- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

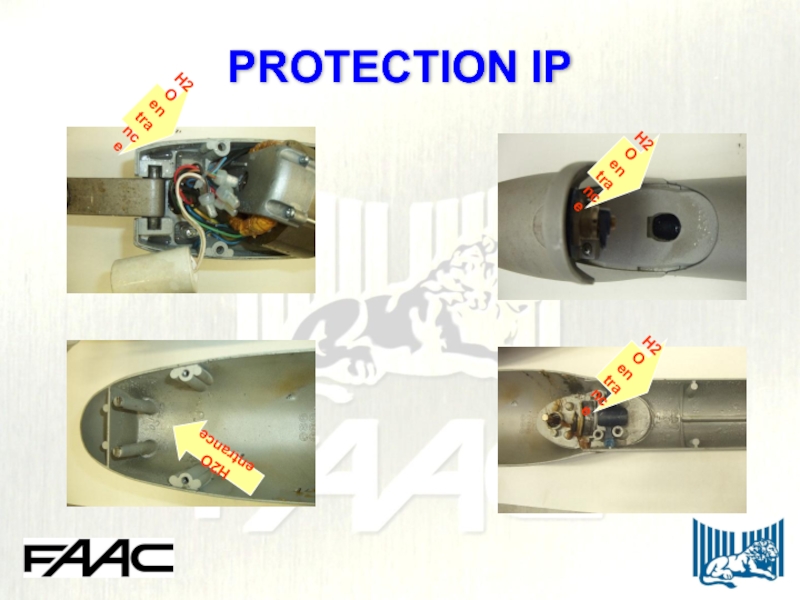

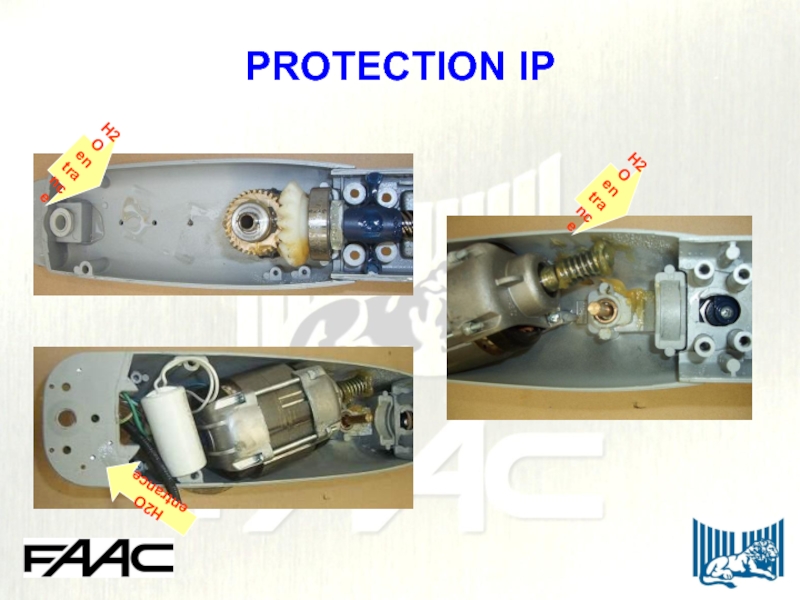

- Шаблоны, картинки для презентаций

- Экология

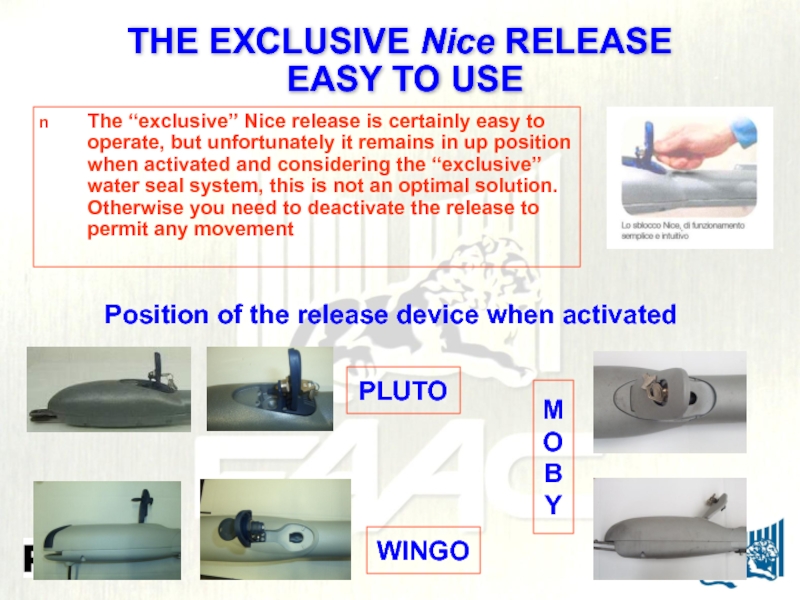

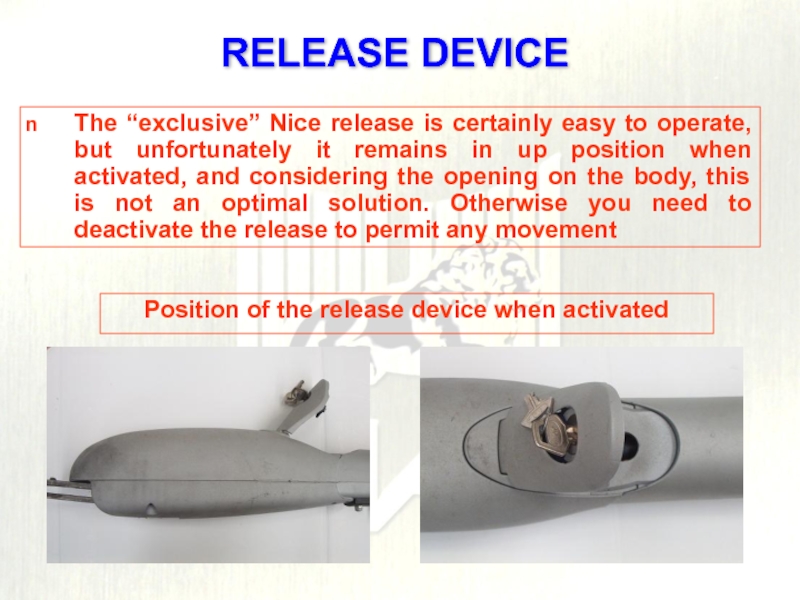

- Экономика

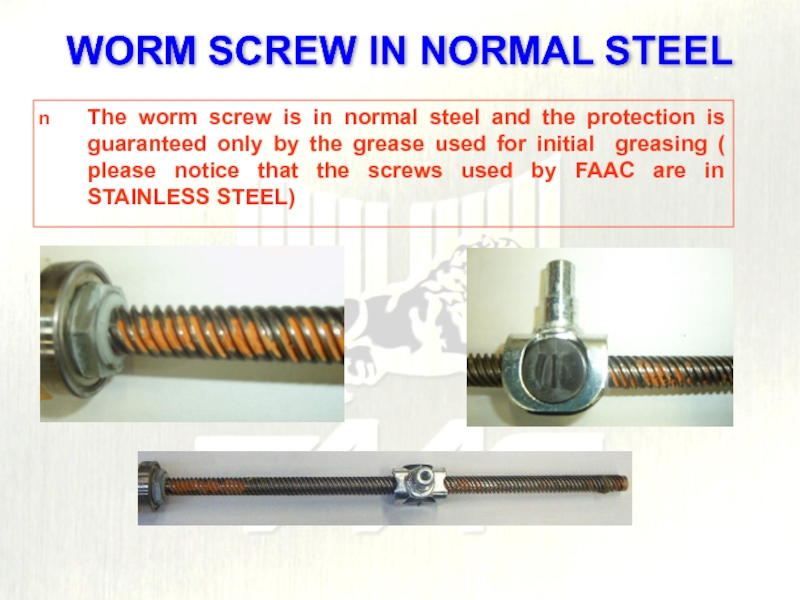

- Юриспруденция

Operators 413/415. Electromechanical operators for swing gates презентация

Содержание

- 1. Operators 413/415. Electromechanical operators for swing gates

- 2. OPERATOR 413

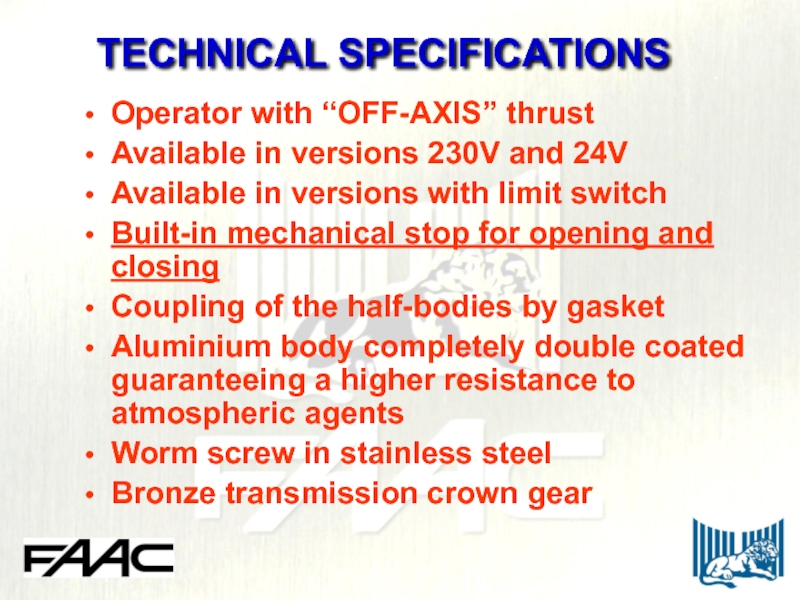

- 3. TECHNICAL SPECIFICATIONS Operator with “OFF-AXIS” thrust Available

- 4. Release device –key protected and easy to operate Numbered locks 1-36 (optional) OPERATOR 413

