- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Pump Genius Application Functionalities for control of Pumps презентация

Содержание

- 1. Pump Genius Application Functionalities for control of Pumps

- 2. Objective Provide the user with flexibility and

- 3. Pump Genius Platform SIMPLEX Only one pump

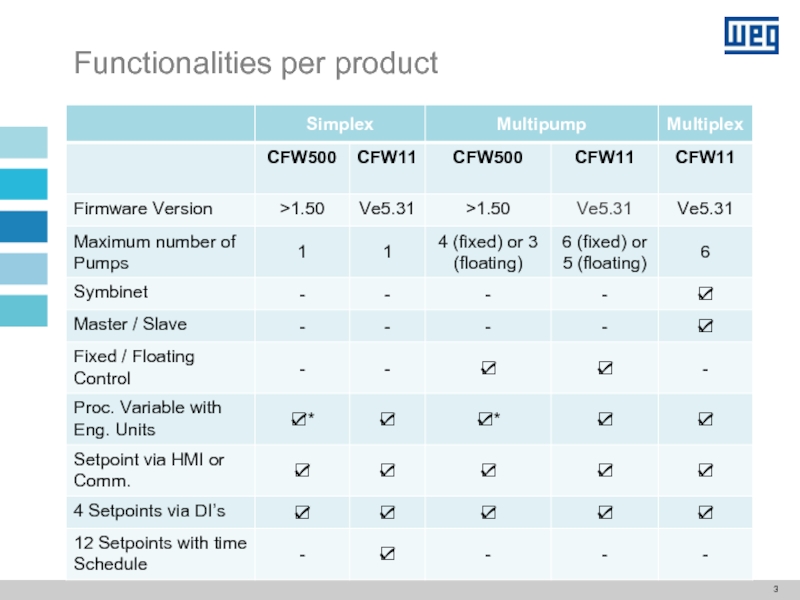

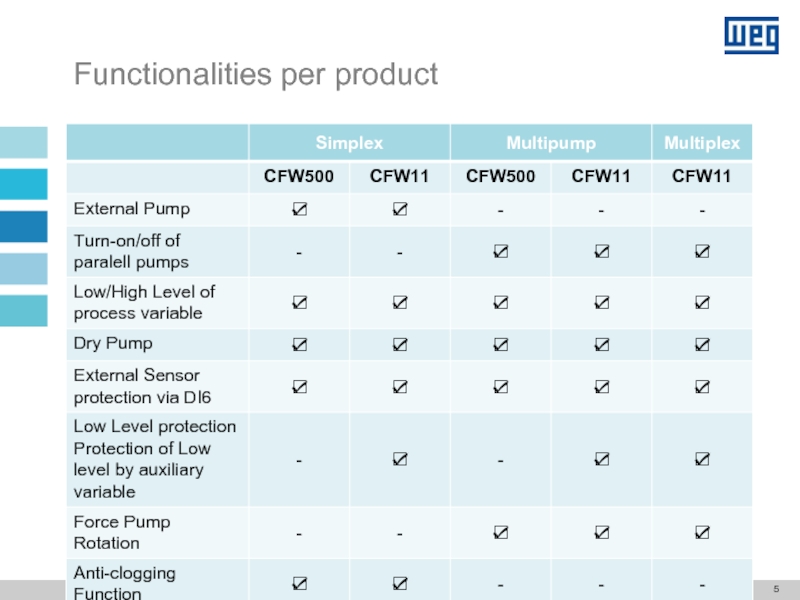

- 4. Functionalities per product

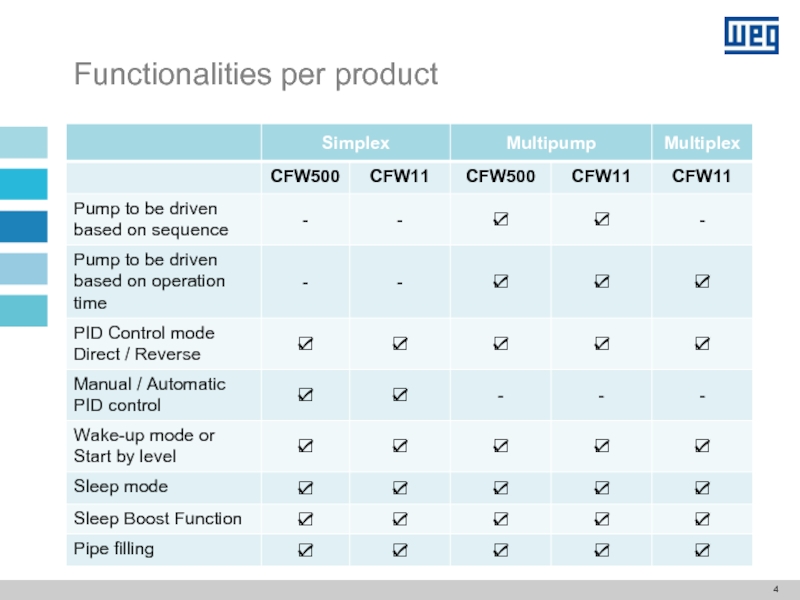

- 5. Functionalities per product

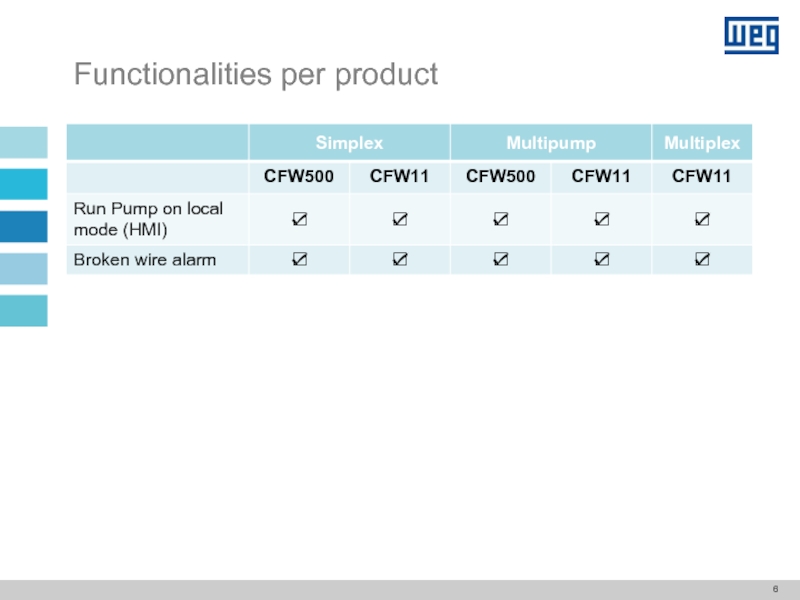

- 6. Pump Genius Software – Funcionalides para Controle de Bombas Functionalities per product

