- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Process, Power and Marine Division. Piping Task презентация

Содержание

- 1. Process, Power and Marine Division. Piping Task

- 2. © 2009. Intergraph Corporation. All Rights Reserved.

- 3. © 20049. Intergraph Corporation. All Rights Reserved.

- 4. © 2009. Intergraph Corporation. All Rights Reserved.

- 5. © 2009. Intergraph Corporation. All Rights Reserved.

- 6. © 2009. Intergraph Corporation. All Rights Reserved.

- 7. © 2009. Intergraph Corporation. All Rights Reserved.

- 8. PIPING HIERARCHY: PIPE FEATURES A pipe feature

- 9. © 2009. Intergraph Corporation. All Rights Reserved.

- 10. © 2009. Intergraph Corporation. All Rights Reserved.

- 11. © 2009. Intergraph Corporation. All Rights Reserved.

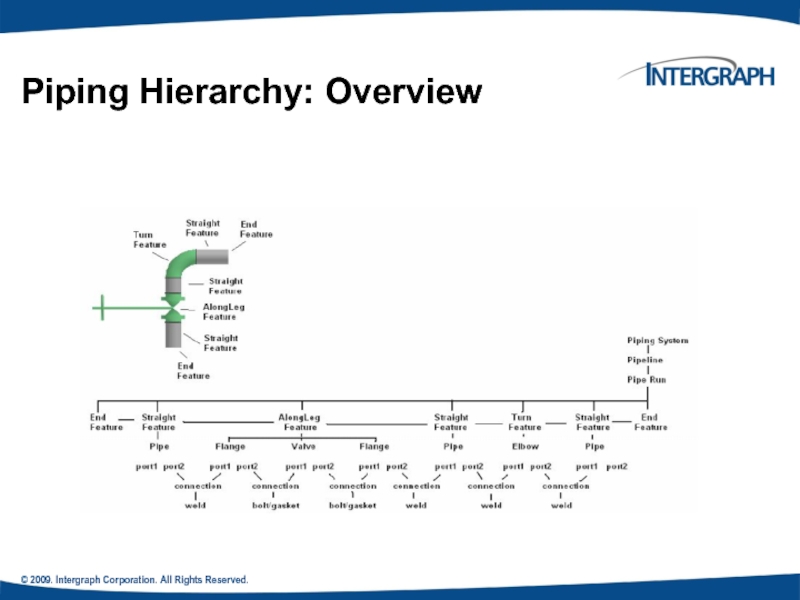

- 12. © 2009. Intergraph Corporation. All Rights Reserved. Piping Hierarchy: Overview

- 13. © 2009. Intergraph Corporation. All Rights Reserved.

- 14. © 2009. Intergraph Corporation. All Rights Reserved.

- 15. © © 2009. Intergraph Corporation. All Rights

- 16. © 2009. Intergraph Corporation. All Rights Reserved.

- 17. © 2009. Intergraph Corporation. All Rights Reserved.

- 18. © 2009. Intergraph Corporation. All Rights Reserved.

- 19. © 2009. Intergraph Corporation. All Rights Reserved.

- 20. © 2009. Intergraph Corporation. All Rights Reserved.

- 21. © 2009. Intergraph Corporation. All Rights Reserved.

- 22. © 2009. Intergraph Corporation. All Rights Reserved.

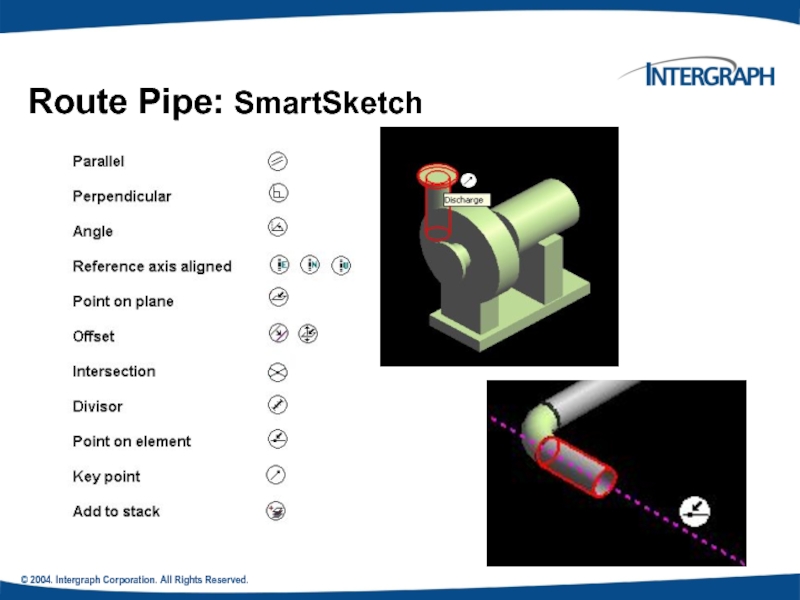

- 23. © 2004. Intergraph Corporation. All Rights Reserved. Route Pipe: SmartSketch

- 24. © 2004. Intergraph Corporation. All Rights Reserved.

- 25. © 2004. Intergraph Corporation. All Rights Reserved.

- 26. © 2004. Intergraph Corporation. All Rights Reserved.

- 27. © 2004. Intergraph Corporation. All Rights Reserved.

- 28. © 2004. Intergraph Corporation. All Rights Reserved.

- 29. © 2004. Intergraph Corporation. All Rights Reserved.

- 30. © 2004. Intergraph Corporation. All Rights Reserved. Example: Delete Straight Features

- 31. © 2004. Intergraph Corporation. All Rights Reserved.

- 32. © 2004. Intergraph Corporation. All Rights Reserved.

- 33. © 2004. Intergraph Corporation. All Rights Reserved.

- 34. © 2004. Intergraph Corporation. All Rights Reserved.

- 35. © 2004. Intergraph Corporation. All Rights Reserved.

- 36. © 2004. Intergraph Corporation. All Rights Reserved.

- 37. © 2004. Intergraph Corporation. All Rights Reserved.

- 38. © 2009. Intergraph Corporation. All Rights Reserved.

- 39. © 2009. Intergraph Corporation. All Rights Reserved.

- 40. © 2009. Intergraph Corporation. All Rights Reserved.

- 41. © 2004. Intergraph Corporation. All Rights Reserved.

- 42. © 2009. Intergraph Corporation. All Rights Reserved.

- 43. © 2009. Intergraph Corporation. All Rights Reserved.

- 44. © 2009. Intergraph Corporation. All Rights Reserved.

- 45. © 2009. Intergraph Corporation. All Rights Reserved.

- 46. © 2009. Intergraph Corporation. All Rights Reserved.

- 47. © 2004. Intergraph Corporation. All Rights Reserved.

- 48. © 2004. Intergraph Corporation. All Rights Reserved.

- 49. © 2009. Intergraph Corporation. All Rights Reserved.

- 50. © 2009. Intergraph Corporation. All Rights Reserved.

- 51. © 2009. Intergraph Corporation. All Rights Reserved.

- 52. © 2009. Intergraph Corporation. All Rights Reserved.

- 53. © 2009. Intergraph Corporation. All Rights Reserved.

- 54. © 2009. Intergraph Corporation. All Rights Reserved.

- 55. © 2004. Intergraph Corporation. All Rights Reserved.

- 56. © 2009. Intergraph Corporation. All Rights Reserved.

- 57. © 2009. Intergraph Corporation. All Rights Reserved.

- 58. © 2009. Intergraph Corporation. All Rights Reserved.

- 59. © 2009. Intergraph Corporation. All Rights Reserved.

- 60. © 2009. Intergraph Corporation. All Rights Reserved.

- 61. © 2009. Intergraph Corporation. All Rights Reserved.

- 62. © 2009. Intergraph Corporation. All Rights Reserved.

- 63. © 2009. Intergraph Corporation. All Rights Reserved.

- 64. © 2009. Intergraph Corporation. All Rights Reserved.

- 65. © 2009. Intergraph Corporation. All Rights Reserved.

- 66. © 2004. Intergraph Corporation. All Rights Reserved.

- 67. © 2009. Intergraph Corporation. All Rights Reserved.

- 68. © 2009. Intergraph Corporation. All Rights Reserved.

- 69. © 2009. Intergraph Corporation. All Rights Reserved.

- 70. © 2009. Intergraph Corporation. All Rights Reserved.

- 71. © 2009. Intergraph Corporation. All Rights Reserved.

- 72. © 2009. Intergraph Corporation. All Rights Reserved.

- 73. © 2009. Intergraph Corporation. All Rights Reserved.