- 5. Limit switch 24 Vdc power supplied to

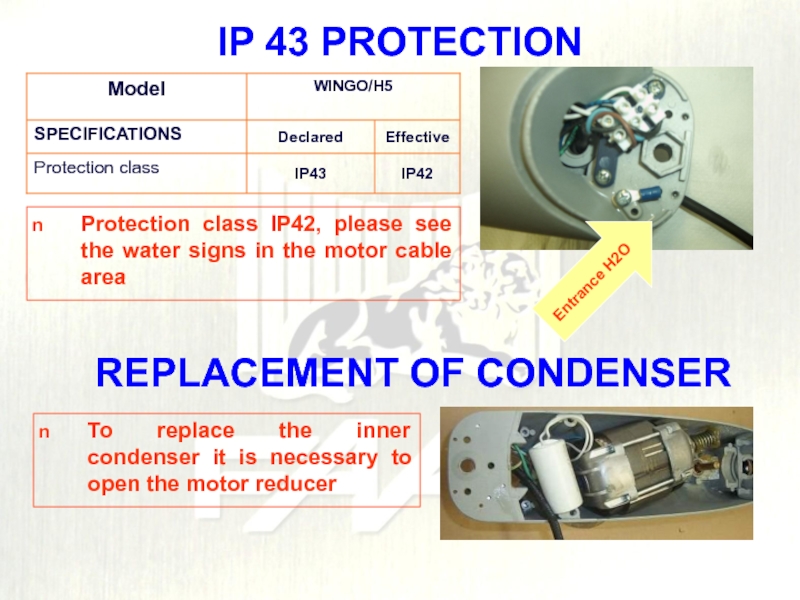

- 6. Horizontal cable exit for installations close to

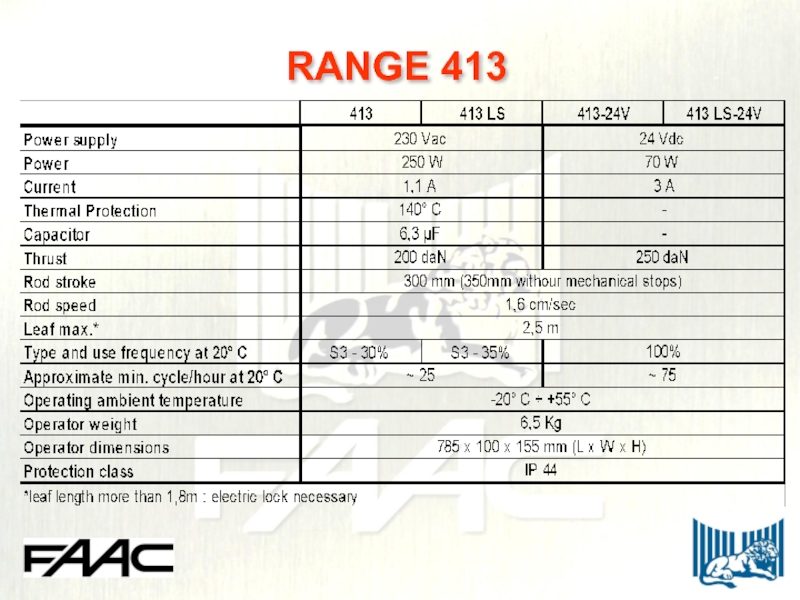

- 7. RANGE 413

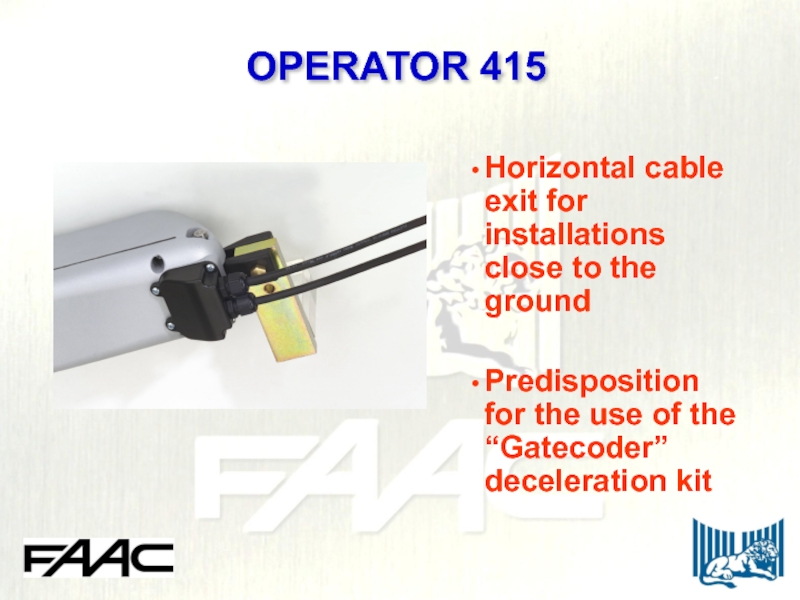

- 8. OPERATOR 415

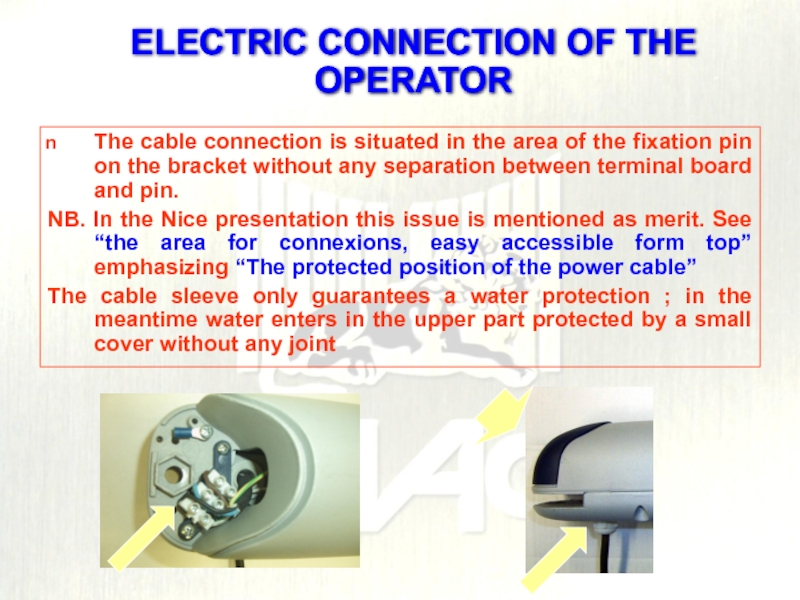

- 9. TECHNICAL SPECIFICATIONS Operator with “IN-AXIS” thrust Available

- 10. Horizontal cable exit for installations close to

- 11. OPERATOR 415 (with carter optional)

- 12. Release device –key protected and easy to operate Numbered locks 1-36 (optional) OPERATOR 415