- 7. Functionalities per product

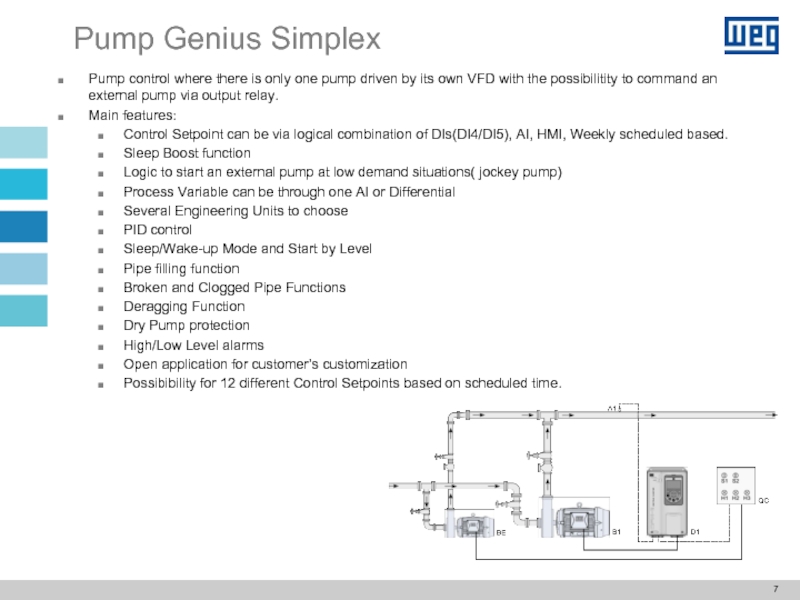

- 8. Pump Genius Simplex Pump control where there

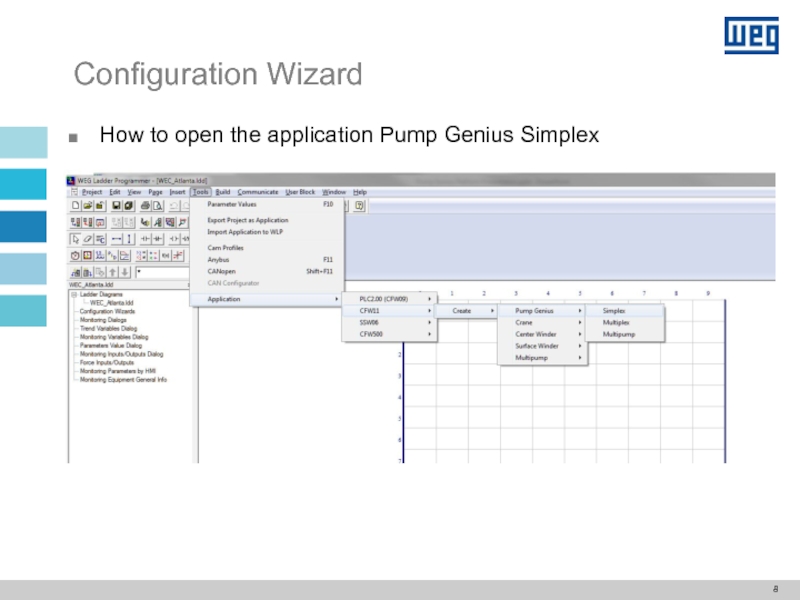

- 9. Configuration Wizard How to open the application Pump Genius Simplex

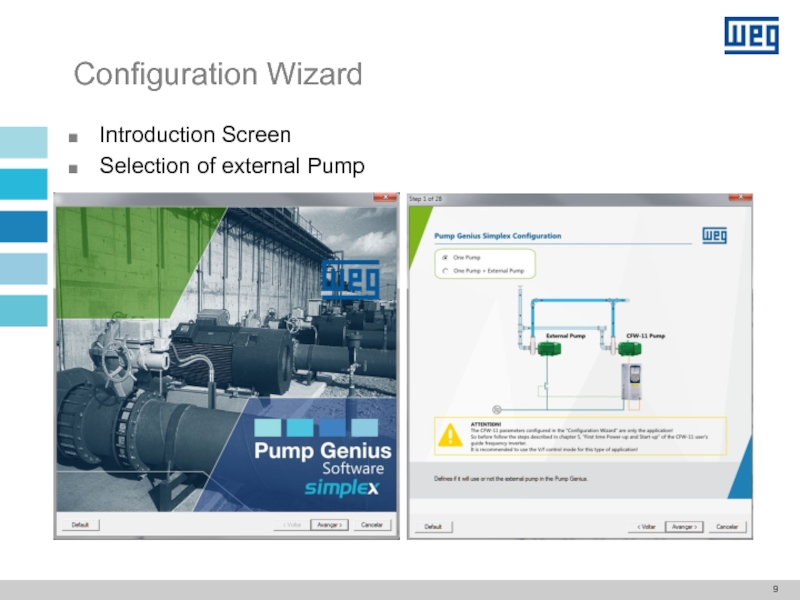

- 10. Configuration Wizard Introduction Screen Selection of external Pump

- 11. Source of commands e I/Os Local/Remote Source

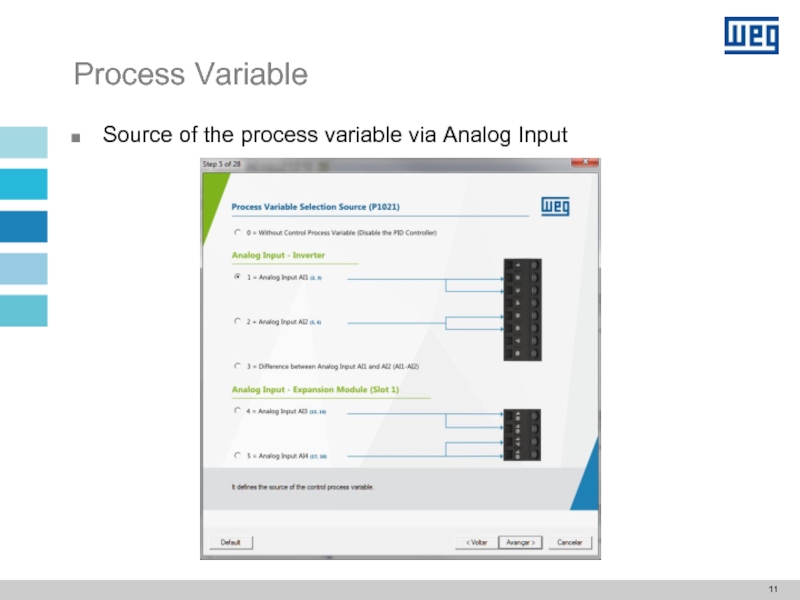

- 12. Process Variable Source of the process variable via Analog Input

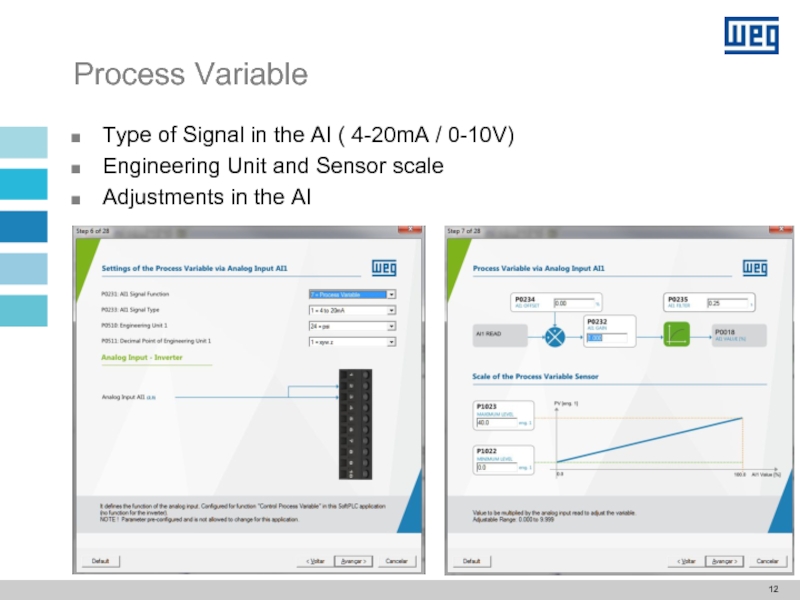

- 13. Process Variable Type of Signal in the

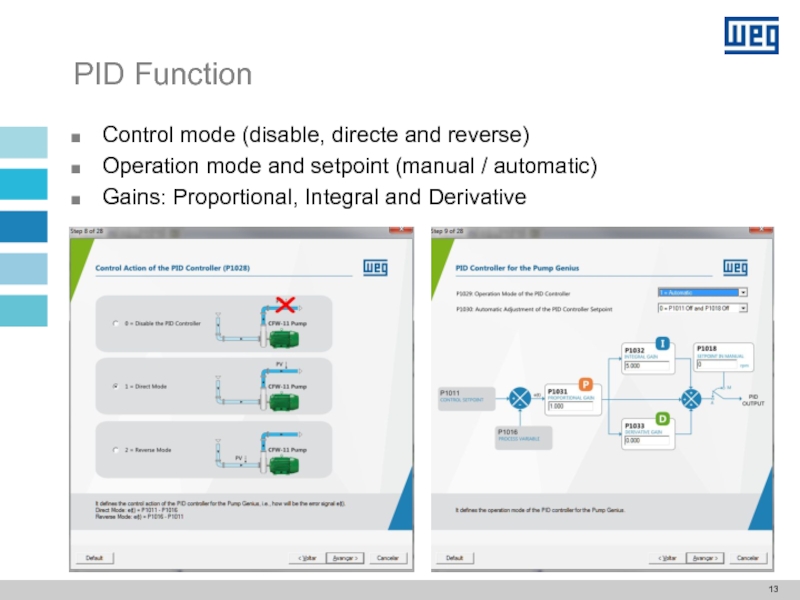

- 14. PID Function Control mode (disable, directe and

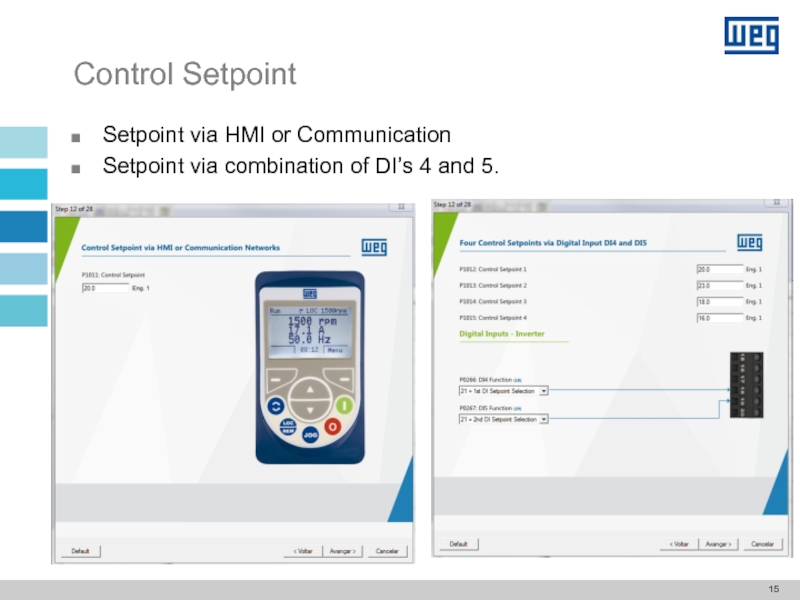

- 15. Control Setpoint Source of the control setpoint

- 16. Control Setpoint Setpoint via HMI or Communication

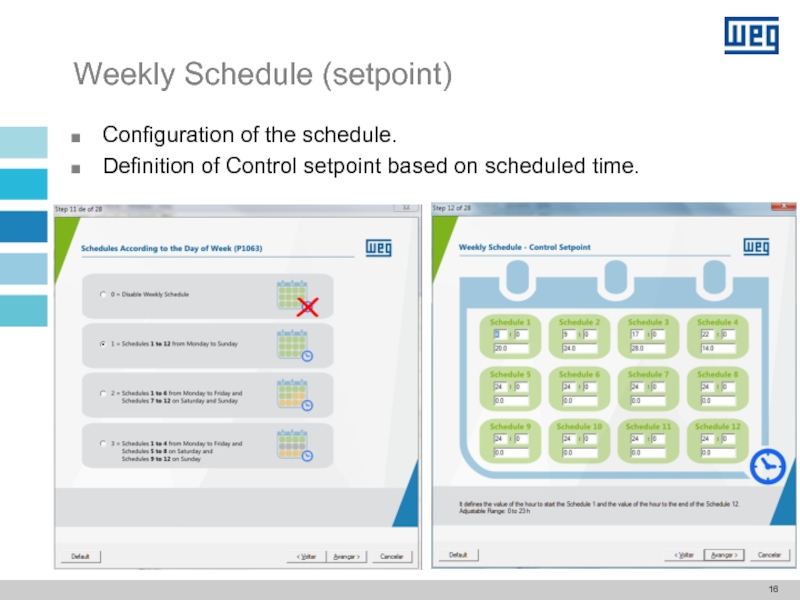

- 17. Weekly Schedule (setpoint) Configuration of the schedule.

