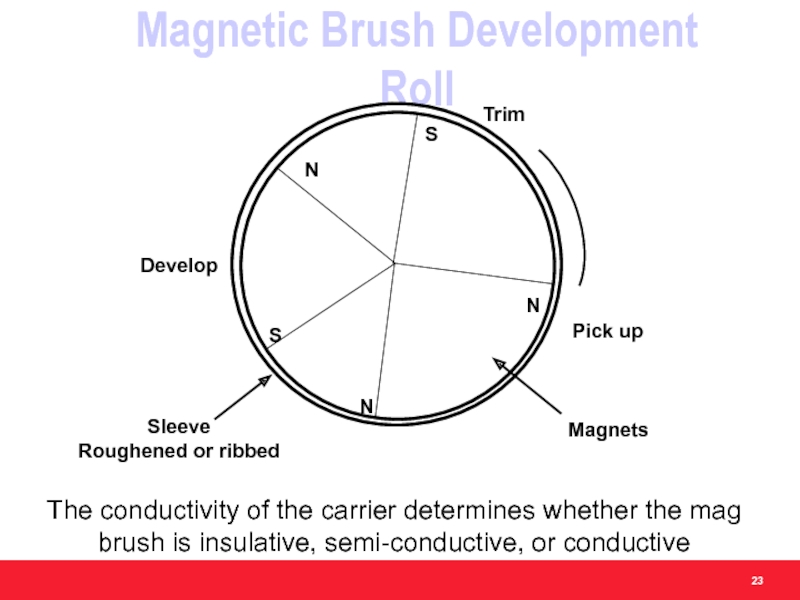

- 23. Magnetic Brush Development Roll The conductivity

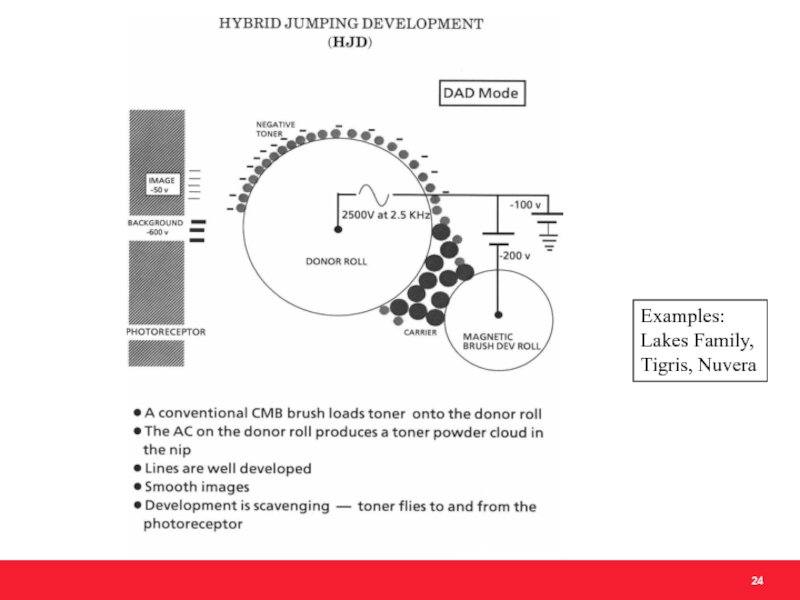

- 24. Examples: Lakes Family, Tigris, Nuvera

- 25. Transfer Moving the toned image to paper

- 26. Major Transfer Drivers Toner properties: Toner shape

- 27. Corona Biased Transfer Roll Transfer Belt Charged

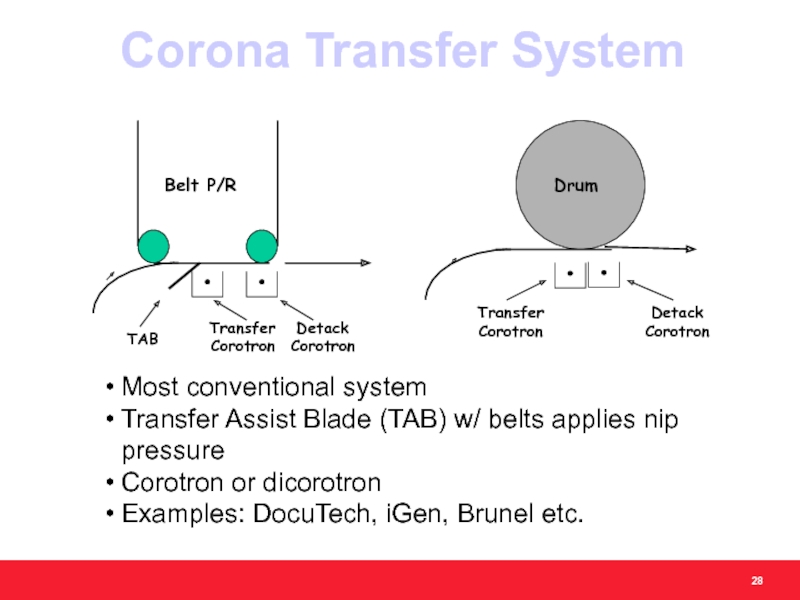

