plastics, their appointment. Usage in technology in the manufacture of dental prostheses and devices "

- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Plastics. General characteristics. Classification. Composition. The main types of plastics, their appointment презентация

Содержание

- 1. Plastics. General characteristics. Classification. Composition. The main types of plastics, their appointment

- 2. Plastics - materials, which are based on

- 3. The main starting materials for polymer

- 4. Polymerization - reaction interconnection monomer compounds

- 5. Classification of plastics: 1.

- 6. 2. By nature: • organic; • inorganic; • organ elemental.

- 7. Main, which are used for removable and

- 8. B) Support, which are used at different

- 9. B) Clinical the temperature conditions of polymerization

- 10. Physical properties of materials Specific gravity

- 11. Mechanical properties of materials Durability -

- 12. Elasticity - material property again to

- 13. KEY (CONSTRUCTION) MATERIALS They should

- 14. The basic materials include: Plastic

- 15. The major components of this type

- 16. Compound of plastic The main component fluids

- 17. Compound of plastic Filler - a substance

- 18. Pigment - a substance imparting dental polymeric

- 19. The catalyst - a substance that accelerates

- 20. Activator - an agent that causes

- 21. Radiopaque material - barium sulphate, barium

- 22. Radiopaque material - barium sulphate, barium

- 23. Basic (BASIC) CONSTRUCTION MATERIALS

- 24. The basis - the foundation of

- 25. Basic materials must have the following

- 26. 4) a small specific gravity and

- 27. 7) does not change color when

- 28. In addition, the base material must meet

- 29. For bases used plastic prostheses following

- 30. Dental copolymers comprise 80% of all

- 31. It is now widely used acrylic

- 32. Colorless plastic base Plastic-based stabilizer

- 33. Colorless base plastic used for manufacturing

- 34. ELASTIC LINING MATERIALS Need to improve

- 35. Materials must meet the following medical

- 36. Indications for use 1) with a sharp

- 37. Indications for use 5) the need

- 38. Resilient Lining materials for denture bases,

- 39. Methods of polymerization of basic plastics

- 40. Methods for forming plastic powder in

- 41. Plastics Polymerization Polymerization - a chemical

- 42. To study the basic acrylic resin polymerization

- 43. 2. The polymerization to dry under pressure;

- 44. 3. Polymerization an improved apparatus for foundry molding.

- 45. Plastics for fixed prostheses Most

- 46. Artificial teeth Sets the front

- 47. Thank you

Слайд 2Plastics - materials, which are based on polymers which are in

the period of formation of products in the viscous fluid or highly elastic, and in the operation - in the glassy or crystalline state.

Polymers - a substance whose molecules consist of a large number of repeating units.

Polymers - a substance whose molecules consist of a large number of repeating units.

Слайд 3 The main starting materials for polymer dental materials are monomers and

oligomers (mono, I-D, tri-, tetra acrylates).

Monocrylat volatile, so they are using in combination with high molecular weight esters, thereby reducing shrinkage of the polymer.

Monocrylat volatile, so they are using in combination with high molecular weight esters, thereby reducing shrinkage of the polymer.

Слайд 4 Polymerization - reaction interconnection monomer compounds with double bonds without the

formation during the reaction of any new substances.

The reaction generated a high molecular compound that is different from the original size of a molecule.

The mechanism of the polymerization reaction is to activate some of the monomer molecules by the action of light, heat or catalysis torus and subsequently joining the already activated molecules to other molecules to form longer chains.

This connection continues as long as the energy is initially activated molecule dissipates.

The reaction generated a high molecular compound that is different from the original size of a molecule.

The mechanism of the polymerization reaction is to activate some of the monomer molecules by the action of light, heat or catalysis torus and subsequently joining the already activated molecules to other molecules to form longer chains.

This connection continues as long as the energy is initially activated molecule dissipates.

Слайд 5

Classification of plastics:

1. origin include:

• natural or biopolymers (proteins,

nucleic acids, natural number rubber);

• synthetic (polyethylene, polyamides, epoxy resins).

• synthetic (polyethylene, polyamides, epoxy resins).

Слайд 7Main, which are used for removable and fixed dentures:

• base

(rigid) polymers;

• elastic polymers or elastomers;

• polymer (plastic) artificial teeth; • polymers for replacement of dental hard tissue defects, materials for fillings, pin teeth and tabs;

• polymeric materials for temporary non-removable dentures;

• facing polymers (for permanent fixed prosthesis);

• restoration polymers

• elastic polymers or elastomers;

• polymer (plastic) artificial teeth; • polymers for replacement of dental hard tissue defects, materials for fillings, pin teeth and tabs;

• polymeric materials for temporary non-removable dentures;

• facing polymers (for permanent fixed prosthesis);

• restoration polymers

Слайд 8B) Support, which are used at different stages of the manufacture

of dentures:

• polymer impression material;

• polymer standard impression trays;

• polymeric materials for the manufacture of individual spoons;

• plastic caps and temporary crown to protect the prepared teeth.