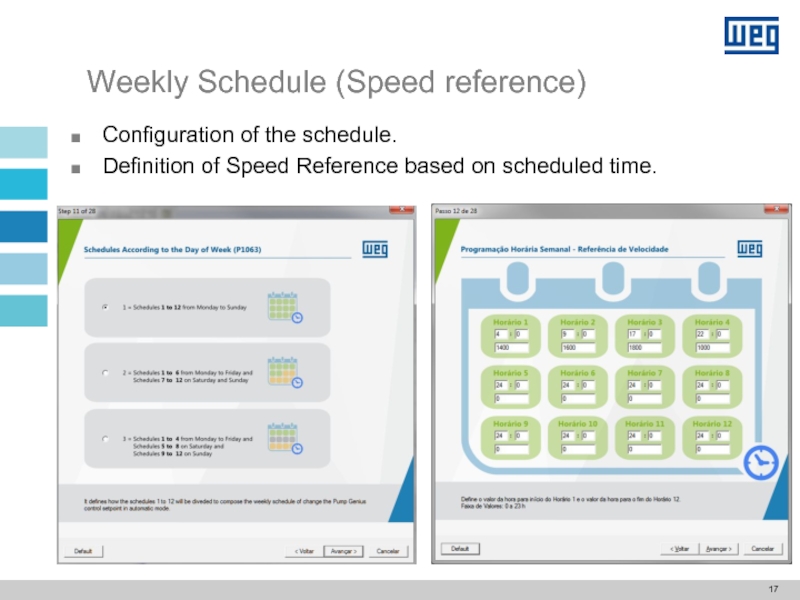

- 18. Configuration of the schedule. Definition of Speed

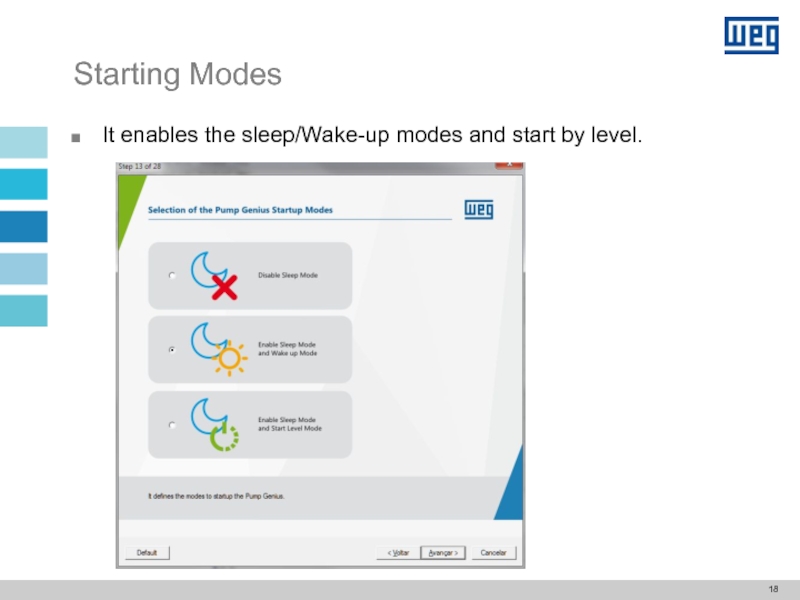

- 19. Starting Modes It enables the sleep/Wake-up modes and start by level.

- 20. Starting Modes It Configures Sleep and Wake-up

- 21. Pump Genius Software – Funcionalides para Controle

- 22. External Pump and Pump protection by Process

- 23. Pump Genius Software – Funcionalides para Controle

- 24. Pump Genius Software – Funcionalides para Controle

- 25. Pump Genius Software – Funcionalides para Controle

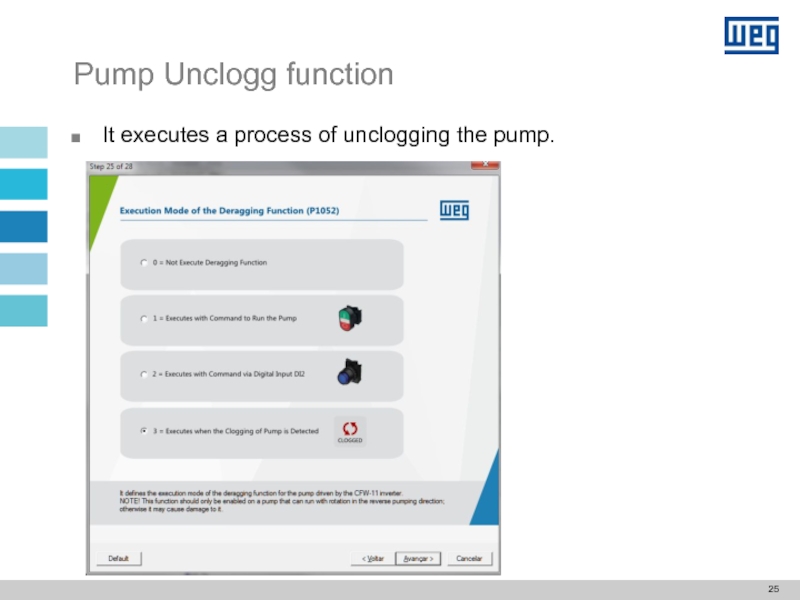

- 26. Pump Unclogg function It executes a process of unclogging the pump.

- 27. Pump Unclogg function It configures the detection

- 28. Monitoring Screen via HMI and Summary It

- 29. System Operation – Use of Jockey Pump

- 30. System Operation – Unclogg function

- 31. System Operation – Setpoint based in time scheduled

- 32. Pump Genius Multiplex Pump control where each

- 33. Pump Genius Software – Funcionalides para Controle de Bombas Power Diagram

- 34. Configuration Wizard Introduction Screen

- 35. Configuration Wizard How to open the application Pump Genius Multiplex

- 36. Configuration Wizard It selects the pump to

- 37. Communication Interface(Symbinet) It configures the Communication with RS-485. It configures the Communication with CAN.

