- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Axles and shafts презентация

Содержание

- 1. Axles and shafts

- 2. AXLES AND SHAFTS Links intended to carry

- 3. AXLES Axles are intended to support rotating

- 4. SHAFTS Shafts are designed to carry links

- 5. CLASSIFICATION OF SHAFTS According to purpose

- 6. CLASSIFICATION OF SHAFTS 2. According to the

- 7. CLASSIFICATION OF SHAFTS 3. According to the

- 8. CLASSIFICATION OF SHAFTS 4. According to the

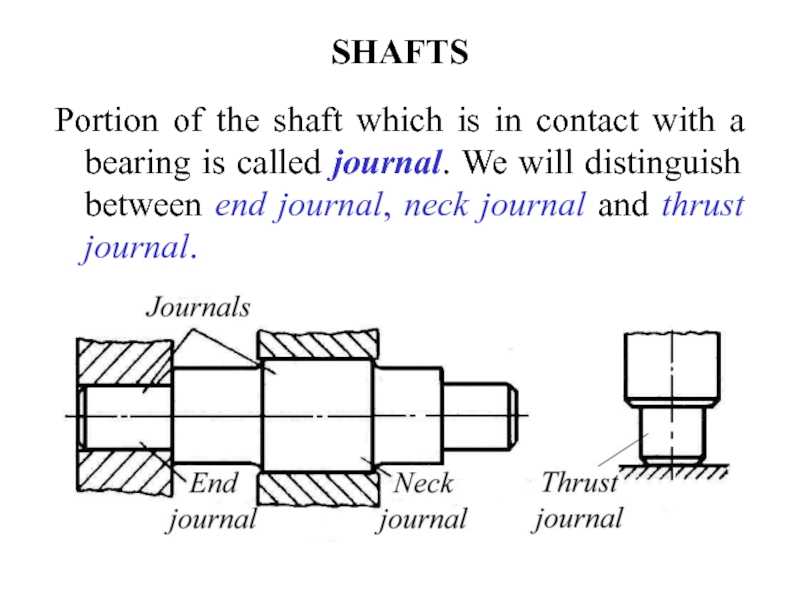

- 9. SHAFTS Portion of the shaft which is

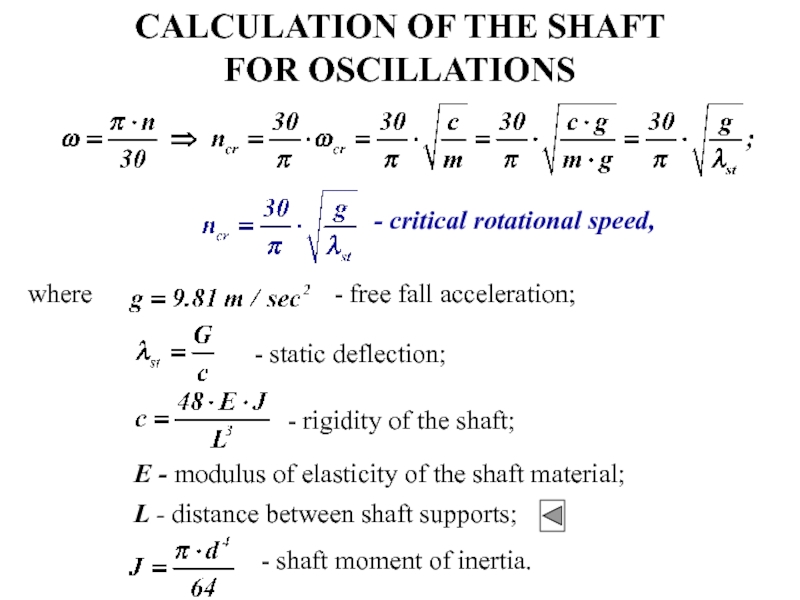

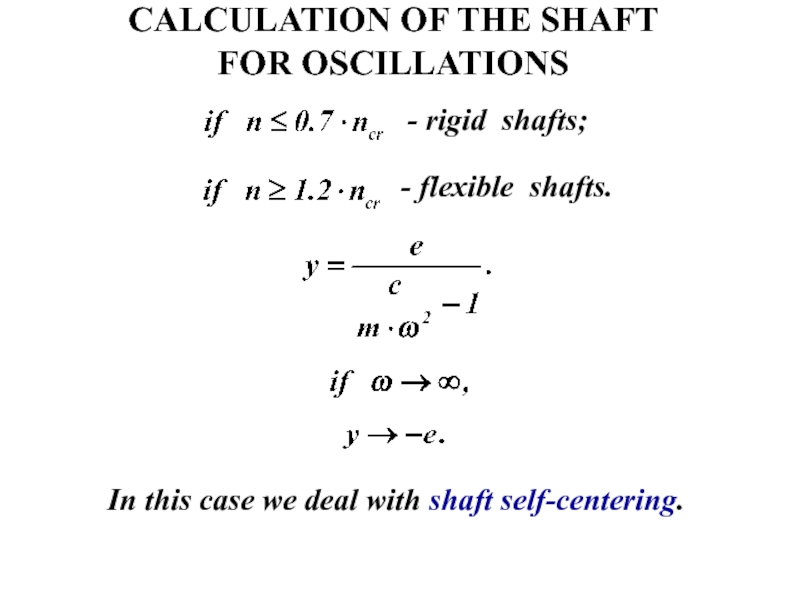

- 10. CALCULATION OF SHAFTS Strength;

- 11. CALCULATION OF SHAFTS FOR STRENGTH Determination

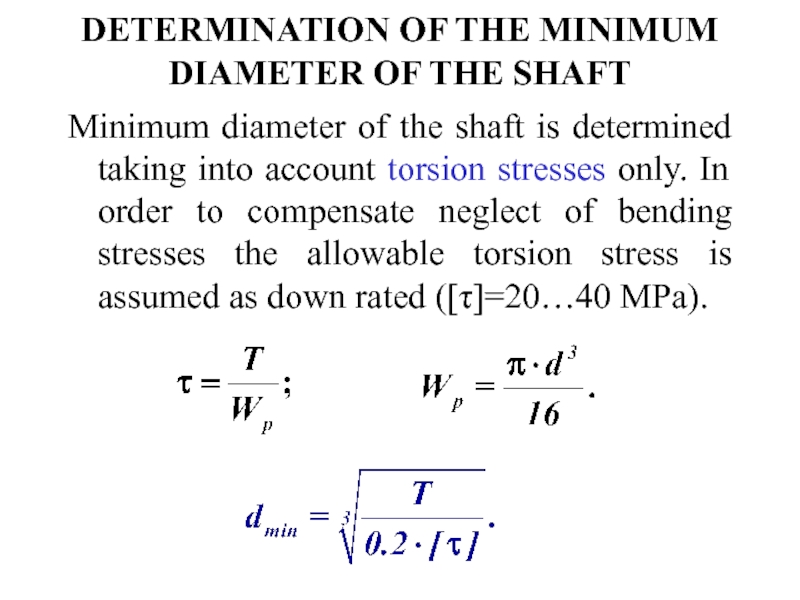

- 12. DETERMINATION OF THE MINIMUM DIAMETER OF THE

- 13. DESIGNING THE SHAFT CONSTRUCTION Input shaft Half coupling Seal Bearing Bearing Pinion