- 74. © 2009. Intergraph Corporation. All Rights Reserved.

- 75. © 2009. Intergraph Corporation. All Rights Reserved.

- 76. © 2009. Intergraph Corporation. All Rights Reserved.

- 77. © 2009. Intergraph Corporation. All Rights Reserved.

- 78. © 2009. Intergraph Corporation. All Rights Reserved.

- 79. © 2009. Intergraph Corporation. All Rights Reserved.

- 80. © 2009. Intergraph Corporation. All Rights Reserved.

- 81. © 2009. Intergraph Corporation. All Rights Reserved.

- 82. © 2009. Intergraph Corporation. All Rights Reserved.

- 83. © 2009. Intergraph Corporation. All Rights Reserved.

- 84. © 2009. Intergraph Corporation. All Rights Reserved.

- 85. © 2004. Intergraph Corporation. All Rights Reserved.

- 86. © 2004. Intergraph Corporation. All Rights Reserved.

- 87. © 2009. Intergraph Corporation. All Rights Reserved.

Слайд 2© 2009. Intergraph Corporation. All Rights Reserved.

Agenda

Piping Hierarchy

Route Pipes

Inserting Components

Routing a

Routing Pipes from the P&ID

Placing Instruments

Placing Piping Specialty Items

Placing Taps

Inserting Splits

Слайд 3© 20049. Intergraph Corporation. All Rights Reserved.

Agenda Conti’

Manipulating Views

Creating Spools

Sequencing Objects

Creating

Слайд 4© 2009. Intergraph Corporation. All Rights Reserved.

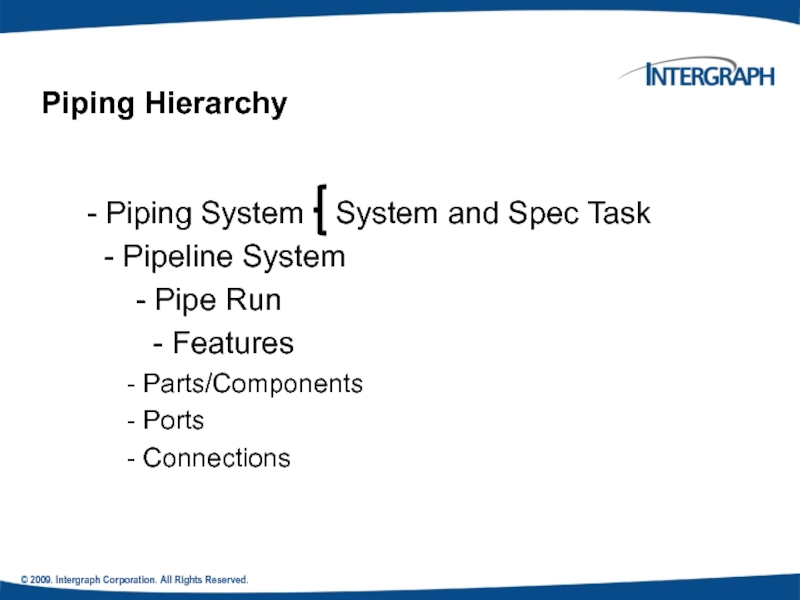

- Piping System System and

- Pipeline System

- Pipe Run

- Features

- Parts/Components

- Ports

- Connections

Piping Hierarchy

Слайд 5© 2009. Intergraph Corporation. All Rights Reserved.

Piping Hierarchy: Pipe System

A piping

Слайд 6© 2009. Intergraph Corporation. All Rights Reserved.

A pipeline system is a

Piping Hierarchy: Pipeline

Слайд 7© 2009. Intergraph Corporation. All Rights Reserved.

.

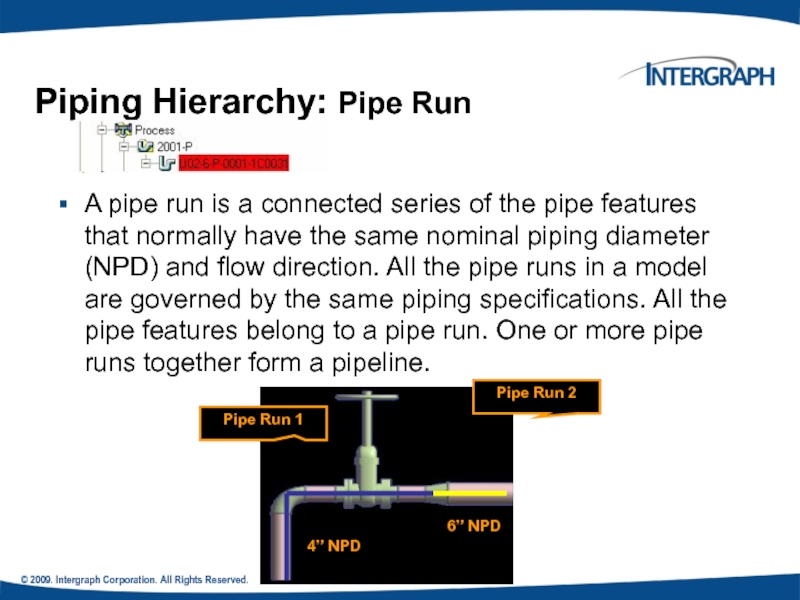

A pipe run is a

Piping Hierarchy: Pipe Run

Pipe Run 1

Pipe Run 2

6” NPD

4” NPD

Слайд 8PIPING HIERARCHY: PIPE FEATURES

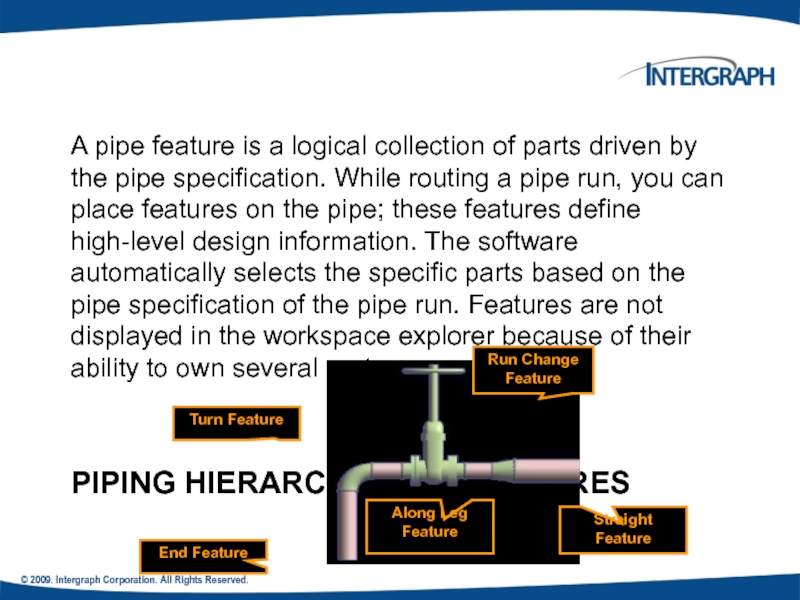

A pipe feature is a logical collection of

© 2009. Intergraph Corporation. All Rights Reserved.

Turn Feature

Straight Feature

End Feature

Run Change Feature

Along Leg Feature

Слайд 9© 2009. Intergraph Corporation. All Rights Reserved.

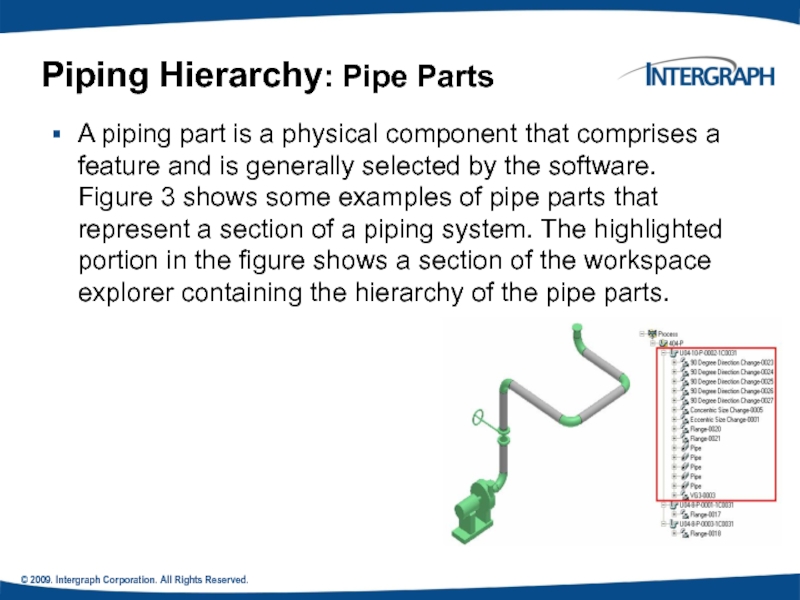

A piping part is a

Piping Hierarchy: Pipe Parts

Слайд 10© 2009. Intergraph Corporation. All Rights Reserved.