- 13. Limit switch 24 Vdc power supplied to

- 14. Horizontal cable exit for installations close to

- 15. RANGE 415

- 16. TECHNICAL REPORT SWING GATE OPERATOR ANALYSIS AMI A180 ATI A3000

- 17. vs 413 CAME BX-A 1) See the test results AMI A180

- 18. AMI A180

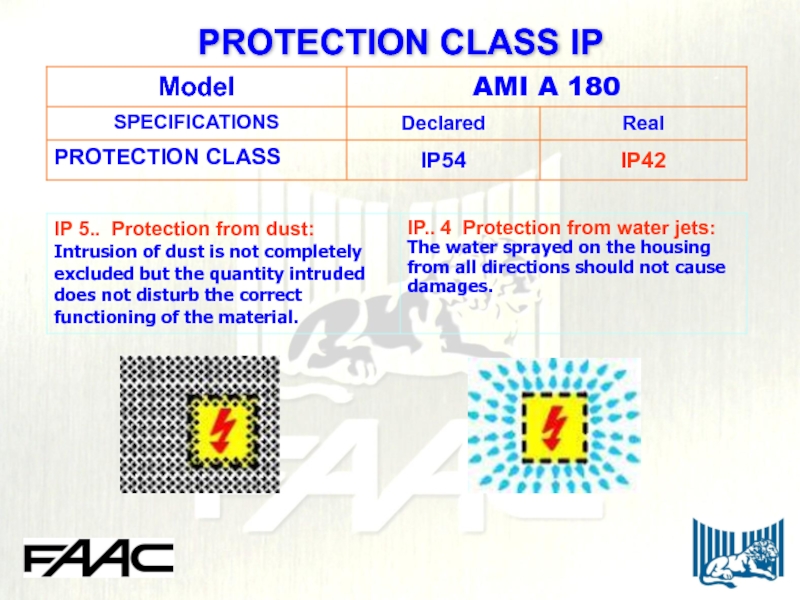

- 19. PROTECTION CLASS IP

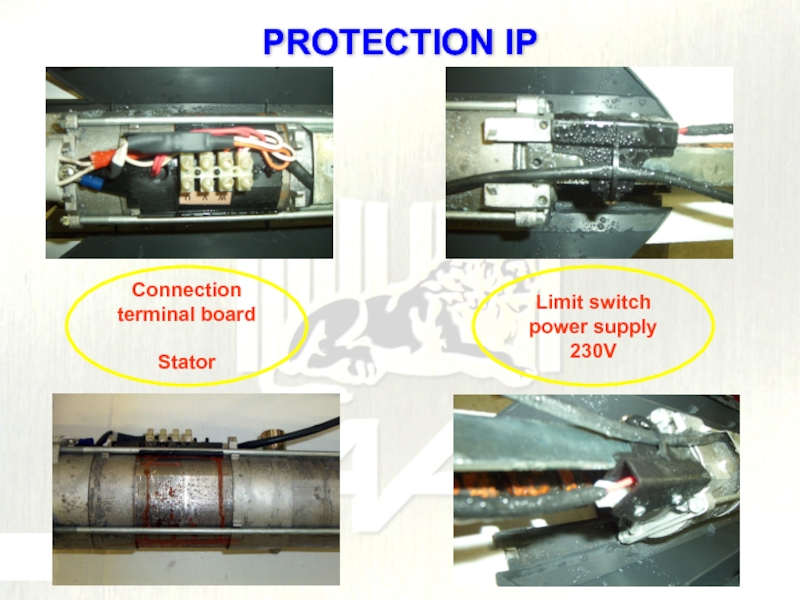

- 20. Connection terminal board Stator

- 21. Very few protection of the reduction gearing

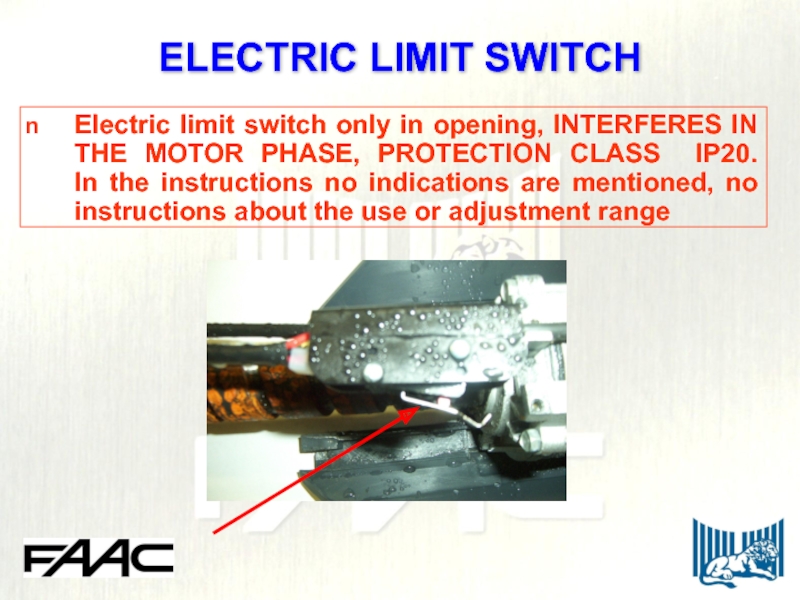

- 22. Electric limit switch only in opening, INTERFERES

- 23. The worm screw is made of “normal”