- 28. Most conventional system Transfer Assist Blade

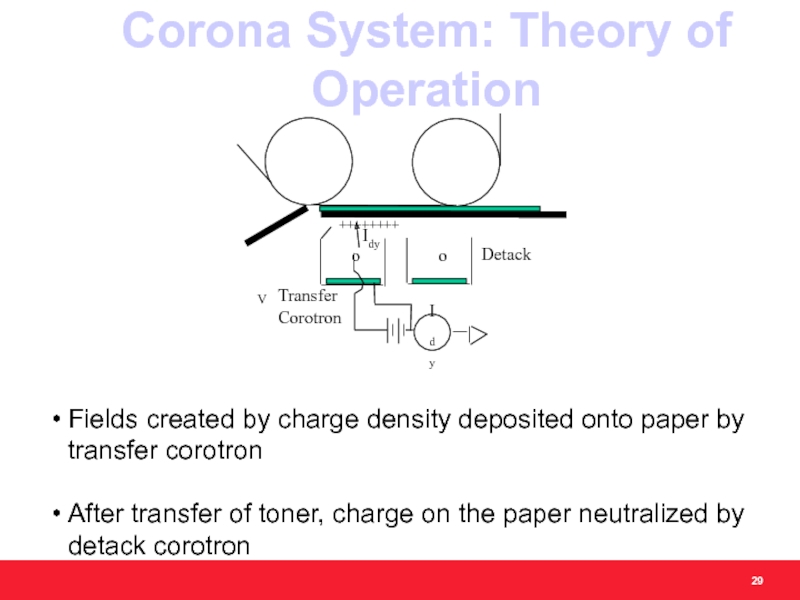

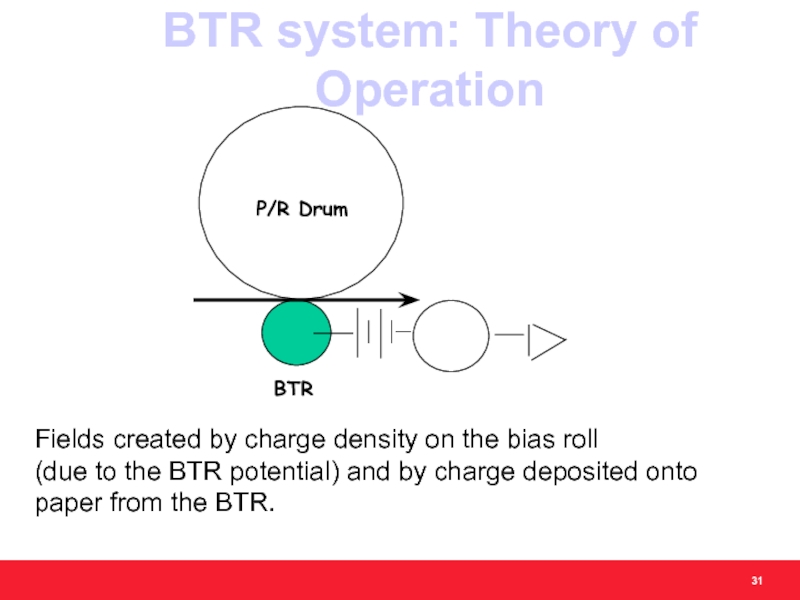

- 29. Fields created by charge

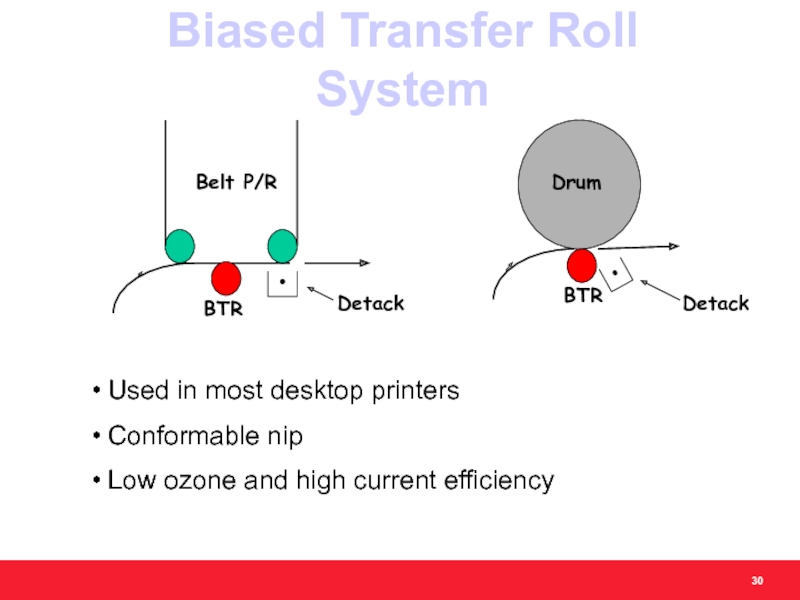

- 30. Biased Transfer Roll System Used in most

- 31. Fields created by charge density

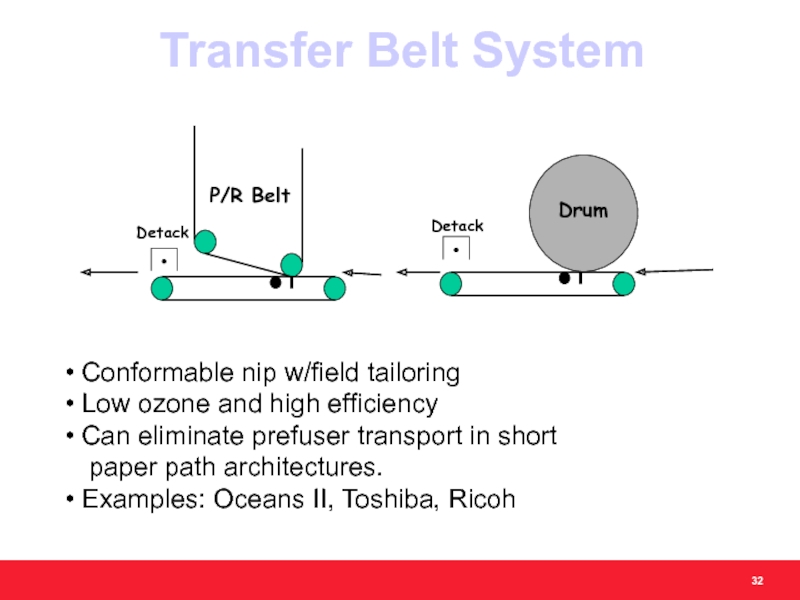

- 32. Transfer Belt System Conformable nip

