- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Oil-free Air Division презентация

Содержание

- 2. ZH-Series The unique packaging

- 3. ZH-Series Unique Package Concept

- 4. COOPER

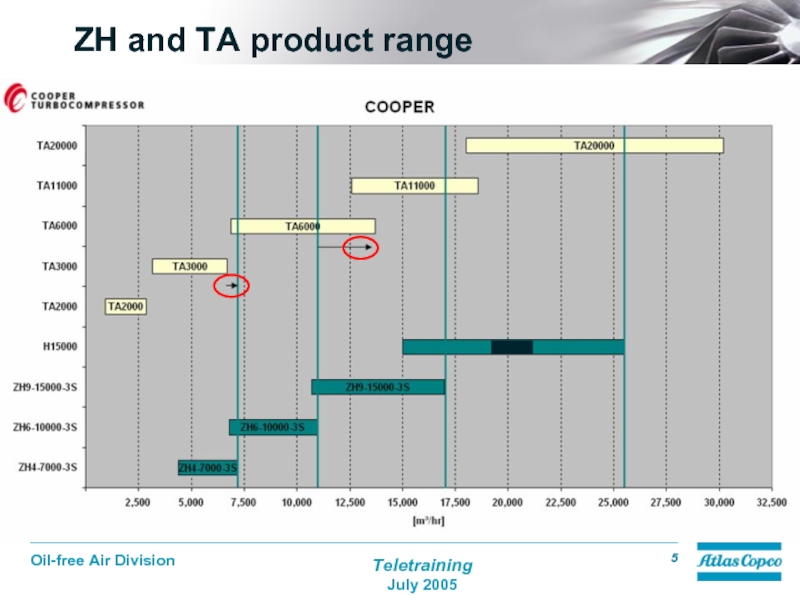

- 5. ZH and TA product range

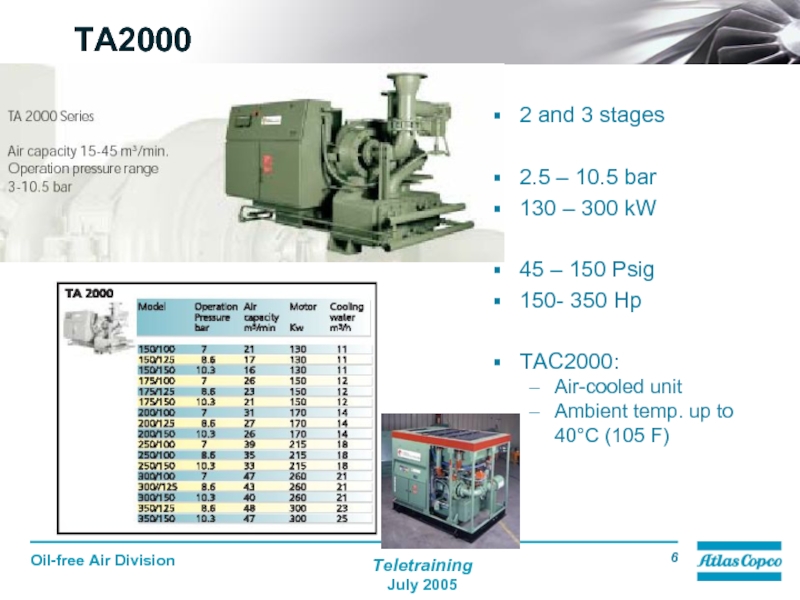

- 6. TA2000 2 and 3 stages 2.5

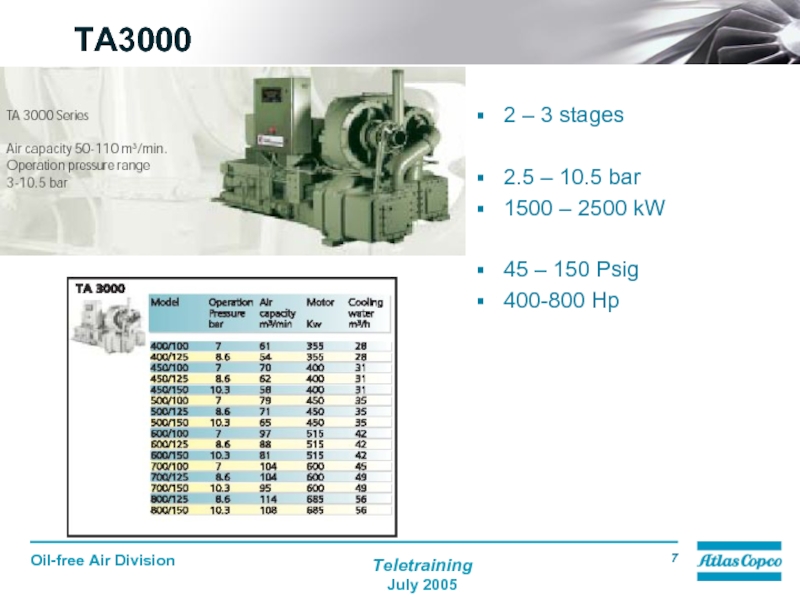

- 7. TA3000 2 – 3 stages 2.5

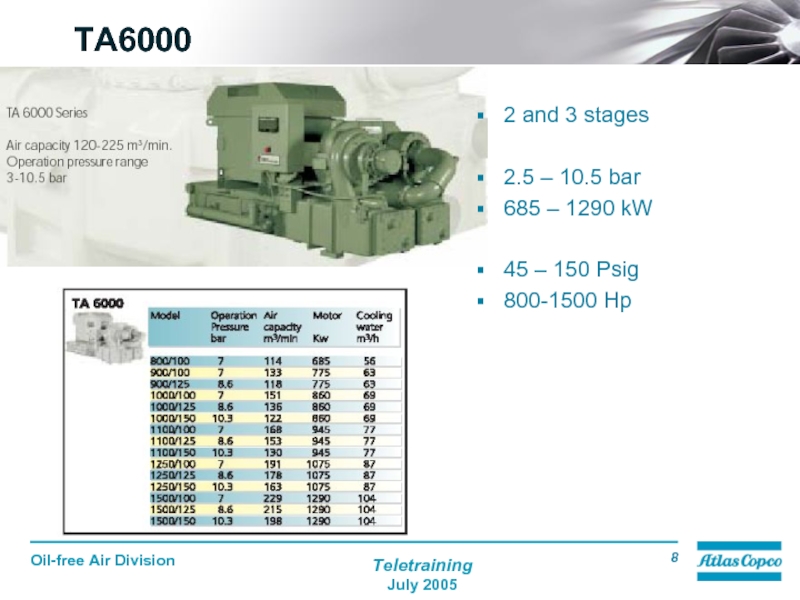

- 8. TA6000 2 and 3 stages 2.5

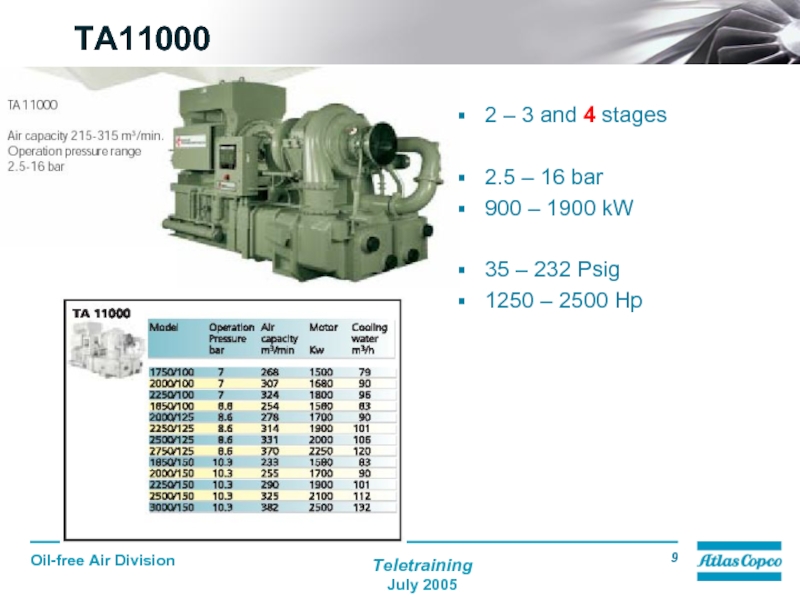

- 9. TA11000 2 – 3 and

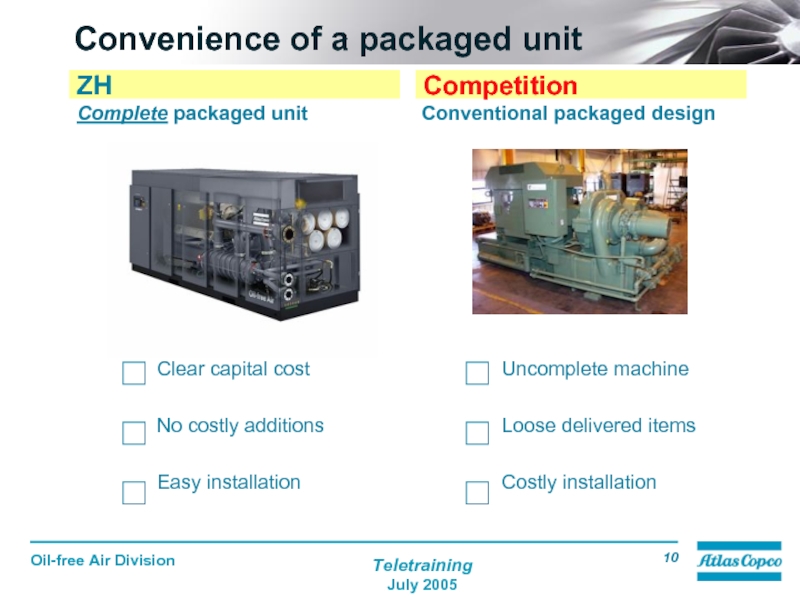

- 10. Convenience of a packaged unit Complete packaged

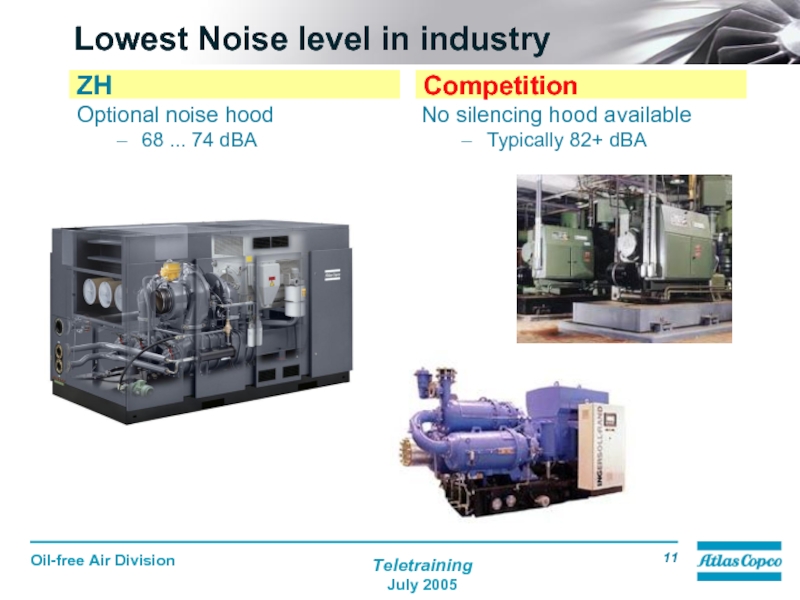

- 11. Lowest Noise level in industry Optional noise

- 12. Convenience of packaged unit Complete packaged unit

- 13. Clear capital cost The complete package includes

- 14. Conventional package $50’000 adders

- 15. Convenience of packaged unit Complete packaged unit

- 16. Convenience of packaged unit INTEGRATED & MOUNTED

- 17. Auto-Dual & Constant Pressure Control Configurations of TA’s

- 18. Convenience of packaged unit INTEGRATED & MOUNTED

- 19. Lasting compressor performance Clearances between impeller and

- 20. Reliability first with Stainless Steel STAINLESS STEEL

- 21. Reliability first with quality gears COMPLETE GEAR/PINIONS

- 22. Designed for easy maintenance MICRO SPLIN Disassembly

- 23. No compromises on reliability ZH Horizontally-split bearings

- 24. No comprises on reliability TILTING PAD HORIZONTALLY-SPLIT

- 25. No comprises on reliability ??