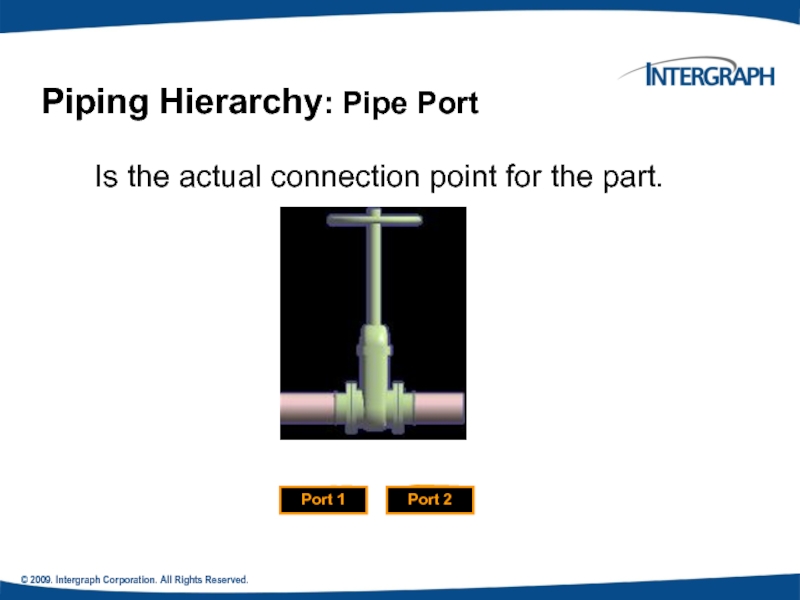

Is the actual connection point

Piping Hierarchy: Pipe Port

Port 2

Port 1

Слайд 11© 2009. Intergraph Corporation. All Rights Reserved.

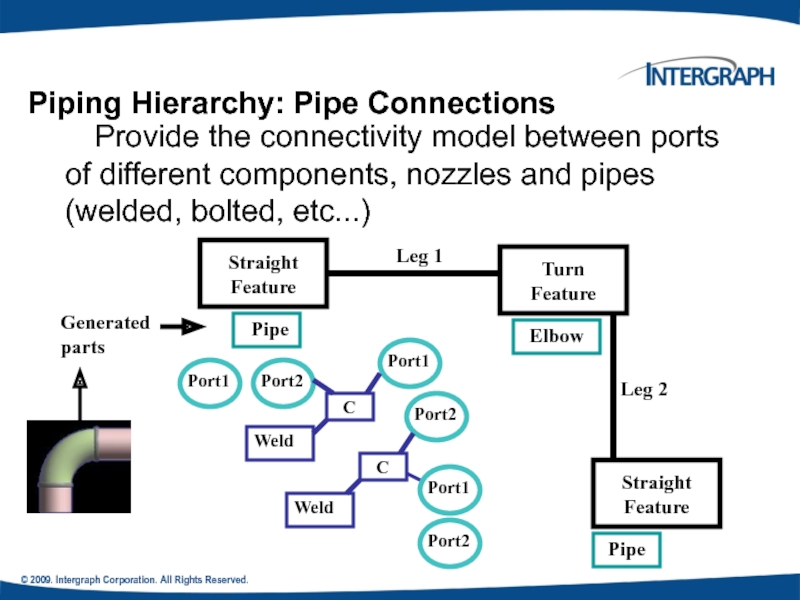

Provide the connectivity model between

Piping Hierarchy: Pipe Connections

Turn Feature

Straight Feature

Straight Feature

Pipe

Elbow

Pipe

Port2

Port1

Port1

Port2

Port1

Port2

C

Leg 1

Generated parts

Weld

Weld

C

Leg 2

Слайд 13© 2009. Intergraph Corporation. All Rights Reserved.

Start routing a Pipe Run

- a nozzle/component port

- a point in space

- an existing pipe run

Route Pipe: Pipe Command

Слайд 14© 2009. Intergraph Corporation. All Rights Reserved.

Route Pipe: Cardinal Points

Route a

Routing by invert elevation is supported for use in modeling underground piping.

Слайд 15© © 2009. Intergraph Corporation. All Rights Reserved.

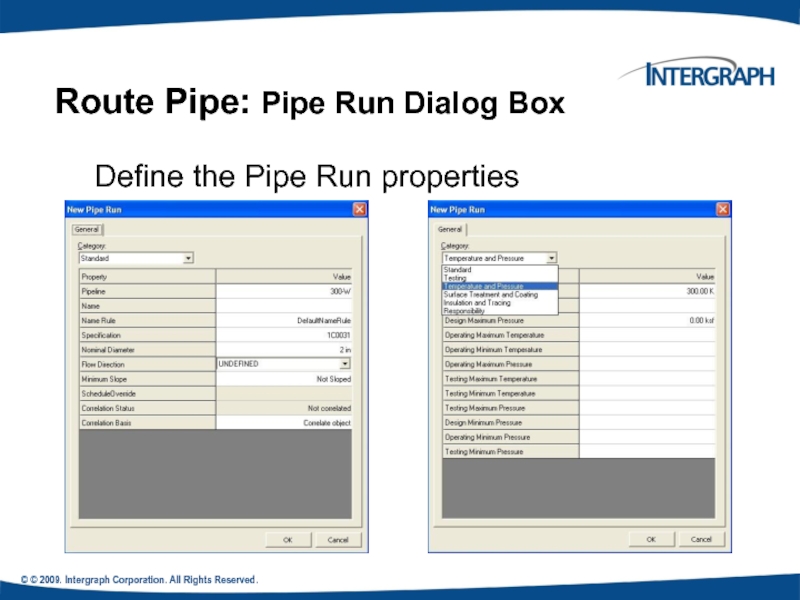

Define the Pipe Run

Route Pipe: Pipe Run Dialog Box

Слайд 16© 2009. Intergraph Corporation. All Rights Reserved.

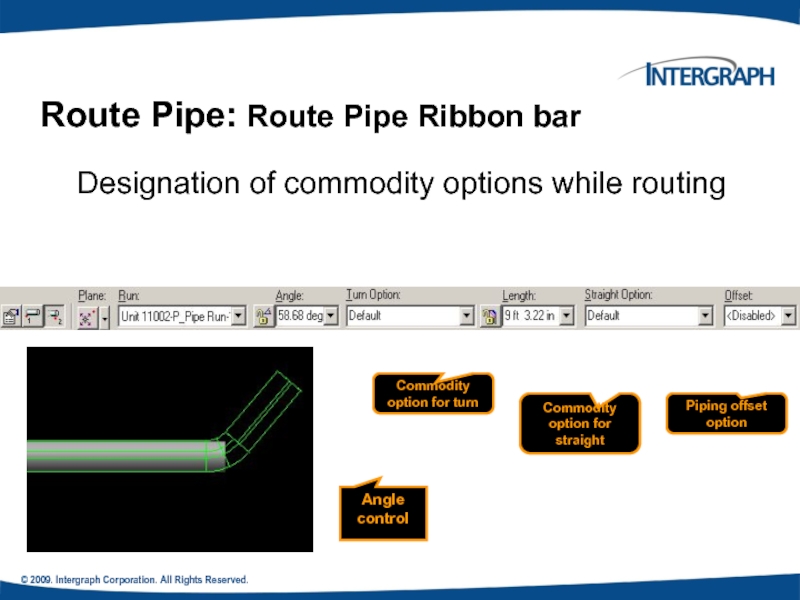

Route Pipe: Route Pipe Ribbon

Designation of commodity options while routing

Commodity option for turn

Commodity option for straight

Angle control

Piping offset option

Слайд 17© 2009. Intergraph Corporation. All Rights Reserved.