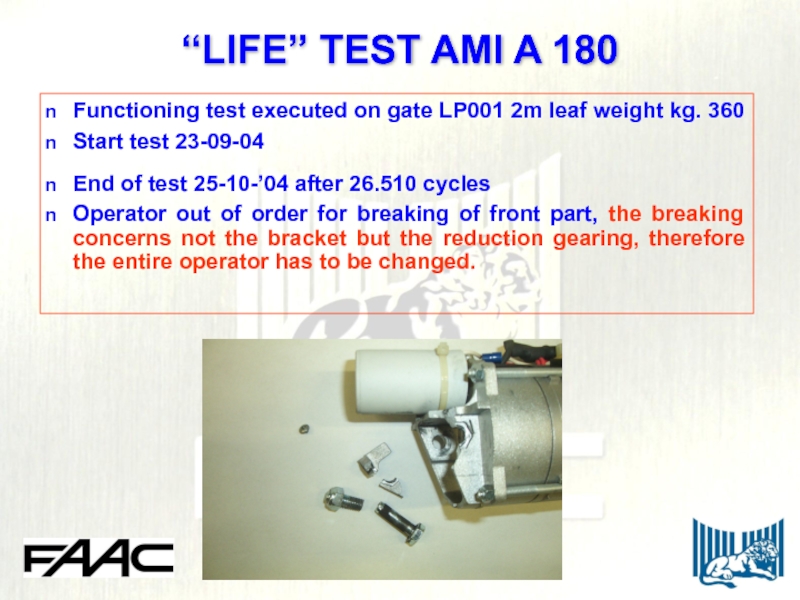

- 24. Functioning test executed on gate LP001 2m

- 25. vs 415 CAME BX-A 1) See the test results ATI A3000

- 26. AMI A3000 AMI A5000

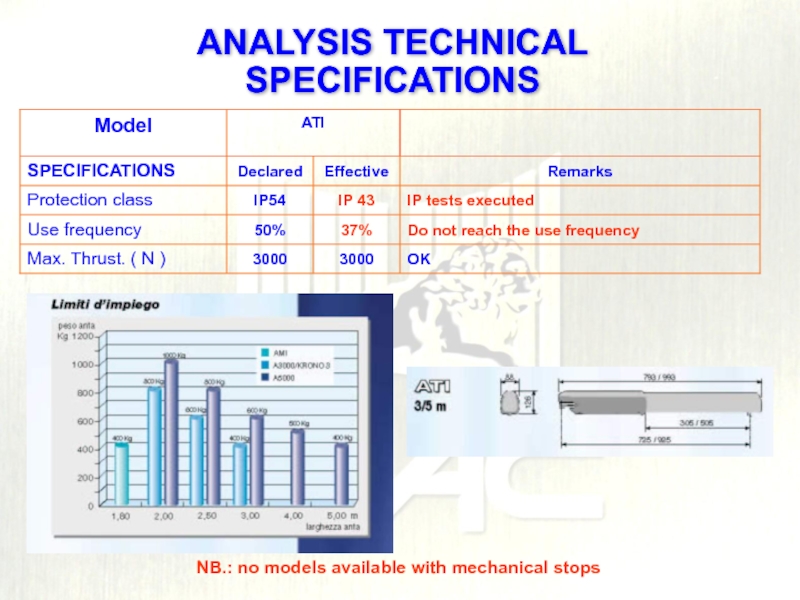

- 27. NB.: no models available with mechanical stops ANALYSIS TECHNICAL SPECIFICATIONS

- 28. PROTECTION IP

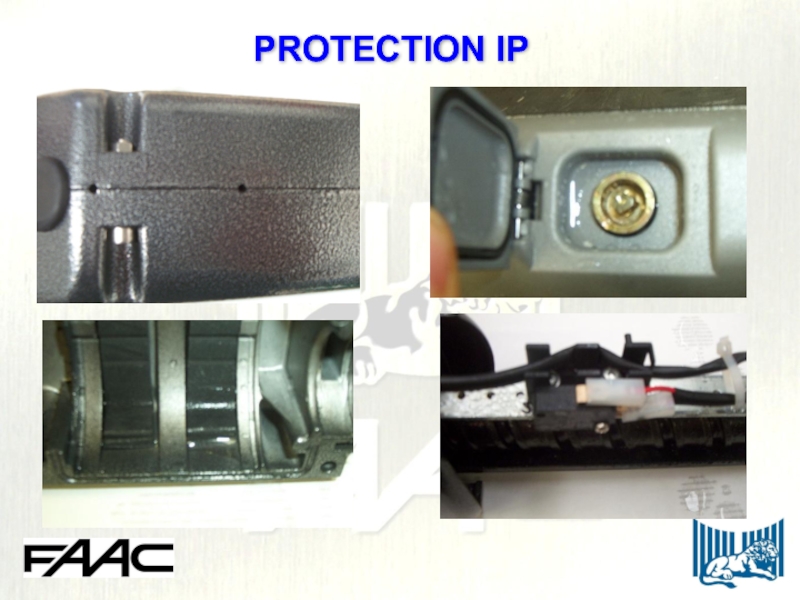

- 29. Concept and matching of the carter imply

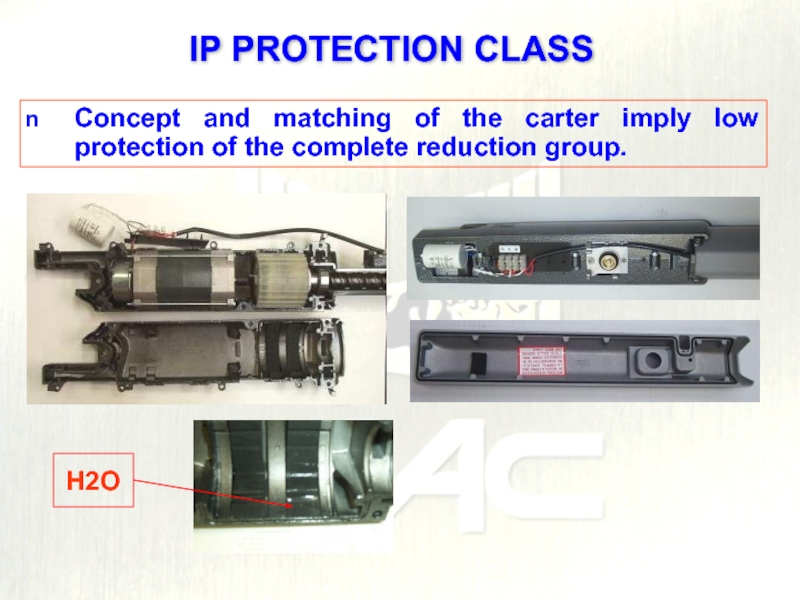

- 30. The normative requires expressly that “the

- 31. MOTION TRANSMISSION BETWEEN ROTOR AND

- 32. Epicycloidal reduction, locking system through electro brake.

