- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Abrasive materials. Classification, structure, properties and applications презентация

Содержание

- 1. Abrasive materials. Classification, structure, properties and applications

- 2. Abrasive materials (Latin abrasio-scraping down)-fine high hardness

- 3. Abrasives are classified: by appointment:

- 4. On the form of the instrument (material):

- 6. Abrasive cutting tools vary in shape, size,

- 7. Dental prostheses of various designs, Maxillofacial and

- 8. The smooth surface of the plastic or

- 9. The surface of the denture process

- 10. Grinding is called surface handling abrasive

- 11. Processing of materials using Abrasives is characterized

- 12. An important property of the abrasive tool

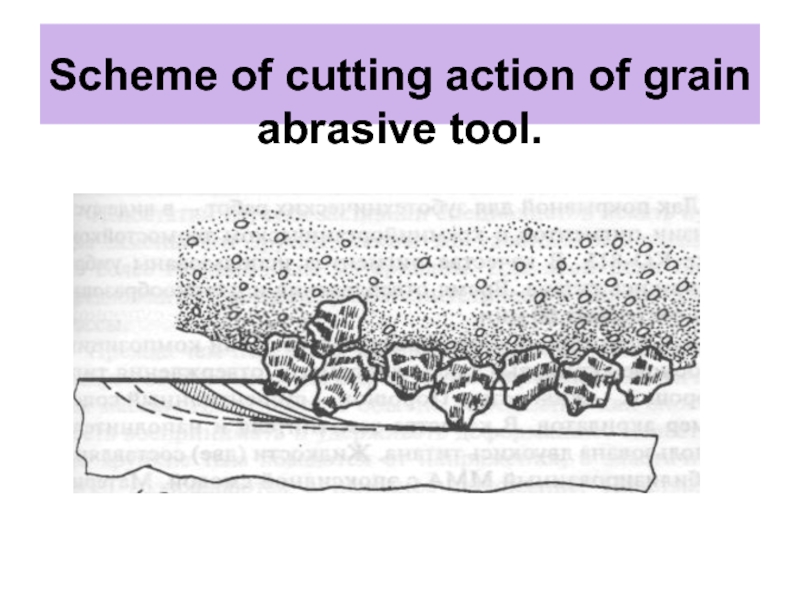

- 13. Scheme of cutting action of grain abrasive tool.

- 14. Abrasives for sanding are divided into

- 15. As a finishing material objects

- 16. Diamond is the hardest mineral is

- 17. Corundum prepares also artificially from the

- 18. Emery — grinding material distributed in

- 19. Carborundum — get artificially, for which a

- 20. Pumice is a rock formed when

- 21. The materials also include grinding machines

- 22. Ceramic binders are based on application

- 23. Bakelite adhesive materials are prepared on

- 24. Vulkanite s.v. are based on application

- 25. Some grinding material (pumice stone, Emery)

- 26. Polishing tools. Polishing is the

- 27. Polishing to abrasion, used in dental

- 28. Polishing process is similar to the

- 29. Introduction denture individual casting using refractory alloys

- 30. they must not contain substances that react

- 31. In modern foundries use plaster molding materials,

- 32. Phosphate molding materials consist of powder (zink

- 33. Siolite The moulding sand is designed for

- 34. Silicate molding materials is almost universally superseded

- 35. Silicate forming masses differ large coefficient of

- 36. Silamin applied when casting refractory models for

- 37. Кристосил-2 — формовочная масса для отливки цельнолитых

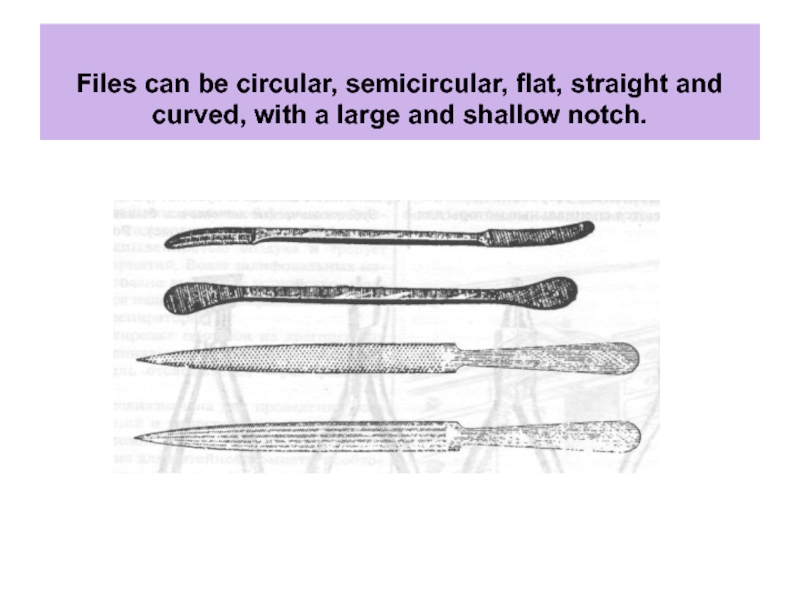

- 38. Files can be circular, semicircular, flat,

- 39. Natfili is the files with a thin notch, used during final processing of metal prostheses