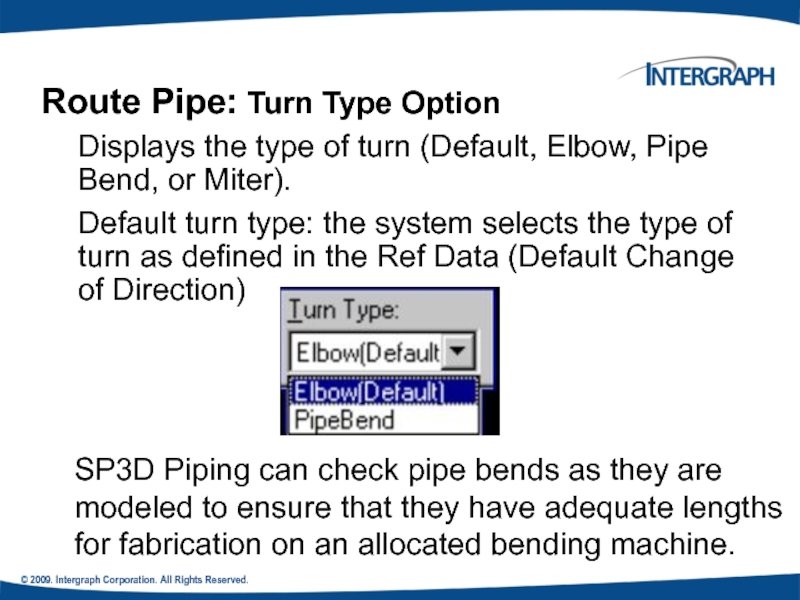

Route Pipe: Turn Type Option

Displays

Default turn type: the system selects the type of turn as defined in the Ref Data (Default Change of Direction)

SP3D Piping can check pipe bends as they are modeled to ensure that they have adequate lengths for fabrication on an allocated bending machine.

Слайд 18© 2009. Intergraph Corporation. All Rights Reserved.

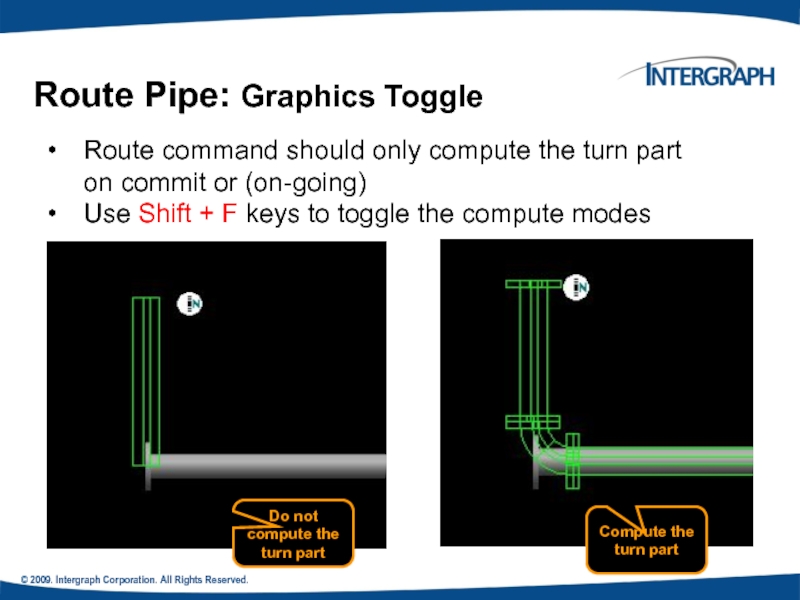

Route Pipe: Graphics Toggle

Route command

Use Shift + F keys to toggle the compute modes

Do not compute the turn part

Compute the turn part

Слайд 19© 2009. Intergraph Corporation. All Rights Reserved.

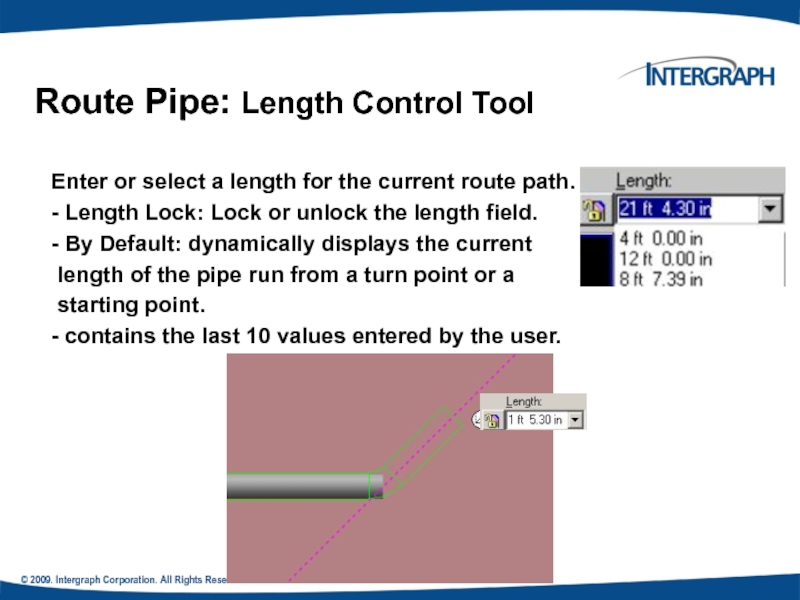

Route Pipe: Length Control Tool

Enter

- Length Lock: Lock or unlock the length field.

- By Default: dynamically displays the current

length of the pipe run from a turn point or a

starting point.

- contains the last 10 values entered by the user.

Слайд 20© 2009. Intergraph Corporation. All Rights Reserved.

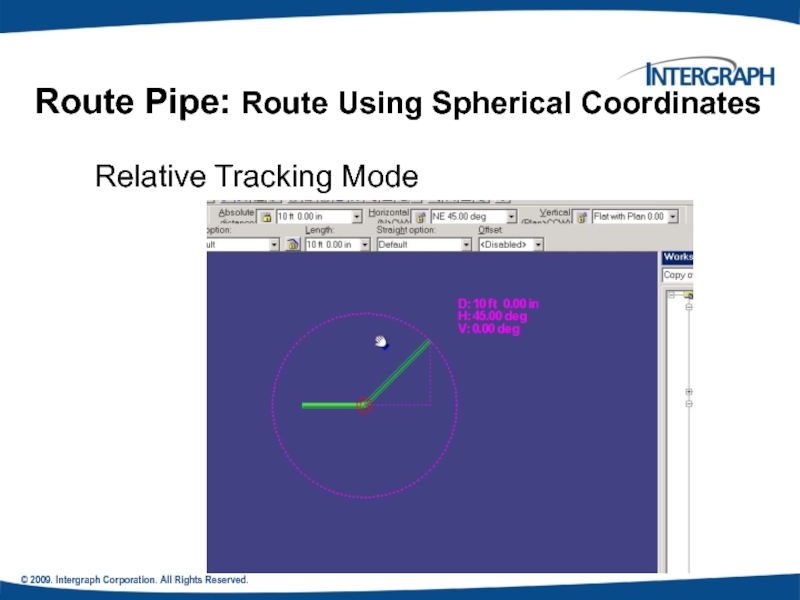

Relative Tracking Mode

Route Pipe: Route

Слайд 21© 2009. Intergraph Corporation. All Rights Reserved.

All Rights Reserved.

Offset Control Tool

If

An offset SmartSketch point is found on either side of the referenced plane or linear element.

Route Pipe: Offset Value

North

Слайд 22© 2009. Intergraph Corporation. All Rights Reserved.

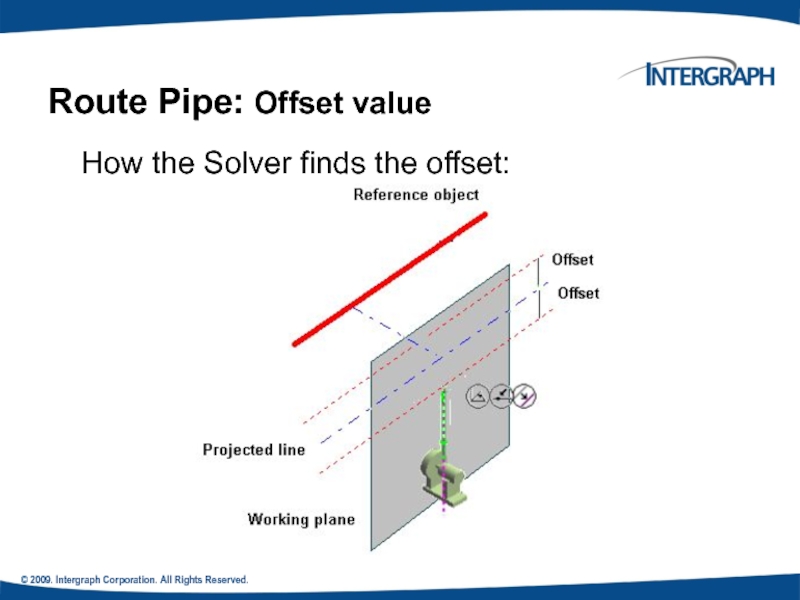

Route Pipe: Offset value

How the

Слайд 24© 2004. Intergraph Corporation. All Rights Reserved.