• polymer impression material;

• polymer standard impression trays;

• polymeric materials for the manufacture of individual spoons;

• plastic caps and temporary crown to protect the prepared teeth.

Слайд 9B) Clinical

the temperature conditions of polymerization plastics are "hot" curing;

cold

curing plastics ( "self-hardening", "quick-hardening").

In the presence of "pink" plastic pigments;

“colorless" plastics; plastic different color impressions.

In the presence of "pink" plastic pigments;

“colorless" plastics; plastic different color impressions.

Слайд 10

Physical properties of materials

Specific gravity - density of the material, the

amount of substance per unit volume and mass of one cm3 of the body, expressed in grams.

Melting point - the temperature at which the substance passes from a solid to a liquid.

Shrinkage of the material - material volume reduction during cooling after casting.

Melting point - the temperature at which the substance passes from a solid to a liquid.

Shrinkage of the material - material volume reduction during cooling after casting.

Слайд 11Mechanical properties of materials

Durability - solid body's ability to resist the

impact of external forces seeking to deform.

Viscosity - the ability of a material under load to stretch, lengthen.

Hardness - The ability of the solid material to enter the soft material under pressure.

Viscosity - the ability of a material under load to stretch, lengthen.

Hardness - The ability of the solid material to enter the soft material under pressure.

Слайд 12 Elasticity - material property again to return to its original state,

acquiring its original shape after the termination of the deforming force.

Plasticity - the ability to change shape and save it as a final deformation.

Fatigue of materials (metals, plastics) occurs when prolonged load, which creates tension.

Removing the friction arises from solid soft material

Plasticity - the ability to change shape and save it as a final deformation.

Fatigue of materials (metals, plastics) occurs when prolonged load, which creates tension.

Removing the friction arises from solid soft material

Слайд 13

KEY (CONSTRUCTION) MATERIALS

They should be harmless, solid, not collapse under the

action of an oral liquid, various nutrients, air, and the pressure withstand chewing process during manufacture in which the prosthesis is subjected to tension, bending, distortion, temperature action.

Dentures should be a natural color, not to have an unpleasant taste and smell are also important availability and cost of material.

Dentures should be a natural color, not to have an unpleasant taste and smell are also important availability and cost of material.

Слайд 15

The major components of this type of plastic compositions are:

1) monomer

- based plastics;

2) binder (phenol-formaldehyde resin, or other);

3) fillers (wood flour, asbestos, glass fiber);

2) binder (phenol-formaldehyde resin, or other);

3) fillers (wood flour, asbestos, glass fiber);

Слайд 16Compound of plastic

The main component fluids "monomer" is a methyl ester

of methacrylic acid stabilized inhibitor.

Each liquid contains a specific modifier to the polymerization type resins and plastics to impart desired performance properties.

Each liquid contains a specific modifier to the polymerization type resins and plastics to impart desired performance properties.

Слайд 17Compound of plastic Filler - a substance that affects the strength, hardness,

shrinkage, thermal conductivity, resistance to aggressive media. Sometimes minimal and organic, powdery and fibrous (silica flour, silica gels, silicates, various grades of finely ground glass).

Слайд 18Pigment - a substance imparting dental polymeric compositions and shades of

colors, imitating the tooth tissue and mucosa.

Requirements: harmlessness, distribution uniformity, stability in maintaining the color under the influence of external factors, good optical properties.

Requirements: harmlessness, distribution uniformity, stability in maintaining the color under the influence of external factors, good optical properties.

Слайд 19The catalyst - a substance that accelerates a chemical reaction.

The

Initiator - a substance which when exposed to heat or other factors (activator) decomposes into free radicals polymerization reaction beginning (benzoyl peroxide).

Слайд 20 Activator - an agent that causes the decomposition of the initiator

with the formation of active growth promoting radical polymer chain and polymerization (dimethylparatoluidine, a tertiary amine).

Plasticizer - a substance that increases the ductility and elasticity of the material (dibutyl phthalate, dioctyl phthalate).

Inhibitor (retarder) - a substance that slows the chemical reactions, preventing spontaneous polymerization during transport and storage (hydroquinone, diphenylolpropane).

Plasticizer - a substance that increases the ductility and elasticity of the material (dibutyl phthalate, dioctyl phthalate).

Inhibitor (retarder) - a substance that slows the chemical reactions, preventing spontaneous polymerization during transport and storage (hydroquinone, diphenylolpropane).