- 33. The motor lock is given by the

- 34. ELECTRIC LIMIT SWITCH Electric limit switch

- 35. REGULATION OF THE ELECTRIC END TRAVELS

- 36. WORM SCREW The worm screw is

- 37. The screw covering solution, although it does

- 38. Execution test of functioning on gate LP011

- 39. TECHNICAL REPORT SWING GATE OPERATOR ANALYSIS PLUTO PL4005 MOBY 4006 WINGOKIT

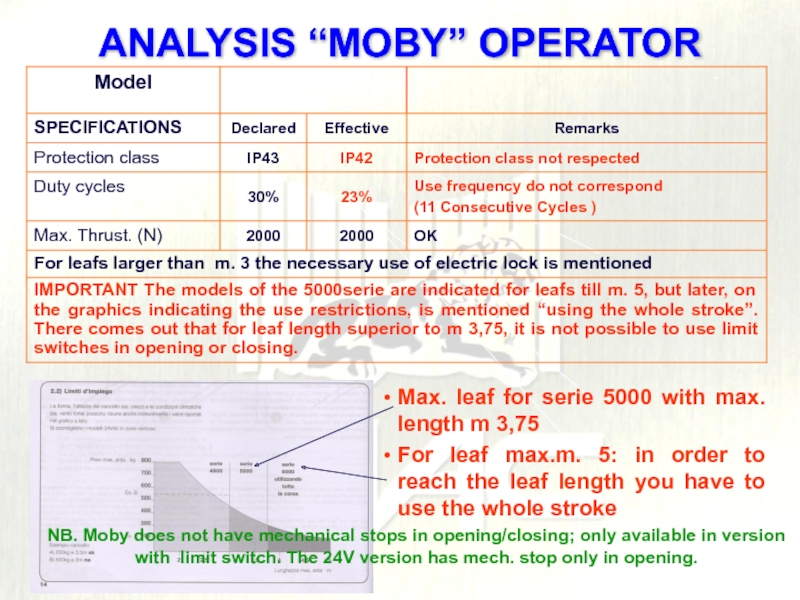

- 40. MOBY

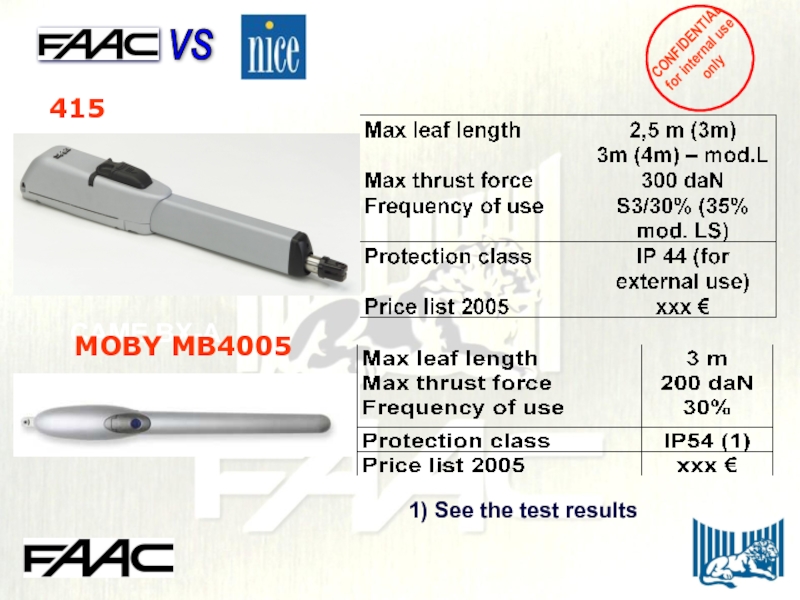

- 41. vs 415 CAME BX-A 1) See the test results MOBY MB4005

- 42. Max. leaf for serie 5000 with max.

- 43. H2O entrance H2O entrance H2O entrance H2O entrance PROTECTION IP

- 44. The Moby model range exists only in

- 45. The “exclusive” Nice release is certainly easy

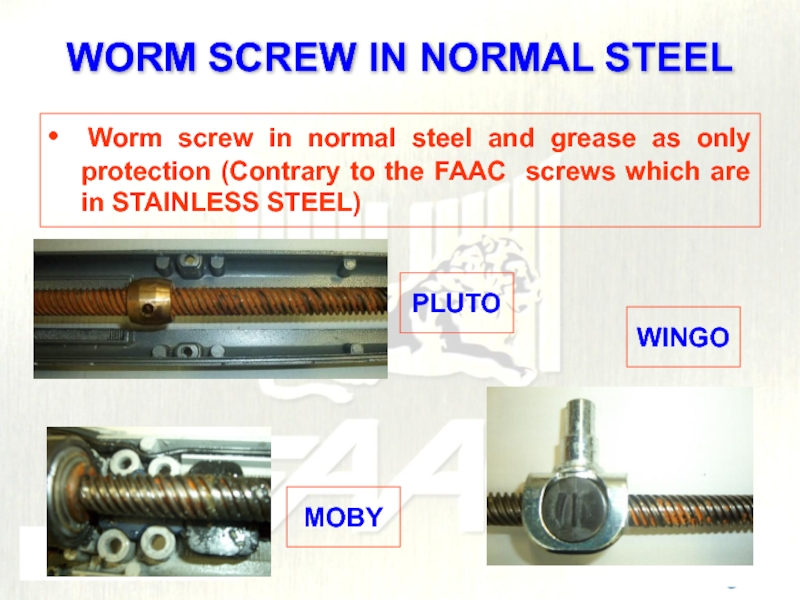

- 46. • Worm screw in normal steel

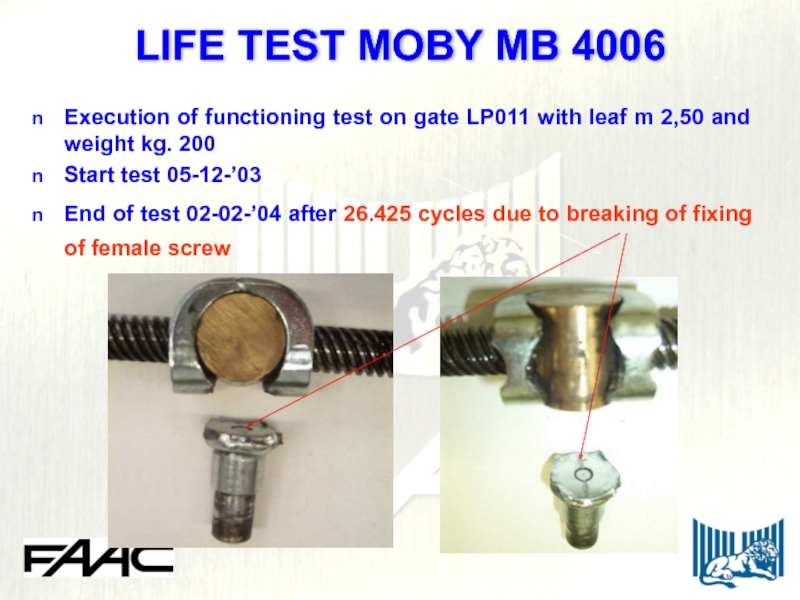

- 47. Execution of functioning test on gate LP011

- 48. Entrata H2O Entrata H2O Entrata H2O Entrata H2O PROTECTION OF THE INTERNAL MECHANICS

- 49. The worm screw is in normal steel

- 50. The “exclusive” Nice release is certainly easy

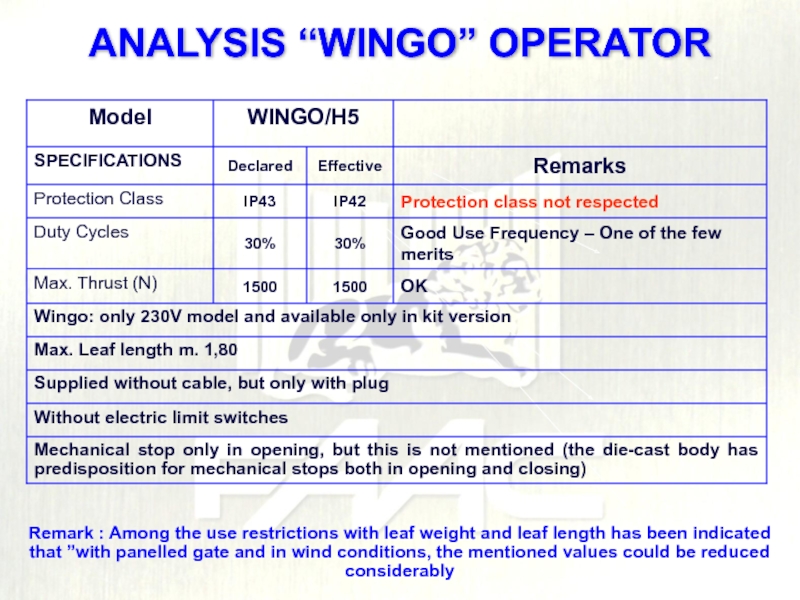

- 51. WINGO

- 52. vs 413 CAME BX-A 1) See the test results WINGOKIT

- 53. Remark : Among the use restrictions with

- 54. Entrance H2O Protection class IP42, please see

- 55. H2O entrance H2O entrance H2O entrance PROTECTION IP

- 56. The worm screw is in normal steel

- 57. The cable connection is situated in the

- 58. The “exclusive” Nice release is certainly easy

- 59. NB. The water you see inside entered

- 60. Execution of functioning test on gate LP011

Слайд 3TECHNICAL SPECIFICATIONS

Operator with “OFF-AXIS” thrust

Available in versions 230V and 24V

Available

Built-in mechanical stop for opening and closing

Coupling of the half-bodies by gasket

Aluminium body completely double coated guaranteeing a higher resistance to atmospheric agents