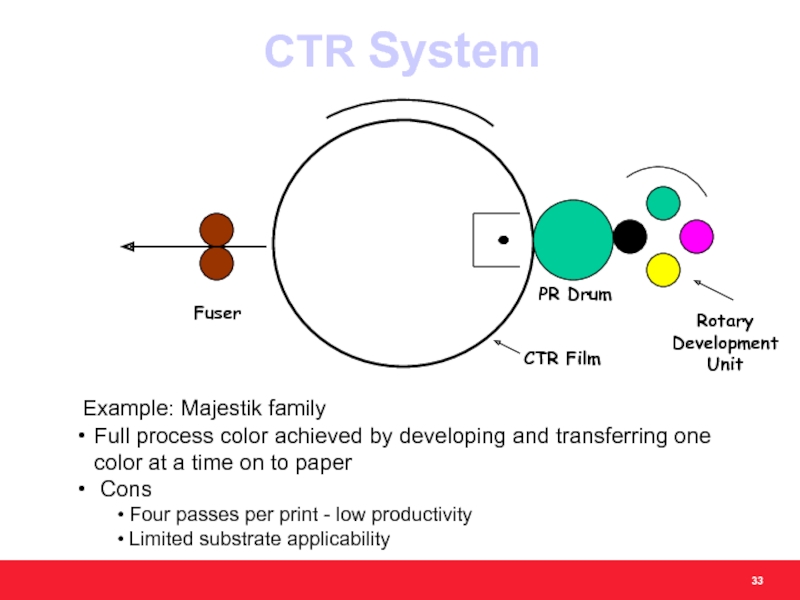

- 33. CTR System Example: Majestik family Full

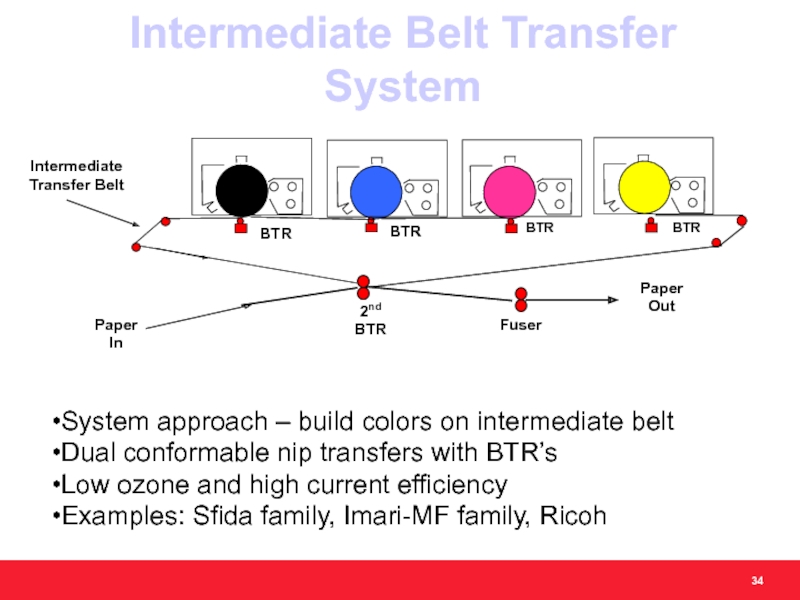

- 34. Intermediate Belt Transfer System System

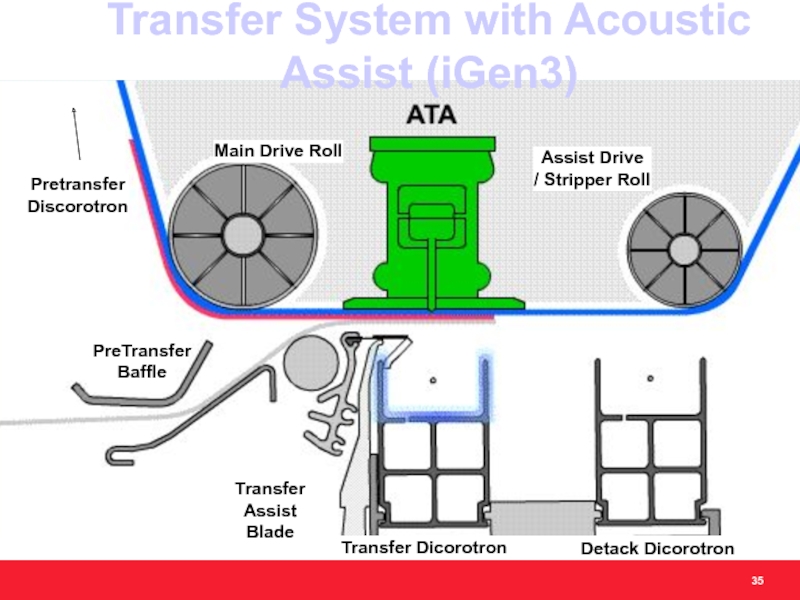

- 35. Transfer Assist Blade PreTransfer Baffle Detack Dicorotron

- 36. Fusing Fixing the image to paper

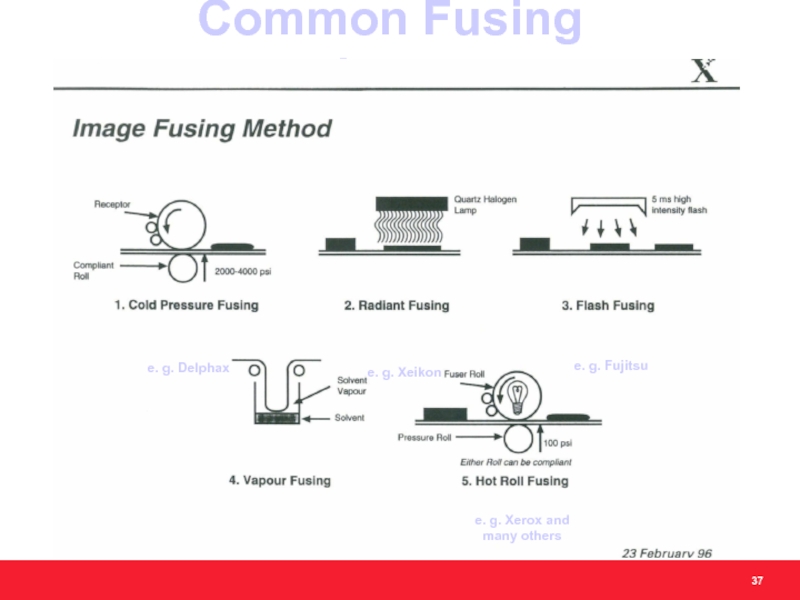

- 37. Common Fusing Techniques e. g. Delphax e.