Слайд 21

Radiopaque material - barium sulphate, barium fluoride, barium and bismuth glass.

Their presence helps to detect polymer fragments with injuries maxillofacial area and the introduction of elements of the prosthesis into the soft tissue.

Слайд 22

Radiopaque material - barium sulphate, barium fluoride, barium and bismuth glass.

Their presence helps to detect polymer fragments with injuries maxillofacial area and the introduction of elements of the prosthesis into the soft tissue.

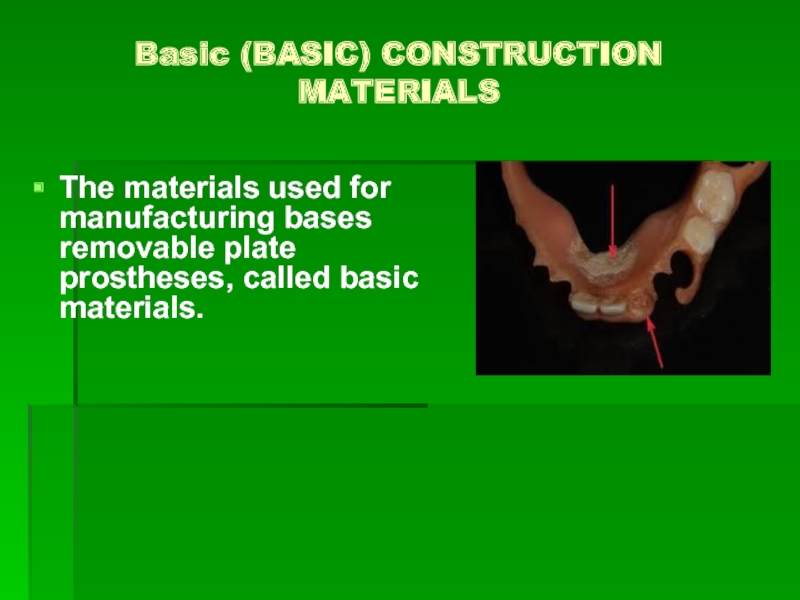

Слайд 23

Basic (BASIC) CONSTRUCTION MATERIALS

The materials used for manufacturing bases removable plate

prostheses, called basic materials.

Слайд 24

The basis - the foundation of the denture: it strengthened artificial

teeth, clasps and other components of the prosthesis.

Слайд 25

Basic materials must have the following characteristics:

1) sufficient strength and elasticity

necessary to ensure the integrity of the prosthesis without deformation under chewing forces;

2) high bending resistance;

3) high resistance to impact;

2) high bending resistance;

3) high resistance to impact;

Слайд 26

4) a small specific gravity and low thermal conductivity;

5) sufficient

rigidity, low abrasion;

6) indifference to the action of saliva and various nutrients

6) indifference to the action of saliva and various nutrients

Слайд 27 7) does not change color when exposed to light, air and

other environmental factors;

8) does not adversely affect oral tissue and organism as a whole;

9) no adsorption of nutrients and microflora in the mouth.

8) does not adversely affect oral tissue and organism as a whole;

9) no adsorption of nutrients and microflora in the mouth.

Слайд 28In addition, the base material must meet the following requirements:

1) firmly

connected with porcelain, metal, plastic;

2) are easily processed into a product with a high accuracy and maintain the shape imparted;

3) be easy to fix;

4) well painted to imitate the natural color of the gums and teeth;

5) can be easily disinfected;

6) does not cause unpleasant taste and odorless.

2) are easily processed into a product with a high accuracy and maintain the shape imparted;

3) be easy to fix;

4) well painted to imitate the natural color of the gums and teeth;

5) can be easily disinfected;

6) does not cause unpleasant taste and odorless.

Слайд 29

For bases used plastic prostheses following types:

acrylic;

vynilacril

modified polystyrene;

copolymers or mixtures of appropriate plastics.

Слайд 30

Dental copolymers comprise 80% of all medical copolymers comprise copolymers acrylmetacrylate

- double or triple copolymers.

Слайд 32

Colorless plastic base

Plastic-based stabilizer purified from polymethylmethacrylate containing Tinuvin which prevents

aging of the plastic under the influence of an aggressive environment.

Слайд 33

Colorless base plastic used for manufacturing dental prostheses bases in cases

where counter-stained basis as well as for other purposes prosthodontics when necessary a transparent base material.

Слайд 34ELASTIC LINING MATERIALS

Need to improve the adhesion of the denture

to the oral mucosa, as well as combined production of dental prostheses resulted in the appearance of soft elastic lining materials for denture base.

They are also used for the production of obturators, maxillofacial prosthetics, elastic pilots, etc.

They are also used for the production of obturators, maxillofacial prosthetics, elastic pilots, etc.