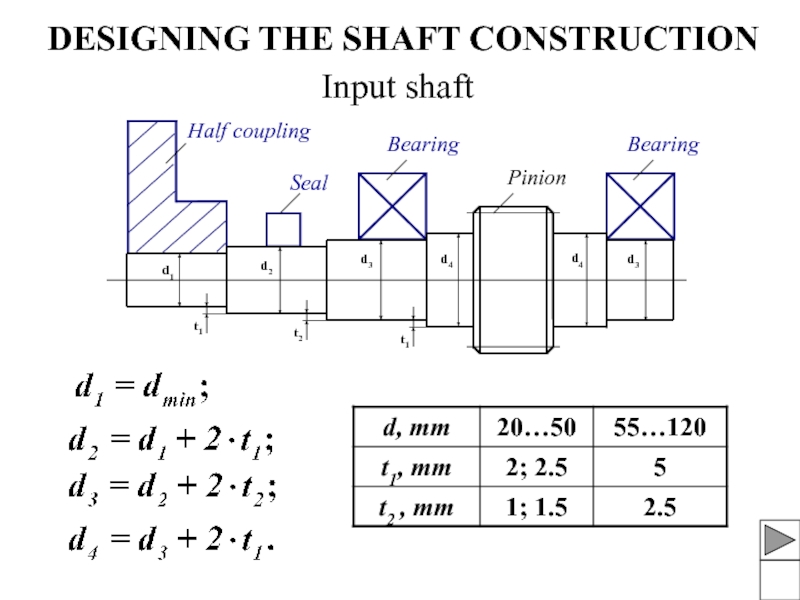

- 14. SEALS Seals are divided into: Commercial

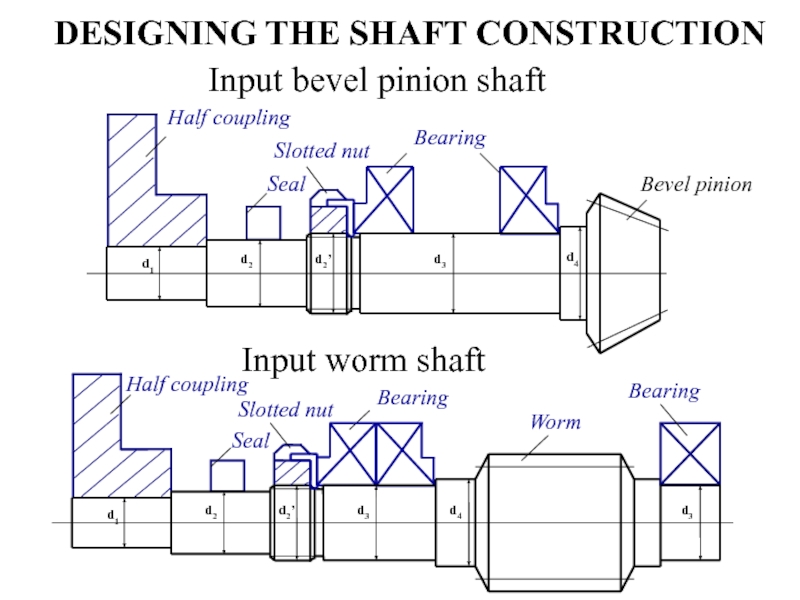

- 15. DESIGNING THE SHAFT CONSTRUCTION Input bevel pinion shaft Input worm shaft

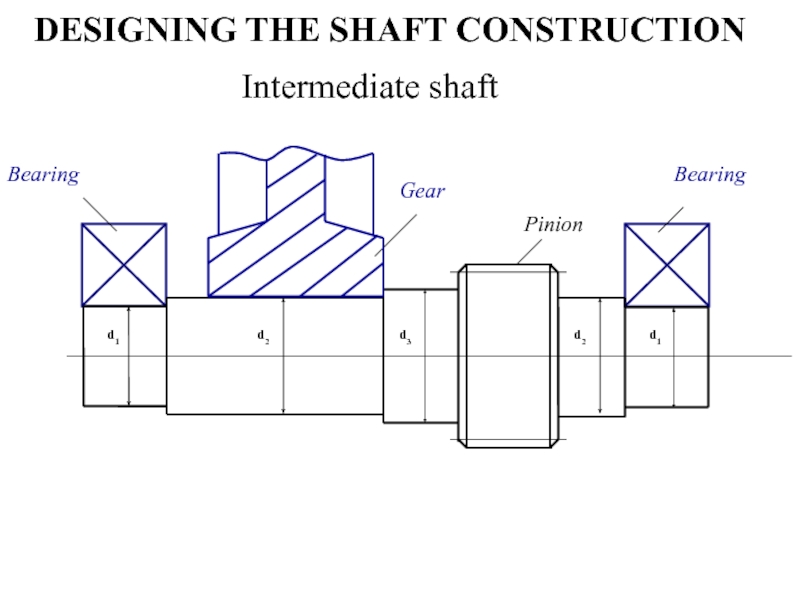

- 16. DESIGNING THE SHAFT CONSTRUCTION Intermediate shaft

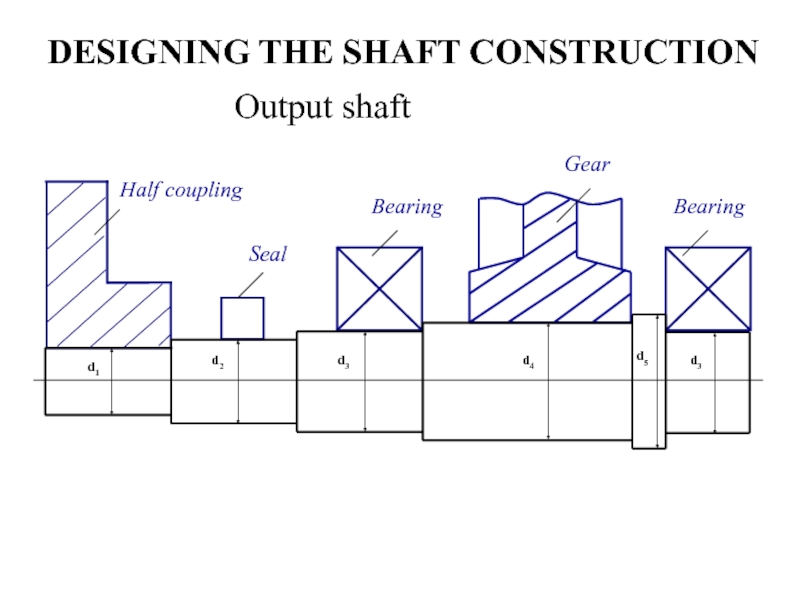

- 17. DESIGNING THE SHAFT CONSTRUCTION Output shaft Bearing

- 18. SPUR GEAR Thickness of the rim

- 19. WORM GEAR Thickness of the bronze ring

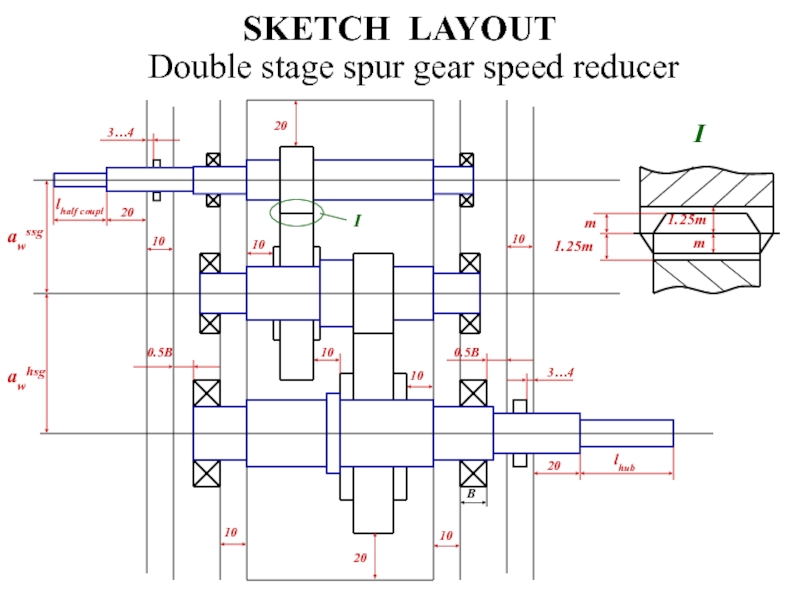