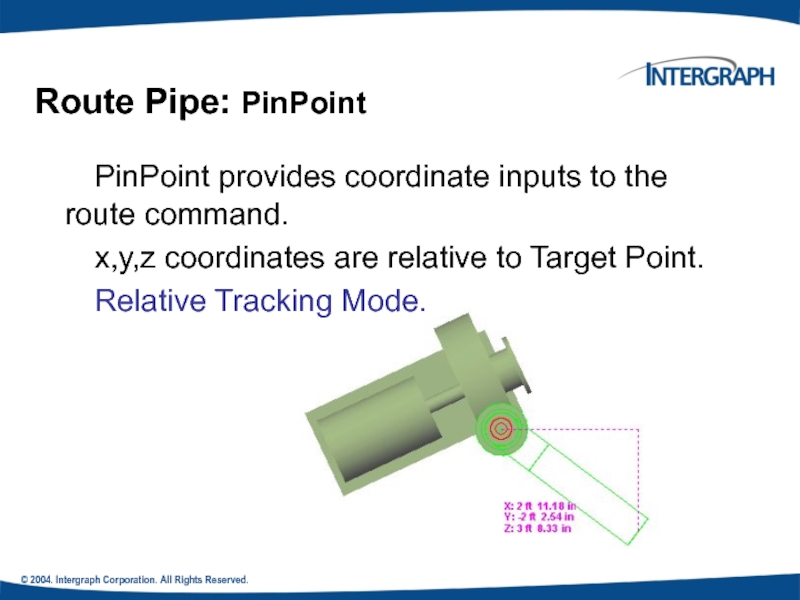

PinPoint provides coordinate inputs to

x,y,z coordinates are relative to Target Point.

Relative Tracking Mode.

Route Pipe: PinPoint

Слайд 25© 2004. Intergraph Corporation. All Rights Reserved.

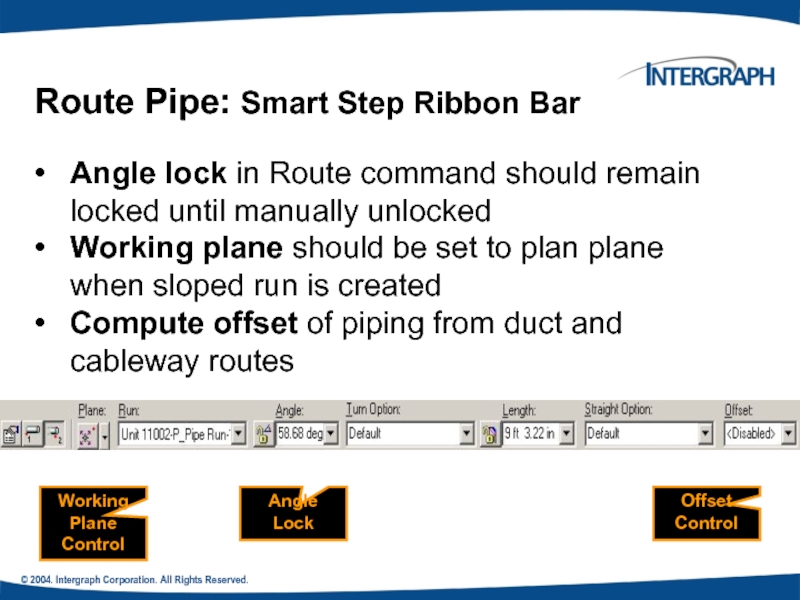

Angle lock in Route command

Working plane should be set to plan plane when sloped run is created

Compute offset of piping from duct and cableway routes

Route Pipe: Smart Step Ribbon Bar

Working Plane Control

Angle Lock

Offset Control

Слайд 26© 2004. Intergraph Corporation. All Rights Reserved.

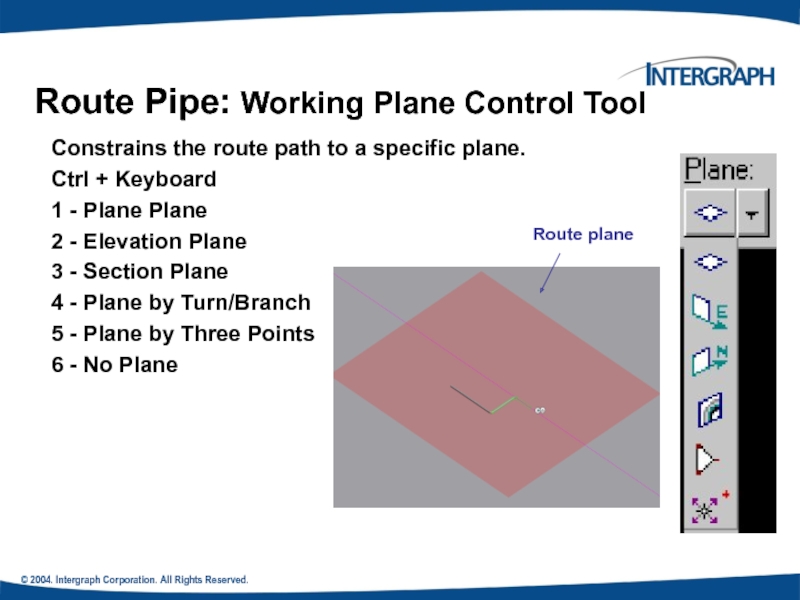

Route Pipe: Working Plane Control

Constrains the route path to a specific plane.

Ctrl + Keyboard

1 - Plane Plane

2 - Elevation Plane

3 - Section Plane

4 - Plane by Turn/Branch

5 - Plane by Three Points

6 - No Plane

Route plane

Слайд 27© 2004. Intergraph Corporation. All Rights Reserved.

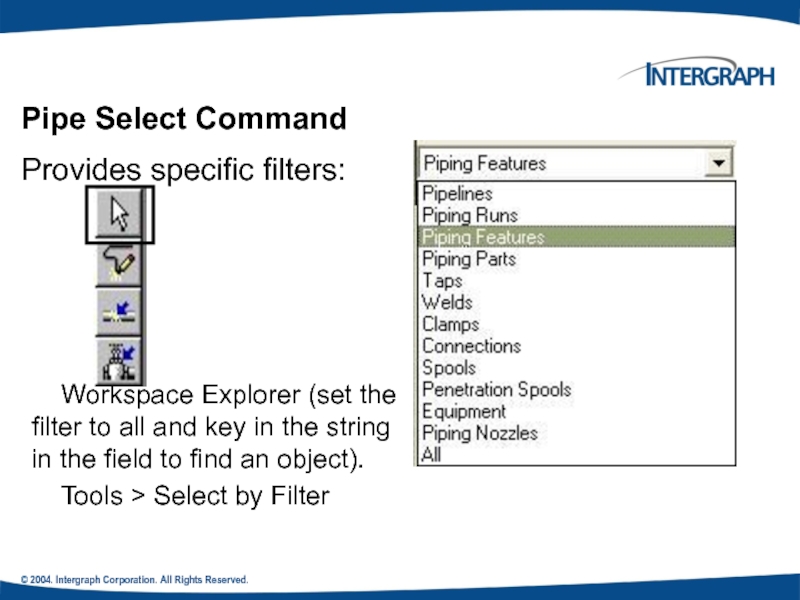

Pipe Select Command

Provides specific filters:

Workspace

Tools > Select by Filter

Слайд 28© 2004. Intergraph Corporation. All Rights Reserved.

Deleting a pipeline deletes all

Delete a Pipeline

Слайд 29© 2004. Intergraph Corporation. All Rights Reserved.

Deleting the run deletes all

The software attempts to maintain the design integrity of the model by adjusting all previously connected features.

Delete a Pipe Run

Слайд 31© 2004. Intergraph Corporation. All Rights Reserved.

When you select an end

Run To or From End Features or Nozzle

Слайд 32© 2004. Intergraph Corporation. All Rights Reserved.