- 26. High speed and Low speed bearings AXIAL

- 27. Lasting compressor performance CARBON RING AIR SEAL

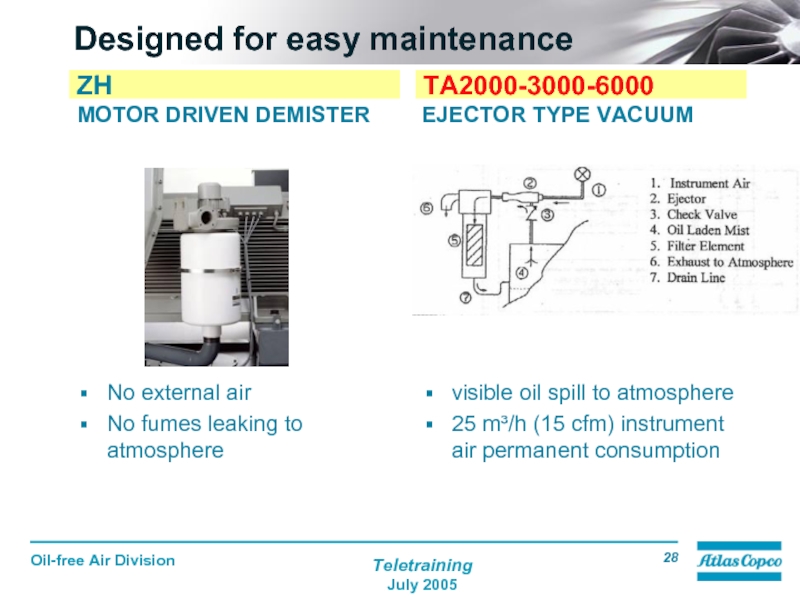

- 28. Designed for easy maintenance MOTOR DRIVEN DEMISTER

- 29. INGERSOLL-RAND

- 30. Ingersoll Rand - Centac Models

- 31. Product range ZH RANGE

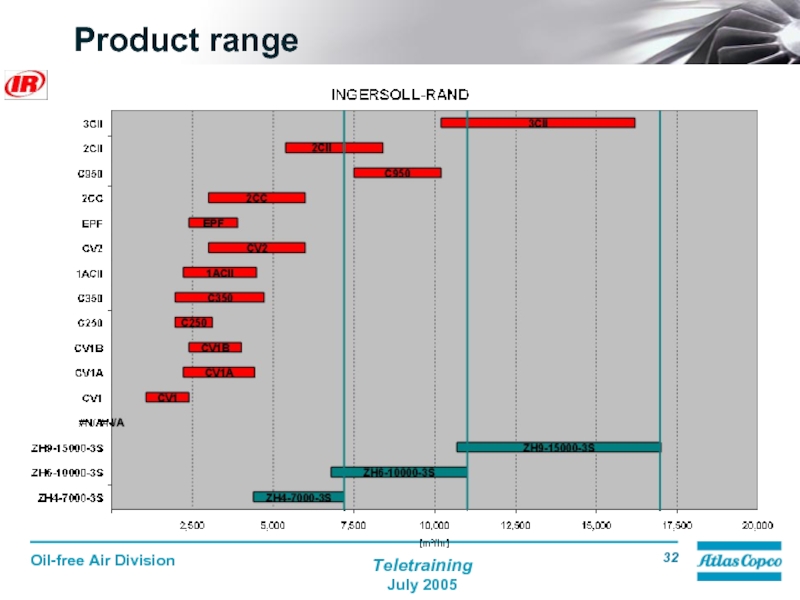

- 32. Product range

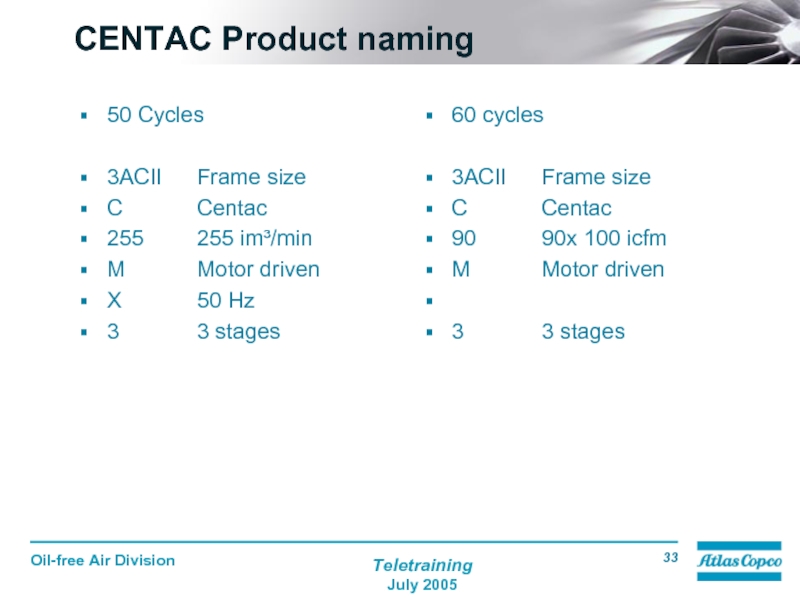

- 33. CENTAC Product naming 50 Cycles 3ACII Frame

- 34. Convenience of a packaged unit Complete packaged

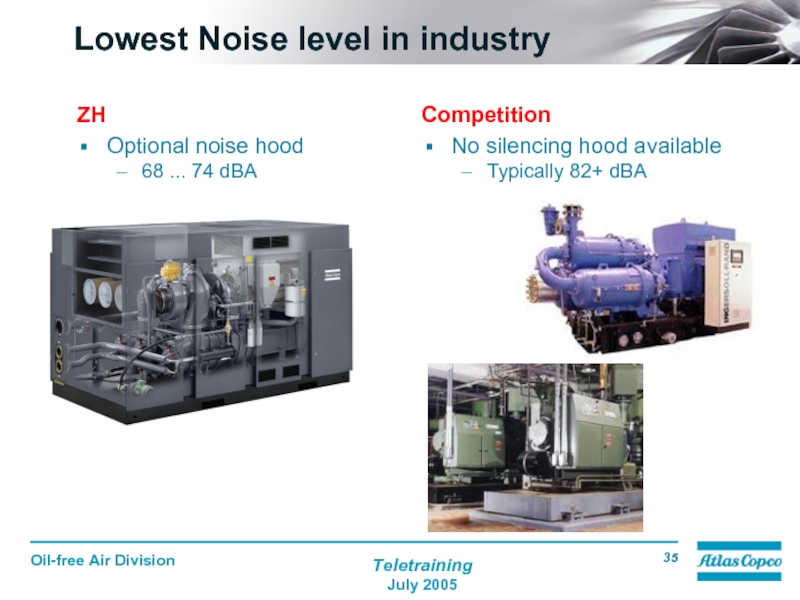

- 35. Lowest Noise level in industry ZH Optional

- 36. Convenience of packaged unit Complete packaged unit

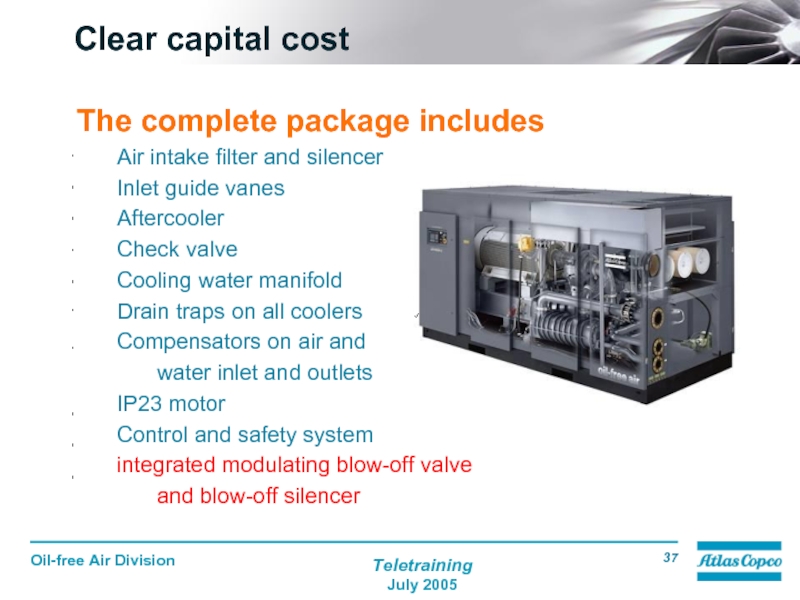

- 37. Clear capital cost The complete package includes

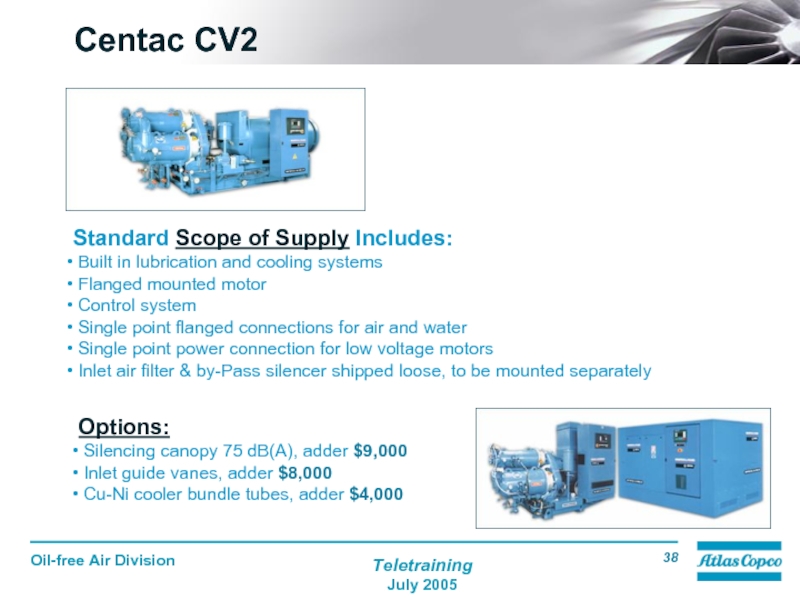

- 38. Standard Scope of Supply Includes: Built

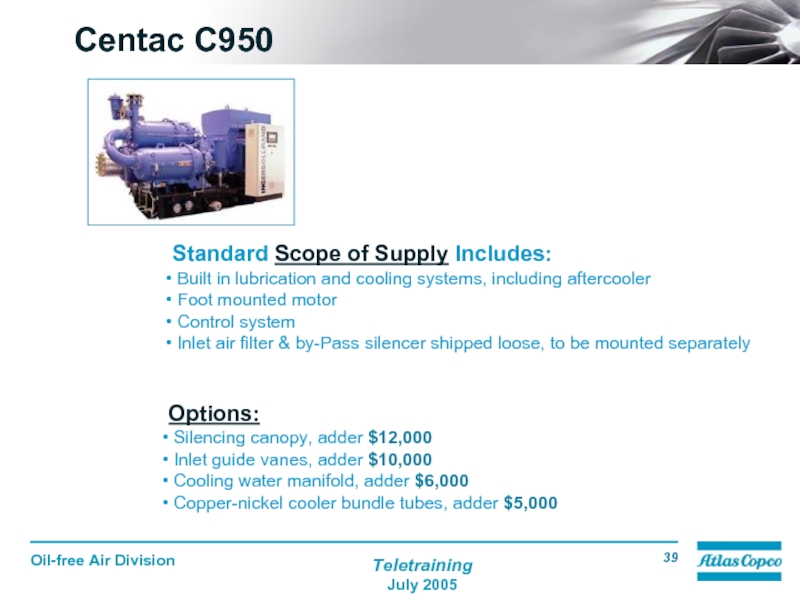

- 39. Standard Scope of Supply Includes: Built

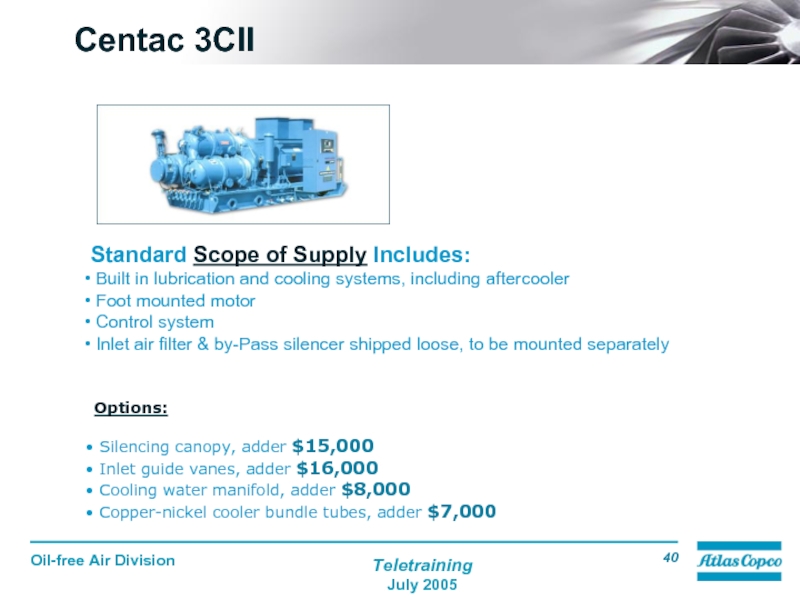

- 40. Standard Scope of Supply Includes: Built

- 41. Convenience of packaged unit Complete packaged unit

- 42. Convenience of packaged unit INTEGRATED & MOUNTED

- 43. Convenience of packaged unit INTEGRATED & MOUNTED

- 44. Gearbox configuration HORIZONTALLY-split gearbox