Worm screw in stainless steel

Bronze transmission crown gear

Слайд 5Limit switch 24 Vdc power supplied to guarantee the highest security

Possibility

Easy adjustment of the limit switches through access from the top

OPERATOR 413

Слайд 6Horizontal cable exit for installations close to the ground

Predisposition for the

OPERATOR 413

Слайд 9TECHNICAL SPECIFICATIONS

Operator with “IN-AXIS” thrust

Available in versions 230V and 24V

Available

Available in versions with limit switch

Coupling of the half-bodies by gasket

Aluminium body completely double coated guaranteeing a higher resistance to atmospheric agents

Available in versions with limit switch

Rod in stainless steel

Слайд 10Horizontal cable exit for installations close to the ground

Predisposition for

OPERATOR 415

Слайд 12Release device –key protected and easy to operate

Numbered locks 1-36 (optional)

OPERATOR 415

Слайд 13Limit switch 24 Vdc power supplied to guarantee the highest security

Possibility

High precision micrometric limit switches, frontal adjustment

OPERATOR 415 (LS models)

Слайд 14Horizontal cable exit for installations close to the ground

Predisposition for

OPERATOR 415

Слайд 21Very few protection of the reduction gearing due to type of

PROTECTION IP : COVER CARTER

Слайд 22Electric limit switch only in opening, INTERFERES IN THE MOTOR PHASE,

ELECTRIC LIMIT SWITCH

Слайд 23The worm screw is made of “normal” steel and protected only

WORM SCREW

Слайд 24Functioning test executed on gate LP001 2m leaf weight kg. 360

Start test 23-09-04

End of test 25-10-’04 after 26.510 cycles

Operator out of order for breaking of front part, the breaking concerns not the bracket but the reduction gearing, therefore the entire operator has to be changed.

“LIFE” TEST AMI A 180

Слайд 29Concept and matching of the carter imply low protection of the

H2O

IP PROTECTION CLASS

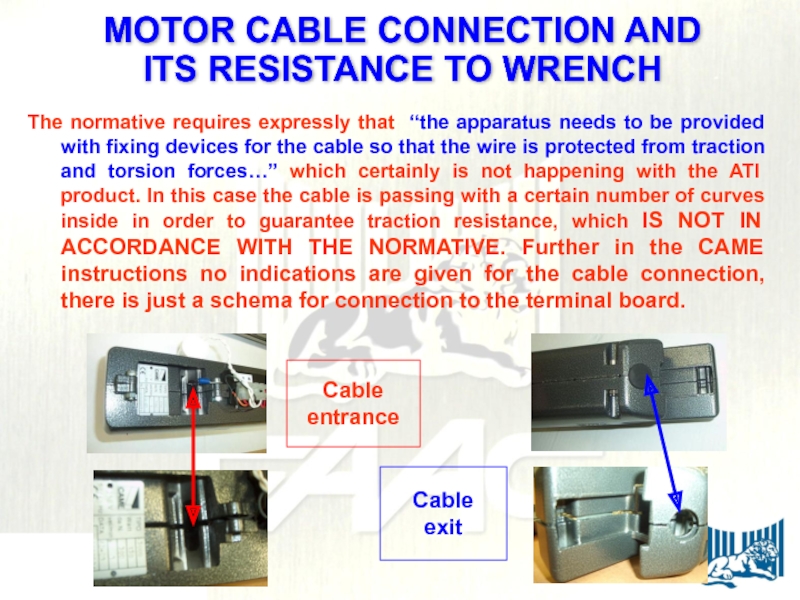

Слайд 30

The normative requires expressly that “the apparatus needs to be provided

Cable

entrance

Cable

exit

MOTOR CABLE CONNECTION AND ITS RESISTANCE TO WRENCH

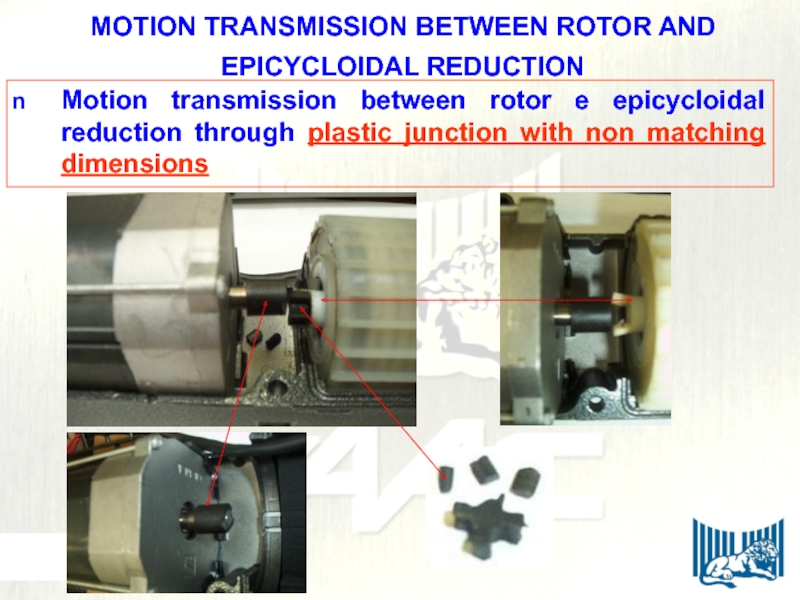

Слайд 31

MOTION TRANSMISSION BETWEEN ROTOR AND

EPICYCLOIDAL REDUCTION

Motion transmission between rotor

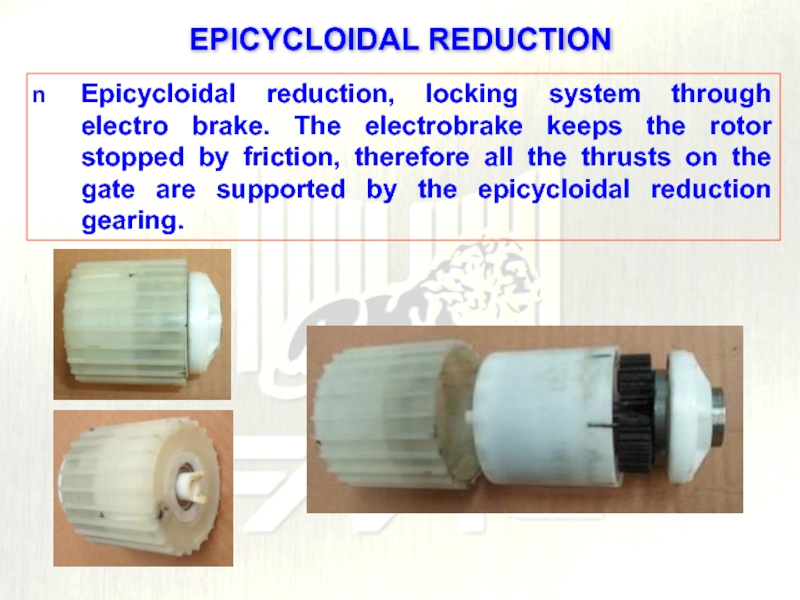

Слайд 32Epicycloidal reduction, locking system through electro brake. The electrobrake keeps the

