- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Introduction to CFX. Workshop 3 Room Temperature Study презентация

Содержание

- 1. Introduction to CFX. Workshop 3 Room Temperature Study

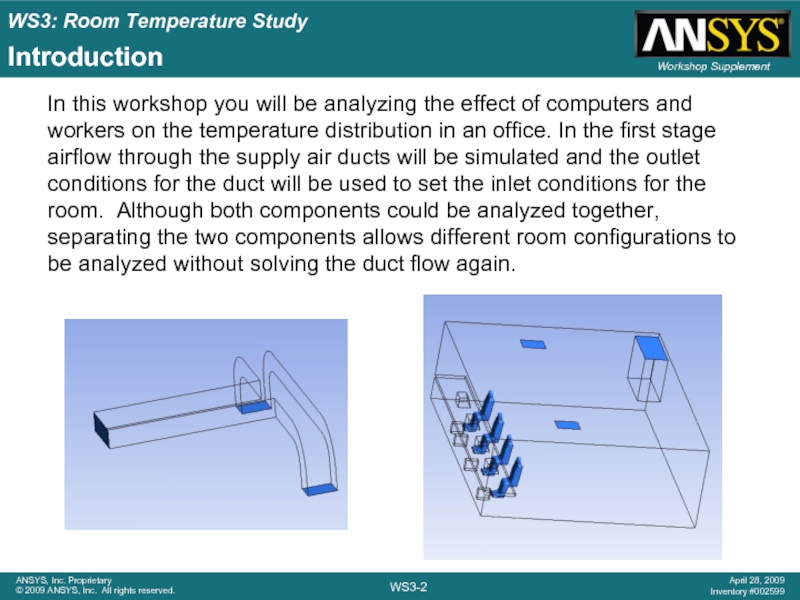

- 2. Introduction In this workshop you will be

- 3. Duct Simulation The operating conditions for the

- 4. Starting CFX in Workbench Open Workbench Drag

- 5. Import Mesh Right-click on Mesh in the

- 6. Create Domain Double-click on Default Domain in

- 7. Create Boundary Conditions INLET Boundary Condition Name:

- 8. Solver Control Double click on Solver Control

- 9. Monitor Point Double click on Output Control

- 10. Monitor Point In the Expression Value field,

- 11. Write Solver File Close CFX-Pre to return

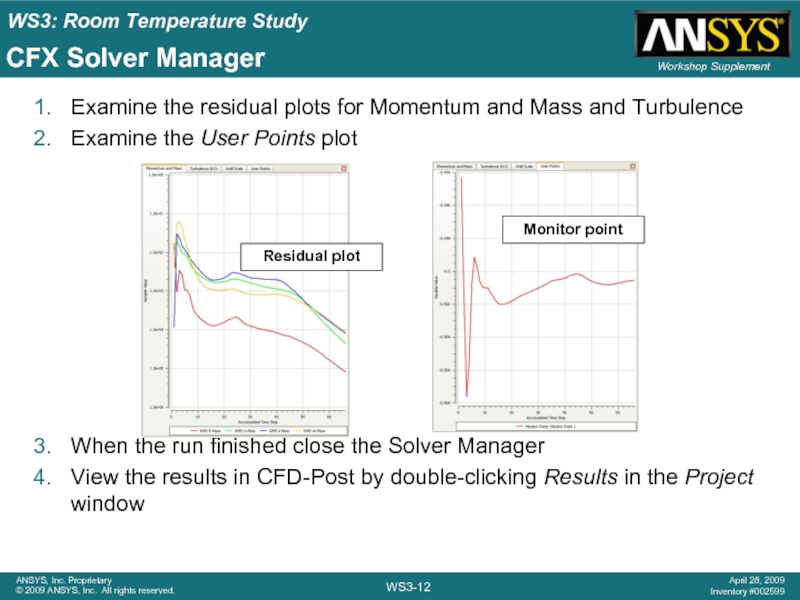

- 12. Examine the residual plots for Momentum and

- 13. CFD-Post Select File > Export Change the

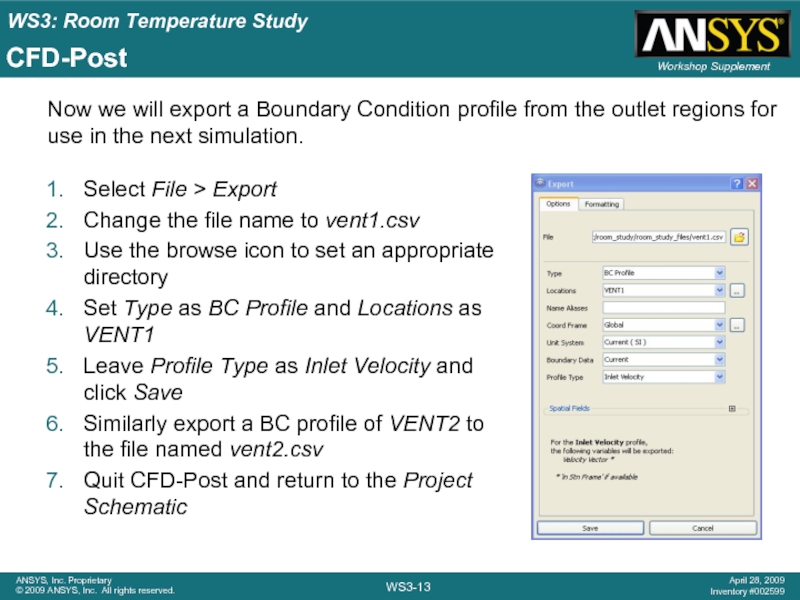

- 14. Operating Conditions The working fluid is Air

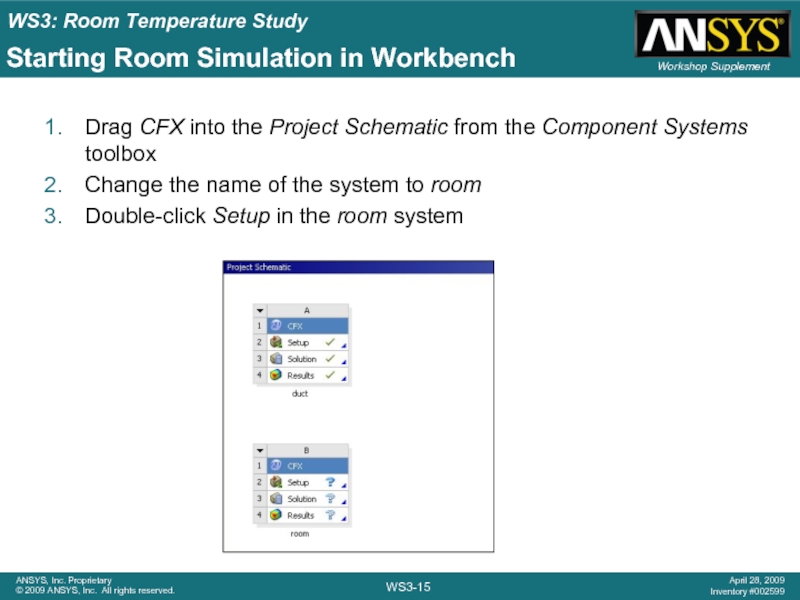

- 15. Starting Room Simulation in Workbench Drag CFX

- 16. Import Mesh Right-click on Mesh in the

- 17. Create Domain Edit Default Domain from the

- 18. Create Domain Switch to the Fluid Models

- 19. Profile data initialization Select Tools >Initialise Profile

- 20. Create Boundary Conditions vent1 Boundary Condition Name:

- 21. vent2 Boundary Condition Name: vent2 Boundary Type:

- 22. outlet Boundary Condition Name: outlet Boundary Type:

- 23. computerVent Boundary Condition Name: computerVent Boundary Type:

- 24. computerIntake Boundary Condition Name: computerIntake Boundary Type:

- 25. Solver Control Edit Solver Control from the

- 26. Monitor Point Edit Output Control from the

- 27. Monitor Point In the Expression Value field,

- 28. Write Solver File Close CFX-Pre to return

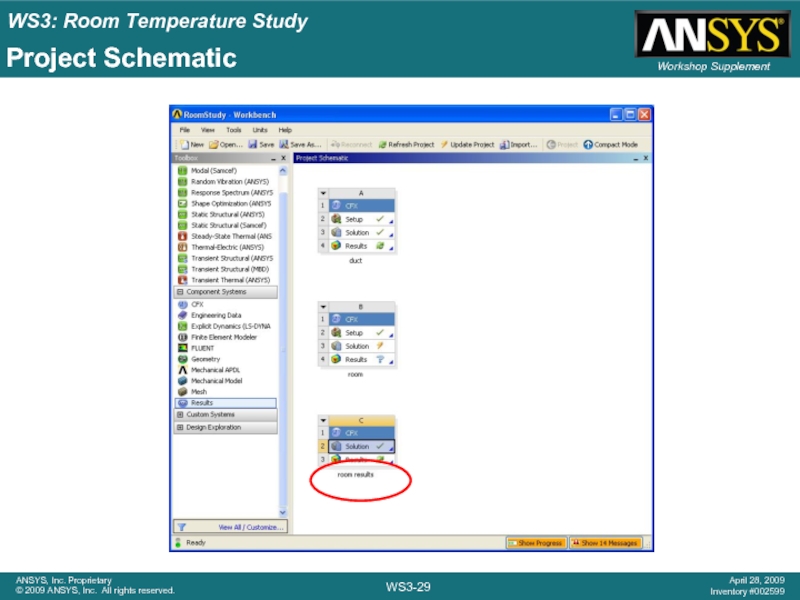

- 29. Project Schematic

- 30. CFX Solver Manager Right-click on Solution in

- 31. Residual and Monitor plot Residual plot Monitor points

- 32. CFX Solver Manager Check the Domain Imbalances

- 33. CFD-Post Select Location > Plane from the

- 34. CFD-Post ZX Plane at Y =

- 35. CFD-Post Click Insert > Vector from the

- 36. Further Steps (Optional) Observe the density variation

Слайд 2Introduction

In this workshop you will be analyzing the effect of computers

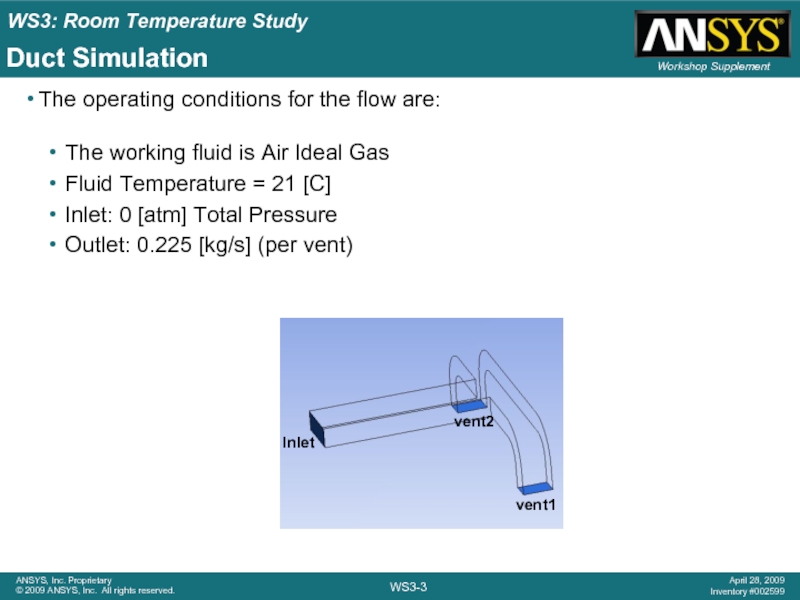

Слайд 3Duct Simulation

The operating conditions for the flow are:

The working fluid is

Fluid Temperature = 21 [C]

Inlet: 0 [atm] Total Pressure

Outlet: 0.225 [kg/s] (per vent)

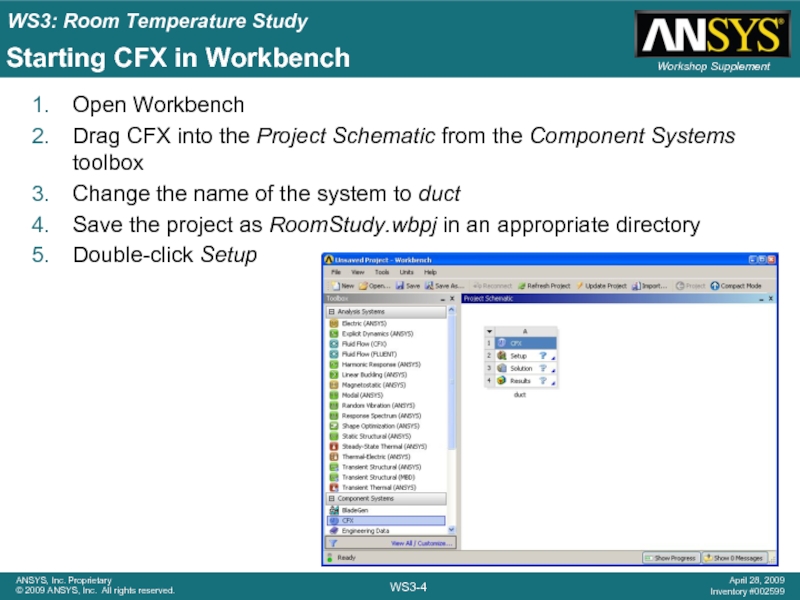

Слайд 4Starting CFX in Workbench

Open Workbench

Drag CFX into the Project Schematic from

Change the name of the system to duct

Save the project as RoomStudy.wbpj in an appropriate directory

Double-click Setup

Слайд 5Import Mesh

Right-click on Mesh in the Outline tree and select Import

Select the file duct_mesh.cfx5

Make sure Mesh Units are in m and click Open to import the mesh

The first step is to import the mesh that has already been created:

Слайд 6Create Domain

Double-click on Default Domain in the Outline tree to edit

On the Basic Settings tab, set the Fluid 1 Material setting to Air Ideal Gas

Switch to the Fluid Models tab

Set the Heat Transfer Option to Isothermal

Heat Transfer is not modeled, but since the working fluid is an ideal gas we need to provide a temperature so its properties can be calculated

Set the Fluid Temperature to 21 [C]

Change the Turbulence Model Option to Shear Stress Transport

Click OK to commit the changes to the domain

You can now create the computational domain:

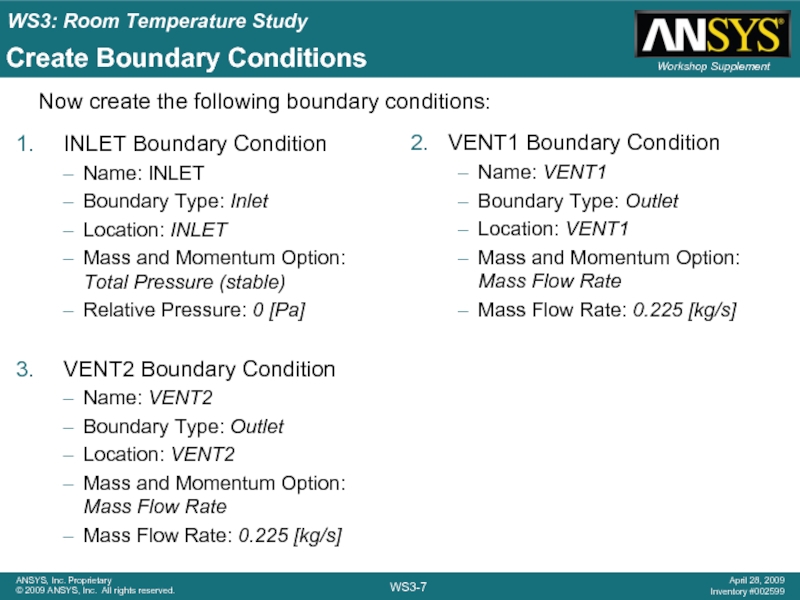

Слайд 7Create Boundary Conditions

INLET Boundary Condition

Name: INLET

Boundary Type: Inlet

Location: INLET

Mass and Momentum

Relative Pressure: 0 [Pa]

VENT2 Boundary Condition

Name: VENT2

Boundary Type: Outlet

Location: VENT2

Mass and Momentum Option: Mass Flow Rate

Mass Flow Rate: 0.225 [kg/s]

Now create the following boundary conditions:

VENT1 Boundary Condition

Name: VENT1

Boundary Type: Outlet

Location: VENT1

Mass and Momentum Option: Mass Flow Rate

Mass Flow Rate: 0.225 [kg/s]

Слайд 8Solver Control

Double click on Solver Control from the Outline tree

Enable the

Click OK to commit the settings

Слайд 9Monitor Point

Double click on Output Control from the Outline tree

Switch to

Under Monitor Points and Expressions, click the New icon

Keep the default name Monitor Point 1

Set the Option to Expression

Monitor points are used to monitor quantities of interest during the solution. They should be used to help judge convergence. In this case you will monitor the velocity of the air that exits through the vent. One measure of a converged solution is when this air has reached a steady-state velocity.

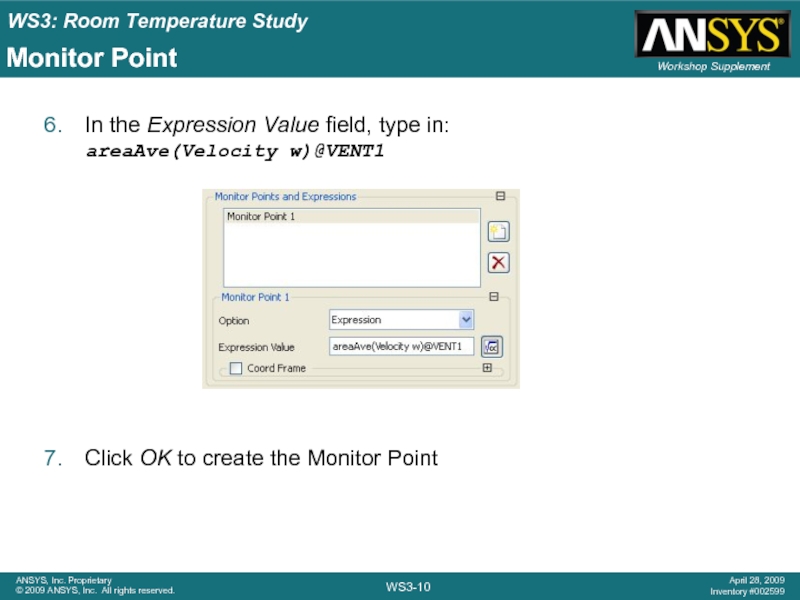

Слайд 10Monitor Point

In the Expression Value field, type in:

areaAve(Velocity w)@VENT1

Click OK to

Слайд 11Write Solver File

Close CFX-Pre to return to Project window

Save the project

Right-click

Choose Start Run

You can now save the project and proceed to write a definition file for the solver:

Слайд 12Examine the residual plots for Momentum and Mass and Turbulence

Examine the

When the run finished close the Solver Manager

View the results in CFD-Post by double-clicking Results in the Project window

CFX Solver Manager

Monitor point

Residual plot

Слайд 13CFD-Post

Select File > Export

Change the file name to vent1.csv

Use the browse

Set Type as BC Profile and Locations as VENT1

Leave Profile Type as Inlet Velocity and click Save

Similarly export a BC profile of VENT2 to the file named vent2.csv

Quit CFD-Post and return to the Project Schematic

Now we will export a Boundary Condition profile from the outlet regions for use in the next simulation.

Слайд 14Operating Conditions

The working fluid is Air Ideal Gas

Computer Monitor Temperature =

Computer Vent Flow Rate: 0.033 [kg/s] @ 40 [C] (per computer)

Ceiling Vents: Profile Data, Temperature=21 [C]

The operating conditions for the flow in the room are:

Слайд 15Starting Room Simulation in Workbench

Drag CFX into the Project Schematic from

Change the name of the system to room

Double-click Setup in the room system

Слайд 16Import Mesh

Right-click on Mesh in the Outline tree and select Import

Select the file room.cfx5

Make sure the Mesh Units are in m and click Open to import the mesh

The first step is to import the mesh that has already been created:

Слайд 17Create Domain

Edit Default Domain from the Outline tree

On the Basic Settings

Set the Buoyancy Option to Buoyant. Set the Buoyancy settings as shown:

Gravity X Dirn. = 0 [ m s^-2 ]

Gravity Y Dirn. = 0 [ m s^-2 ]

Gravity Z Dirn. = -g (first, click the Enter Expression icon )

Buoy. Ref. Density = 1.185 [ kg m^-3 ]

You can now create the computational domain:

Слайд 18Create Domain

Switch to the Fluid Models tab

Change the Heat Transfer Option

Change the Turbulence Model Option to Shear Stress Transport

Switch to the Initialisation tab

Check the Domain Initialisation box

Set the Temperature Option to Automatic with Value. Set the Temperature to 21 [C]

Click OK to commit the changes to the domain

Слайд 19Profile data initialization

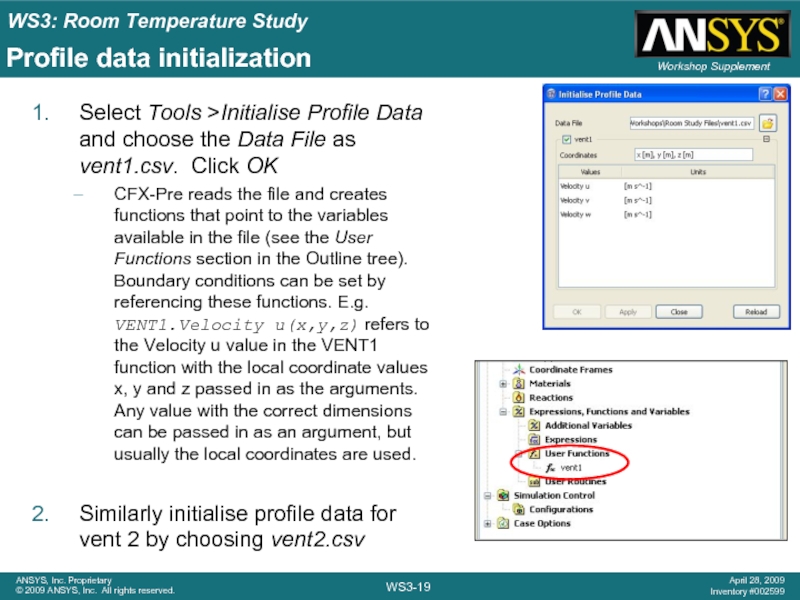

Select Tools >Initialise Profile Data and choose the Data

CFX-Pre reads the file and creates functions that point to the variables available in the file (see the User Functions section in the Outline tree). Boundary conditions can be set by referencing these functions. E.g. VENT1.Velocity u(x,y,z) refers to the Velocity u value in the VENT1 function with the local coordinate values x, y and z passed in as the arguments. Any value with the correct dimensions can be passed in as an argument, but usually the local coordinates are used.