- 45. High speed and Low speed bearings AXIAL

- 46. Designed for easy maintenance HORIZONTALLY-split

- 47. Reliability first with quality gears COMPLETE GEAR/PINIONS

- 48. Designed for easy maintenance MICRO SPLIN Disassembly

- 49. Designed for easy maintenance FIXED GEOMETRY Less

- 50. No dependence on external air ZH

- 51. Reliability first with Stainless Steel STAINLESS STEEL

- 52. Designed for easy maintenance COPPER Coolers are

- 53. Designed for easy maintenance HORIZONTALLY-split gearbox Only

- 54. Designed for easy maintenance MOTOR DRIVEN DEMISTER

- 55. Efficient operation with IGV INLET GUIDE VANES

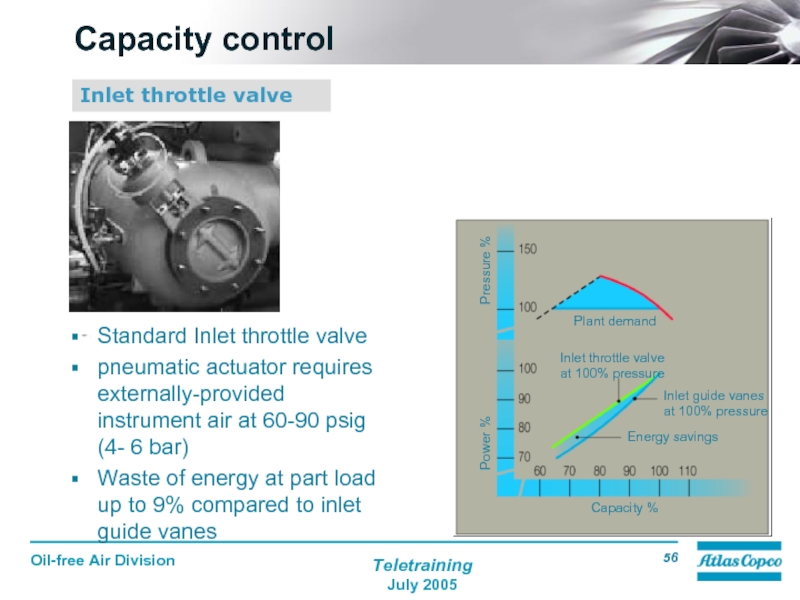

- 56. Capacity control Inlet throttle valve Standard

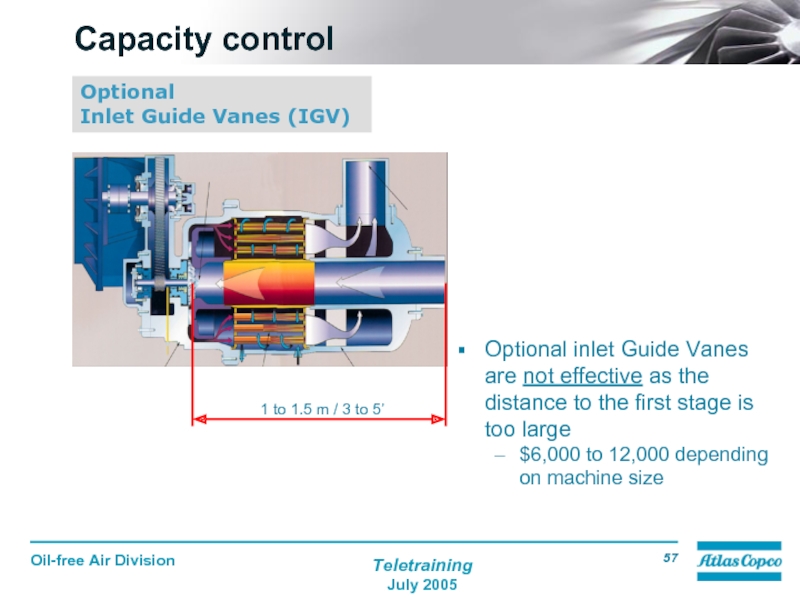

- 57. Capacity control Optional inlet Guide Vanes are

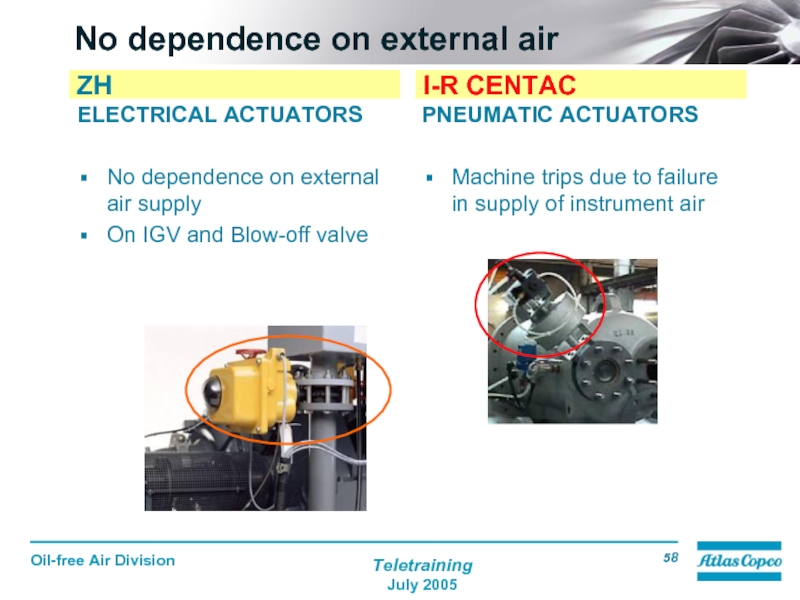

- 58. No dependence on external air ELECTRICAL ACTUATORS

- 59. Aftercooler Cooling Water Manifold Check Valve Blow-off

- 60. Thank You

Слайд 2

ZH-Series

The unique packaging concept

Convenience of the

Integrated

Packaged Unit

Performances of a

State-of-the-art

Process compressor

Слайд 6TA2000

2 and 3 stages

2.5 – 10.5 bar

130 – 300 kW

45 –

150- 350 Hp

TAC2000:

Air-cooled unit

Ambient temp. up to 40°C (105 F)