- 38. Activation of pumps in the system and

- 39. Pump Genius Software – Funcionalides para Controle

- 40. Pump Genius Software – Funcionalides para Controle

- 41. Force Rotation of Pumps It configures the

- 42. Pump Genius Software – Funcionalides para Controle

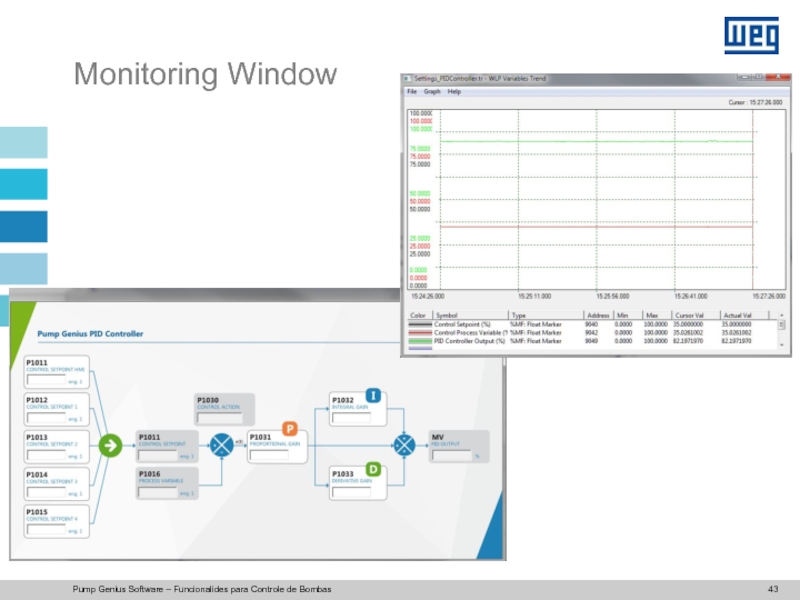

- 43. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

- 44. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

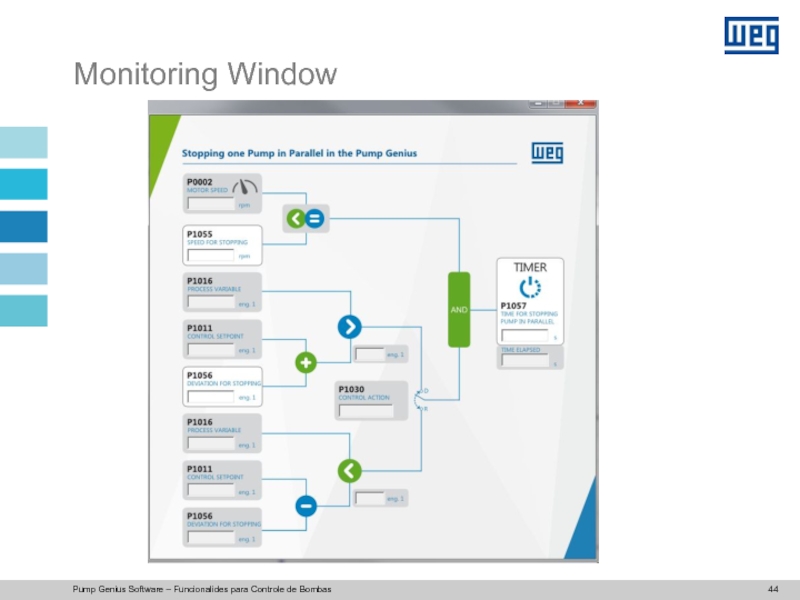

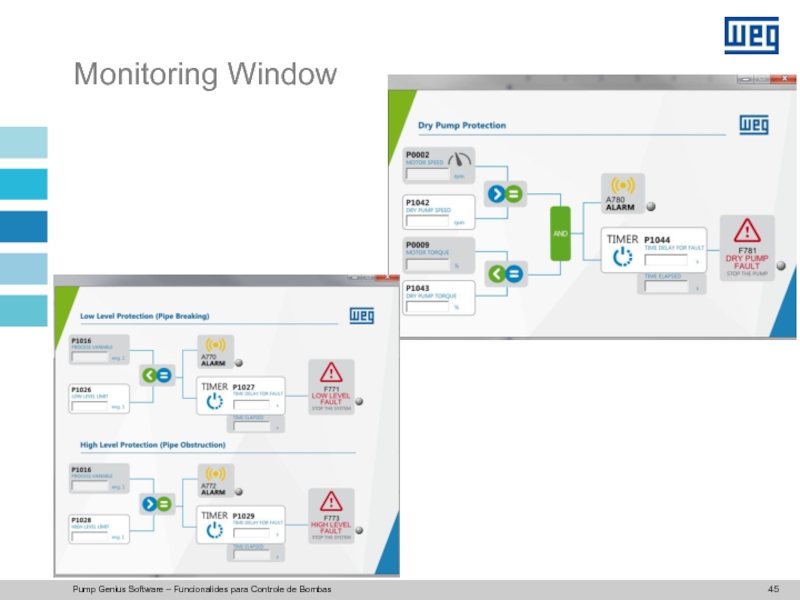

- 45. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

- 46. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

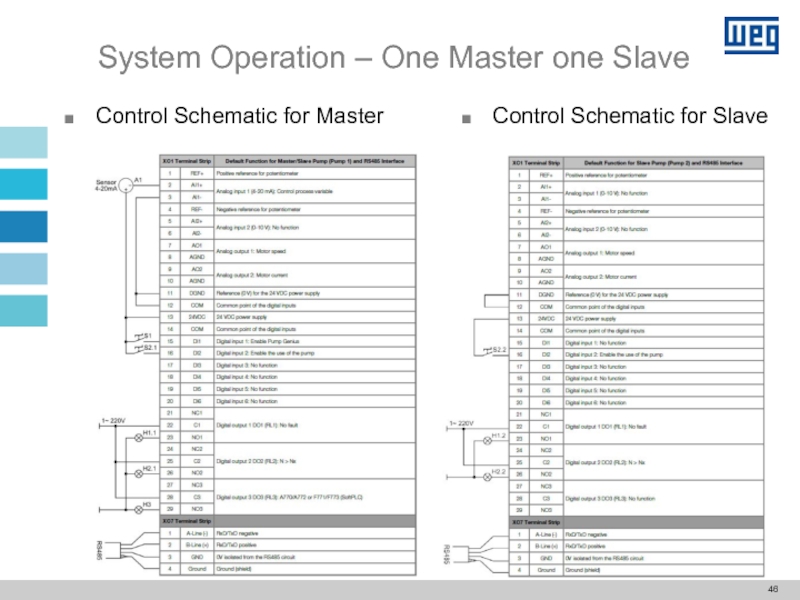

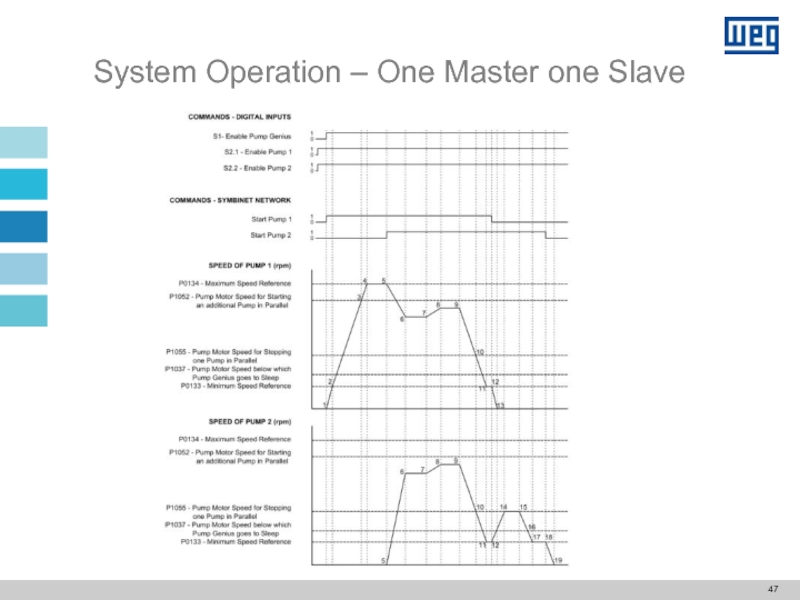

- 47. System Operation – One Master one Slave

- 48. System Operation – One Master one Slave

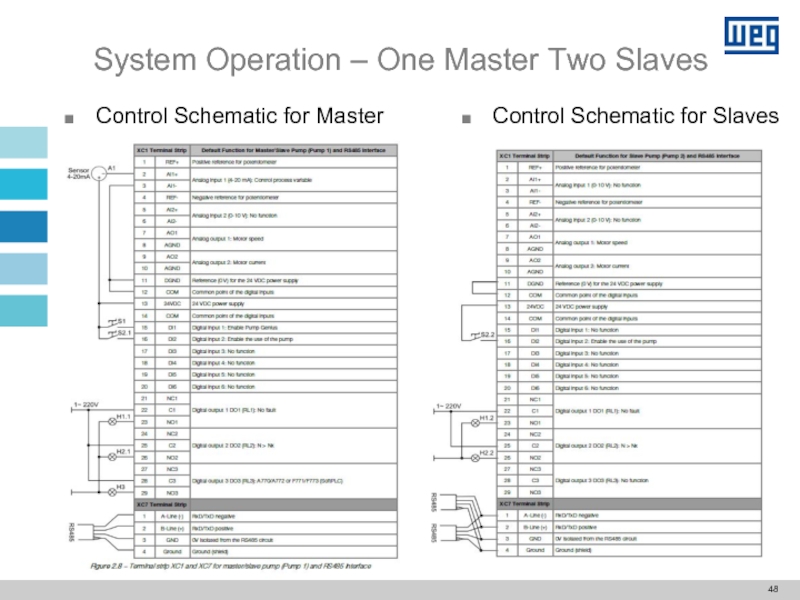

- 49. System Operation – One Master Two Slaves

- 50. System Operation – One Master Two Slaves

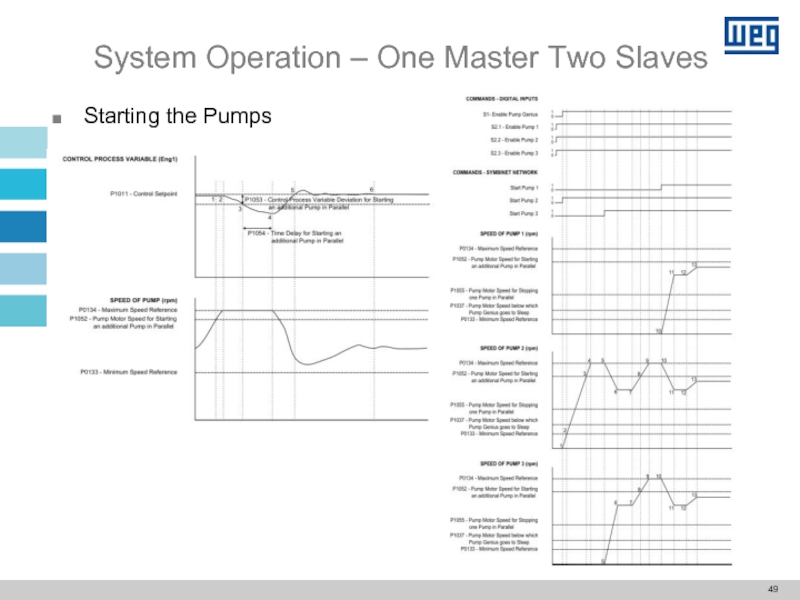

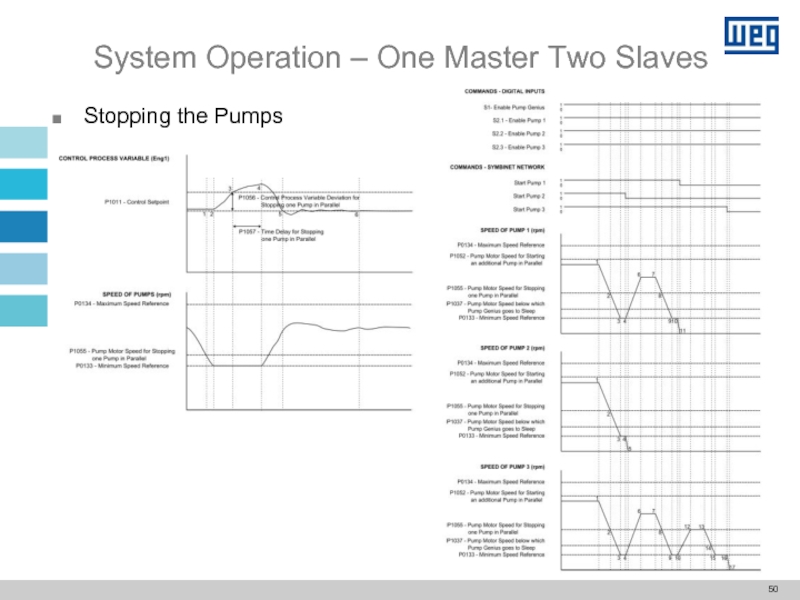

- 51. System Operation – One Master Two Slaves

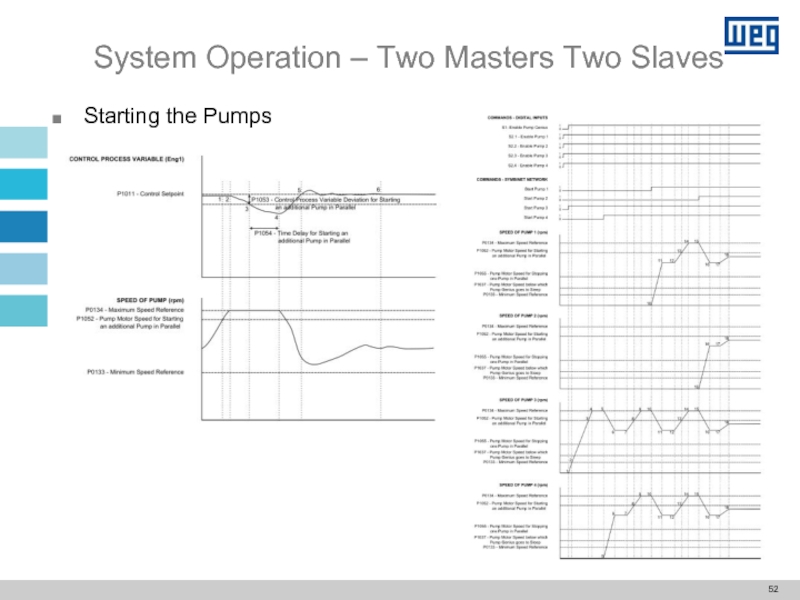

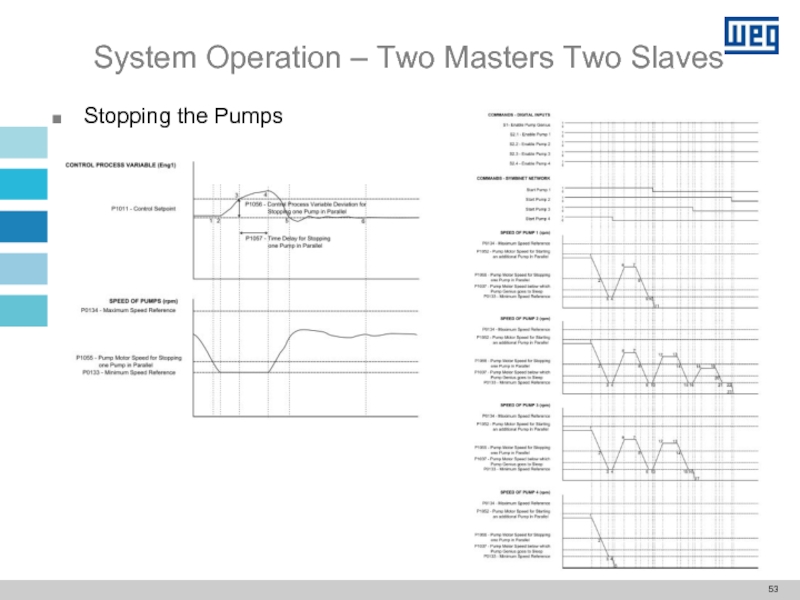

- 52. System Operation – Two Masters Two Slaves

- 53. System Operation – Two Masters Two Slaves

- 54. System Operation – Two Masters Two Slaves

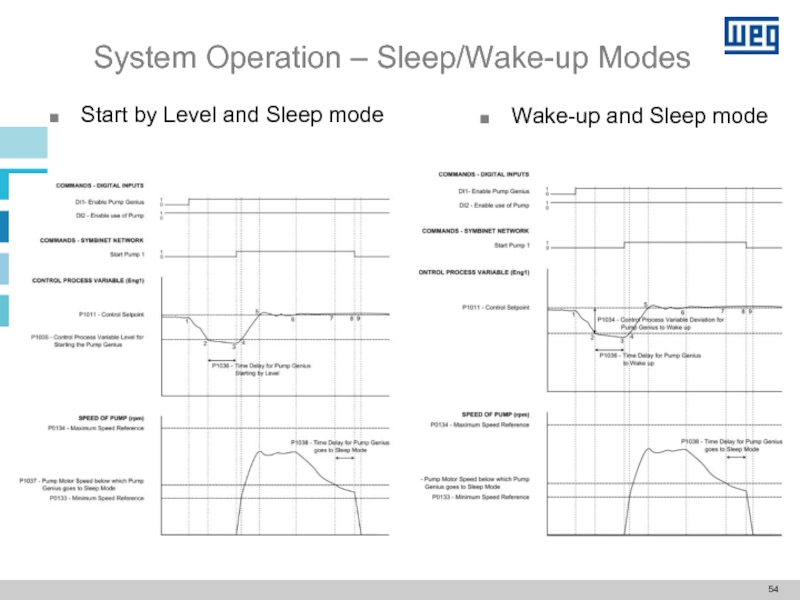

- 55. System Operation – Sleep/Wake-up Modes Start by

- 56. System Operation – Sleep mode w/ Sleep boost enabled

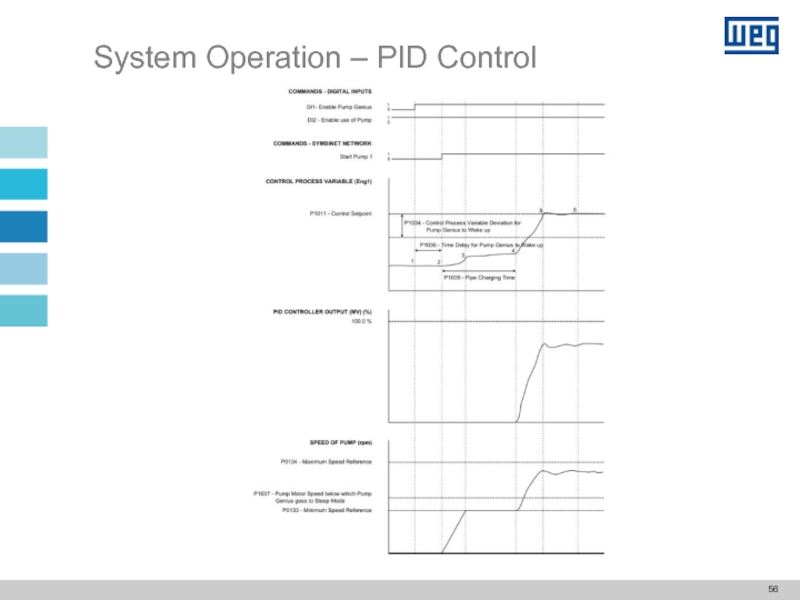

- 57. System Operation – PID Control

Слайд 2Objective

Provide the user with flexibility and fast setup process when configuring

It uses tools of ladder language offered by WLP along with configuration and monitoring assistants.

Слайд 3Pump Genius Platform

SIMPLEX

Only one pump with speed controlled

It uses only one

Start/Stop commands for external pump (low demand) using drive output relay.

MULTIPUMP