- 20. SKETCH LAYOUT Double stage spur gear speed

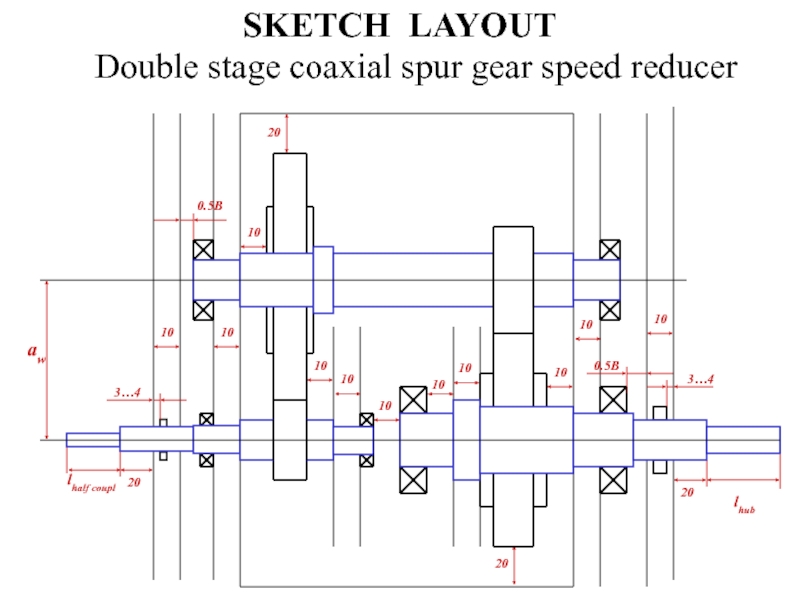

- 21. SKETCH LAYOUT Double stage coaxial spur gear

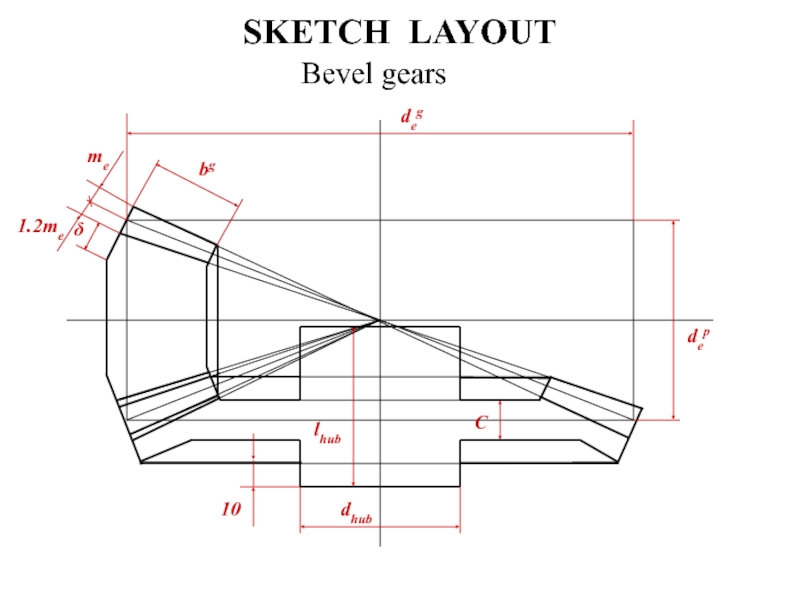

- 22. SKETCH LAYOUT Bevel gears

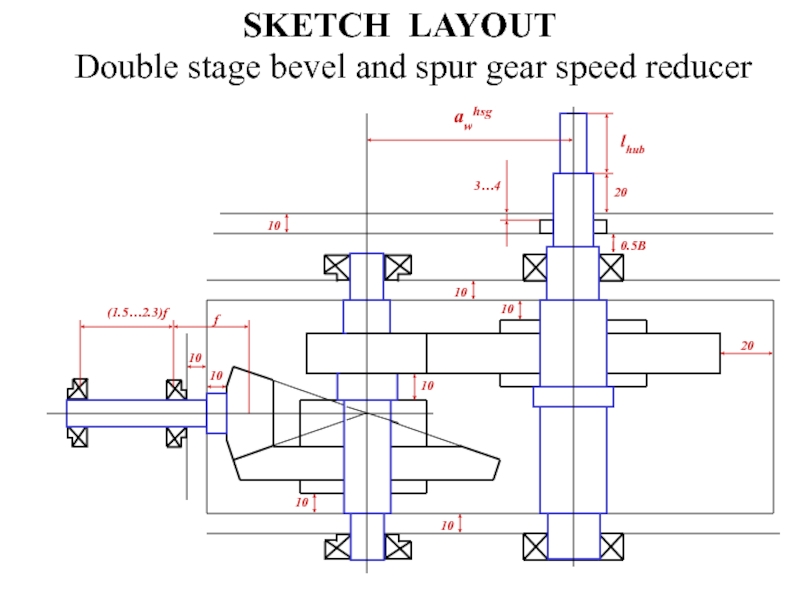

- 23. SKETCH LAYOUT Double stage bevel and spur

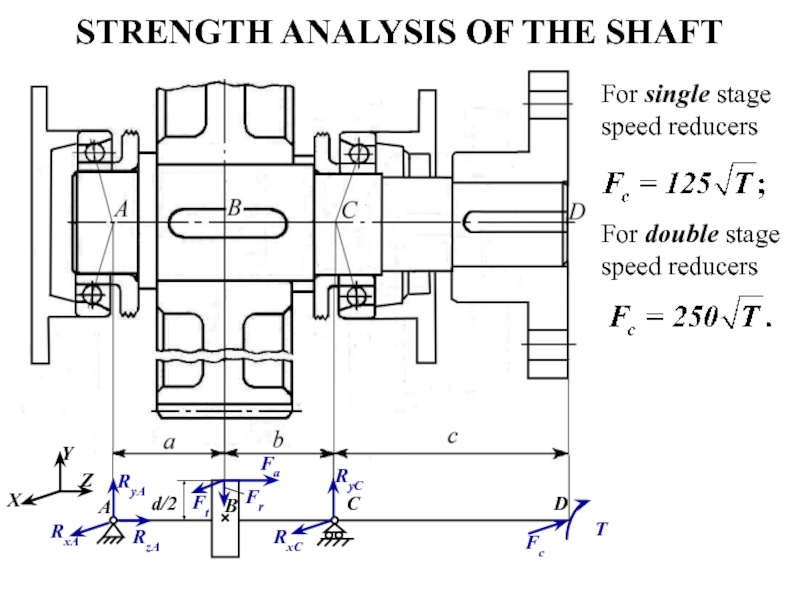

- 24. STRENGTH ANALYSIS OF THE SHAFT For single

- 25. STRENGTH ANALYSIS OF THE SHAFT 1. Draw

- 26. STRENGTH ANALYSIS OF THE SHAFT Checking:

- 27. STRENGTH ANALYSIS OF THE SHAFT T 7.