Слайд 10Convenience of a packaged unit

Complete packaged unit

Clear capital cost

No costly additions

Easy

Conventional packaged design

Uncomplete machine

Loose delivered items

Costly installation

ZH

Competition

Слайд 11Lowest Noise level in industry

Optional noise hood

68 ... 74 dBA

No silencing

Typically 82+ dBA

ZH

Competition

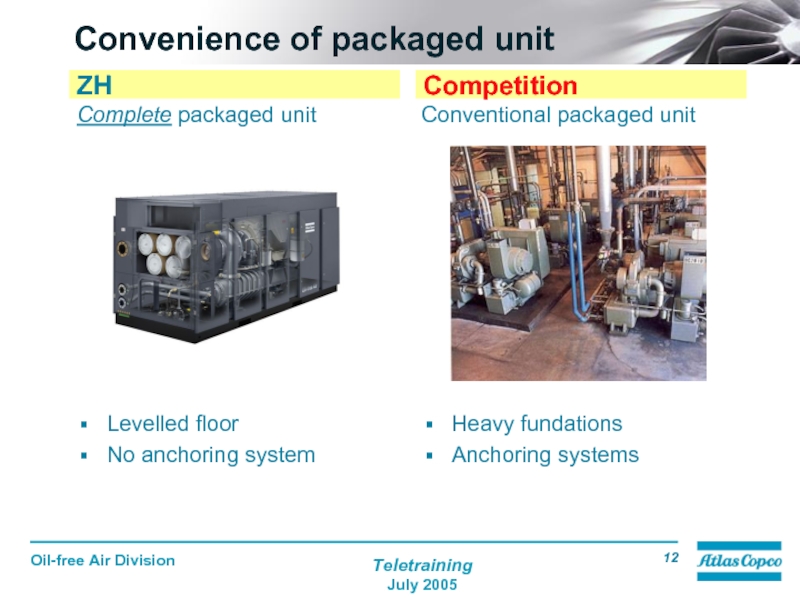

Слайд 12Convenience of packaged unit

Complete packaged unit

Levelled floor

No anchoring system

Conventional packaged unit

Heavy

Anchoring systems

ZH

Competition

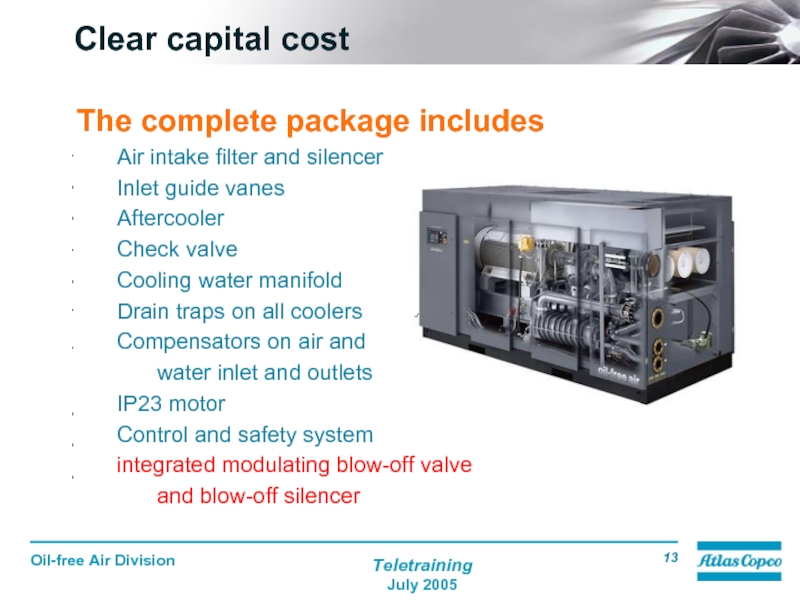

Слайд 13Clear capital cost

The complete package includes

Air intake filter and silencer

Inlet guide

Aftercooler

Check valve

Cooling water manifold

Drain traps on all coolers

Compensators on air and

water inlet and outlets

IP23 motor

Control and safety system

integrated modulating blow-off valve

and blow-off silencer

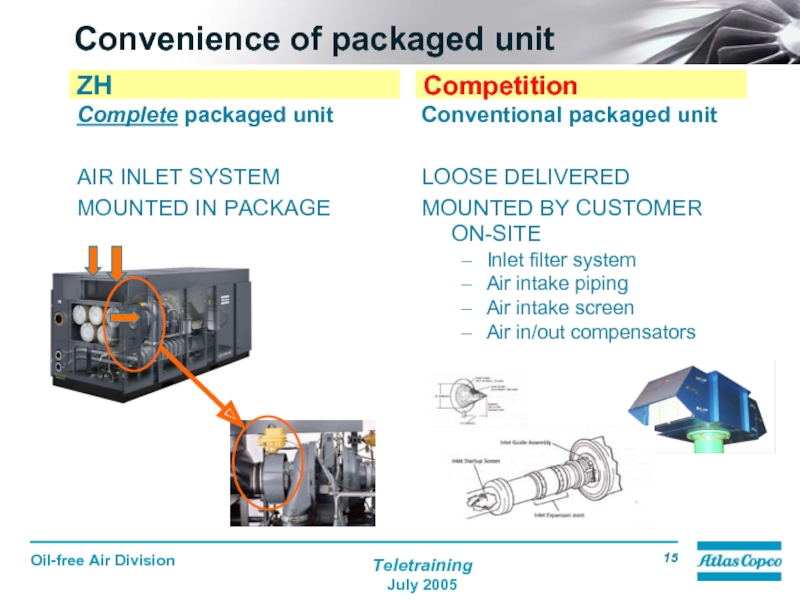

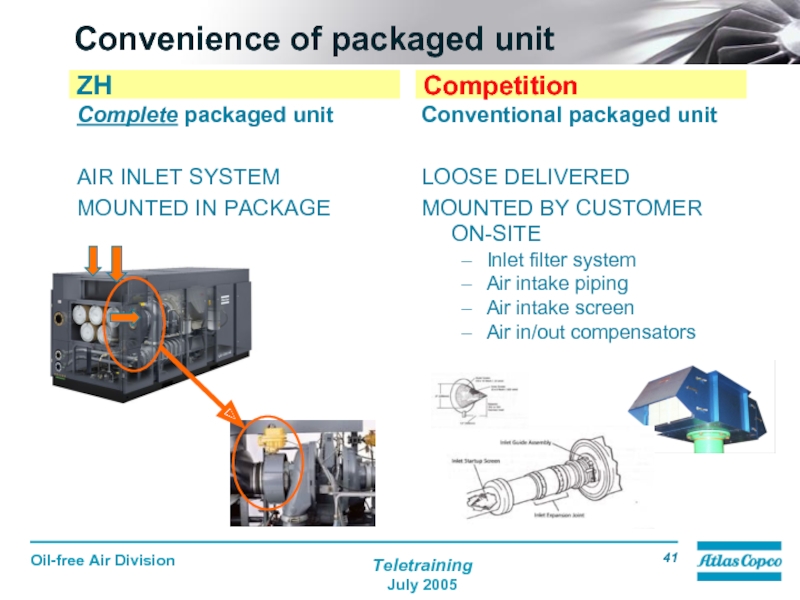

Слайд 15Convenience of packaged unit

Complete packaged unit

AIR INLET SYSTEM

MOUNTED IN PACKAGE

Conventional

LOOSE DELIVERED

MOUNTED BY CUSTOMER ON-SITE

Inlet filter system

Air intake piping

Air intake screen

Air in/out compensators

ZH

Competition

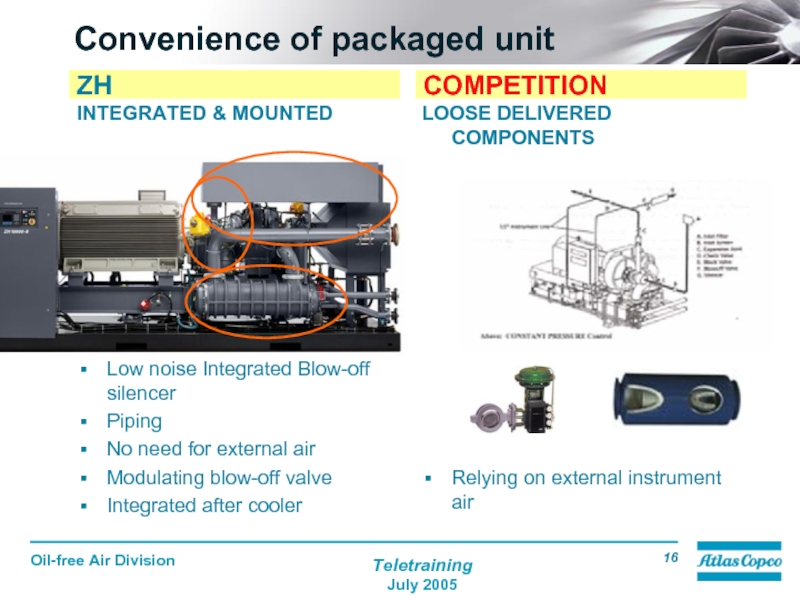

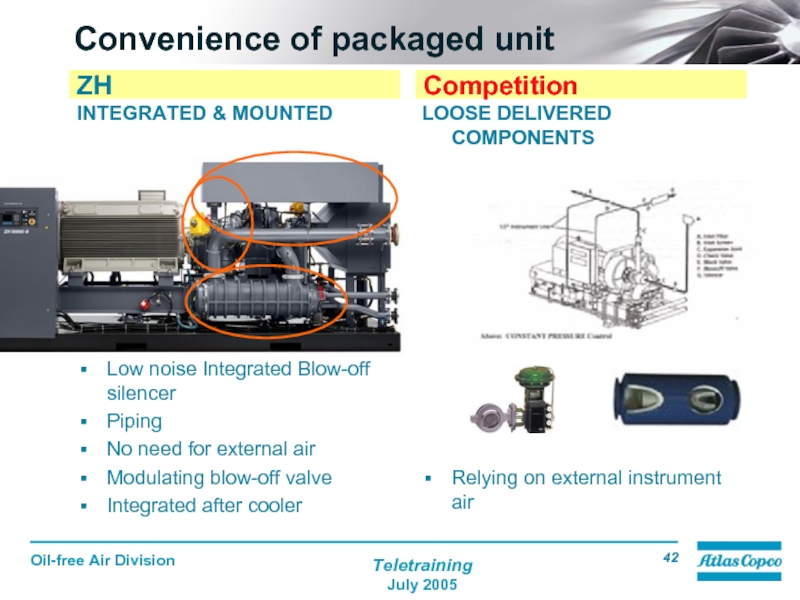

Слайд 16Convenience of packaged unit

INTEGRATED & MOUNTED

Low noise Integrated Blow-off silencer

Piping

No need

Modulating blow-off valve

Integrated after cooler

LOOSE DELIVERED COMPONENTS

Relying on external instrument air

ZH

COMPETITION

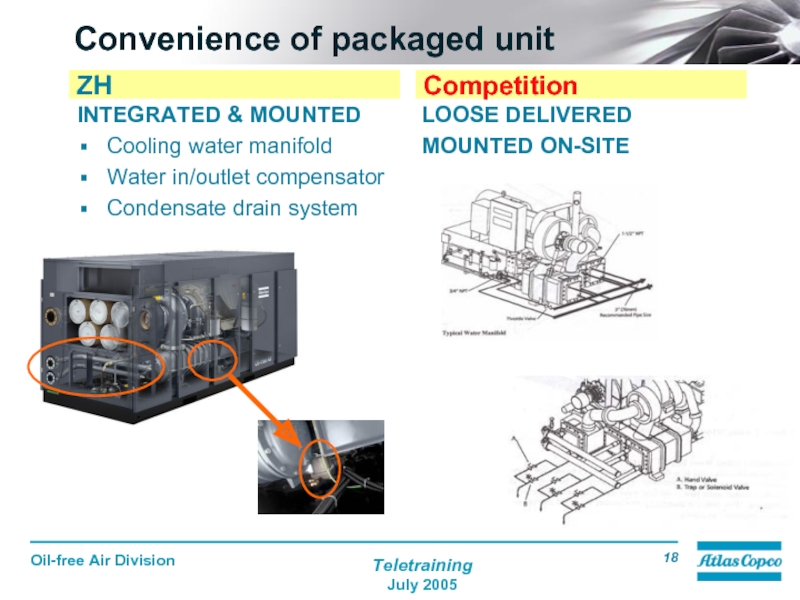

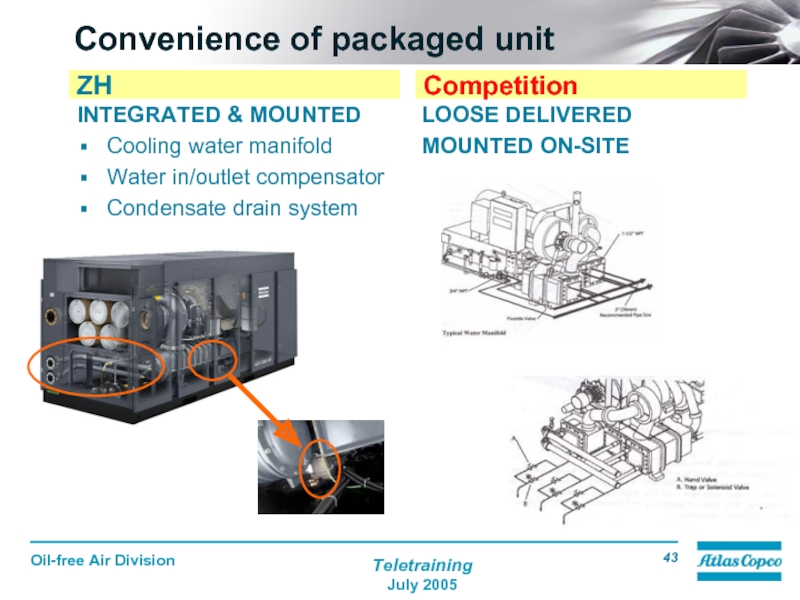

Слайд 18Convenience of packaged unit

INTEGRATED & MOUNTED

Cooling water manifold