It controls the speed of only one paralell pump.

It uses only one drive

Start/Stop commands for paralell pumps via output relays.

MULTIPLEX

Each of the paralell pumps has speed control.

Up to 6 drives can be used.

Each paralell pump is drive driven and it can be configured as master/slave( lead/lag).

Слайд 8Pump Genius Simplex

Pump control where there is only one pump driven

Main features:

Control Setpoint can be via logical combination of DIs(DI4/DI5), AI, HMI, Weekly scheduled based.

Sleep Boost function

Logic to start an external pump at low demand situations( jockey pump)

Process Variable can be through one AI or Differential

Several Engineering Units to choose

PID control

Sleep/Wake-up Mode and Start by Level

Pipe filling function

Broken and Clogged Pipe Functions

Deragging Function

Dry Pump protection

High/Low Level alarms

Open application for customer’s customization

Possibibility for 12 different Control Setpoints based on scheduled time.

Слайд 13Process Variable

Type of Signal in the AI ( 4-20mA / 0-10V)

Engineering Unit and Sensor scale

Adjustments in the AI

Слайд 14PID Function

Control mode (disable, directe and reverse)

Operation mode and setpoint (manual

Gains: Proportional, Integral and Derivative

Слайд 15Control Setpoint

Source of the control setpoint

Type of signal and adjustments of

Слайд 17Weekly Schedule (setpoint)

Configuration of the schedule.

Definition of Control setpoint based on

Слайд 18Configuration of the schedule.

Definition of Speed Reference based on scheduled time.

Weekly Schedule (Speed reference)

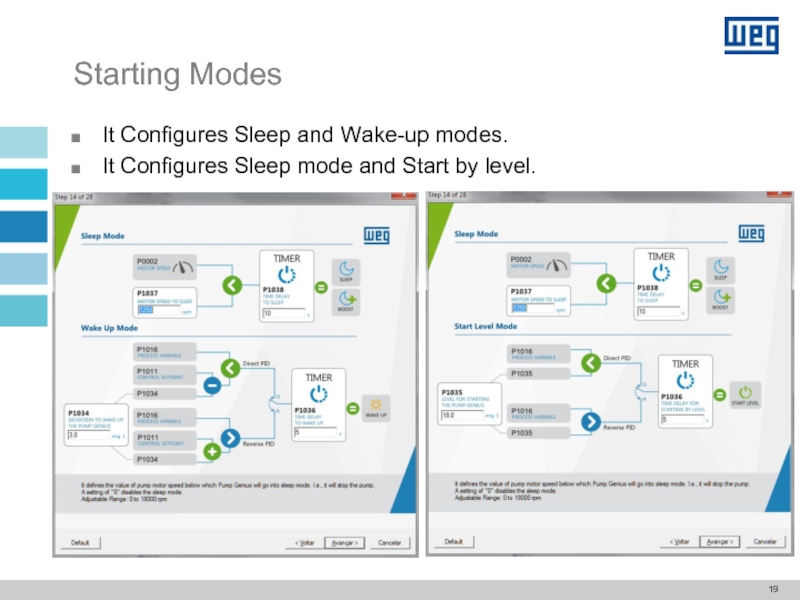

Слайд 20Starting Modes

It Configures Sleep and Wake-up modes.

It Configures Sleep mode and

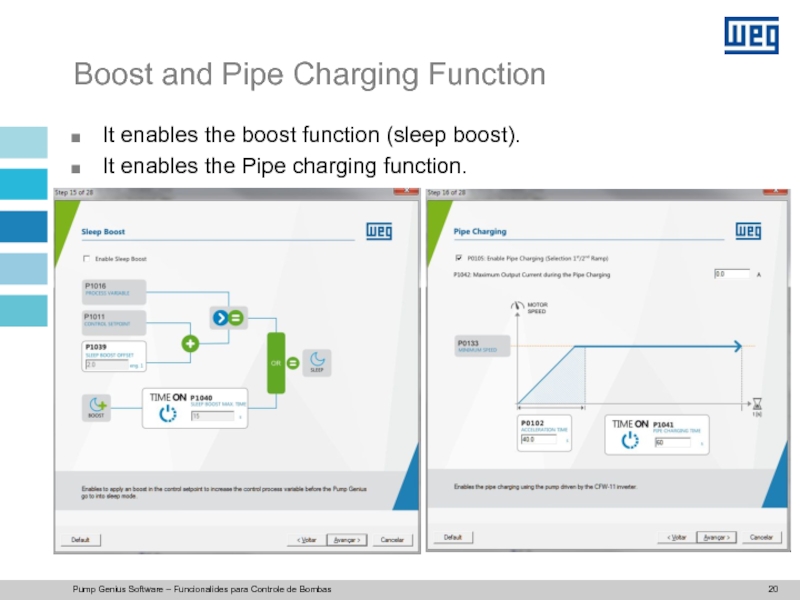

Слайд 21Pump Genius Software – Funcionalides para Controle de Bombas

Boost and Pipe

It enables the boost function (sleep boost).

It enables the Pipe charging function.