- 28. STRENGTH ANALYSIS OF THE SHAFT Calculation of

- 29. STRENGTH ANALYSIS OF THE SHAFT Calculation of

- 30. STRENGTH ANALYSIS OF THE SHAFT ψσ =

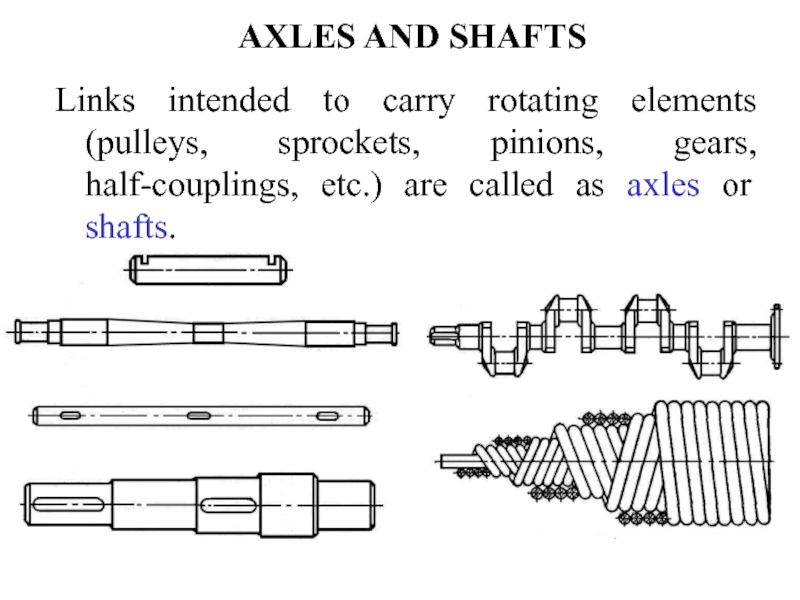

Слайд 2AXLES AND SHAFTS

Links intended to carry rotating elements (pulleys, sprockets, pinions,

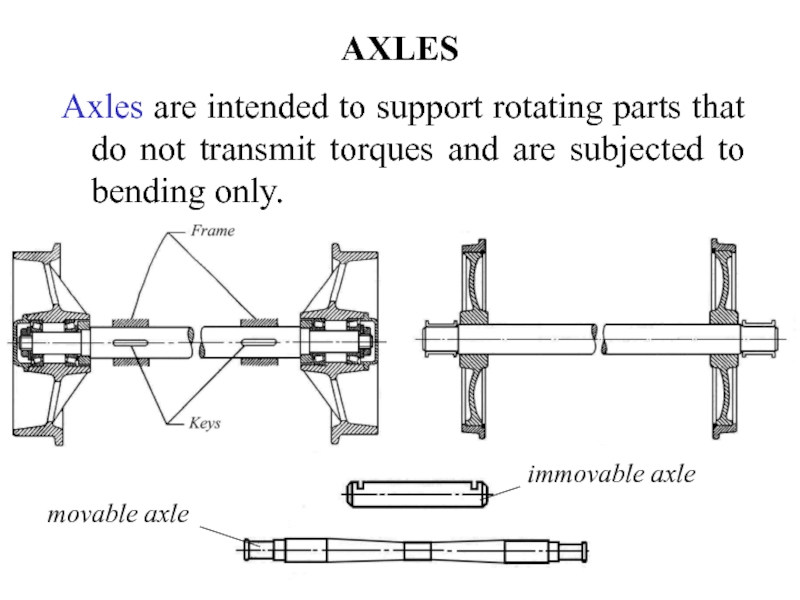

Слайд 3AXLES

Axles are intended to support rotating parts that do not transmit

immovable axle

movable axle

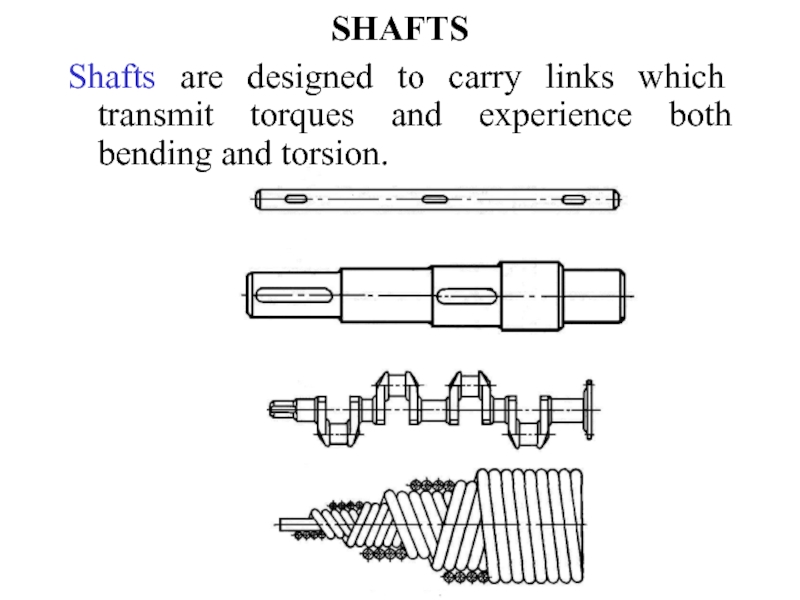

Слайд 4SHAFTS

Shafts are designed to carry links which transmit torques and experience

Слайд 5CLASSIFICATION OF SHAFTS

According to purpose