Слайд 2Abrasive materials (Latin abrasio-scraping down)-fine high hardness substances used for surface

In a processed form of abrasive materials are used for stripping, stripping metal grinding, grinding, grinding, surface finishing the prosthesis.

They are solid crystalline or powdered minerals.

Слайд 3Abrasives are classified:

by appointment:

grinding;

polishing.

On the nature of

ceramic;

bakelite;

vulkanitovye;

Paste.

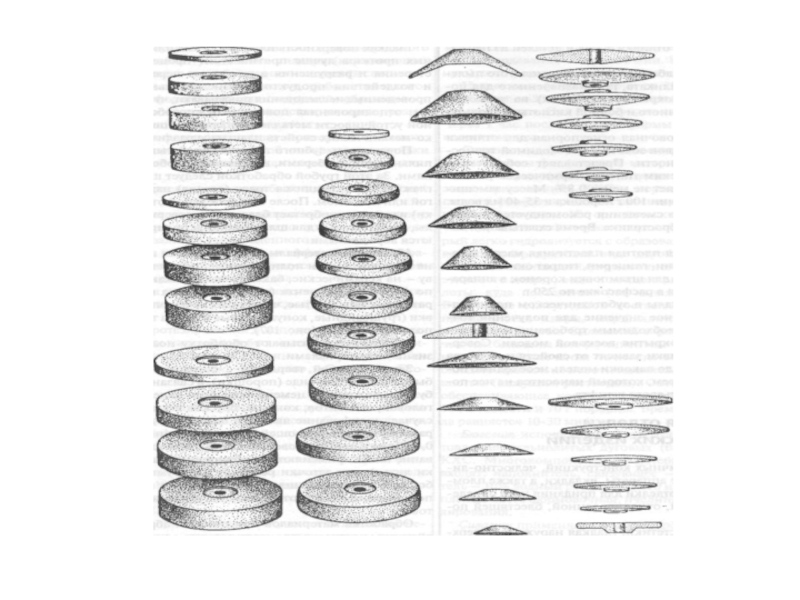

Слайд 4On the form of the instrument (material):

circles of various sizes

Emery cloth and paper.

Origin: natural; artificial.

Слайд 6Abrasive cutting tools vary in shape, size, hardness, grit abrasive nature

Abrasive properties:

hardness and strength;

form of abrasive particles or grains;

abrasive capacity;

the graininess.

Слайд 7Dental prostheses of various designs, Maxillofacial and orthodontic apparatus, tabs, as

forming plaque and solid deposits that form on the insufficiently polished places contribute irritate mucous membranes and are etiological factors of occurrence of some diseases of the oral cavity (stomatitis, gingivitis, dekubitale ulcers, etc.). Insufficiently polished surface, removable dentures, is a hotbed of formation of halitosis.

Слайд 8The smooth surface of the plastic or combined dentures better resists

Слайд 9

The surface of the denture process first files, scrapers, carbon.

For

After final finish (buffing) acquires a shiny surface. Materials used for grinding and polishing are referred to as abrasive.

Слайд 10

Grinding is called surface handling abrasive materials.

Grain hardness with sharp edges

In most cases, is selected to finish grinding operation, providing high accuracy (sometimes up to 0.002 mm) and surface finish (6-10 grades).

Grinding is also used for work (for cleaning castings), for sharpening cutting tools etc.

Слайд 11Processing of materials using Abrasives is characterized by the participation in

Слайд 12An important property of the abrasive tool is its ability to

Restoring the cutting capacity is due to the fact that when abrasive grains is blunt increasing cutting force and grains are destroyed exposing the other below

Слайд 14

Abrasives for sanding are divided into natural and artificial

To include the

Слайд 15 As a finishing material objects used for grinding, must meet certain

the hardness of the materials used must not be

hardness below which has been polished material;

grinding tools "salted", if it hardness too great to handle this material, or premature wear, if this hardness is low;

the shape of the abrasive grains must be multi-faceted to

provide cutting edge; materials must be manufacturable in use;

possess the ability to stick together (seal)

and well maintained in binders.