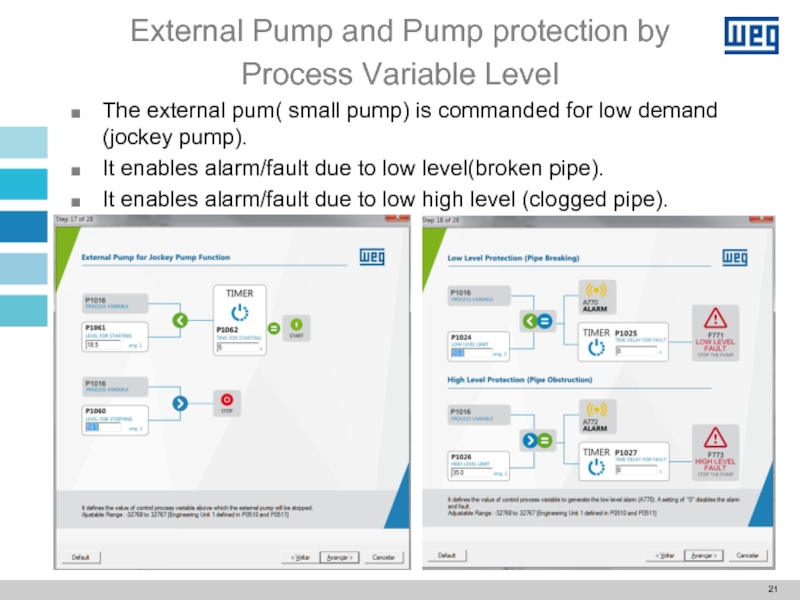

Слайд 22External Pump and Pump protection by Process Variable Level

The external pum(

It enables alarm/fault due to low level(broken pipe).

It enables alarm/fault due to low high level (clogged pipe).

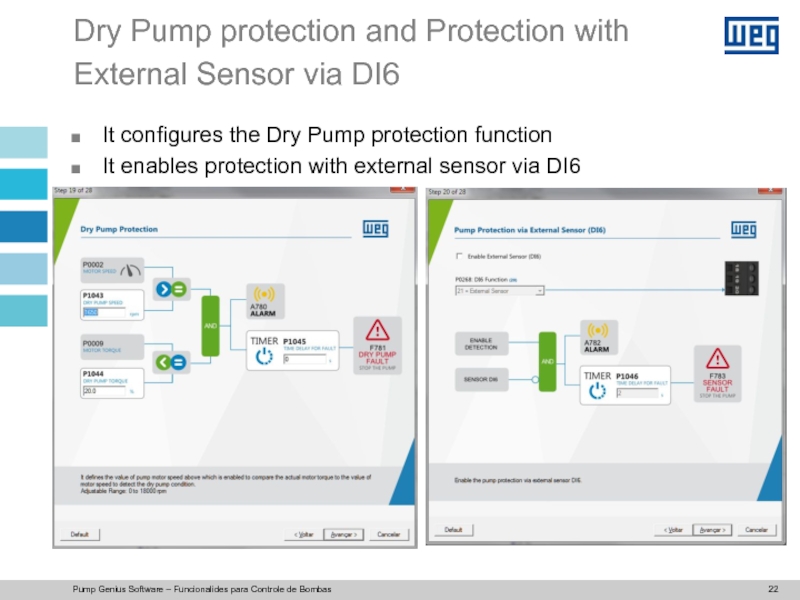

Слайд 23Pump Genius Software – Funcionalides para Controle de Bombas

Dry Pump protection

It configures the Dry Pump protection function

It enables protection with external sensor via DI6

Слайд 24Pump Genius Software – Funcionalides para Controle de Bombas

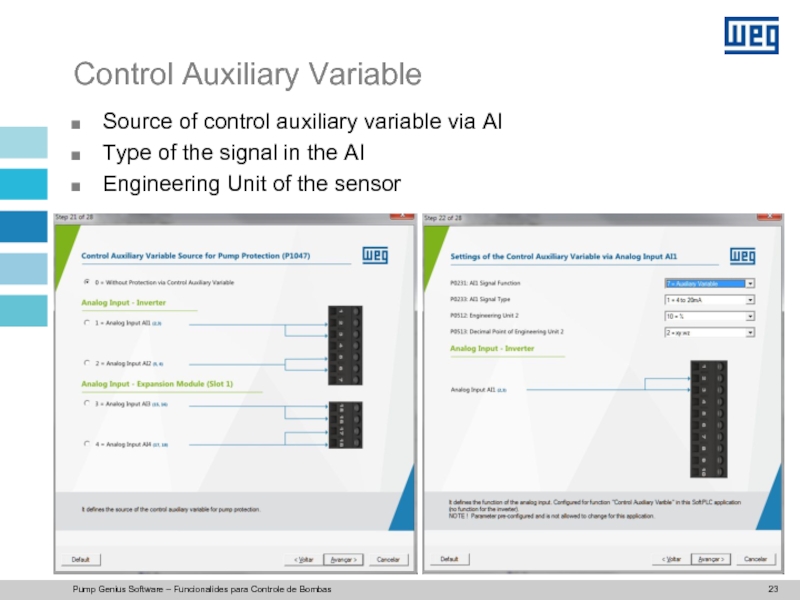

Control Auxiliary Variable

Source

Type of the signal in the AI

Engineering Unit of the sensor

Слайд 25Pump Genius Software – Funcionalides para Controle de Bombas

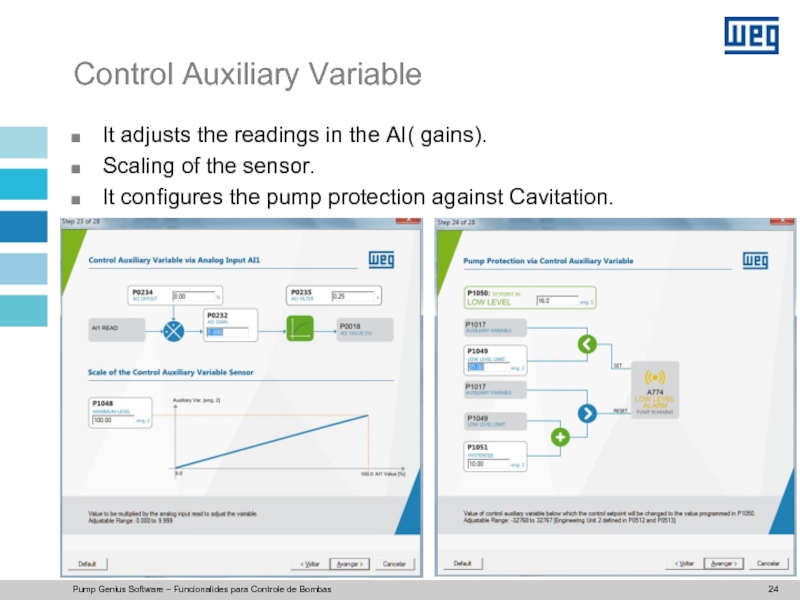

Control Auxiliary Variable

It

Scaling of the sensor.

It configures the pump protection against Cavitation.

Слайд 27Pump Unclogg function

It configures the detection of the clogging.

It enables the

It configures the unclog function

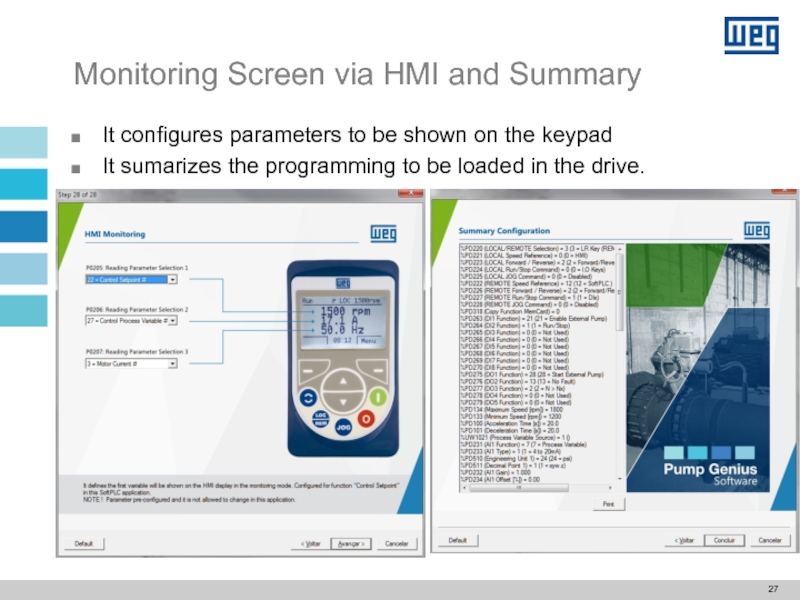

Слайд 28Monitoring Screen via HMI and Summary

It configures parameters to be shown

It sumarizes the programming to be loaded in the drive.

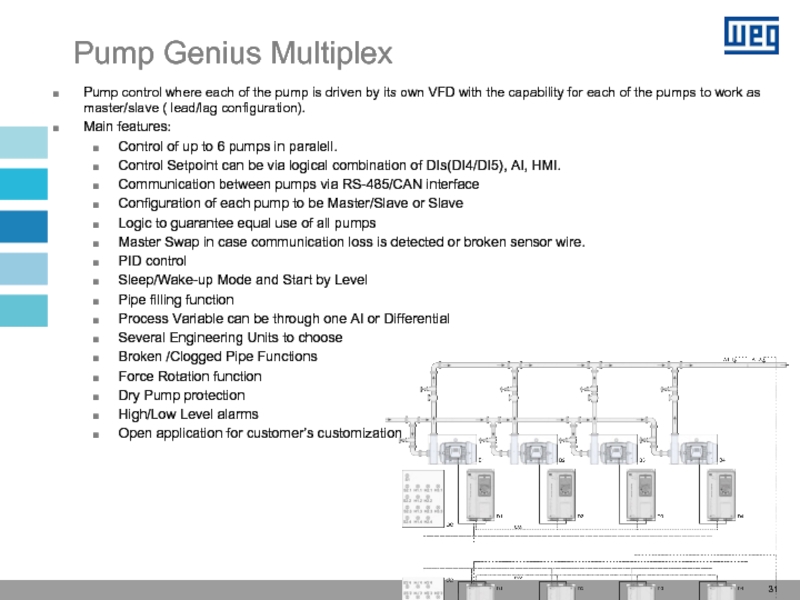

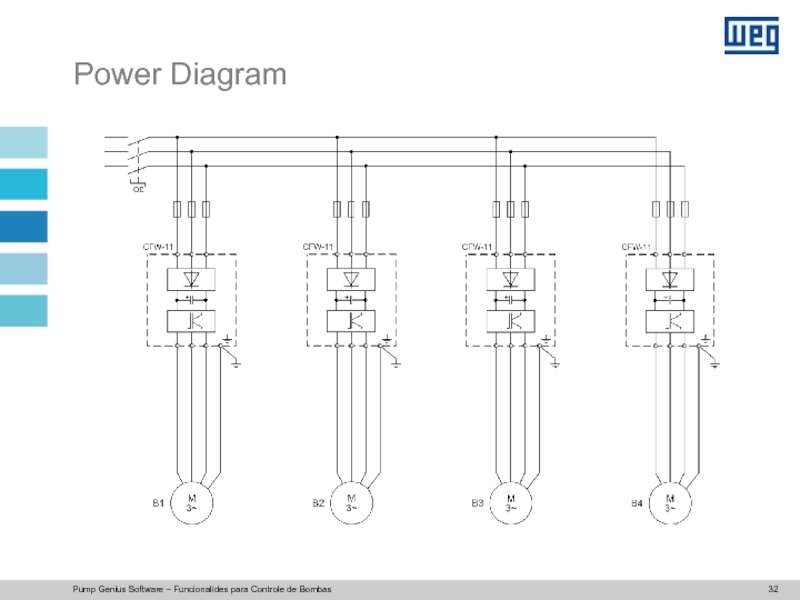

Слайд 32Pump Genius Multiplex

Pump control where each of the pump is driven

Main features:

Control of up to 6 pumps in paralell.