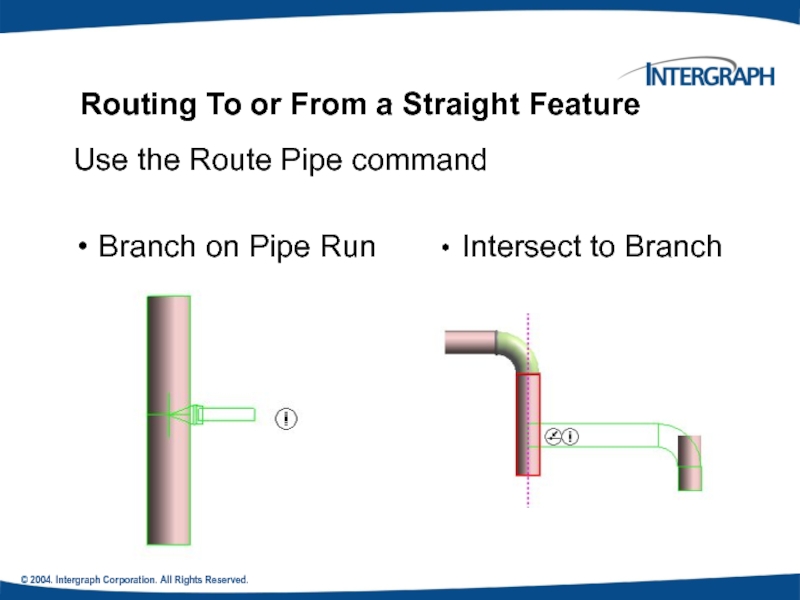

Routing To or From a

Use the Route Pipe command

Branch on Pipe Run

Intersect to Branch

Слайд 33© 2004. Intergraph Corporation. All Rights Reserved.

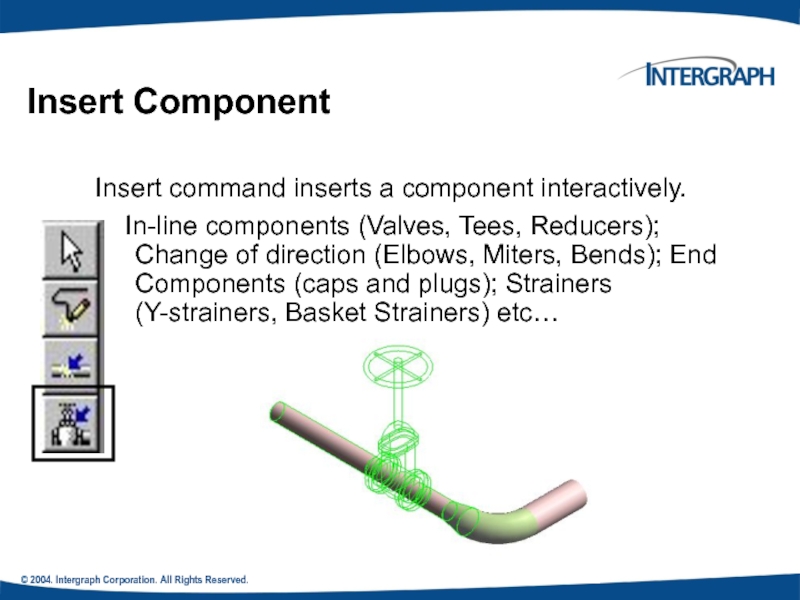

Insert Component

Insert command inserts a

In-line components (Valves, Tees, Reducers); Change of direction (Elbows, Miters, Bends); End Components (caps and plugs); Strainers (Y-strainers, Basket Strainers) etc…

Слайд 34© 2004. Intergraph Corporation. All Rights Reserved.

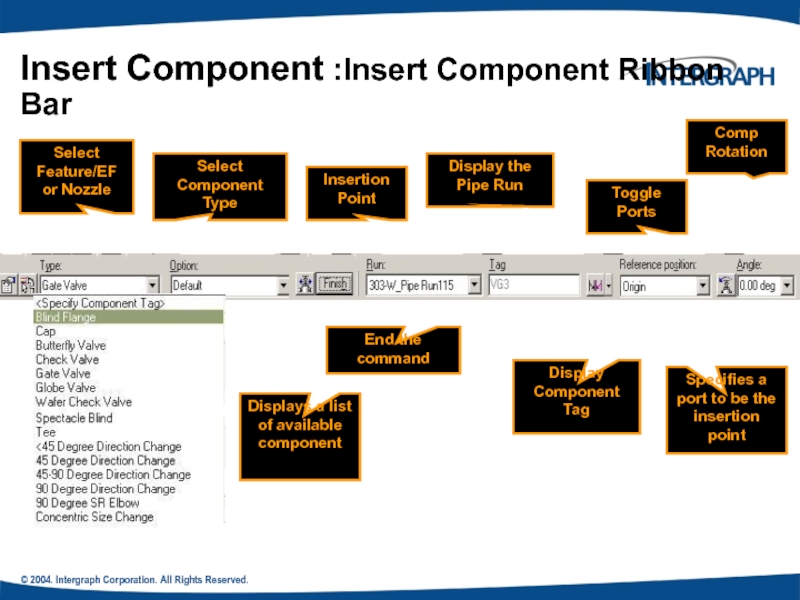

Insert Component :Insert Component Ribbon

Select Feature/EF or Nozzle

Select Component Type

Displays a list of available component

Insertion Point

End the command

Display the Pipe Run

Display Component Tag

Toggle Ports

Specifies a port to be the insertion point

Comp Rotation

Слайд 35© 2004. Intergraph Corporation. All Rights Reserved.

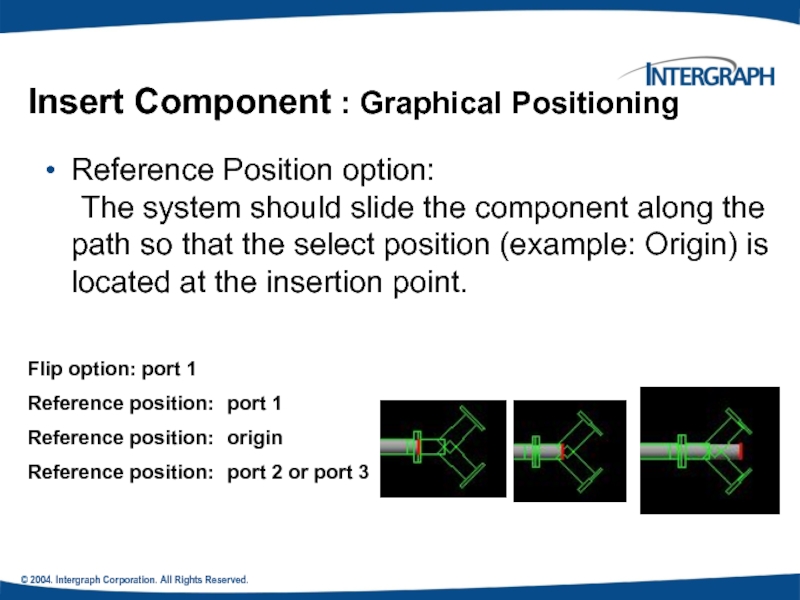

Insert Component : Graphical Positioning

Reference Position option:

The system should slide the component along the path so that the select position (example: Origin) is located at the insertion point.

Flip option: port 1

Reference position: port 1

Reference position: origin

Reference position: port 2 or port 3

Слайд 36© 2004. Intergraph Corporation. All Rights Reserved.

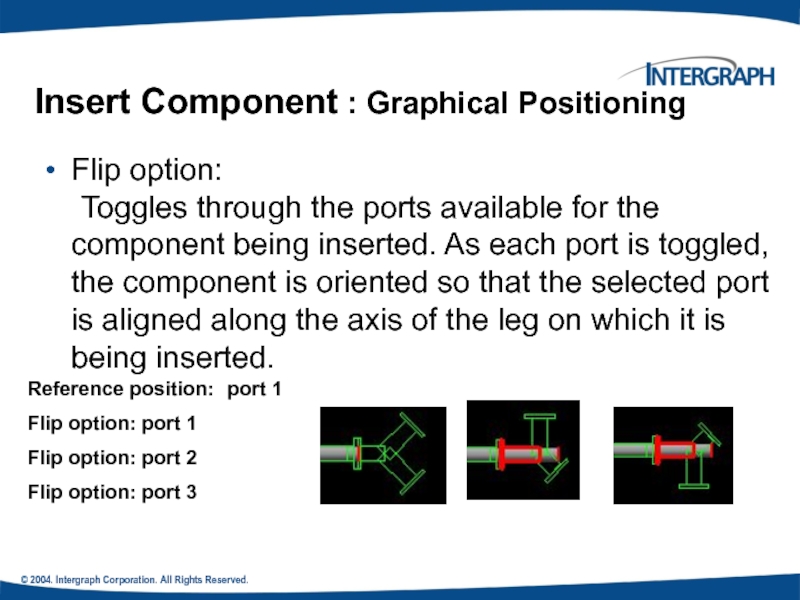

Insert Component : Graphical Positioning

Flip

Toggles through the ports available for the component being inserted. As each port is toggled, the component is oriented so that the selected port is aligned along the axis of the leg on which it is being inserted.