Water in/outlet compensator

Condensate drain

LOOSE DELIVERED

MOUNTED ON-SITE

ZH

Competition

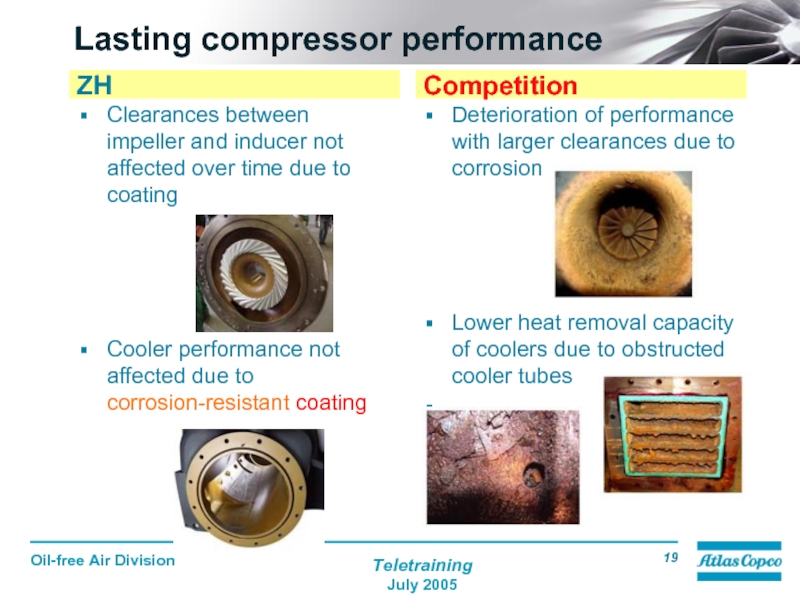

Слайд 19Lasting compressor performance

Clearances between impeller and inducer not affected over time

Cooler performance not affected due to corrosion-resistant coating

Deterioration of performance with larger clearances due to corrosion

Lower heat removal capacity of coolers due to obstructed cooler tubes

ZH

Competition

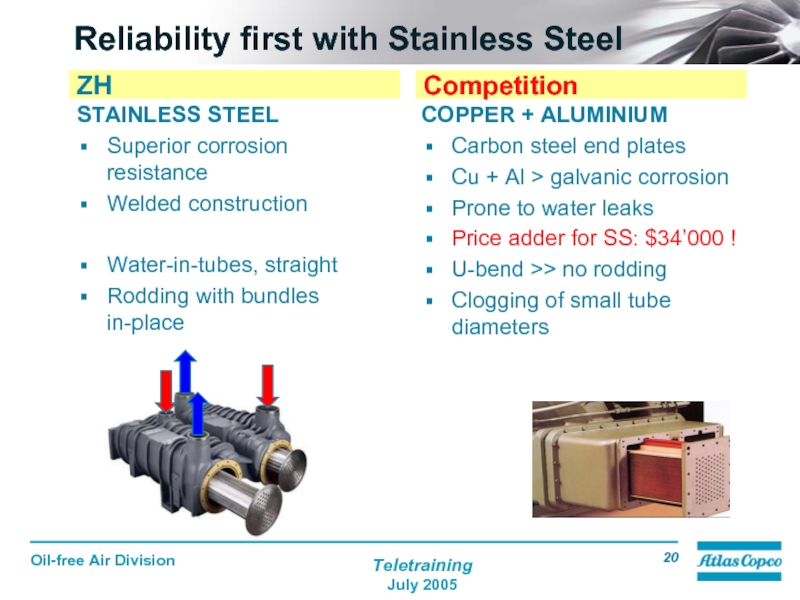

Слайд 20Reliability first with Stainless Steel

STAINLESS STEEL

Superior corrosion resistance

Welded construction

Water-in-tubes, straight

Rodding with

COPPER + ALUMINIUM

Carbon steel end plates

Cu + Al > galvanic corrosion

Prone to water leaks

Price adder for SS: $34’000 !

U-bend >> no rodding

Clogging of small tube diameters

ZH

Competition

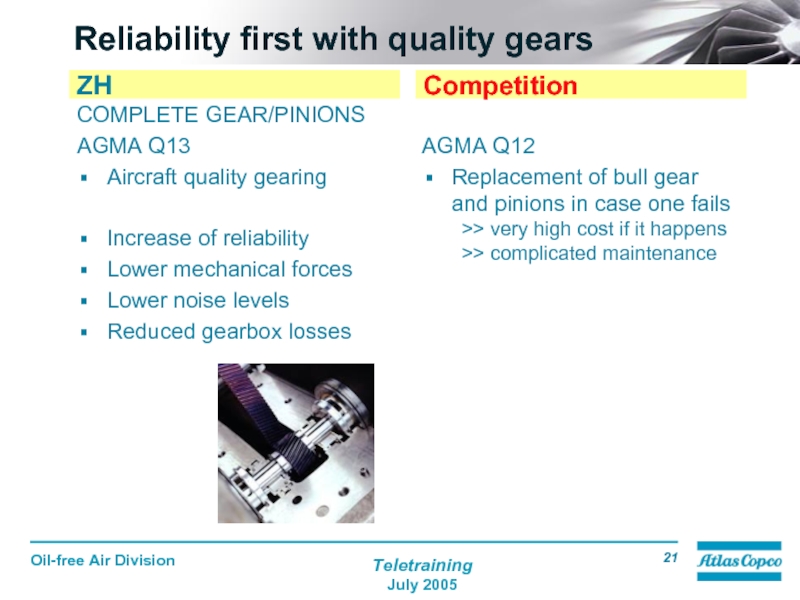

Слайд 21Reliability first with quality gears

COMPLETE GEAR/PINIONS

AGMA Q13

Aircraft quality gearing

Increase of reliability

Lower

Lower noise levels

Reduced gearbox losses

AGMA Q12

Replacement of bull gear and pinions in case one fails

>> very high cost if it happens

>> complicated maintenance

ZH

Competition

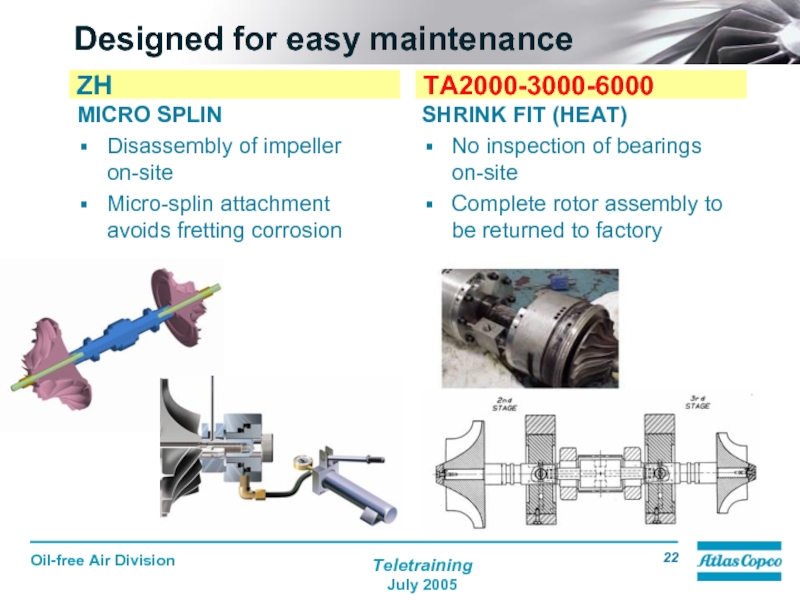

Слайд 22Designed for easy maintenance

MICRO SPLIN

Disassembly of impeller on-site

Micro-splin attachment avoids fretting

SHRINK FIT (HEAT)

No inspection of bearings on-site

Complete rotor assembly to be returned to factory

ZH

TA2000-3000-6000

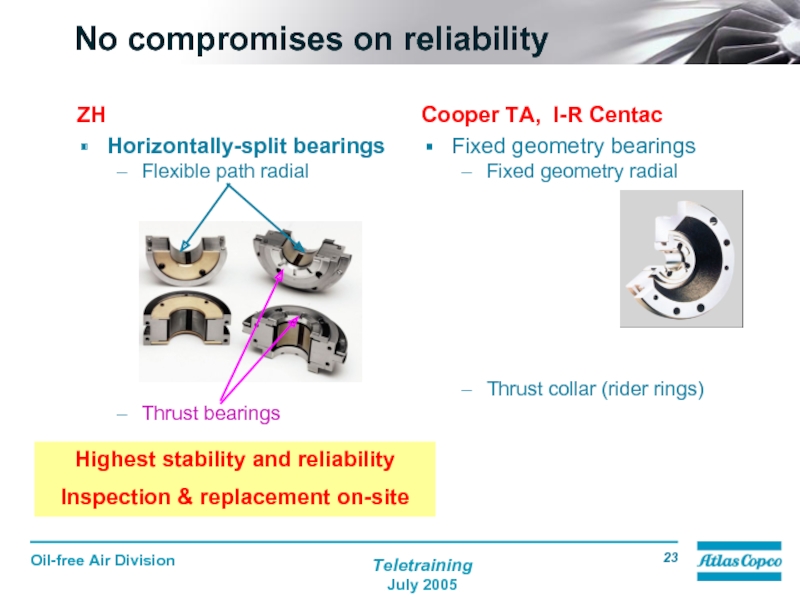

Слайд 23No compromises on reliability

ZH

Horizontally-split bearings

Flexible path radial

Thrust bearings

Cooper TA, I-R Centac

Fixed

Fixed geometry radial

Thrust collar (rider rings)