Control Setpoint can be via logical combination of DIs(DI4/DI5), AI, HMI.

Communication between pumps via RS-485/CAN interface

Configuration of each pump to be Master/Slave or Slave

Logic to guarantee equal use of all pumps

Master Swap in case communication loss is detected or broken sensor wire.

PID control

Sleep/Wake-up Mode and Start by Level

Pipe filling function

Process Variable can be through one AI or Differential

Several Engineering Units to choose

Broken /Clogged Pipe Functions

Force Rotation function

Dry Pump protection

High/Low Level alarms

Open application for customer’s customization

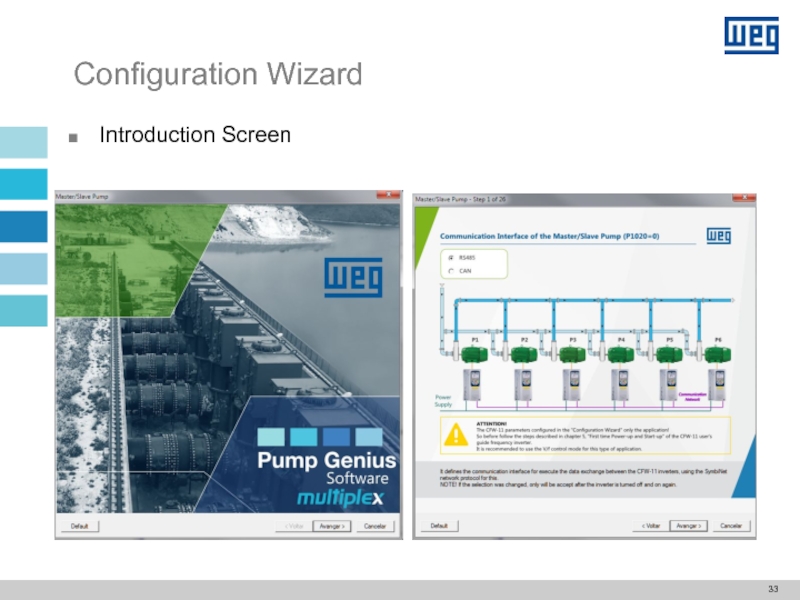

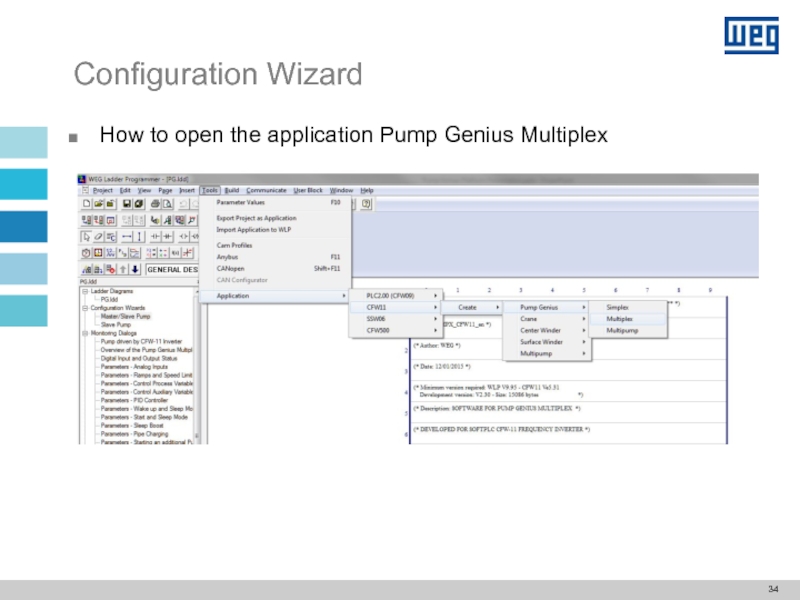

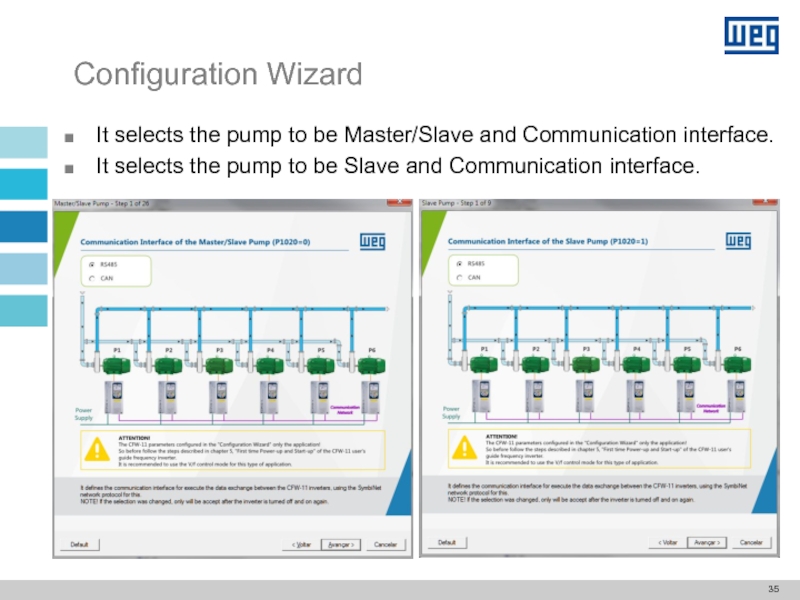

Слайд 36Configuration Wizard

It selects the pump to be Master/Slave and Communication interface.

It

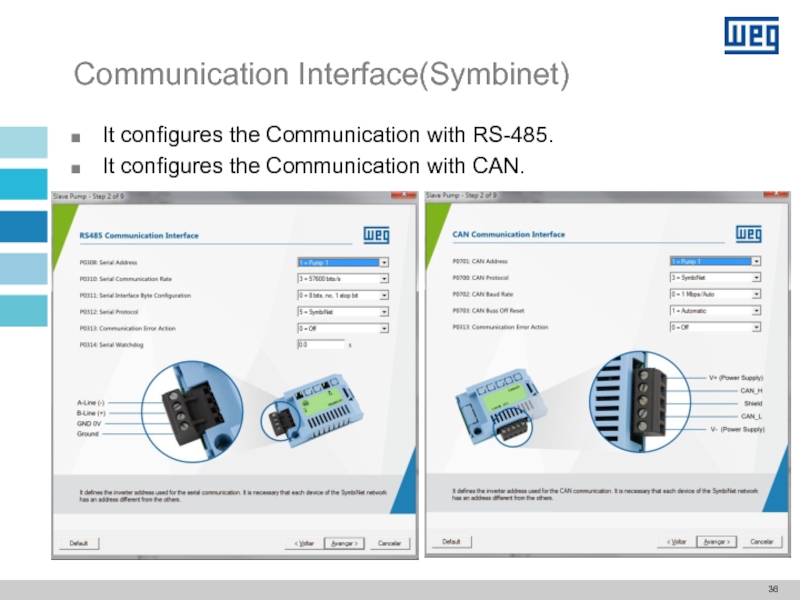

Слайд 37Communication Interface(Symbinet)

It configures the Communication with RS-485.

It configures the Communication with

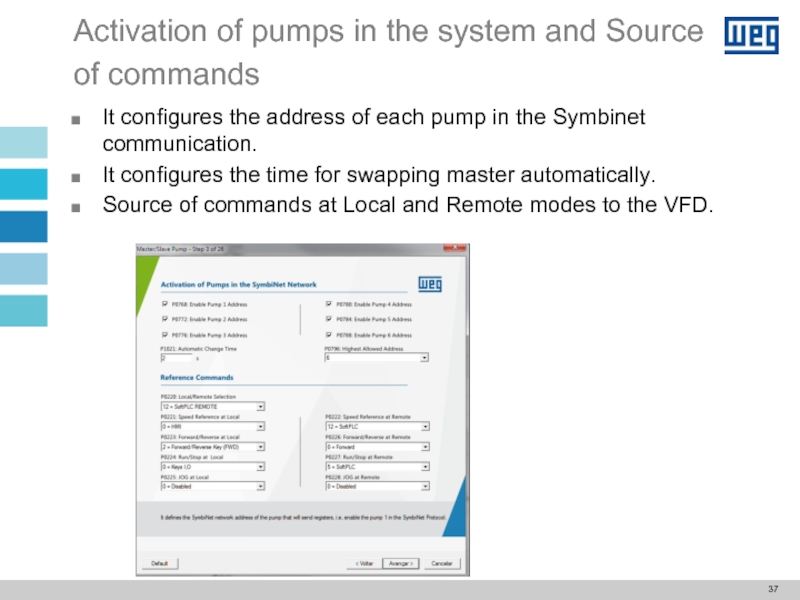

Слайд 38Activation of pumps in the system and Source of commands

It configures

It configures the time for swapping master automatically.

Source of commands at Local and Remote modes to the VFD.