EPICYCLOIDAL REDUCTION

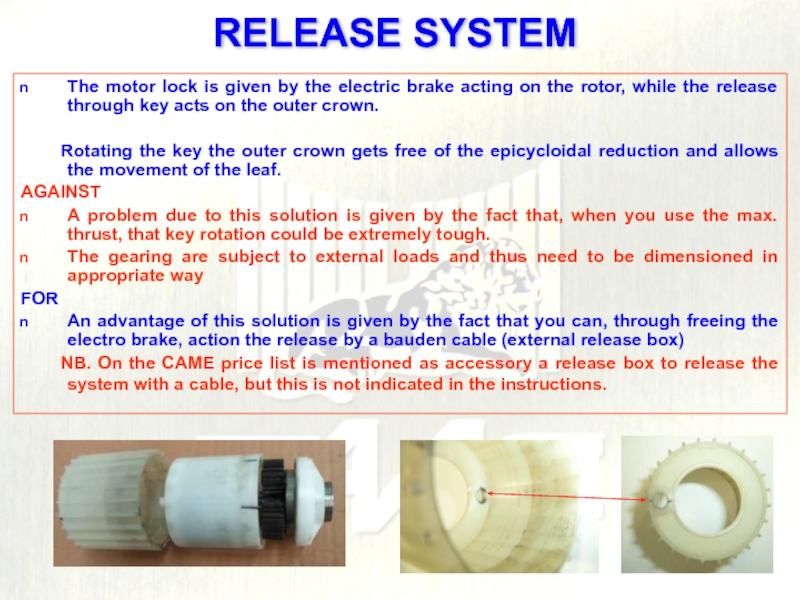

Слайд 33The motor lock is given by the electric brake acting on

Rotating the key the outer crown gets free of the epicycloidal reduction and allows the movement of the leaf.

AGAINST

A problem due to this solution is given by the fact that, when you use the max. thrust, that key rotation could be extremely tough.

The gearing are subject to external loads and thus need to be dimensioned in appropriate way

FOR

An advantage of this solution is given by the fact that you can, through freeing the electro brake, action the release by a bauden cable (external release box)

NB. On the CAME price list is mentioned as accessory a release box to release the system with a cable, but this is not indicated in the instructions.

RELEASE SYSTEM

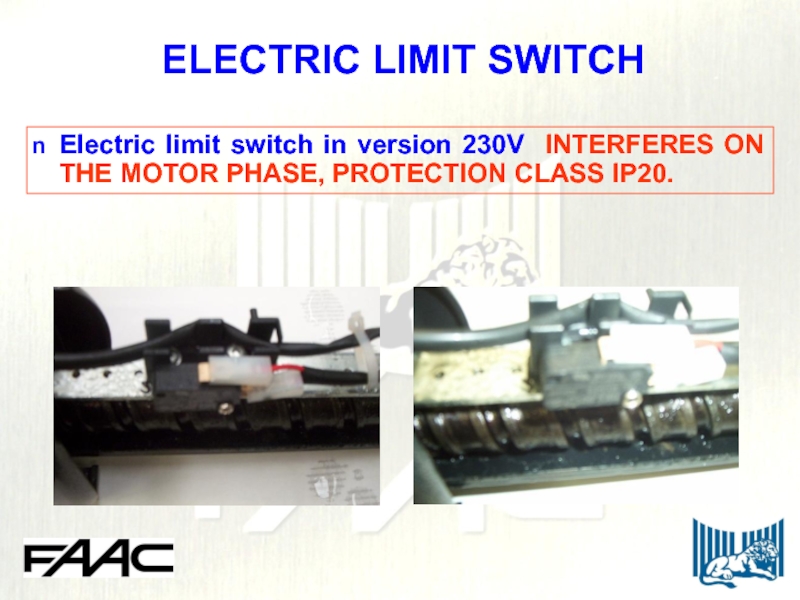

Слайд 34ELECTRIC LIMIT SWITCH

Electric limit switch in version 230V INTERFERES ON

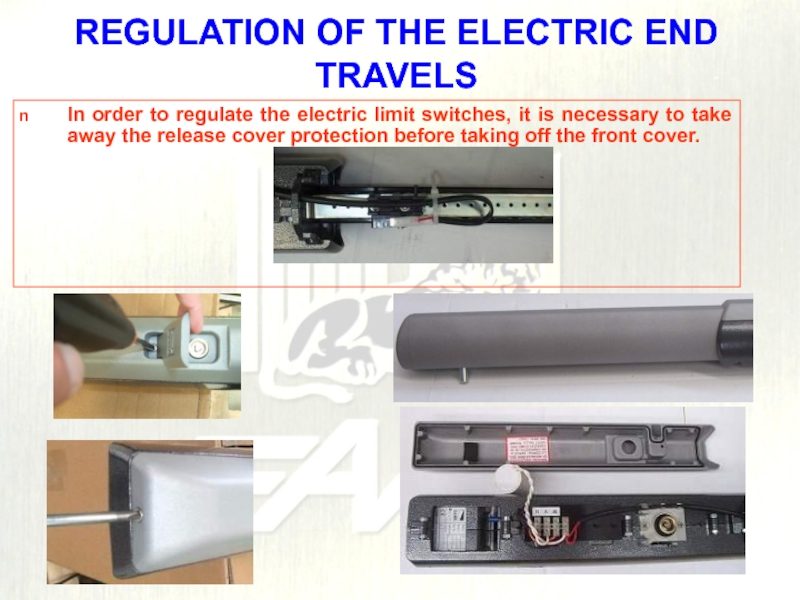

Слайд 35REGULATION OF THE ELECTRIC END TRAVELS

In order to regulate the

Слайд 36WORM SCREW

The worm screw is made of “normal” steel and

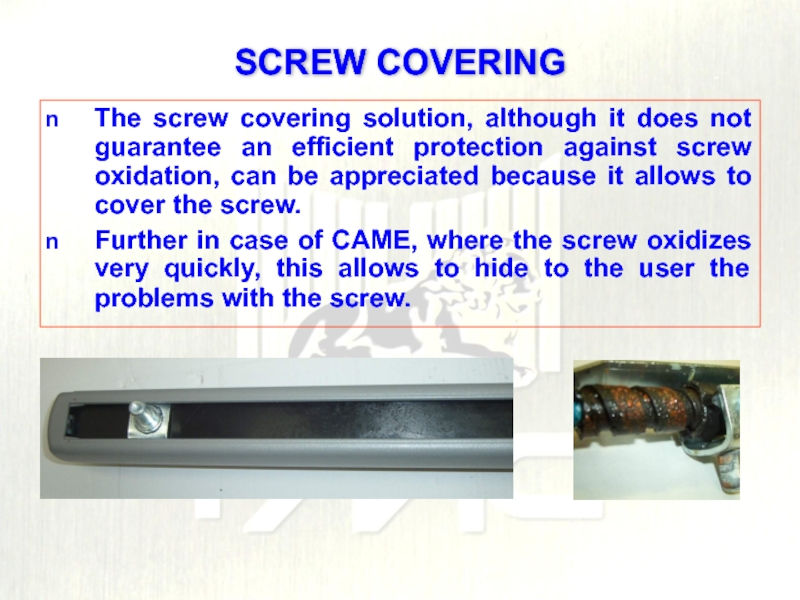

Слайд 37The screw covering solution, although it does not guarantee an efficient

Further in case of CAME, where the screw oxidizes very quickly, this allows to hide to the user the problems with the screw.

SCREW COVERING

Слайд 38Execution test of functioning on gate LP011 with 4m leaf and

Start 1° test: 17-12-’04

End test 22 – 12 - ’04 after 2.217 cycles due to breaking of coupling

Start 2° test: 04-03-’05

End test 07 – 03 - ’05 after 1.350 cycles due to breaking of coupling

“LIFE” TEST ATI 5000

Слайд 42Max. leaf for serie 5000 with max. length m 3,75

For leaf

NB. Moby does not have mechanical stops in opening/closing; only available in version with limit switch. The 24V version has mech. stop only in opening.