Слайд 35

Materials must meet the following medical and technical requirements:

1) is firmly

connected with the base material;

2) be non-toxic;

3) to maintain the elasticity;

4) good wetting;

5) does not dissolve in the mouth;

6) have a high resistance to wear;

7) does not change color;

8) to be technologically advanced.

2) be non-toxic;

3) to maintain the elasticity;

4) good wetting;

5) does not dissolve in the mouth;

6) have a high resistance to wear;

7) does not change color;

8) to be technologically advanced.

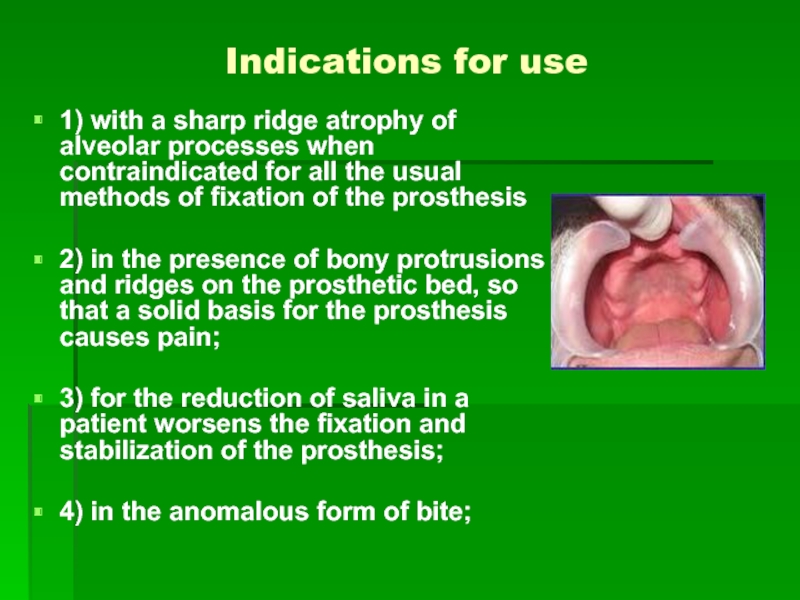

Слайд 36Indications for use

1) with a sharp ridge atrophy of alveolar processes

when contraindicated for all the usual methods of fixation of the prosthesis

2) in the presence of bony protrusions and ridges on the prosthetic bed, so that a solid basis for the prosthesis causes pain;

3) for the reduction of saliva in a patient worsens the fixation and stabilization of the prosthesis;

4) in the anomalous form of bite;

2) in the presence of bony protrusions and ridges on the prosthetic bed, so that a solid basis for the prosthesis causes pain;

3) for the reduction of saliva in a patient worsens the fixation and stabilization of the prosthesis;

4) in the anomalous form of bite;

Слайд 37Indications for use

5) the need to create an increased adhesion of

the prosthesis (for musicians playing wind instruments);

6) to create a new form of an old or bad adjacent denture base;

7) for manufacturing obturators;

6) to create a new form of an old or bad adjacent denture base;

7) for manufacturing obturators;

Слайд 38 Resilient Lining materials for denture bases, depending on the nature of

the material is divided into four types:

acrylic

pliable

silicone based

fluorine rubber

acrylic

pliable

silicone based

fluorine rubber

Слайд 39

Methods of polymerization of basic plastics

Plastics made acrylic-based - is the

main structural material for the manufacture of removable plate dentures and orthodontic appliances.

Слайд 40

Methods for forming plastic powder in pasty condition divided into two

types: casting and compression molding.

Слайд 41Plastics Polymerization

Polymerization - a chemical reaction in which there is an

association of molecules of the same low molecular weight substances.

Because this reaction produces high molecular weight compounds that are similar in composition to the primary material, but it differs from the quantity and properties of molecules.

Because this reaction produces high molecular weight compounds that are similar in composition to the primary material, but it differs from the quantity and properties of molecules.

Слайд 42To study the basic acrylic resin polymerization quality using three methods:

1.

Polymerization for "water bath" in the cell in a plaster mold;

Слайд 45

Plastics for fixed prostheses

Most plastics used

"Sinma-M" and

"Sinma-74."

This acrylic

hot curing plastic such as "powder-liquid."

Слайд 46

Artificial teeth

Sets the front teeth are divided into 17 sizes.

The main part of the headset upper anterior teeth is made up of 3 styles: rectangular, wedge-shaped and oval.

Sets the lower anterior teeth are available in two styles: rectangular and wedge.

Sets of posterior teeth are available in 5 styles with increasing size. Teeth are available 7 colors.

Sets the lower anterior teeth are available in two styles: rectangular and wedge.

Sets of posterior teeth are available in 5 styles with increasing size. Teeth are available 7 colors.