Reference position: port 1

Flip option: port 1

Flip option: port 2

Flip option: port 3

Слайд 37© 2004. Intergraph Corporation. All Rights Reserved.

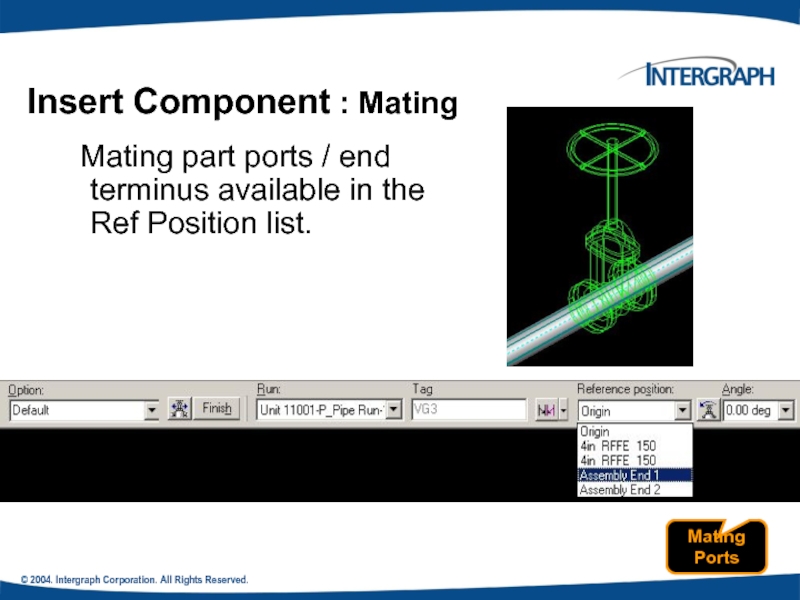

Insert Component : Mating

Mating part

Mating Ports

Слайд 38© 2009. Intergraph Corporation. All Rights Reserved.

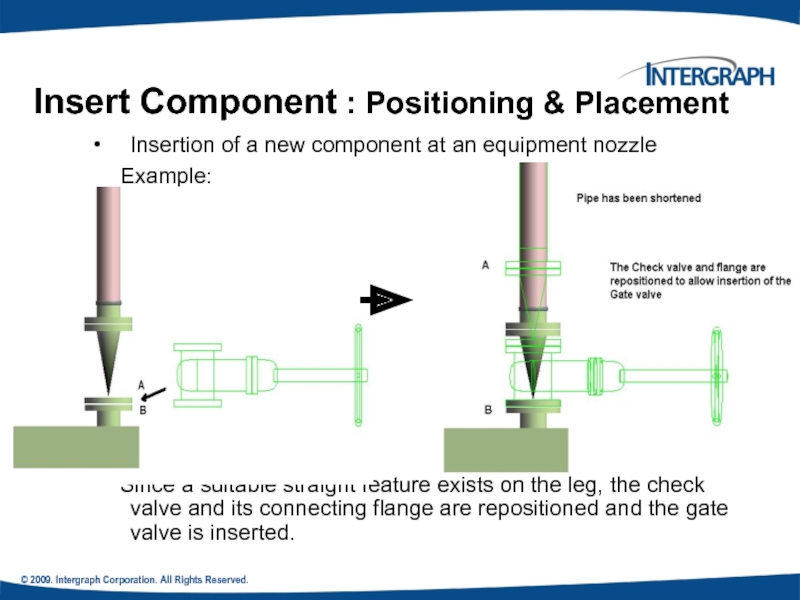

Insert Component : Positioning &

Insertion of a new component at an equipment nozzle

Example:

Since a suitable straight feature exists on the leg, the check valve and its connecting flange are repositioned and the gate valve is inserted.

Слайд 39© 2009. Intergraph Corporation. All Rights Reserved.

Routing Sloped Pipe

Underground piping collects

Слайд 41© 2004. Intergraph Corporation. All Rights Reserved.

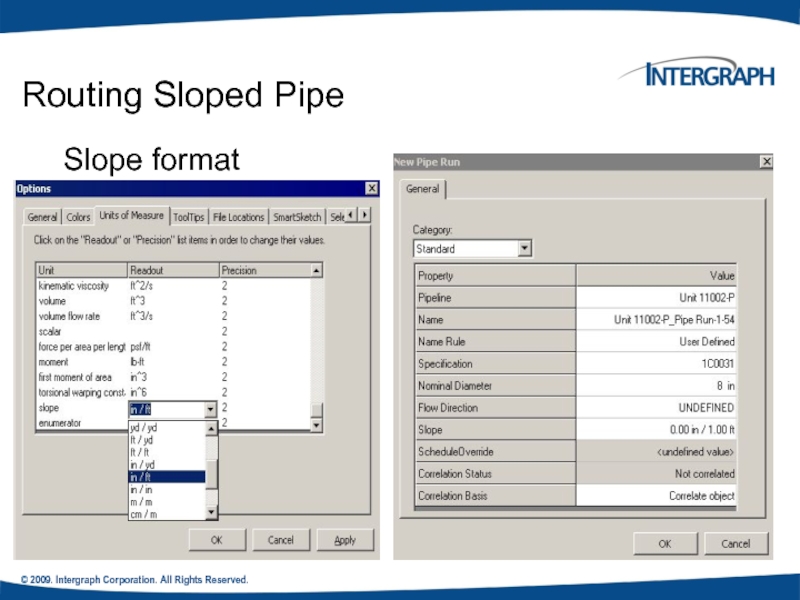

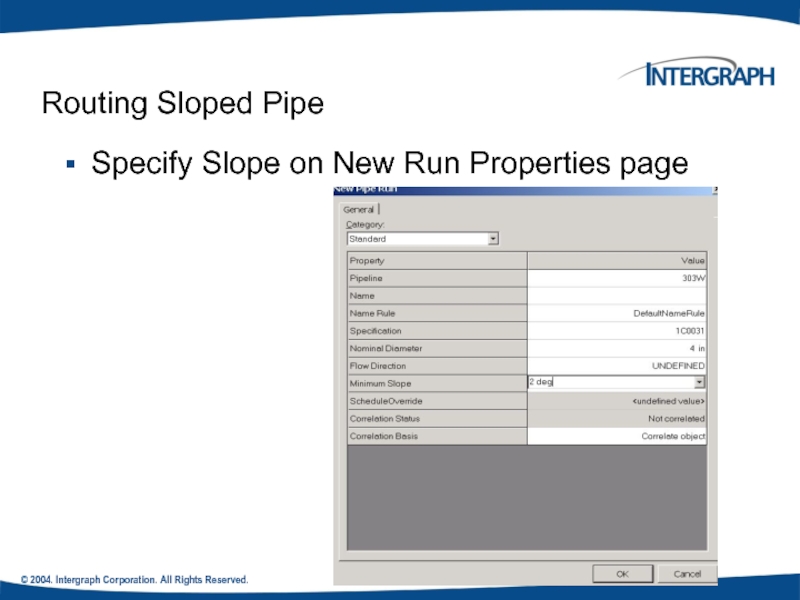

Routing Sloped Pipe

Specify Slope on

Слайд 42© 2009. Intergraph Corporation. All Rights Reserved.

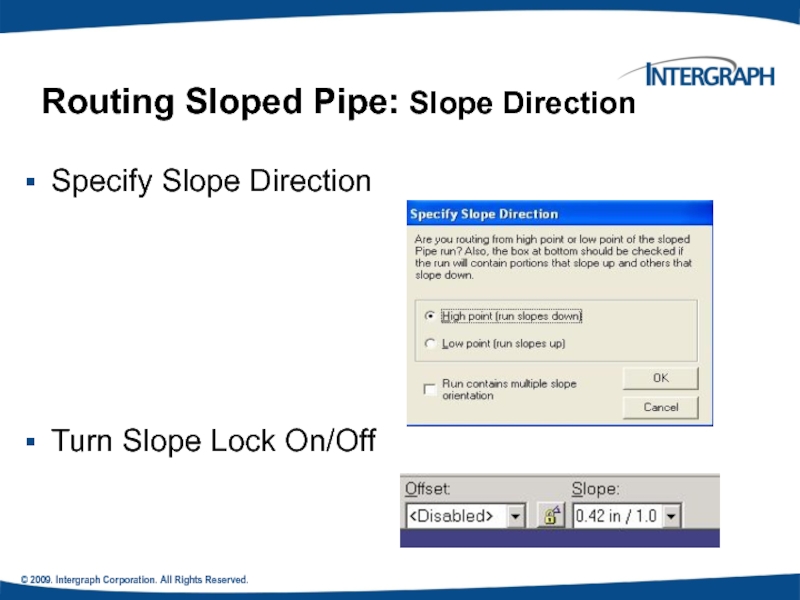

Routing Sloped Pipe: Slope Direction

Specify Slope Direction

Turn Slope Lock On/Off

Слайд 43© 2009. Intergraph Corporation. All Rights Reserved.