Shafts of various drives (gear drives, belt

Main shafts of mechanisms and machines whose function is to carry not only drive elements but other elements that do not transmit torques such as rotors, fly-wheels, turbine disks, etc.

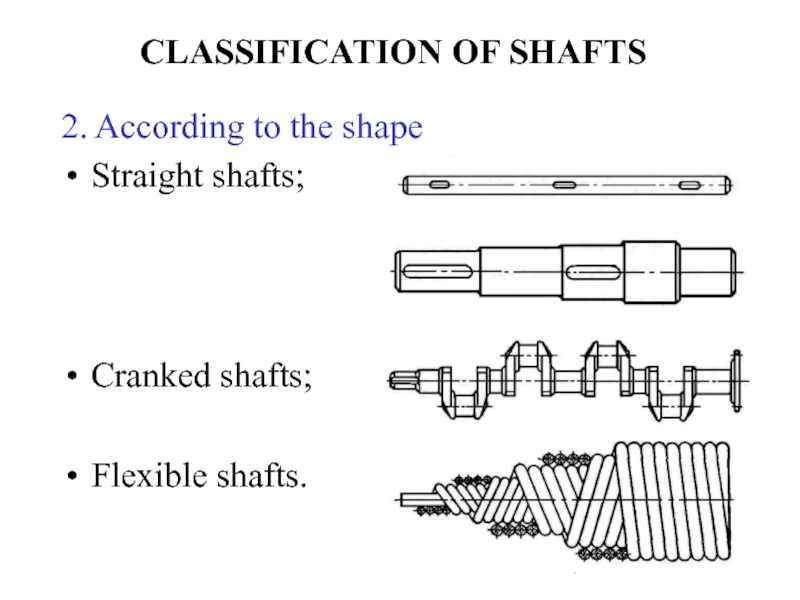

Слайд 6CLASSIFICATION OF SHAFTS

2. According to the shape

Straight shafts;

Cranked shafts;

Flexible shafts.

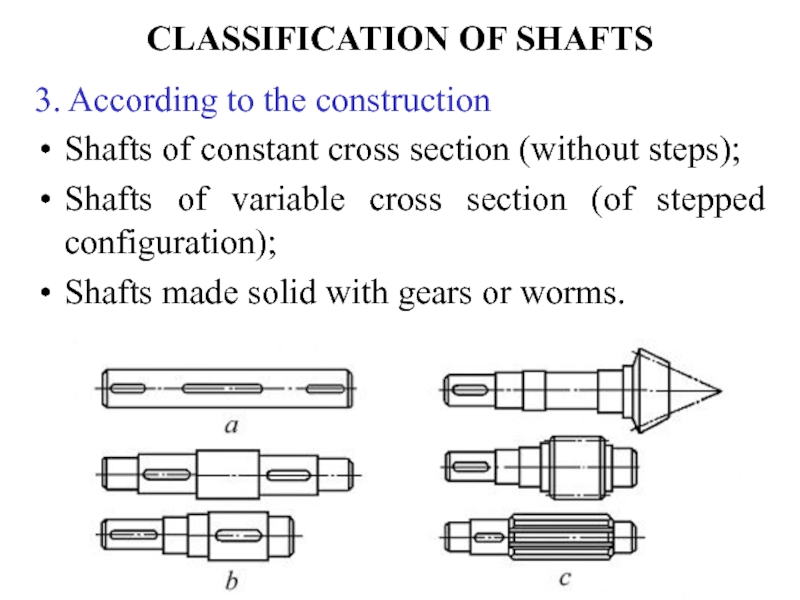

Слайд 7CLASSIFICATION OF SHAFTS

3. According to the construction

Shafts of constant cross section

Shafts of variable cross section (of stepped configuration);

Shafts made solid with gears or worms.