Highest stability and reliability

Inspection & replacement on-site

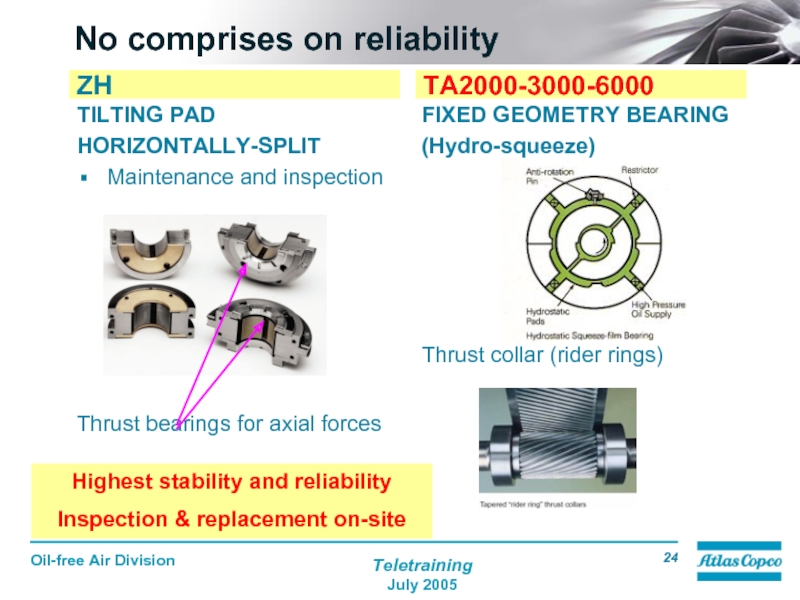

Слайд 24No comprises on reliability

TILTING PAD

HORIZONTALLY-SPLIT

Maintenance and inspection

Thrust bearings for axial forces

FIXED

(Hydro-squeeze)

Thrust collar (rider rings)

ZH

TA2000-3000-6000

Highest stability and reliability

Inspection & replacement on-site

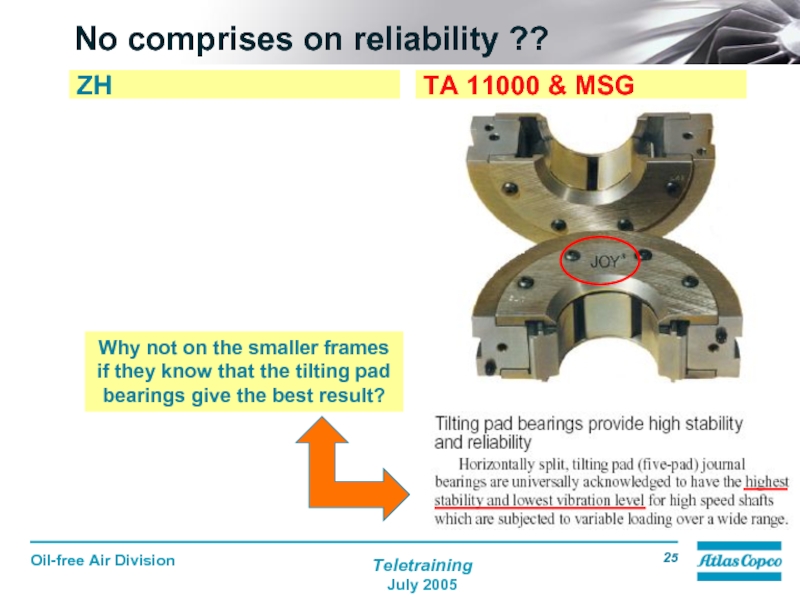

Слайд 25No comprises on reliability ??

ZH

TA 11000 & MSG

Why not on the

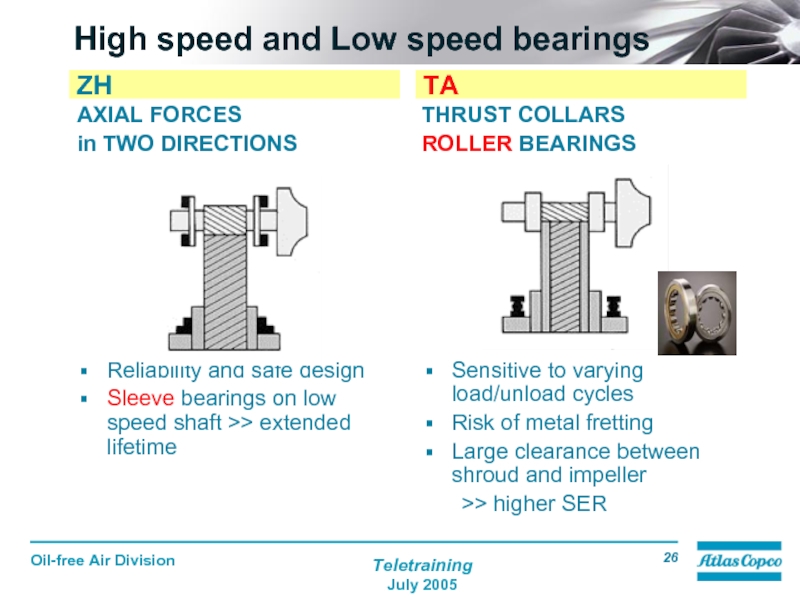

Слайд 26High speed and Low speed bearings

AXIAL FORCES

in TWO DIRECTIONS

Reliability and

Sleeve bearings on low speed shaft >> extended lifetime

THRUST COLLARS

ROLLER BEARINGS

Sensitive to varying load/unload cycles

Risk of metal fretting

Large clearance between shroud and impeller

>> higher SER

ZH

TA

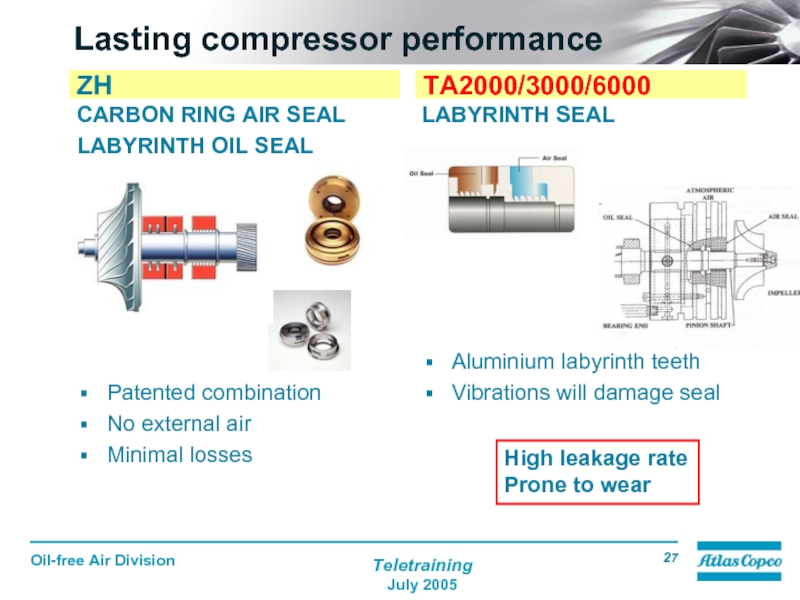

Слайд 27Lasting compressor performance

CARBON RING AIR SEAL

LABYRINTH OIL SEAL

Patented combination

No external air

Minimal losses

LABYRINTH SEAL

Aluminium labyrinth teeth

Vibrations will damage seal

ZH

TA2000/3000/6000

High leakage rate

Prone to wear

Слайд 28Designed for easy maintenance

MOTOR DRIVEN DEMISTER

No external air

No fumes leaking to

EJECTOR TYPE VACUUM

visible oil spill to atmosphere

25 m³/h (15 cfm) instrument air permanent consumption

ZH

TA2000-3000-6000

Слайд 33CENTAC Product naming

50 Cycles

3ACII Frame size

C Centac

255 255 im³/min

M Motor driven

X 50 Hz

3 3 stages

60 cycles

3ACII Frame size

C Centac

90 90x

M Motor driven

3 3 stages

Слайд 34Convenience of a packaged unit

Complete packaged unit

Clear capital cost

No costly additions

Easy

Conventional packaged design

Uncomplete machine

Loose delivered items

Costly installation

ZH

I-R CENTAC

Слайд 35Lowest Noise level in industry

ZH

Optional noise hood

68 ... 74 dBA

Competition

No silencing

Typically 82+ dBA

Слайд 36Convenience of packaged unit

Complete packaged unit

Levelled floor

No anchoring system

Conventional packaged unit

Heavy

Anchoring systems

ZH

Competition

Слайд 37Clear capital cost

The complete package includes

Air intake filter and silencer

Inlet guide

Aftercooler

Check valve

Cooling water manifold

Drain traps on all coolers

Compensators on air and

water inlet and outlets

IP23 motor

Control and safety system

integrated modulating blow-off valve

and blow-off silencer

Слайд 38Standard Scope of Supply Includes:

Built in lubrication and cooling systems

Control system

Single point flanged connections for air and water

Single point power connection for low voltage motors

Inlet air filter & by-Pass silencer shipped loose, to be mounted separately

Options:

Silencing canopy 75 dB(A), adder $9,000

Inlet guide vanes, adder $8,000

Cu-Ni cooler bundle tubes, adder $4,000

Centac CV2

Слайд 39Standard Scope of Supply Includes:

Built in lubrication and cooling systems,

Foot mounted motor

Control system

Inlet air filter & by-Pass silencer shipped loose, to be mounted separately

Options:

Silencing canopy, adder $12,000

Inlet guide vanes, adder $10,000

Cooling water manifold, adder $6,000

Copper-nickel cooler bundle tubes, adder $5,000

Centac C950

Слайд 40Standard Scope of Supply Includes:

Built in lubrication and cooling systems,

Foot mounted motor

Control system

Inlet air filter & by-Pass silencer shipped loose, to be mounted separately

Options:

Silencing canopy, adder $15,000

Inlet guide vanes, adder $16,000

Cooling water manifold, adder $8,000

Copper-nickel cooler bundle tubes, adder $7,000

Centac 3CII

Слайд 41Convenience of packaged unit

Complete packaged unit

AIR INLET SYSTEM

MOUNTED IN PACKAGE

Conventional

LOOSE DELIVERED

MOUNTED BY CUSTOMER ON-SITE

Inlet filter system

Air intake piping

Air intake screen

Air in/out compensators

ZH

Competition

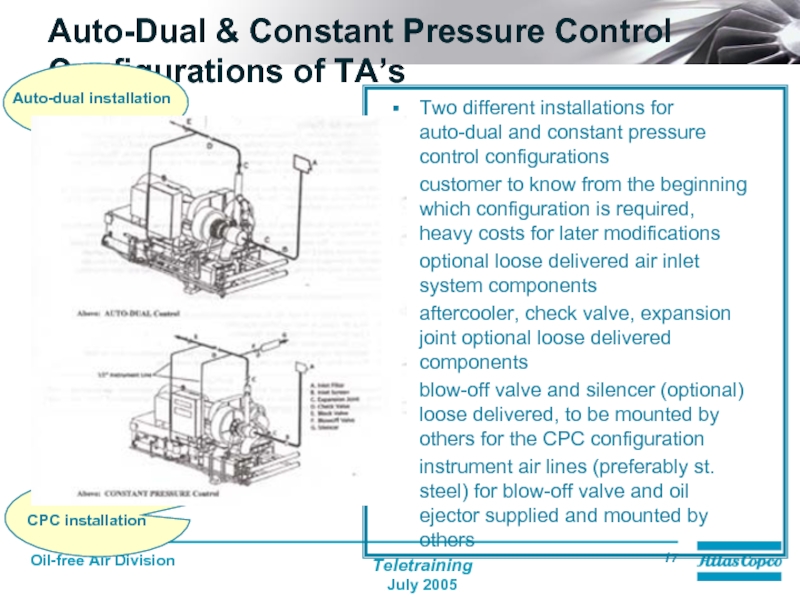

Слайд 42Convenience of packaged unit

INTEGRATED & MOUNTED

Low noise Integrated Blow-off silencer

Piping

No need

Modulating blow-off valve

Integrated after cooler

LOOSE DELIVERED COMPONENTS

Relying on external instrument air

ZH

Competition

Слайд 43Convenience of packaged unit

INTEGRATED & MOUNTED

Cooling water manifold

Water in/outlet compensator

Condensate drain

LOOSE DELIVERED

MOUNTED ON-SITE

ZH

Competition

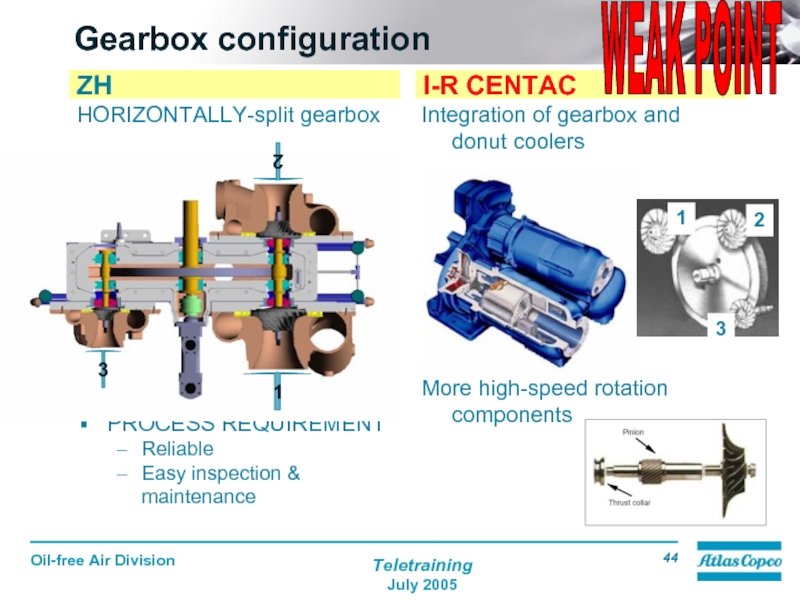

Слайд 44Gearbox configuration

HORIZONTALLY-split gearbox

PROCESS REQUIREMENT

Reliable

Easy inspection & maintenance

Integration of gearbox and donut

More high-speed rotation components

ZH

I-R CENTAC

1

3

2

WEAK POINT

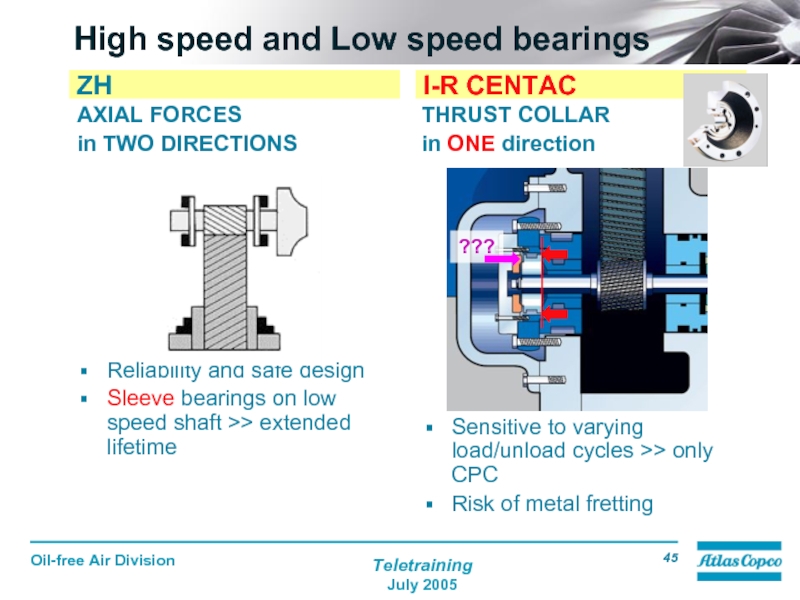

Слайд 45High speed and Low speed bearings

AXIAL FORCES

in TWO DIRECTIONS

Reliability and

Sleeve bearings on low speed shaft >> extended lifetime

THRUST COLLAR

in ONE direction

Sensitive to varying load/unload cycles >> only CPC

Risk of metal fretting

ZH

I-R CENTAC

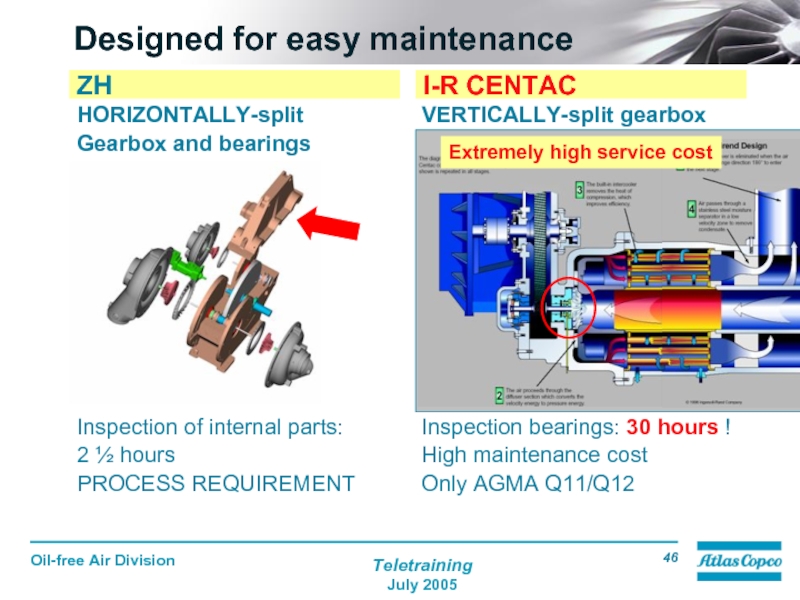

Слайд 46

Designed for easy maintenance

HORIZONTALLY-split

Gearbox and bearings

Inspection of internal parts:

2 ½

PROCESS REQUIREMENT

VERTICALLY-split gearbox

Inspection bearings: 30 hours !