Similarly initialise profile data for vent 2 by choosing vent2.csv

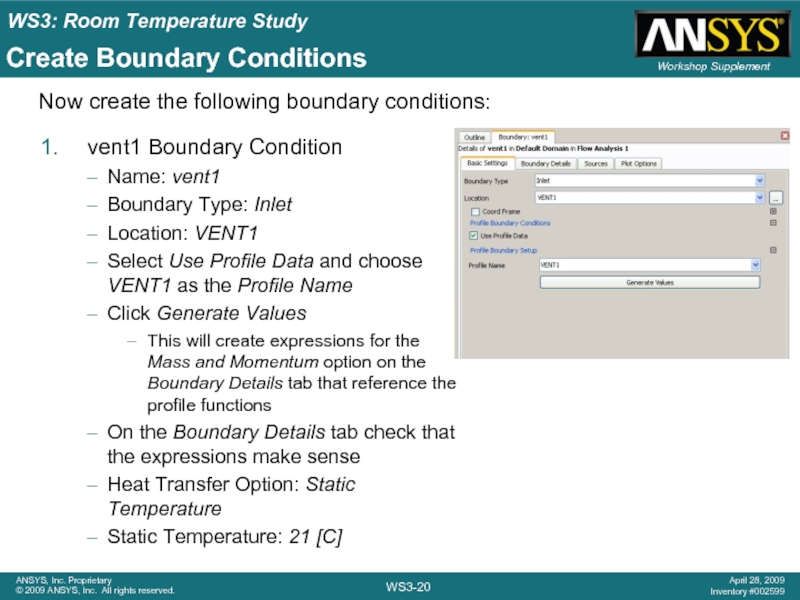

Слайд 20Create Boundary Conditions

vent1 Boundary Condition

Name: vent1

Boundary Type: Inlet

Location: VENT1

Select Use Profile

Click Generate Values

This will create expressions for the Mass and Momentum option on the Boundary Details tab that reference the profile functions

On the Boundary Details tab check that the expressions make sense

Heat Transfer Option: Static Temperature

Static Temperature: 21 [C]

Now create the following boundary conditions:

Слайд 21vent2 Boundary Condition

Name: vent2

Boundary Type: Inlet

Location: VENT2

Select Use Profile Data and

Click Generate Values

The Mass and Momentum Option will be automatically updated

Heat Transfer Option: Static Temperature

Static Temperature: 21 [C]

workers Boundary Condition

Name: workers

Boundary Type: Wall

Location: WORKERS

Heat Transfer Option: Temperature

Fixed Temperature: 37 [C]

Create Boundary Conditions

Слайд 22outlet Boundary Condition

Name: outlet

Boundary Type: Opening

Location: OUTLET

Mass and Momentum Option: Opening

Relative Pressure: 0 [Pa]

Heat Transfer Option: Opening Temperature

Opening Temperature: 21 [C]

monitors Boundary Condition

Name: monitors

Boundary Type: Wall

Location: monitors

Heat Transfer Option: Temperature

Fixed Temperature: 30 [C]

Create Boundary Conditions

Слайд 23computerVent Boundary Condition

Name: computerVent

Boundary Type: Inlet

Location: COMPUTER1VENT, COMPUTER2VENT, COMPUTER3VENT, COMPUTER4VENT

Mass and

Mass Flow Rate: 0.132 [kg/s]

Heat Transfer Option: Static Temperature

Static Temperature: 40 [C]

Create Boundary Conditions

Слайд 24computerIntake Boundary Condition

Name: computerIntake

Boundary Type: Outlet

Location: COMPUTER1INTAKE, COMPUTER2INTAKE, COMPUTER3INTAKE, COMPUTER4INTAKE

Mass and

Mass Flow Rate: 0.132 [kg/s]

Mass Flow Update Option: Constant Flux

This enforces a uniform mass flow across the entire boundary region, rather than letting a natural velocity profile develop. It is used here to make sure the flow rate through each intake is the same.

Create Boundary Conditions

Слайд 25Solver Control

Edit Solver Control from the Outline tree

Due to nature of

Increase the Max. Iterations to 750

Change the Timescale Control to Physical Timescale

Set a Physical Timescale of 2 [s]

Enable the Conservation Target toggle

Click OK to commit the settings

Слайд 26Monitor Point

Edit Output Control from the Outline tree

Switch to the Monitor

Under Monitor Points and Expressions, click the New icon

Enter the Name as temp

Set the Option to Expression

Monitor points are used to monitor quantities of interest during the solution. They should be used to help judge convergence. In this case you will monitor the temperature of the air that exits through the outlet. One measure of a converged solution is when this air has reached a steady-state temperature.