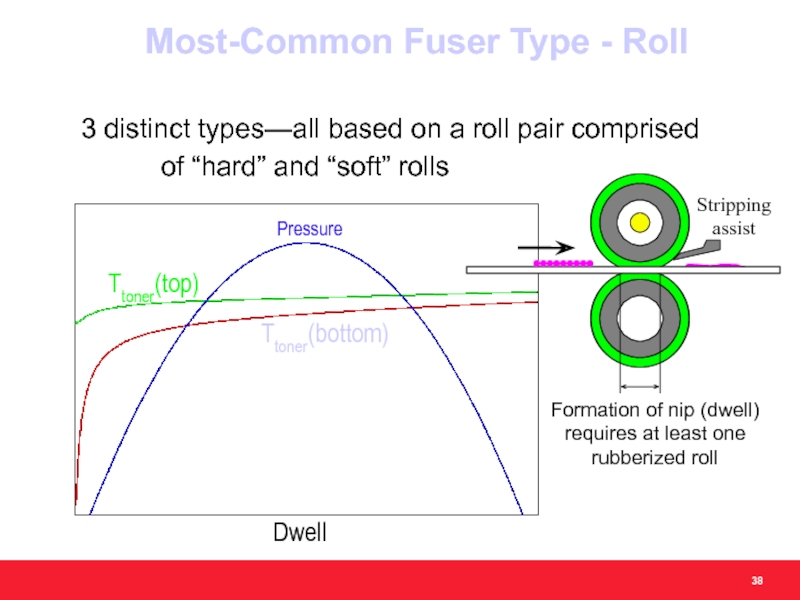

- 38. 3 distinct types—all based on a roll

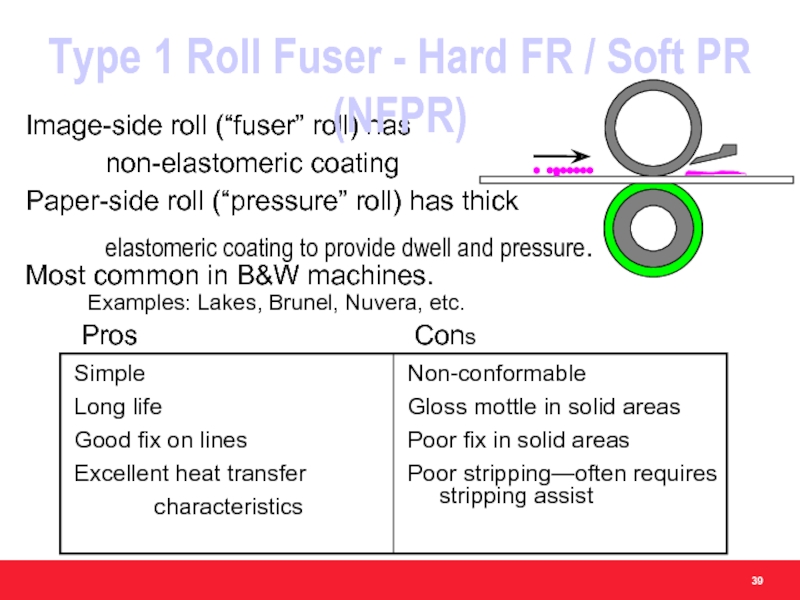

- 39. Image-side roll (“fuser” roll) has non-elastomeric

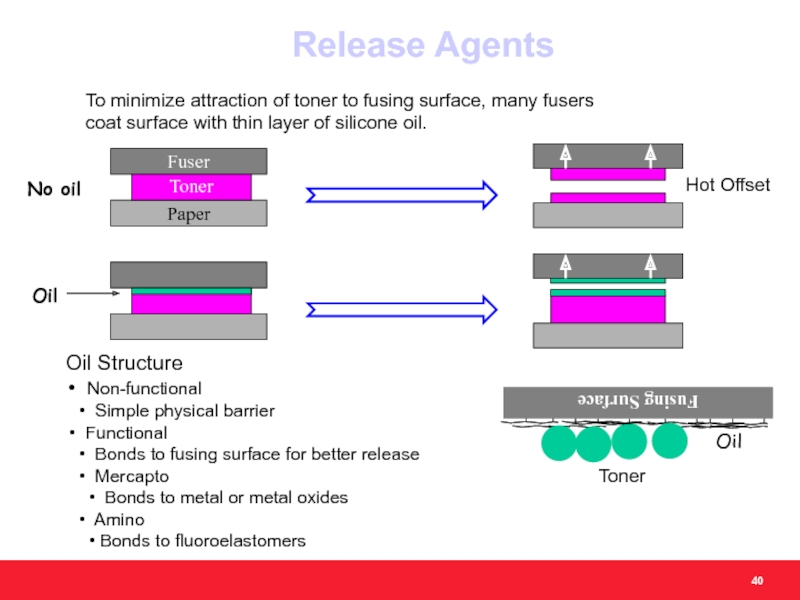

- 40. Oil Structure Non-functional Simple physical

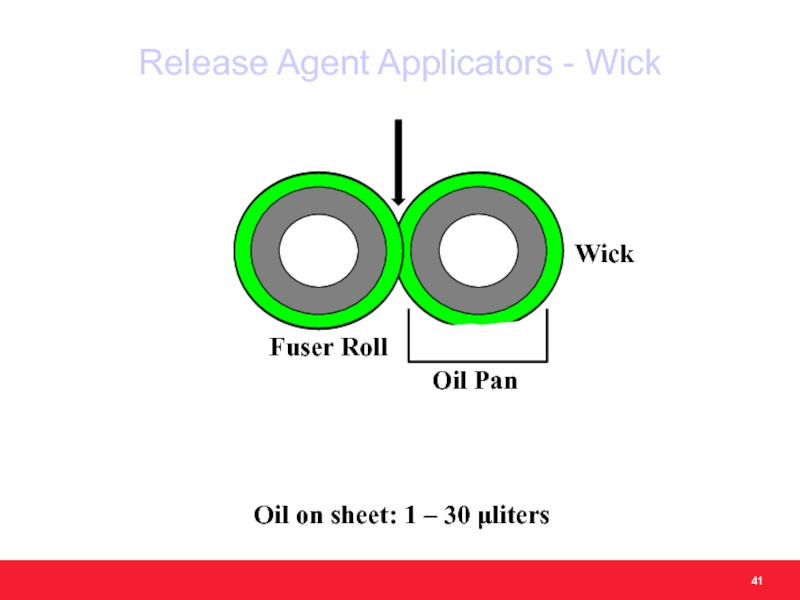

- 41. Oil on sheet: 1 – 30 μliters Release Agent Applicators - Wick Wick

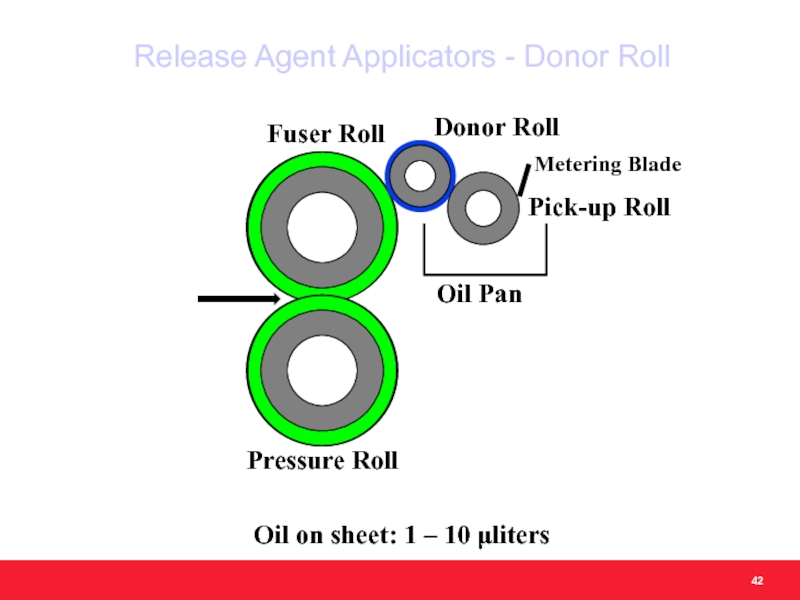

- 42. Release Agent Applicators - Donor Roll Metering Blade Oil on sheet: 1 – 10 μliters