Слайд 39Pump Genius Software – Funcionalides para Controle de Bombas

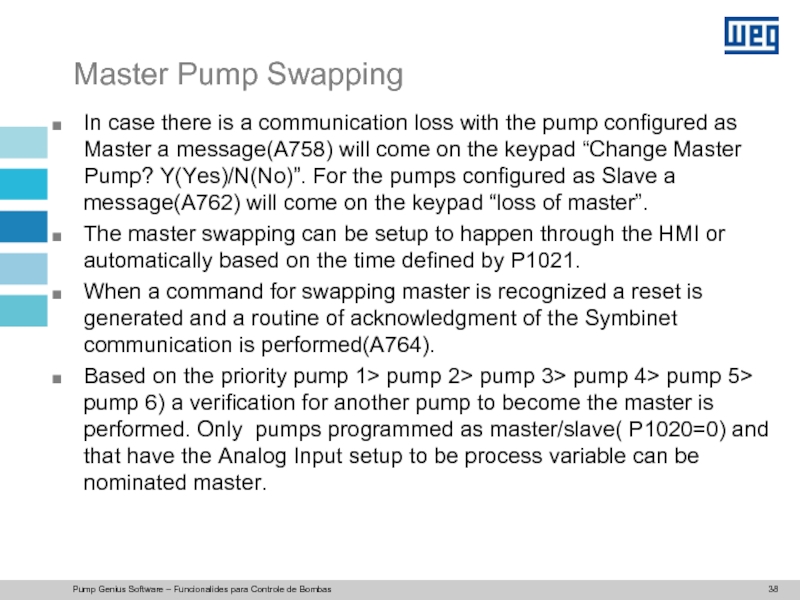

Master Pump Swapping

In

The master swapping can be setup to happen through the HMI or automatically based on the time defined by P1021.

When a command for swapping master is recognized a reset is generated and a routine of acknowledgment of the Symbinet communication is performed(A764).

Based on the priority pump 1> pump 2> pump 3> pump 4> pump 5> pump 6) a verification for another pump to become the master is performed. Only pumps programmed as master/slave( P1020=0) and that have the Analog Input setup to be process variable can be nominated master.

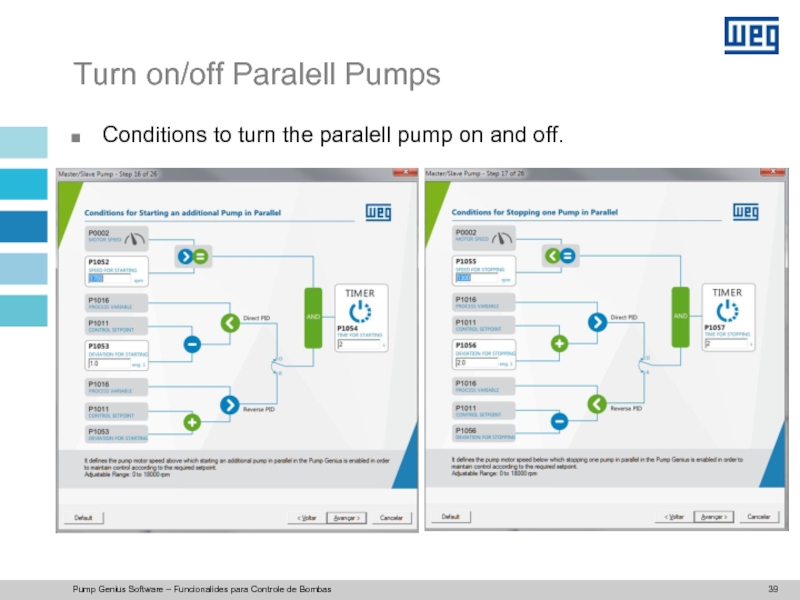

Слайд 40Pump Genius Software – Funcionalides para Controle de Bombas

Turn on/off Paralell

Conditions to turn the paralell pump on and off.

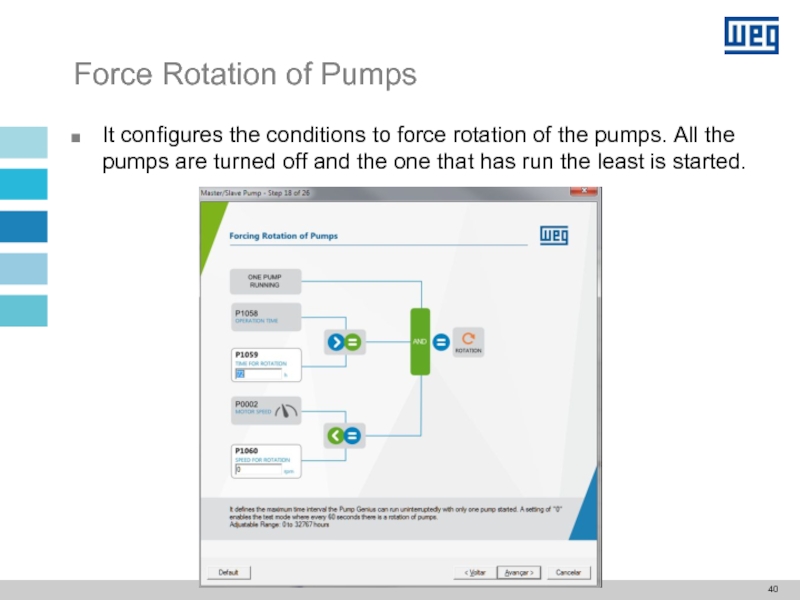

Слайд 41Force Rotation of Pumps

It configures the conditions to force rotation of

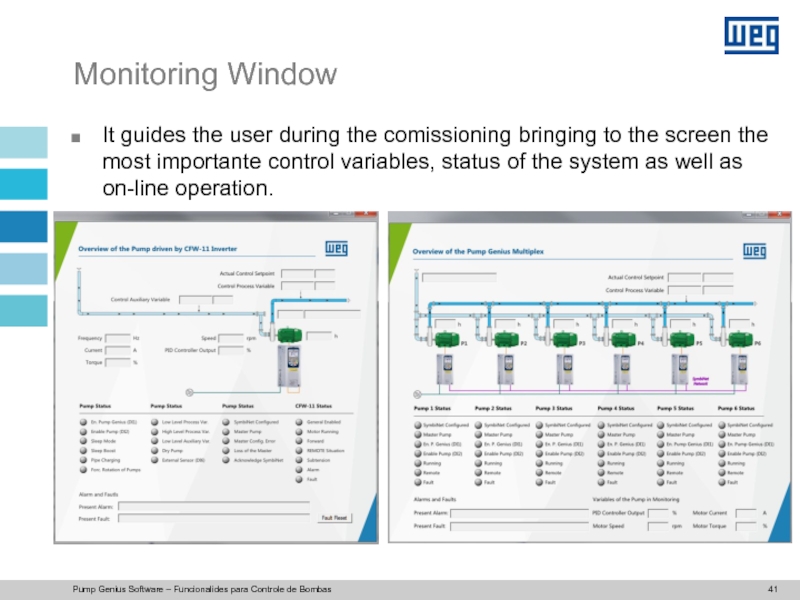

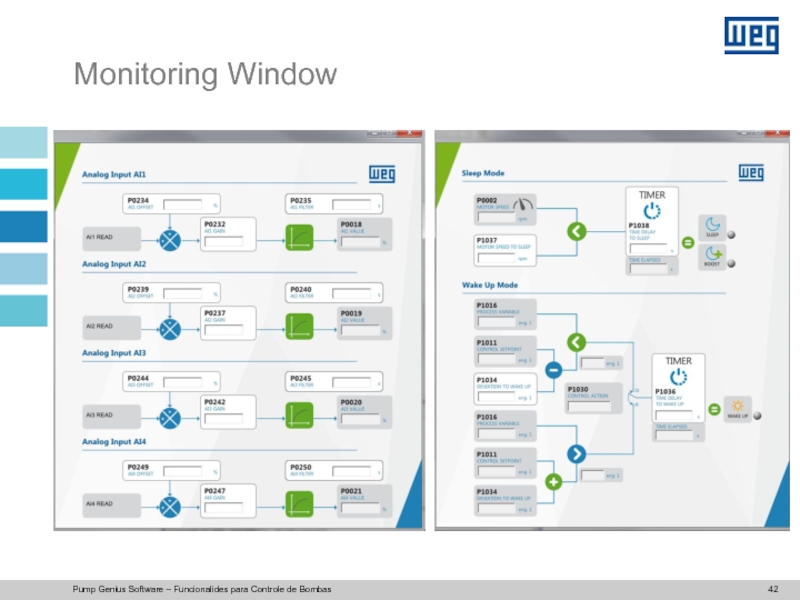

Слайд 42Pump Genius Software – Funcionalides para Controle de Bombas

Monitoring Window

It guides

Слайд 47System Operation – One Master one Slave

Control Schematic for Master

Control Schematic for Slave

Слайд 49System Operation – One Master Two Slaves

Control Schematic for Master

Control Schematic for Slaves

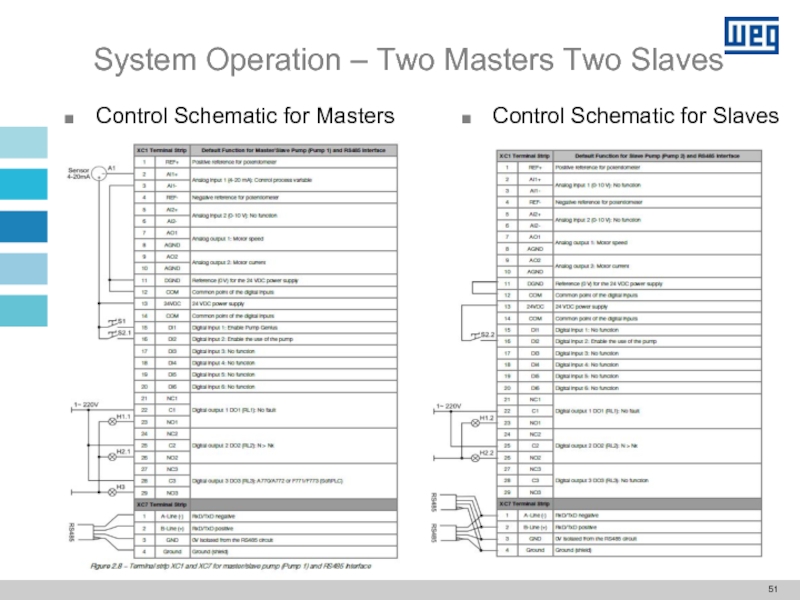

Слайд 52System Operation – Two Masters Two Slaves

Control Schematic for Masters

Control Schematic for Slaves