High maintenance cost

Only AGMA Q11/Q12

ZH

I-R CENTAC

Extremely high service cost

Слайд 47Reliability first with quality gears

COMPLETE GEAR/PINIONS

AGMA Q13

Highest quality in industry

Increase of

Lower mechanical forces

Lower noise levels

Reduced gearbox losses

AGMA Q12

Replacement item

ZH

Competition

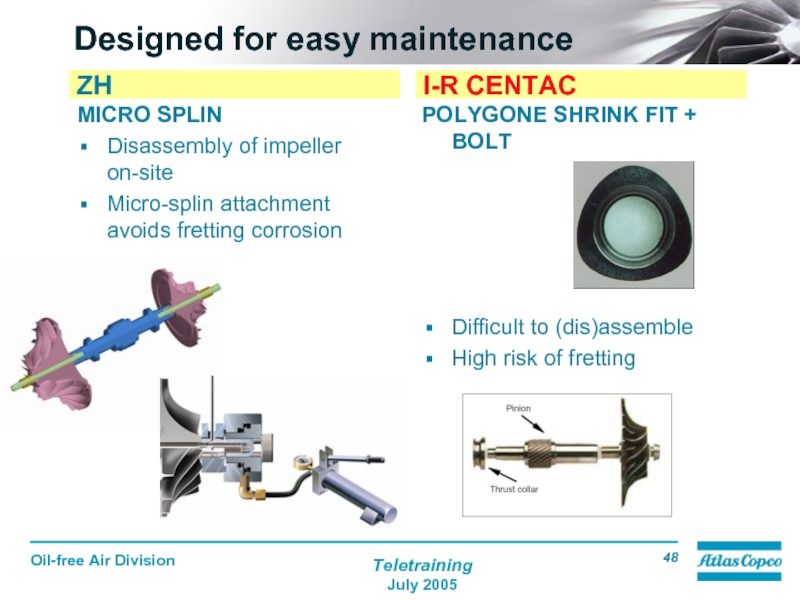

Слайд 48Designed for easy maintenance

MICRO SPLIN

Disassembly of impeller on-site

Micro-splin attachment avoids fretting

POLYGONE SHRINK FIT + BOLT

Difficult to (dis)assemble

High risk of fretting

ZH

I-R CENTAC

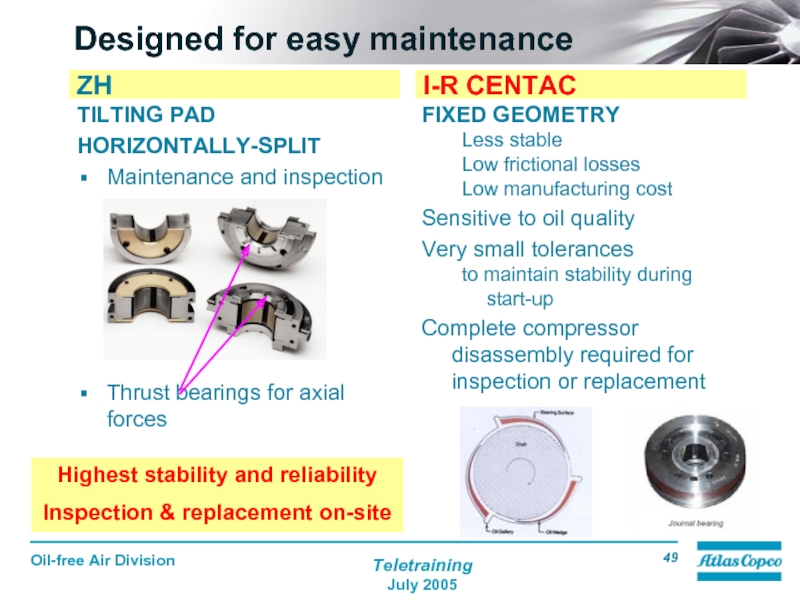

Слайд 49Designed for easy maintenance

FIXED GEOMETRY

Less stable

Low frictional losses

Low manufacturing cost

Sensitive to

Very small tolerances

to maintain stability during start-up

Complete compressor disassembly required for inspection or replacement

ZH

I-R CENTAC

TILTING PAD

HORIZONTALLY-SPLIT

Maintenance and inspection

Thrust bearings for axial forces

Highest stability and reliability

Inspection & replacement on-site

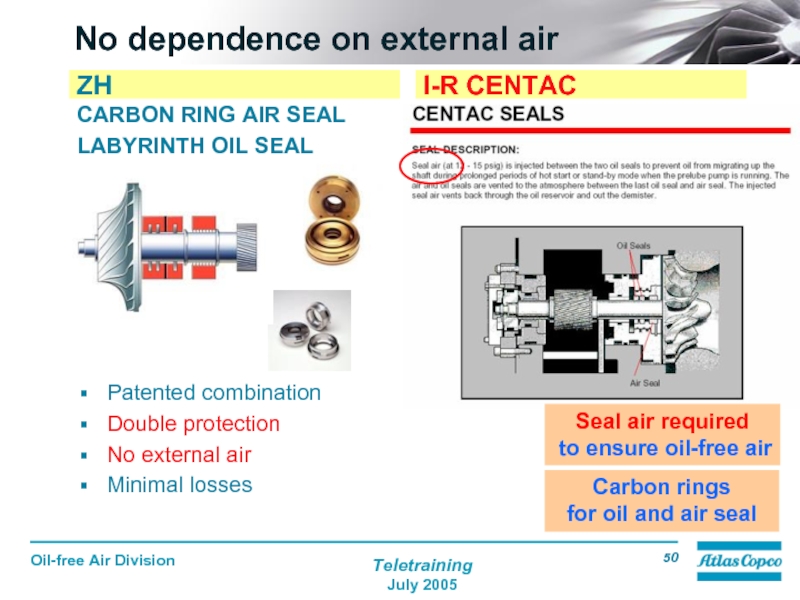

Слайд 50No dependence on external air

ZH

I-R CENTAC

Carbon rings

for oil and air

Seal air required

to ensure oil-free air

CARBON RING AIR SEAL

LABYRINTH OIL SEAL

Patented combination

Double protection

No external air

Minimal losses

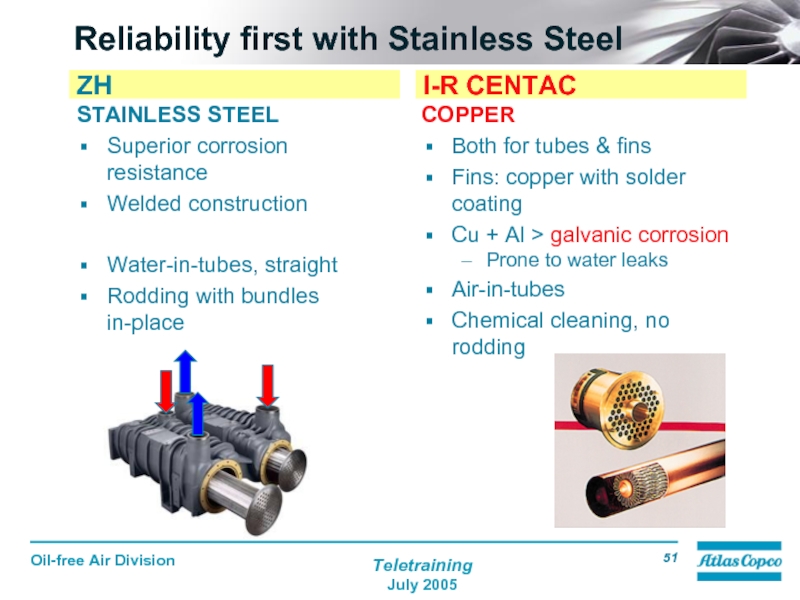

Слайд 51Reliability first with Stainless Steel

STAINLESS STEEL

Superior corrosion resistance

Welded construction

Water-in-tubes, straight

Rodding with

COPPER

Both for tubes & fins

Fins: copper with solder coating

Cu + Al > galvanic corrosion

Prone to water leaks

Air-in-tubes

Chemical cleaning, no rodding

ZH

I-R CENTAC

Слайд 52Designed for easy maintenance

COPPER

Coolers are consumable parts

Chemical cleaning

Corrosed internals

Stainless steel extremely

Copper Nickel optionally

ZH

I-R CENTAC

Cooler performance not affected due to corrosion-resistant coating

Clearances between impeller and inducer not affected over time due to coating

WEAK POINT

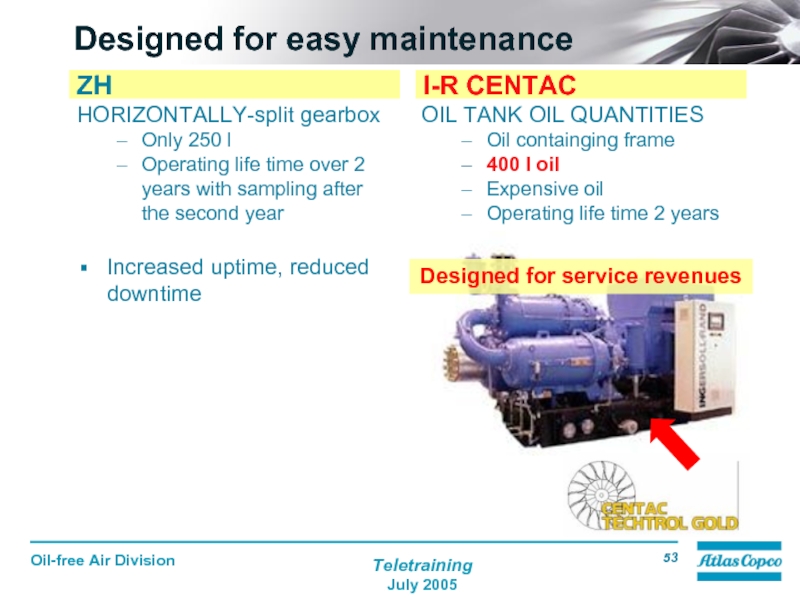

Слайд 53Designed for easy maintenance

HORIZONTALLY-split gearbox

Only 250 l

Operating life time over 2

Increased uptime, reduced downtime

OIL TANK OIL QUANTITIES

Oil containging frame

400 l oil

Expensive oil

Operating life time 2 years

ZH

I-R CENTAC

Designed for service revenues

Слайд 54Designed for easy maintenance

MOTOR DRIVEN DEMISTER

No external air

No fumes leaking to

CARTRIDGE

visible oil spill to atmosphere

ZH

I-R CENTAC

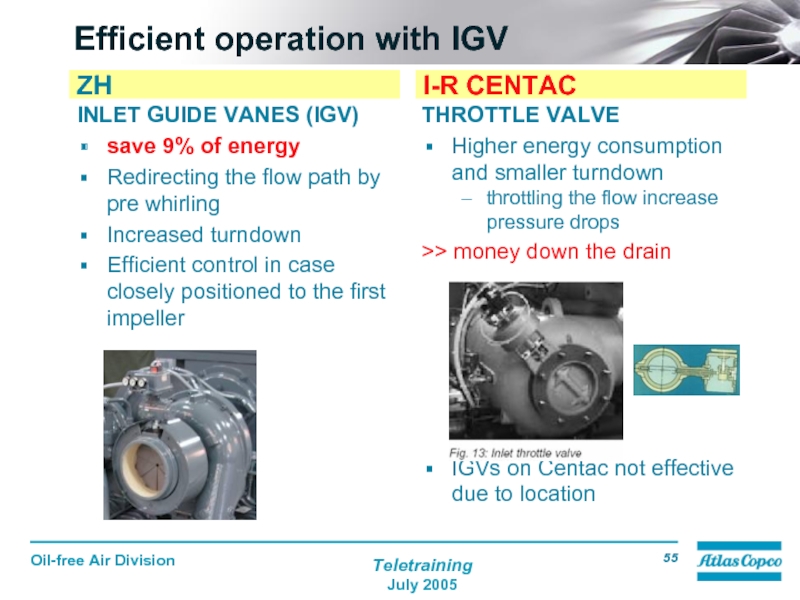

Слайд 55Efficient operation with IGV

INLET GUIDE VANES (IGV)

save 9% of energy

Redirecting

Increased turndown

Efficient control in case closely positioned to the first impeller

THROTTLE VALVE

Higher energy consumption and smaller turndown

throttling the flow increase pressure drops

>> money down the drain

IGVs on Centac not effective due to location

ZH

I-R CENTAC

Слайд 56Capacity control

Inlet throttle valve

Standard Inlet throttle valve

pneumatic actuator requires externally-provided instrument

Waste of energy at part load up to 9% compared to inlet guide vanes

Слайд 57Capacity control

Optional inlet Guide Vanes are not effective as the distance

$6,000 to 12,000 depending on machine size

Optional

Inlet Guide Vanes (IGV)

Слайд 58No dependence on external air

ELECTRICAL ACTUATORS

No dependence on external air supply

On

PNEUMATIC ACTUATORS

Machine trips due to failure in supply of instrument air

ZH

I-R CENTAC

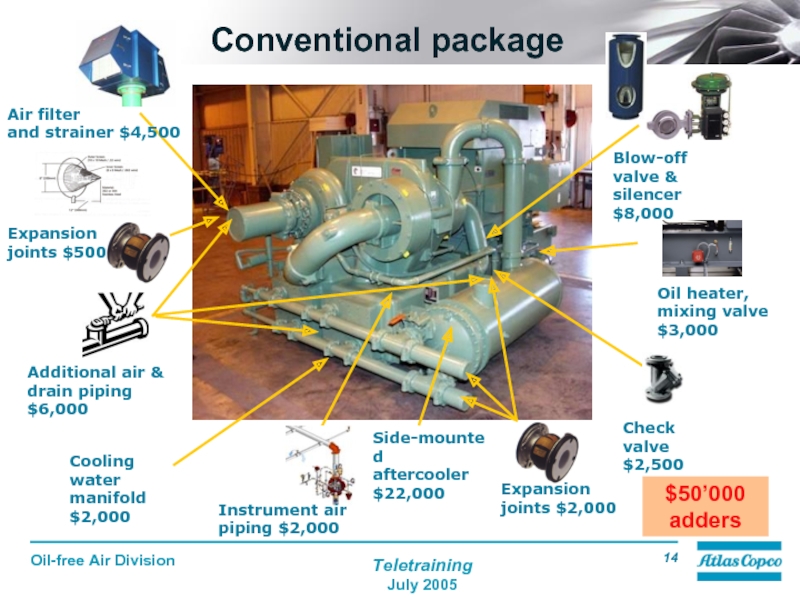

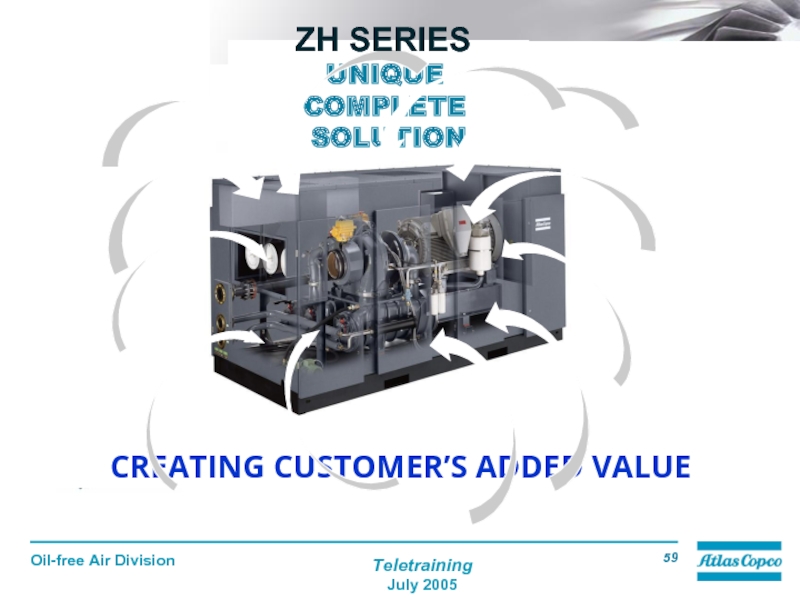

Слайд 59Aftercooler

Cooling Water Manifold

Check Valve

Blow-off Valve

Blow-off Silencer

Control Valve

Inlet Filter/Silencer

Anchor Bolts

Special Foundation

Inlet Compensator

Outlet

Additional Piping

External Buffer Air

UNIQUE

COMPLETE

SOLUTION

CREATING CUSTOMER’S ADDED VALUE

Competitor’s Puzzle

ZH SERIES