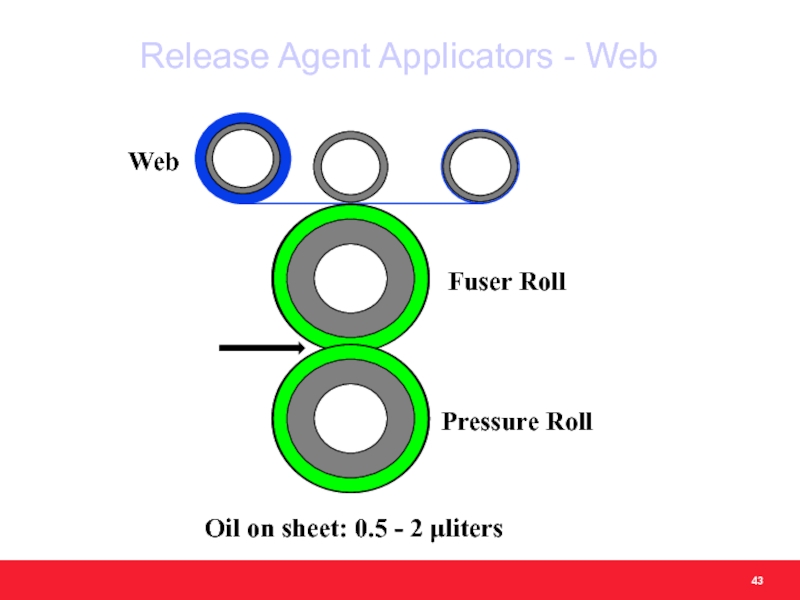

- 43. Release Agent Applicators - Web Oil on

- 44. Release Agent Issues Undesirable feel Inability to

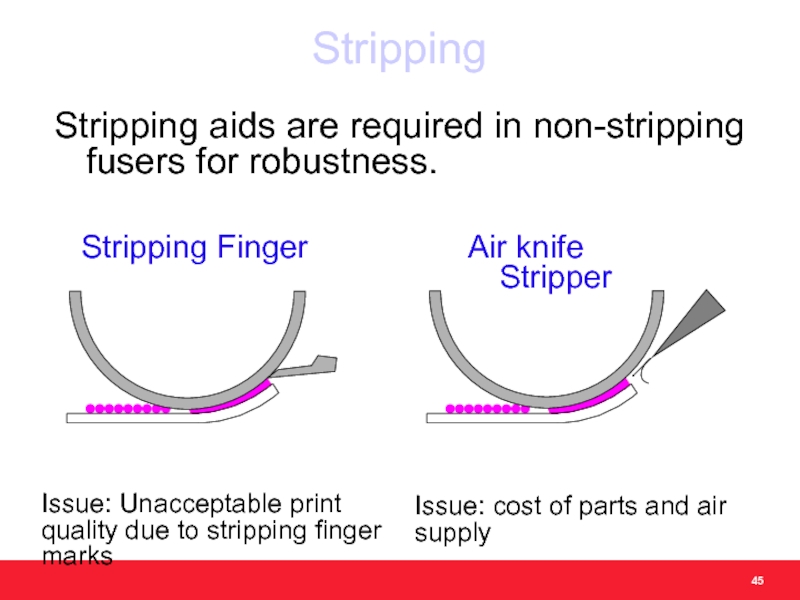

- 45. Stripping aids are required in non-stripping fusers

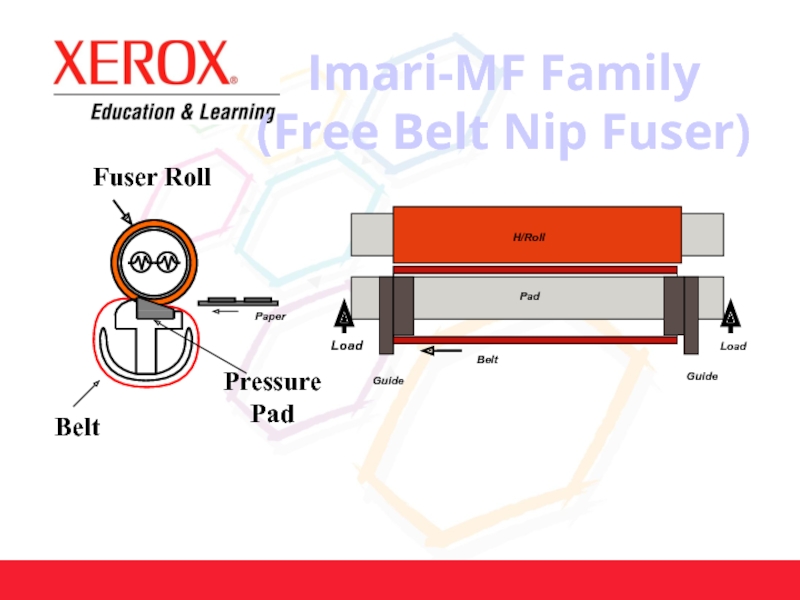

- 46. Imari-MF Family (Free Belt Nip Fuser) Fuser Roll Belt Pressure Pad

- 47. Erase Removing the charge from the photoreceptor

- 48. Erase Erase is the process of eliminating

- 49. Cleaning Removing the residues from the photoreceptor

- 50. Types of Residual Materials Toner Paper Debris

- 51. Methods of Cleaning Toner Mechanical Forces Blade

- 52. Methods of Cleaning Other Residuals Disturber Brushes

- 53. Common Cleaning Systems

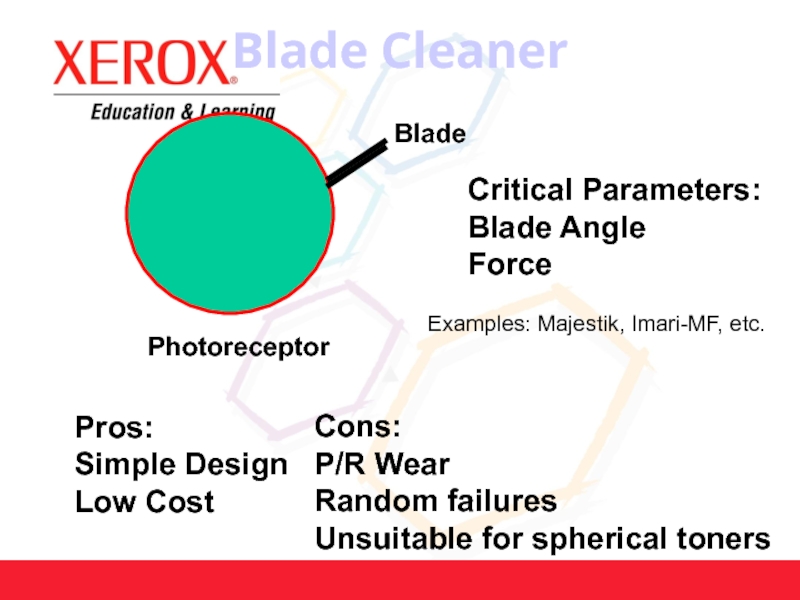

- 54. Blade Cleaner Photoreceptor Blade Critical Parameters:

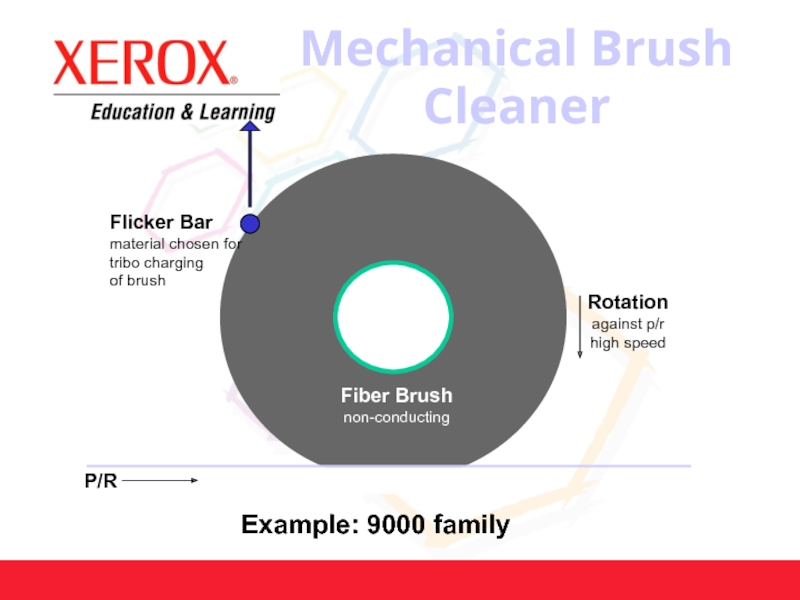

- 55. Mechanical Brush Cleaner Example: 9000 family

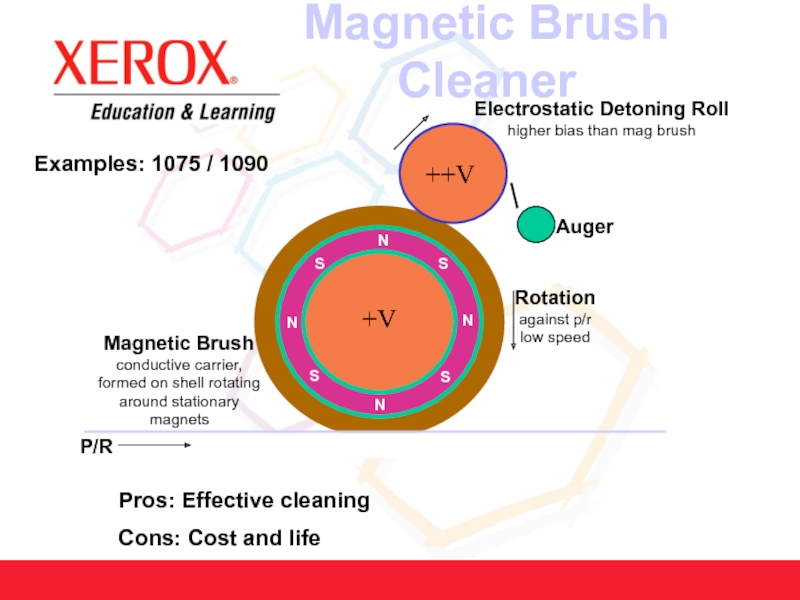

- 56. Magnetic Brush Cleaner Examples: 1075 / 1090 Pros: Effective cleaning Cons: Cost and life

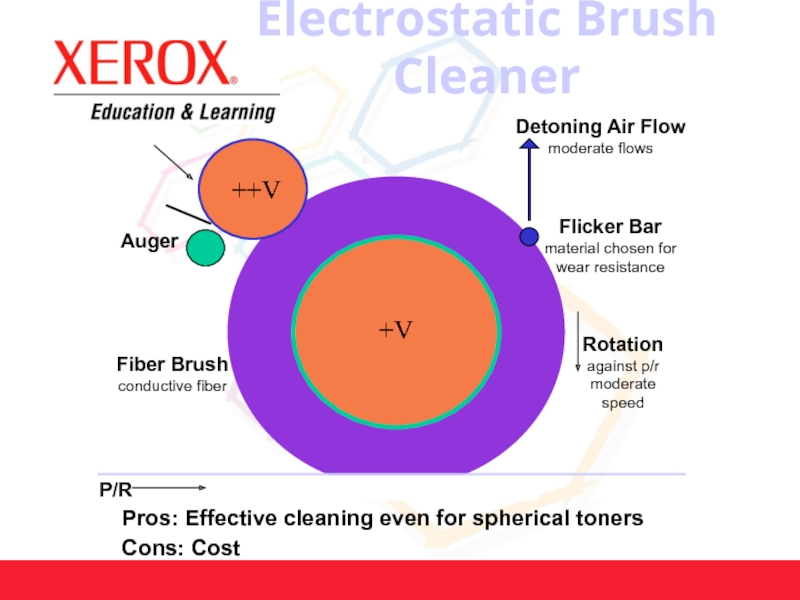

- 57. Electrostatic Brush Cleaner Pros: Effective cleaning even for spherical toners Cons: Cost

- 58. TONER

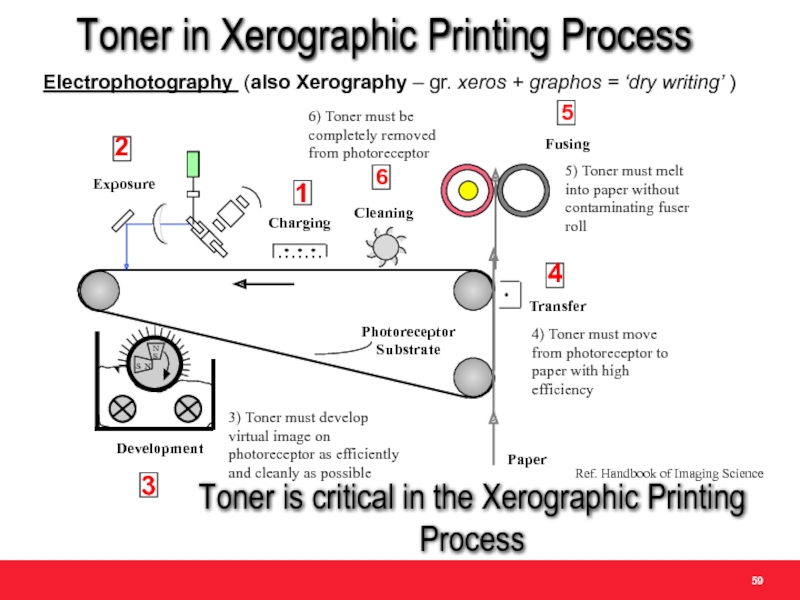

- 59. Toner in Xerographic Printing Process Electrophotography (also

- 60. From Larger to Smaller by Uncontrolled Breakage

- 61. Irregular shape Wider distribution

- 62. Toner

- 63. Dry toner is a

Слайд 2OBJECTIVE

By the end of this course you will have completed the

Laser Safety

Safe Lifting

Electrical competence

Basic Xerography

Toner Types

Electronic Imaging

Laptop Skills

Electro Static Discharge

Colour Theory

Customer Handling Skills

Слайд 4

Course Objective

The Xerographic Process

Charging

Photoreceptors

Charging Devices

Exposing

Development

Transfer

Fusing

Cleaning

Questions & Answers

Agenda

Слайд 8Configurations of Photoreceptors

Drum:

Smaller size

No seam

Wider choice of photoconductor materials

No tracking problems

Easier

Belt:

Flexible configuration

Full frame exposure possible

Discharge from backside possible

Radius at transfer can be varied

Longer relaxation time

Lower cost per unit area

Слайд 11Bias Charging Roll – Pros & cons

Advantages:

Size

Low Ozone emissions

Lower power requirements

Disadvantages:

Limited

Uniform charging requires AC

Adds to power supply

AC decreases conventional PR life

Слайд 16Development

Two Main Schemes:

Single Component Development (SCD)

Toner only

Two Component Development (TCD)

Developer (Toner

Materials

Toner size 5 to 15 mm

Carrier size 35 to 150 mm

Theory of Operation:

Electric charge is created on the toner via friction (SCD) or interaction with carrier (TCD)

Charged toner is deposited on the latent image on PR

Слайд 19Why DAD?