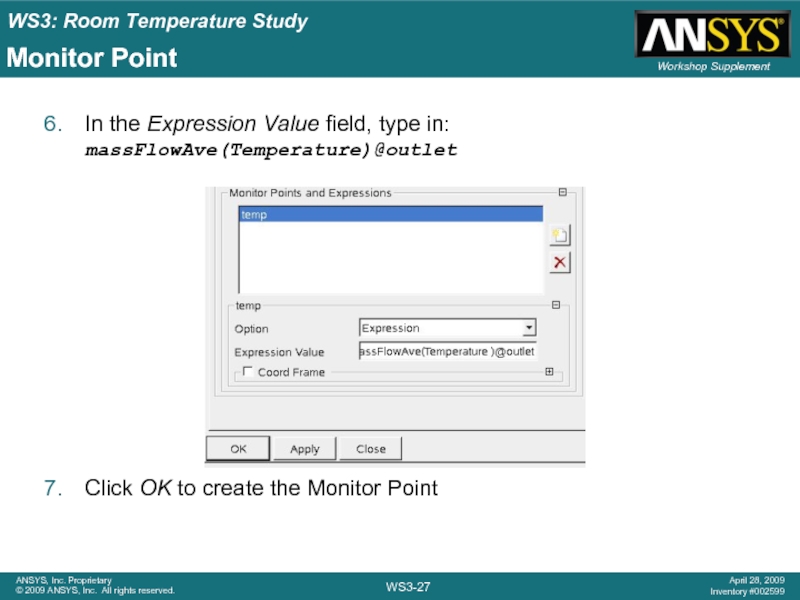

Слайд 27Monitor Point

In the Expression Value field, type in:

massFlowAve(Temperature)@outlet

Click OK to create

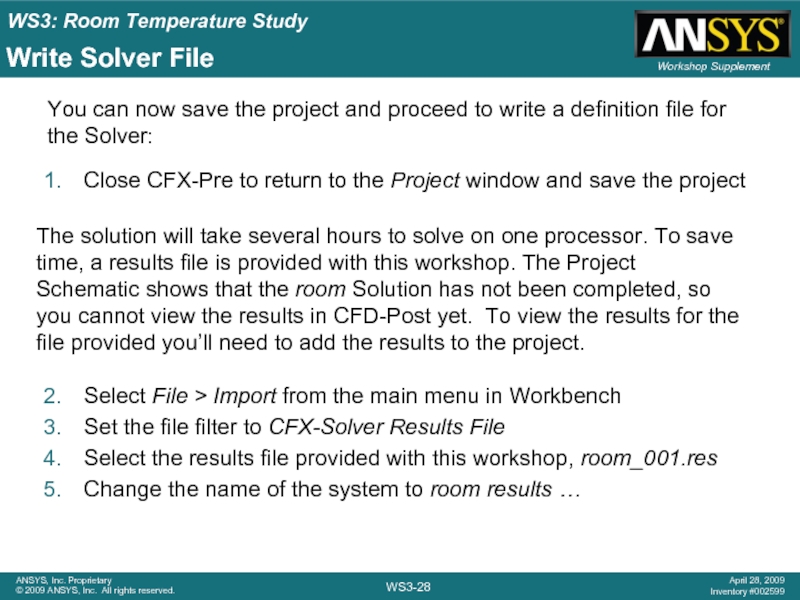

Слайд 28Write Solver File

Close CFX-Pre to return to the Project window and

Select File > Import from the main menu in Workbench

Set the file filter to CFX-Solver Results File

Select the results file provided with this workshop, room_001.res

Change the name of the system to room results …

You can now save the project and proceed to write a definition file for the Solver:

The solution will take several hours to solve on one processor. To save time, a results file is provided with this workshop. The Project Schematic shows that the room Solution has not been completed, so you cannot view the results in CFD-Post yet. To view the results for the file provided you’ll need to add the results to the project.