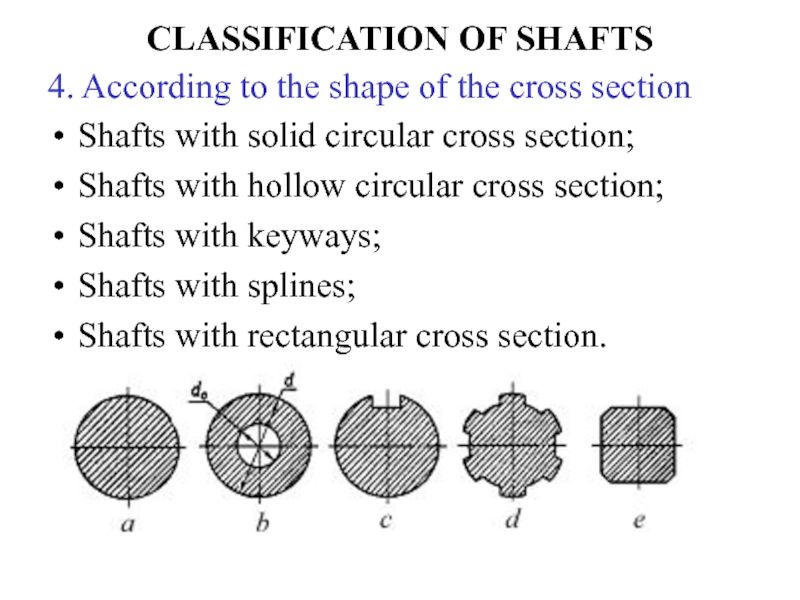

Слайд 8CLASSIFICATION OF SHAFTS

4. According to the shape of the cross section

Shafts

Shafts with hollow circular cross section;

Shafts with keyways;

Shafts with splines;

Shafts with rectangular cross section.

Слайд 9SHAFTS

Portion of the shaft which is in contact with a bearing

Слайд 11CALCULATION OF SHAFTS

FOR STRENGTH

Determination of the minimum diameter of the

Designing the shaft construction;

Strength analysis of the shaft.

Calculation of shafts for strength is divided into 3 stages:

Слайд 12DETERMINATION OF THE MINIMUM DIAMETER OF THE SHAFT

Minimum diameter of the

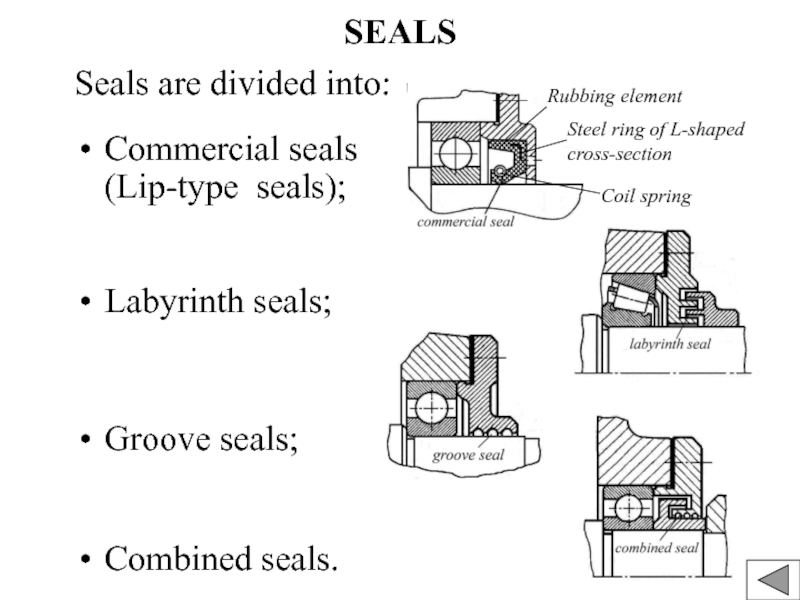

Слайд 14SEALS

Seals are divided into:

Commercial seals (Lip-type seals);

Labyrinth seals;

Groove seals;

Combined seals.

Rubbing element

Steel

Coil spring

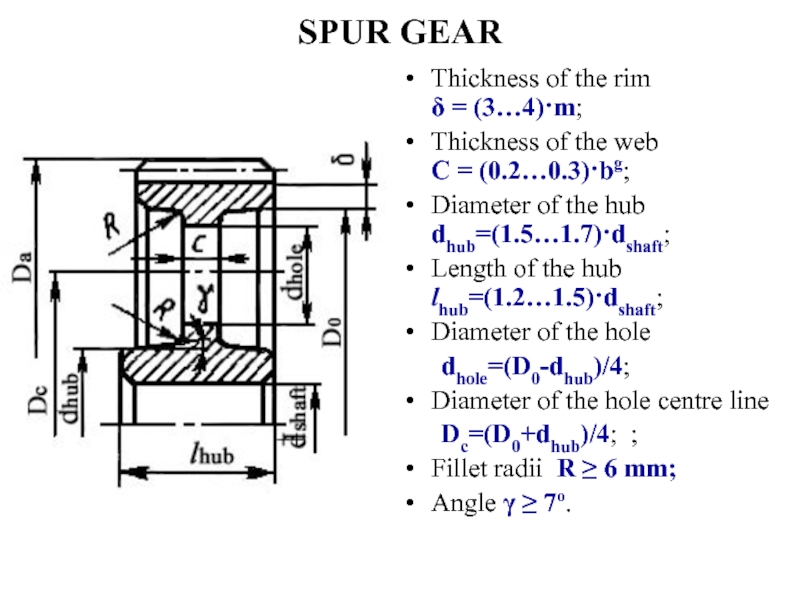

Слайд 18SPUR GEAR

Thickness of the rim

Thickness of the web C = (0.2…0.3)·bg;

Diameter of the hub dhub=(1.5…1.7)·dshaft;

Length of the hub lhub=(1.2…1.5)·dshaft;

Diameter of the hole

dhole=(D0-dhub)/4;

Diameter of the hole centre line

Dc=(D0+dhub)/4; ;

Fillet radii R ≥ 6 mm;

Angle γ ≥ 7º.