Only the area that needs to be developed is exposed

Lower exposure power requirements

Lasers / LED bars vs. exposure lamps

Less optical fatigue on photoreceptor

Extends life

Слайд 23Magnetic Brush Development Roll

The conductivity of the carrier determines whether

Слайд 26Major Transfer Drivers

Toner properties:

Toner shape

Toner size distribution

Tribo

Paper properties:

Electrical properties (surface &

Thickness, formation, roughness, porosity

Hardware:

Transfer field (current)

Air gaps, etc.

Слайд 27Corona

Biased Transfer Roll

Transfer Belt

Charged Transfer Roll (CTR)

Intermediate Transfer Belt

Acoustic Transfer Assist

Common Transfer Systems

Слайд 28

Most conventional system

Transfer Assist Blade (TAB) w/ belts applies nip pressure

Corotron

Examples: DocuTech, iGen, Brunel etc.

Corona Transfer System

Transfer Corotron

Detack Corotron

Detack Corotron

Transfer Corotron

TAB

Слайд 29

Fields created by charge density deposited onto paper by transfer corotron

After

V

Corona System: Theory of Operation

Слайд 30Biased Transfer Roll System

Used in most desktop printers

Conformable nip

Low ozone and

Слайд 31

Fields created by charge density on the bias roll

(due to the

BTR system: Theory of Operation

Слайд 32Transfer Belt System

Conformable nip w/field tailoring

Low ozone and high

Can eliminate prefuser transport in short

paper path architectures.

Examples: Oceans II, Toshiba, Ricoh

Drum

P/R Belt

Detack

Detack

Слайд 33CTR System

Example: Majestik family

Full process color achieved by developing and

Cons

Four passes per print - low productivity

Limited substrate applicability

Fuser

Rotary

Development

Unit

PR Drum

.

CTR Film

Слайд 34Intermediate Belt Transfer System

System approach – build colors on intermediate belt

Dual

Low ozone and high current efficiency

Examples: Sfida family, Imari-MF family, Ricoh

Intermediate Transfer Belt

Слайд 35Transfer

Assist

Blade

PreTransfer

Baffle

Detack Dicorotron

Transfer Dicorotron

Main Drive Roll

Assist Drive

/ Stripper Roll

Pretransfer

Discorotron

Transfer System with

Слайд 383 distinct types—all based on a roll pair comprised

of “hard” and

Dwell

Pressure

Ttoner(top)

Ttoner(bottom)

Formation of nip (dwell)

requires at least one rubberized roll

Stripping assist

Most-Common Fuser Type - Roll

Слайд 39Image-side roll (“fuser” roll) has

non-elastomeric coating

Paper-side roll (“pressure” roll) has

elastomeric coating to provide dwell and pressure.

Most common in B&W machines.

Type 1 Roll Fuser - Hard FR / Soft PR (NFPR)

Examples: Lakes, Brunel, Nuvera, etc.

Слайд 40Oil Structure

Non-functional

Simple physical barrier

Functional

Bonds to fusing surface

Mercapto

Bonds to metal or metal oxides

Amino

Bonds to fluoroelastomers

Fusing Surface

Release Agents

To minimize attraction of toner to fusing surface, many fusers

coat surface with thin layer of silicone oil.

Paper

Toner

Fuser

No oil

Oil

Hot Offset

Oil

Toner

Слайд 44Release Agent Issues

Undesirable feel

Inability to write on the print or to

“Post-it” notes

Impact on projection efficiency

Additional hardware, service, and consumables cost

The trend is to use wax in the toner formulation to avoid the above stated issues

Слайд 45Stripping aids are required in non-stripping fusers for robustness.

Stripping

Issue: Unacceptable print

Issue: cost of parts and air supply

Слайд 48Erase

Erase is the process of eliminating any electric memory of the

A combination of uniform light exposure and uniform charge exposure is used

Light exposure is provided by an exposure lamp

The remaining electric charge is neutralized using a corona device

Слайд 50Types of Residual Materials

Toner

Paper Debris

Fibers

Fillers: Talc, Kaolin (clays), etc.

Adhesives (e.g. ream

Carrier Beads

Machine Wear Debris

Airborne Fibers, Adhesives, Etc.

Слайд 51Methods of Cleaning Toner

Mechanical Forces

Blade

Multi – Blades

Mechanical Brush

Foam Roll

Web

Electrostatic Forces

Electrostatic Brush

Magnetic

Magnetic Brush (a.k.a., mag brush)

Слайд 52Methods of Cleaning Other Residuals

Disturber Brushes

Paper fibers and debris

Films from toner

Comets from toner additives

Spots Blades

Spots

Слайд 54Blade Cleaner

Photoreceptor

Blade

Critical Parameters:

Blade Angle

Force

Pros:

Simple Design

Low Cost

Cons:

P/R Wear

Random failures

Unsuitable for

Examples: Majestik, Imari-MF, etc.

Слайд 59Toner in Xerographic Printing Process

Electrophotography (also Xerography – gr. xeros +

Toner is critical in the Xerographic Printing Process

Ref. Handbook of Imaging Science

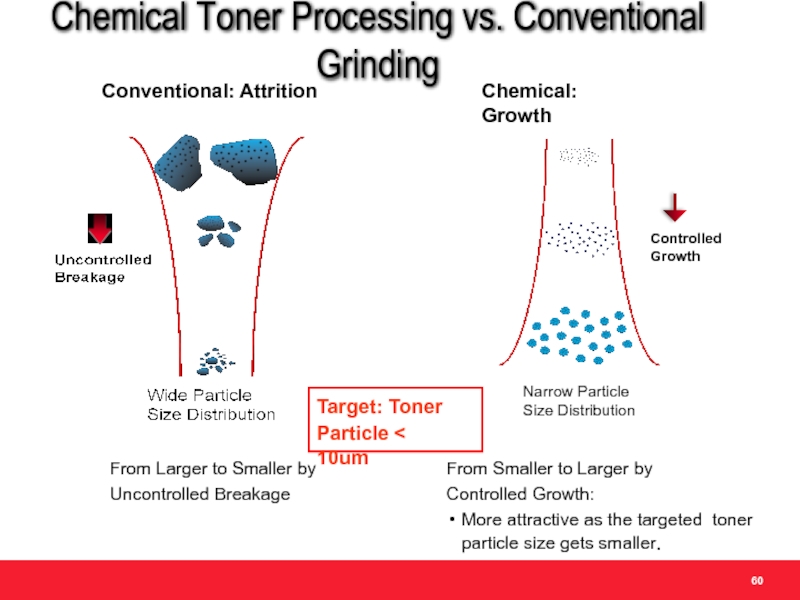

Слайд 60From Larger to Smaller by

Uncontrolled Breakage

Conventional: Attrition

Narrow Particle Size Distribution

From Smaller

Controlled Growth:

More attractive as the targeted toner particle size gets smaller.