ANALYSIS “MOBY” OPERATOR

Слайд 44The Moby model range exists only in version with electric limit

Only the 24 V version has the mechanical stop IN OPENING, but without electric limit switch and the encoder has been introduced in the basic model.

AVAILABLE ONLY IN VERSION WITH ELECTRIC LIMIT SWITCH

“ no mechanical stops ”

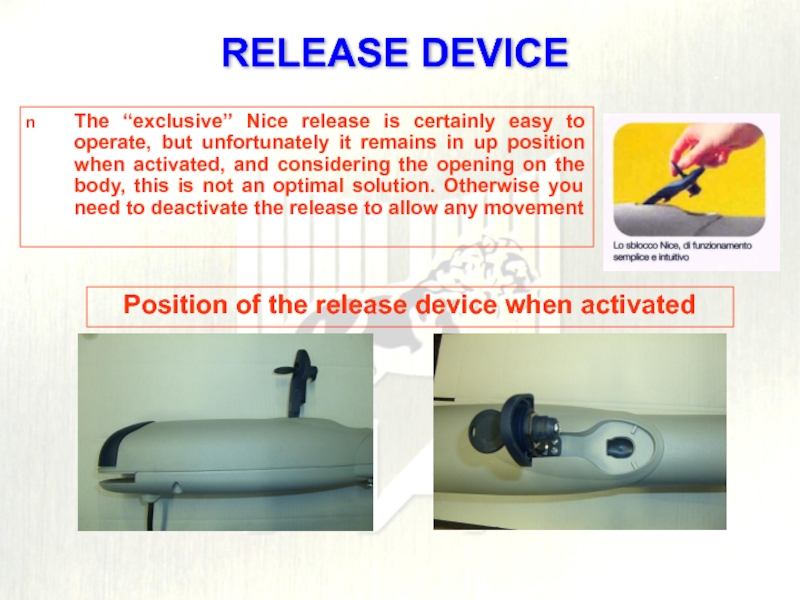

Слайд 45The “exclusive” Nice release is certainly easy to operate, but unfortunately

M

O

B

Y

PLUTO

WINGO

THE EXCLUSIVE Nice RELEASE

EASY TO USE

Position of the release device when activated

Слайд 46

• Worm screw in normal steel and grease as only protection (Contrary

MOBY

PLUTO

WINGO

WORM SCREW IN NORMAL STEEL

Слайд 47Execution of functioning test on gate LP011 with leaf m 2,50

Start test 05-12-’03

End of test 02-02-’04 after 26.425 cycles due to breaking of fixing of female screw

LIFE TEST MOBY MB 4006

Слайд 49The worm screw is in normal steel and the protection is

Oxidation starts very quickly

WORM SCREW IN NORMAL STEEL

Слайд 50The “exclusive” Nice release is certainly easy to operate, but unfortunately

Position of the release device when activated

RELEASE DEVICE

Слайд 53Remark : Among the use restrictions with leaf weight and leaf

ANALYSIS “WINGO” OPERATOR

Слайд 54Entrance H2O

Protection class IP42, please see the water signs in the

To replace the inner condenser it is necessary to open the motor reducer

REPLACEMENT OF CONDENSER

IP 43 PROTECTION

Слайд 56The worm screw is in normal steel and the protection is

WORM SCREW IN NORMAL STEEL

Слайд 57The cable connection is situated in the area of the fixation

NB. In the Nice presentation this issue is mentioned as merit. See “the area for connexions, easy accessible form top” emphasizing “The protected position of the power cable”

The cable sleeve only guarantees a water protection ; in the meantime water enters in the upper part protected by a small cover without any joint

ELECTRIC CONNECTION OF THE OPERATOR

Слайд 58The “exclusive” Nice release is certainly easy to operate, but unfortunately

Position of the release device when activated

RELEASE DEVICE

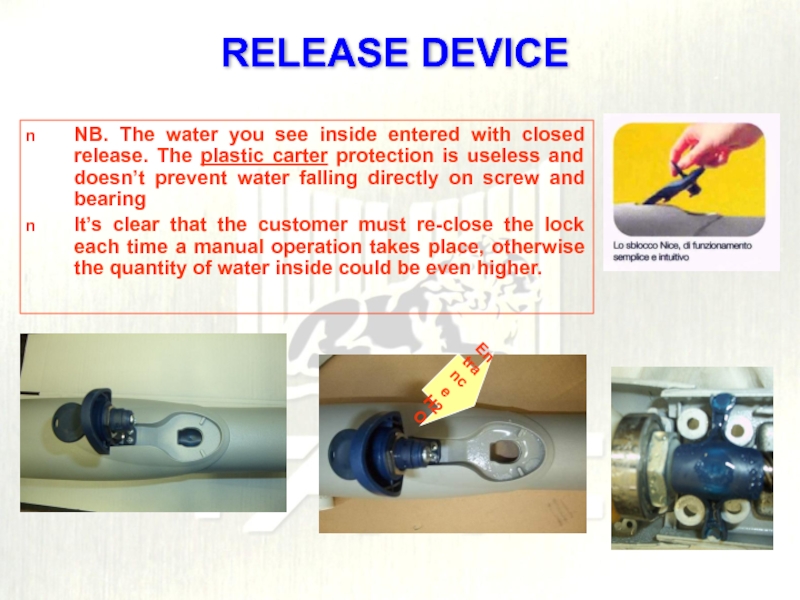

Слайд 59NB. The water you see inside entered with closed release. The

It’s clear that the customer must re-close the lock each time a manual operation takes place, otherwise the quantity of water inside could be even higher.

Entrance H2O

RELEASE DEVICE

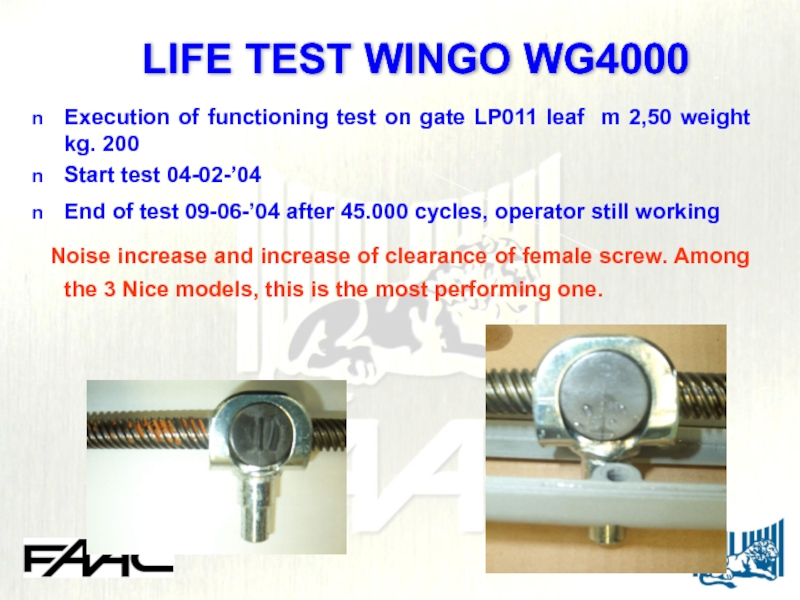

Слайд 60Execution of functioning test on gate LP011 leaf m 2,50 weight

Start test 04-02-’04

End of test 09-06-’04 after 45.000 cycles, operator still working

Noise increase and increase of clearance of female screw. Among the 3 Nice models, this is the most performing one.

LIFE TEST WINGO WG4000