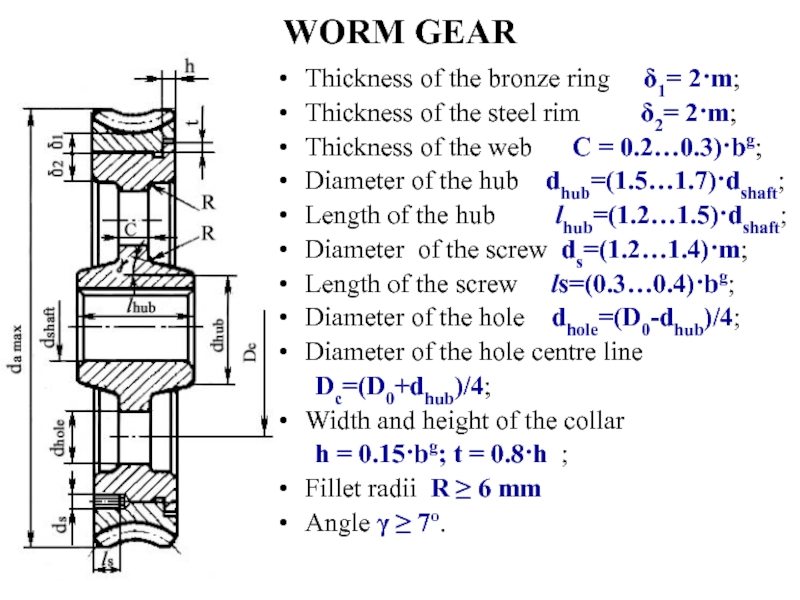

Слайд 19WORM GEAR

Thickness of the bronze ring δ1= 2·m;

Thickness of

Thickness of the web C = 0.2…0.3)·bg;

Diameter of the hub dhub=(1.5…1.7)·dshaft;

Length of the hub lhub=(1.2…1.5)·dshaft;

Diameter of the screw ds=(1.2…1.4)·m;

Length of the screw ls=(0.3…0.4)·bg;

Diameter of the hole dhole=(D0-dhub)/4;

Diameter of the hole centre line

Dc=(D0+dhub)/4;

Width and height of the collar

h = 0.15·bg; t = 0.8·h ;

Fillet radii R ≥ 6 mm

Angle γ ≥ 7º.

Слайд 24STRENGTH ANALYSIS OF THE SHAFT

For single stage

speed reducers

For double stage

speed reducers

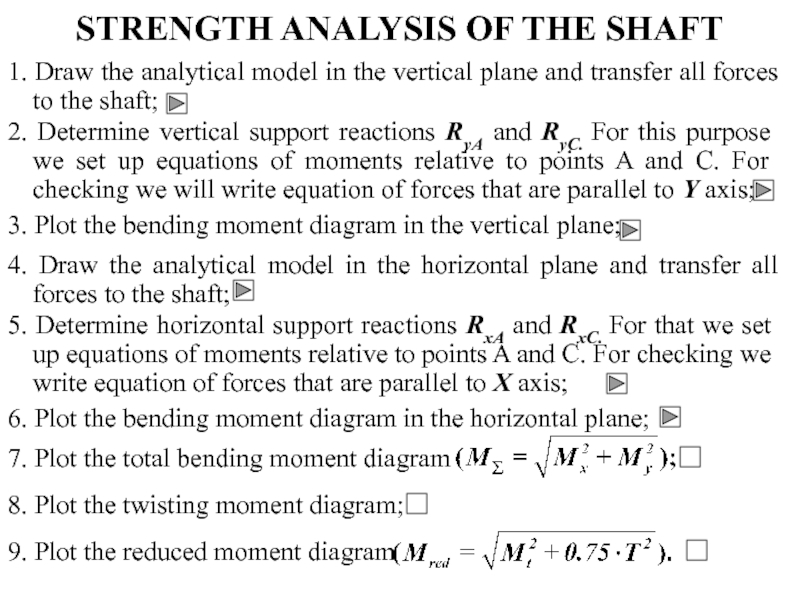

Слайд 25STRENGTH ANALYSIS OF THE SHAFT

1. Draw the analytical model in the

2. Determine vertical support reactions RyA and RyC. For this purpose we set up equations of moments relative to points A and C. For checking we will write equation of forces that are parallel to Y axis;

3. Plot the bending moment diagram in the vertical plane;

4. Draw the analytical model in the horizontal plane and transfer all forces to the shaft;

5. Determine horizontal support reactions RxA and RxC. For that we set up equations of moments relative to points A and C. For checking we write equation of forces that are parallel to X axis;

6. Plot the bending moment diagram in the horizontal plane;

7. Plot the total bending moment diagram

8. Plot the twisting moment diagram;

9. Plot the reduced moment diagram

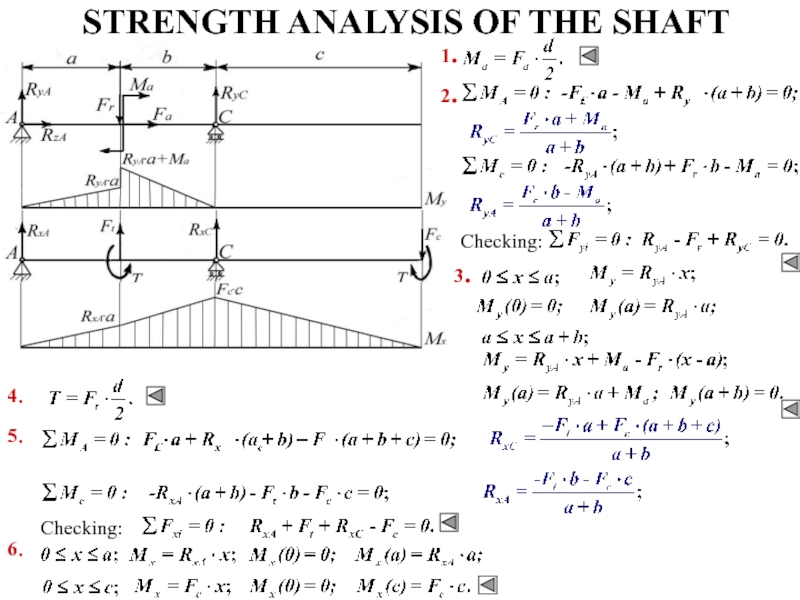

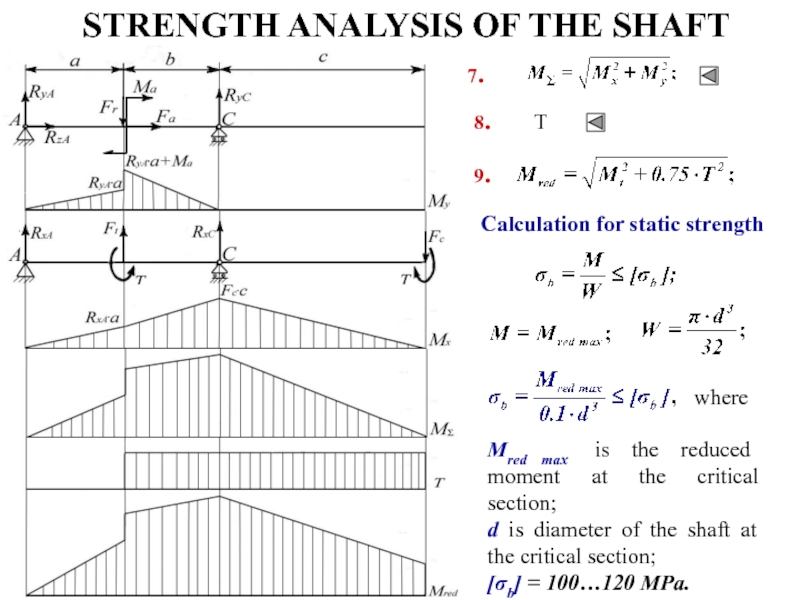

Слайд 27STRENGTH ANALYSIS OF THE SHAFT

T

7.