Chemical: Growth

Chemical Toner Processing vs. Conventional Grinding

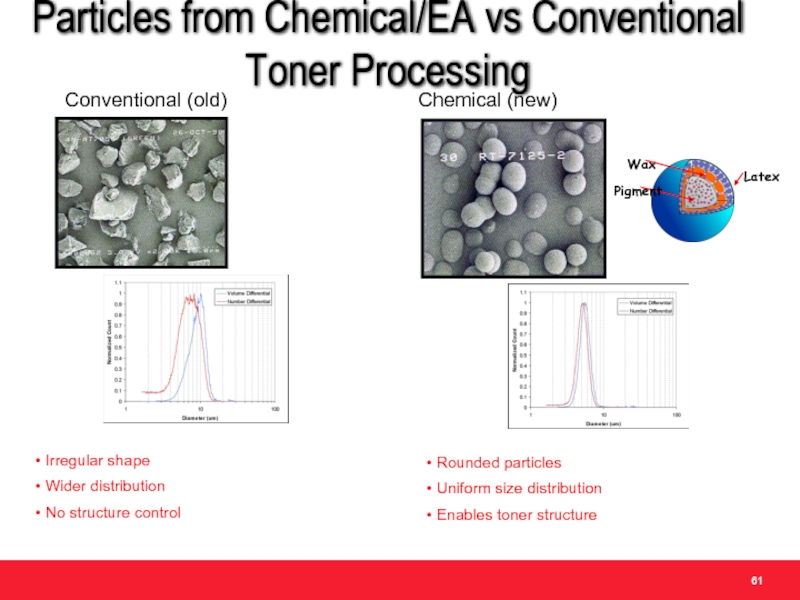

Слайд 61 Irregular shape

Wider distribution

No structure control

Particles from Chemical/EA

Conventional (old)

Chemical (new)

Rounded particles

Uniform size distribution

Enables toner structure

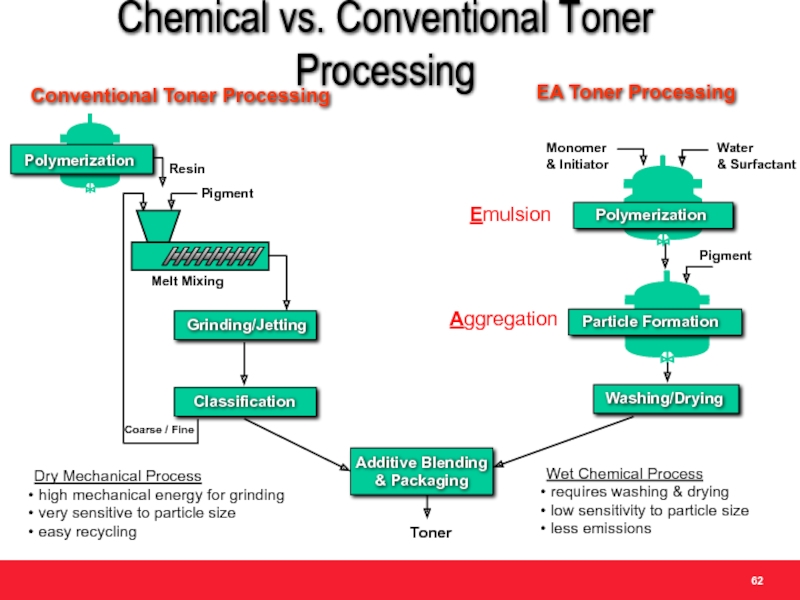

Слайд 62

Toner

Additive Blending & Packaging

Melt Mixing

Coarse / Fine

Resin

Pigment

Grinding/Jetting

Classification

Polymerization

Conventional Toner Processing

Chemical vs. Conventional

Dry Mechanical Process

high mechanical energy for grinding

very sensitive to particle size

easy recycling

Слайд 63

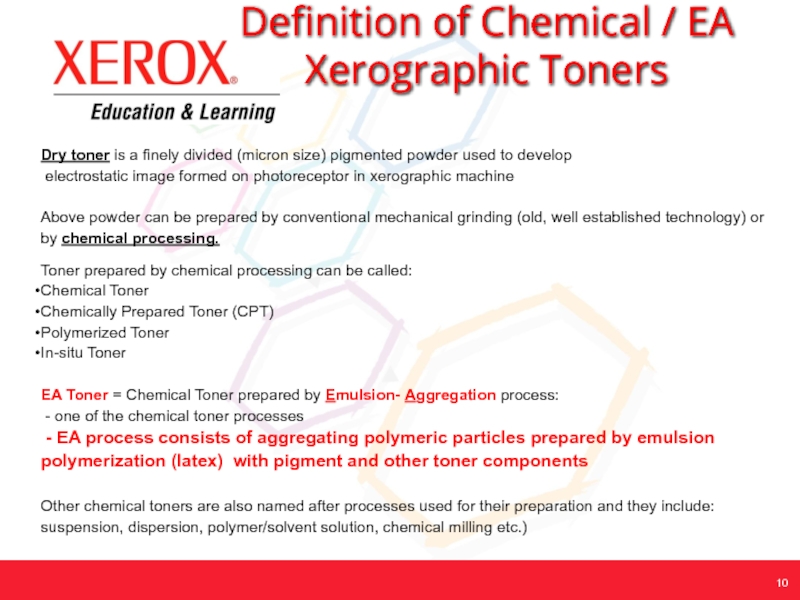

Dry toner is a finely divided (micron size) pigmented

electrostatic image formed on photoreceptor in xerographic machine

Above powder can be prepared by conventional mechanical grinding (old, well established technology) or by chemical processing.

Toner prepared by chemical processing can be called:

Chemical Toner

Chemically Prepared Toner (CPT)

Polymerized Toner

In-situ Toner

EA Toner = Chemical Toner prepared by Emulsion- Aggregation process:

- one of the chemical toner processes

- EA process consists of aggregating polymeric particles prepared by emulsion polymerization (latex) with pigment and other toner components

Other chemical toners are also named after processes used for their preparation and they include: suspension, dispersion, polymer/solvent solution, chemical milling etc.)

Definition of Chemical / EA Xerographic Toners

10