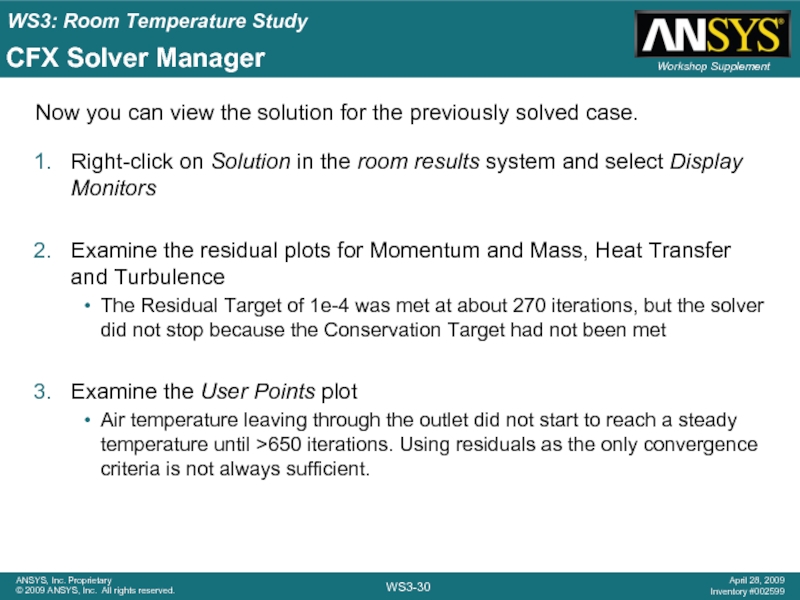

Слайд 30CFX Solver Manager

Right-click on Solution in the room results system and

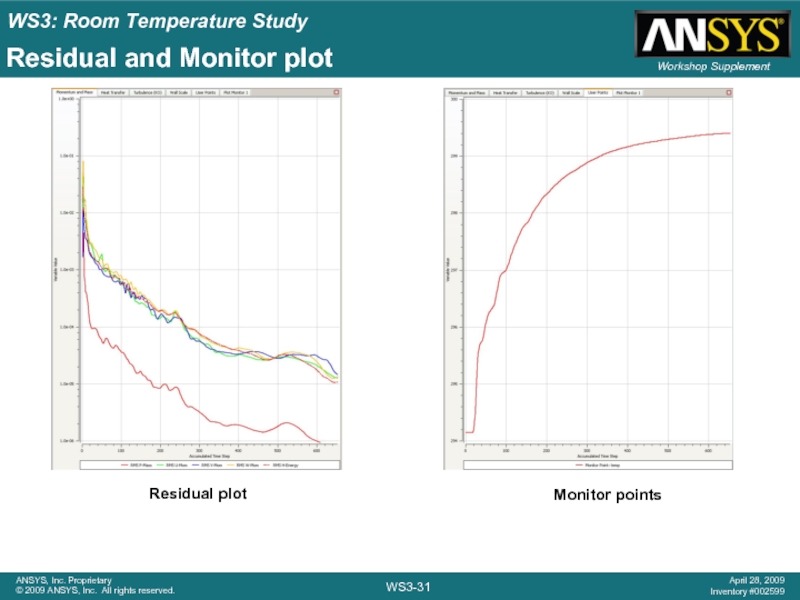

Examine the residual plots for Momentum and Mass, Heat Transfer and Turbulence

The Residual Target of 1e-4 was met at about 270 iterations, but the solver did not stop because the Conservation Target had not been met

Examine the User Points plot

Air temperature leaving through the outlet did not start to reach a steady temperature until >650 iterations. Using residuals as the only convergence criteria is not always sufficient.

Now you can view the solution for the previously solved case.

Слайд 32CFX Solver Manager

Check the Domain Imbalances at the end of the

You can right click in the text monitor, select Find… and search for “Domain Imbalance” to find the appropriate section

An imbalance is given for the U-Mom, V-Mom, W-Mom, P-Mass and H-Energy equations

It took 653 iterations to satisfy the Conservation Target of 1% for the H-Energy equation – see the Plot Monitor 1 tab

Close the Solver Manager

View the results in CFD-Post by double-clicking Results in the Project Schematic from the room system

Слайд 33CFD-Post

Select Location > Plane from the toolbar

In the Details windows on

Set Y to 1.2 [m]

On the Colour tab set Mode to Variable

Set Variable to Temperature

Set Range to Local and click Apply

Observe the temperature distribution (for example, how the warm air collects under the table)

Start by creating a ZX Plane at Y = 1.2 [m]

Слайд 34CFD-Post

ZX Plane at Y = 2 [m]

ZX Plane at

XY Plane at Z = 0.25 [m]

When finished observing the temperature distribution, uncheck the visibility boxes of the planes that you created

Using the same procedure, create several other planes displaying the temperature profile:

Слайд 35CFD-Post

Click Insert > Vector from the main menu

In the Details windows

Click Apply

After observing the flow behavior on Plane 2, switch the Location to Plane 4

Plot vector plots on the planes that you created:

Слайд 36Further Steps (Optional)

Observe the density variation at various planes

Create a streamline

You may want to adjust the values on the Limits tab (Max. Segments)

Animate the streamlines

Right-click on the Streamlines in the 3D viewer and select Animate

Create an isosurface based on different temperatures (e.g., 22 [C], 24 [C], etc.)

Calculate the areaAve of Wall Heat Flux on the workers

Click Tools > Function Calculator

Time permitting, you may want to try the following:

![Operating ConditionsThe working fluid is Air Ideal GasComputer Monitor Temperature = 30 [C]Computer Vent Flow](/img/tmb/1/31759/fb1253db2d421726e0eed9c7af00db90-800x.jpg)

![CFD-Post ZX Plane at Y = 2 [m] ZX Plane at Y = 5.1 [m]](/img/tmb/1/31759/80cbfa5b692930ccf23d554062270f8e-800x.jpg)