8.

9.

Calculation for static strength

Mred max is the

d is diameter of the shaft at the critical section;

[σb] = 100…120 MPa.

where

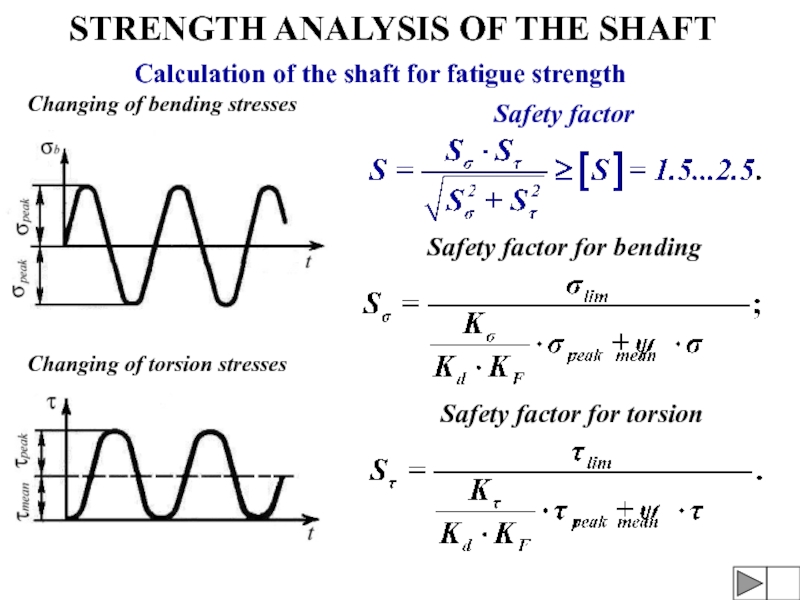

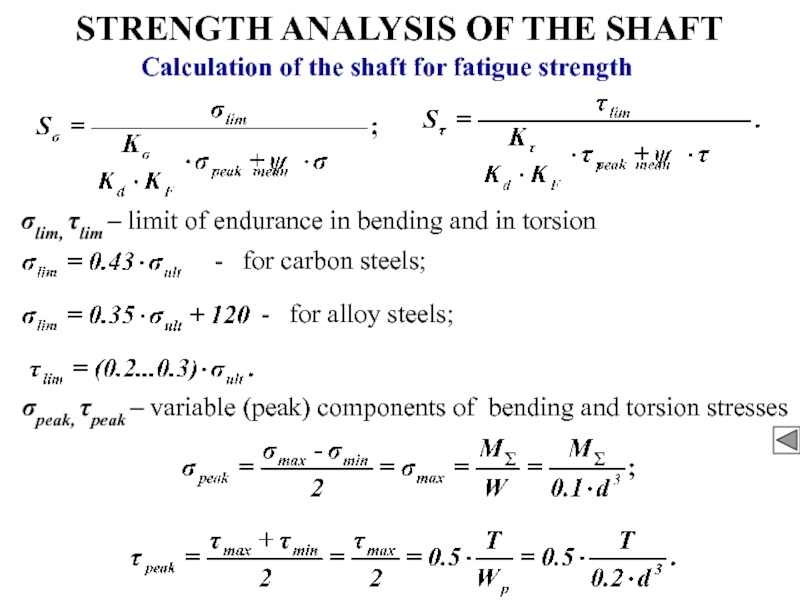

Слайд 28STRENGTH ANALYSIS OF THE SHAFT

Calculation of the shaft for fatigue strength

Changing

Changing of torsion stresses

Safety factor

Safety factor for bending

Safety factor for torsion

Слайд 29STRENGTH ANALYSIS OF THE SHAFT

Calculation of the shaft for fatigue strength

σlim,

- for carbon steels;

- for alloy steels;

σpeak, τpeak – variable (peak) components of bending and torsion stresses

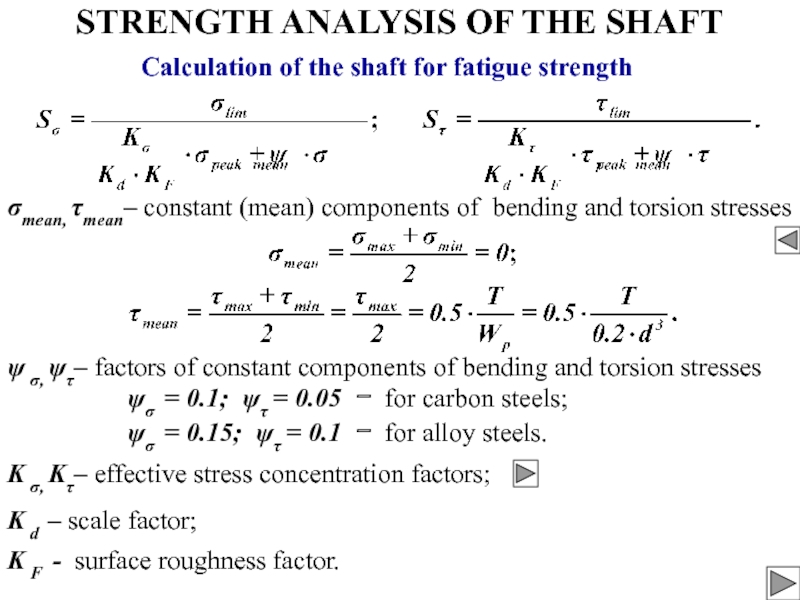

Слайд 30STRENGTH ANALYSIS OF THE SHAFT

ψσ = 0.1; ψτ = 0.05 −

ψσ = 0.15; ψτ = 0.1 − for alloy steels.

Calculation of the shaft for fatigue strength

σmean, τmean– constant (mean) components of bending and torsion stresses

ψ σ, ψτ– factors of constant components of bending and torsion stresses

K σ, Κτ– effective stress concentration factors;

K d – scale factor;

K F - surface roughness factor.