Слайд 16 Diamond is the hardest mineral is a crystalline form of carbon.

In the form of dust stuck on metal wheels and circles, it is used for preparation of the teeth before covering their crowns.

Corundum ranks second in hardness, it is a crystalline form of aluminium oxide (AlOz).

Слайд 17 Corundum prepares also artificially from the mineral bauxite, which does not

To obtain a crystalline alumina (corundum) smelting of bauxite is mixed with Coke. Hardness artificial corundum with increased content of aluminum oxide increases.

Especially solid highest grade corundum applied for grinding high hardness steels.

Слайд 18 Emery — grinding material distributed in nature in the form of

Слайд 19Carborundum — get artificially, for which a mixture consisting of Coke,

Silicone carbide grains differ by the exigencies of their faces and high hardness. A significant disadvantage is its large silicone fragility. Its grain is easy to break under load. Silicon carbide is used mainly in the form of grinding wheels and disks.

Слайд 20 Pumice is a rock formed when volcanic eruptions, has porous structure.

Слайд 21

The materials also include grinding machines quartz, glass and porcelain

For manufacturing

Слайд 22 Ceramic binders are based on application of a mixture of clay

This ligament is fire safe and possesses high mechanical strength. Used for the manufacture of various types of grinding wheels. Flawed products on this basis are the fragility and sensitivity to shock, so articles on ceramic Binder material used in installations with low turnover. The advantages of such bundles are moisture resistance and uniform hardness.

Слайд 23 Bakelite adhesive materials are prepared on the basis of bakelite, less

Circles or other forms of abrasives on this basis different elasticity, resistance to impact, smooth surface. This kind of cords used for the manufacture of an Emery paper or glass on a grinding cloth

Слайд 24 Vulkanite s.v. are based on application of a mixture of rubber

These bundles have greater elasticity and density than bakelite, but differ elasticity. Crop circles vulcanite bundle are indispensable when sanding, when of the circle requires not only grinding but also polishing effect. Polishing effect of these circles is due to the fluctuation of the ligament at a temperature in the working area of about 150° c and extruding abrasive grains in this wobbly bundle.

Слайд 25 Some grinding material (pumice stone, Emery) are applied in the form

Слайд 26

Polishing tools. Polishing is the

technical processing of the product (material) with

Слайд 27 Polishing to abrasion, used in dental practice, include the Fe2Oz iron

Слайд 28 Polishing process is similar to the process for grinding, but are

Слайд 29Introduction denture individual casting using refractory alloys (stainless steels, KHS) has

Слайд 30they must not contain substances that react with the casting, the

the form surface should not to the casting; to ensure the quality of the casting surface fire retardant powder must have a high degree of dispersion;

solidification time must be within 7-10 minutes;

they should create a wrapper to be able to absorb the gases produced by pouring molten metal;

they must have a value of coefficient of thermal expansion, sufficient to compensate for the shrinkage of metal solidifying.

Слайд 31In modern foundries use plaster molding materials, as well as phosphate

Plaster moulding material consists of gypsum (20-40%) and Silicon oxide. Plaster in this case is binding. Silicon monoxide attaches weight necessary amount of shrinkage strain and heat resistant. As regulators of solidification velocity and coefficient of thermal expansion in a mixture is added 2-3% sodium chloride or boric acid. Is kneaded mass on the water at temperature 18-20° c. Nominal temperature of heating form similar to pouring metal is 700-750° c.

Слайд 32Phosphate molding materials consist of powder (zink phosphate cement, quartz powder,,

These molding materials offset shrinkage during cooling of stainless steels that have temperature cubic dilation coefficient about 0.027 to-1. Shrinkage gold alloys is about 1.25%, and this compensates for shrinkage of gypsum form. Phosphate forms depending on the composition of 10-15 mines continues.

Слайд 33Siolite

The moulding sand is designed for fixed (including metal) prosthesis. Consists

Слайд 34Silicate molding materials is almost universally superseded phosphate materials. They have

Слайд 35Silicate forming masses differ large coefficient of thermal expansion. To ensure

Слайд 36Silamin applied when casting refractory models for manufacturing solid arc (CLASP)

Thermal expansion of the mass at a temperature of 500-700° c is not less than 0.6% -0.7. The beginning shvatyvanija mass stupalo through 10 minutes final hardening through 60 minutes. Ignition cracks formed.