Reserved.

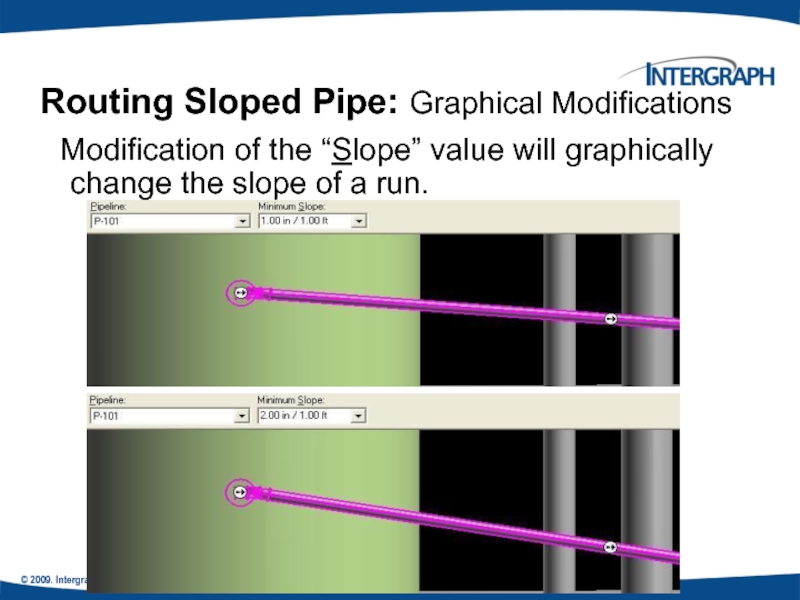

Modification of the “Slope” value

Routing Sloped Pipe: Graphical Modifications

Слайд 44© 2009. Intergraph Corporation. All Rights Reserved.

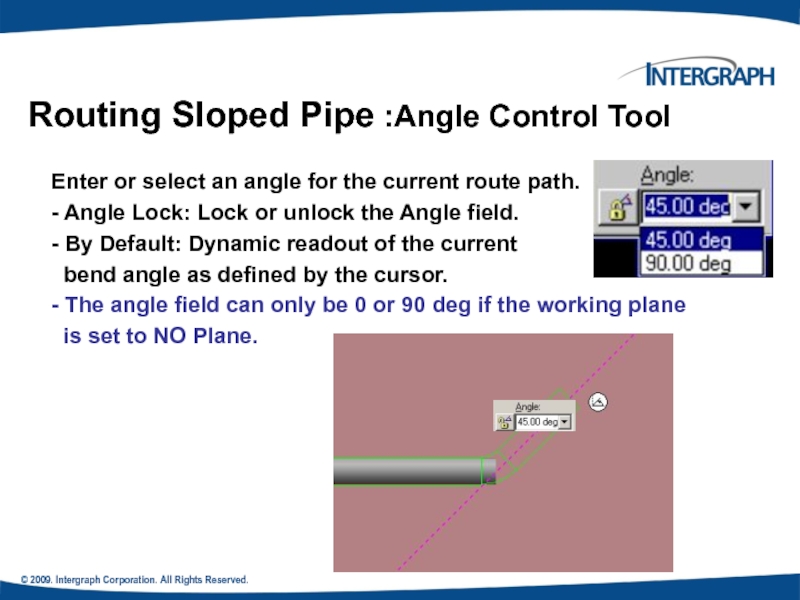

Routing Sloped Pipe :Angle Control

Enter or select an angle for the current route path.

- Angle Lock: Lock or unlock the Angle field.

- By Default: Dynamic readout of the current

bend angle as defined by the cursor.

- The angle field can only be 0 or 90 deg if the working plane

is set to NO Plane.

Слайд 45© 2009. Intergraph Corporation. All Rights Reserved.

Piping Practice Labs

Route Pipes

Inserting Components

Routing Sloped Pipe

Слайд 46© 2009. Intergraph Corporation. All Rights Reserved.

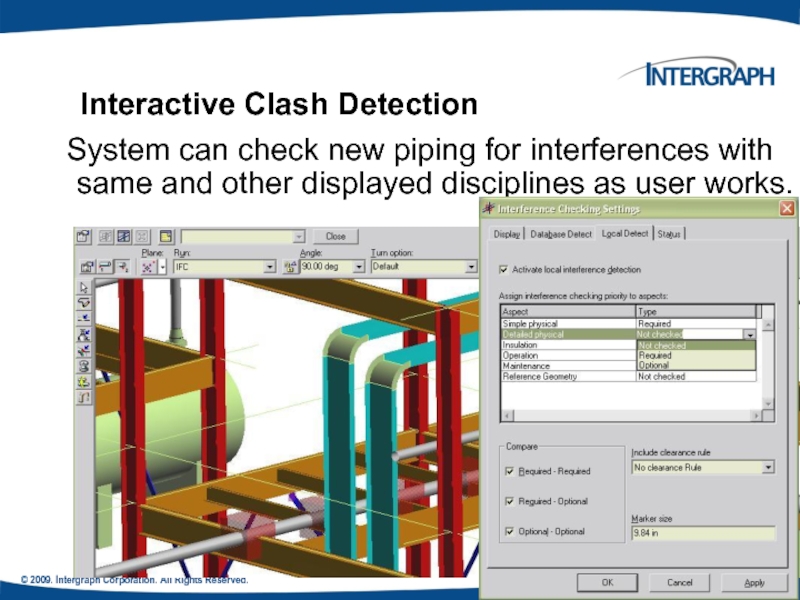

Integrated Environment

While designing or

In an integrated environment, you publish and retrieve data from and to SP3D by using a central repository. During a publish operation, data such as drawings, reports, and 3D models transfers to a central repository. During a retrieve operation, the system retrieves P&IDs, Plant Break Down Structure, Project List, Work Breakdown Structure, Electrical Cable Schedules, and Instrumentation Dimensional Data Sheets from the central repository

Слайд 47© 2004. Intergraph Corporation. All Rights Reserved.

Retrieving Data from a P&ID

You can retrieve piping, instrumentation, and equipment data from P&ID in the integrated environment. You can use P&ID to access items, such as equipment, piping information, and SmartPlant Instrumentation dimension data, to help create the appropriate 3D design objects. For example, after you retrieve data from P&ID, you can use the P&ID File Viewer window in SP3D for guidance in routing pipes, inserting components and instruments, and placing equipment in the 3D model.

Слайд 48© 2004. Intergraph Corporation. All Rights Reserved.

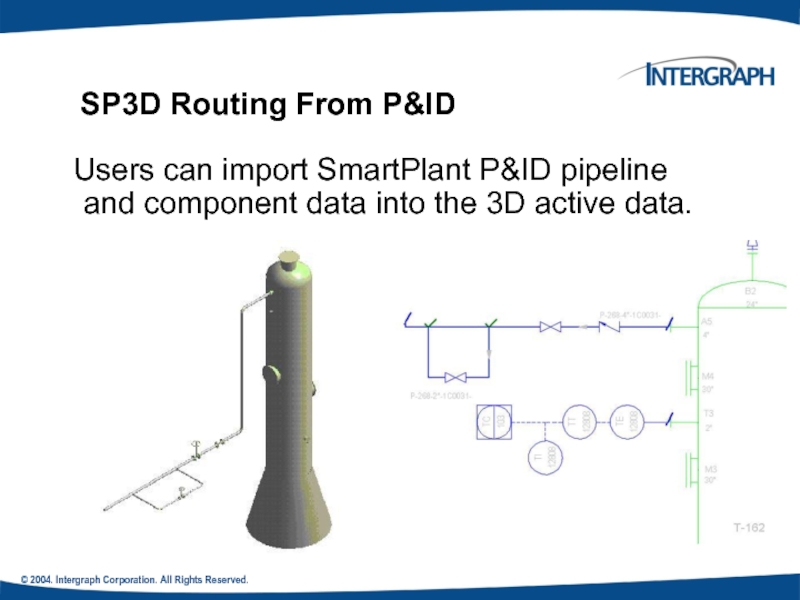

SP3D Routing From P&ID

Users can

Слайд 49© 2009. Intergraph Corporation. All Rights Reserved.

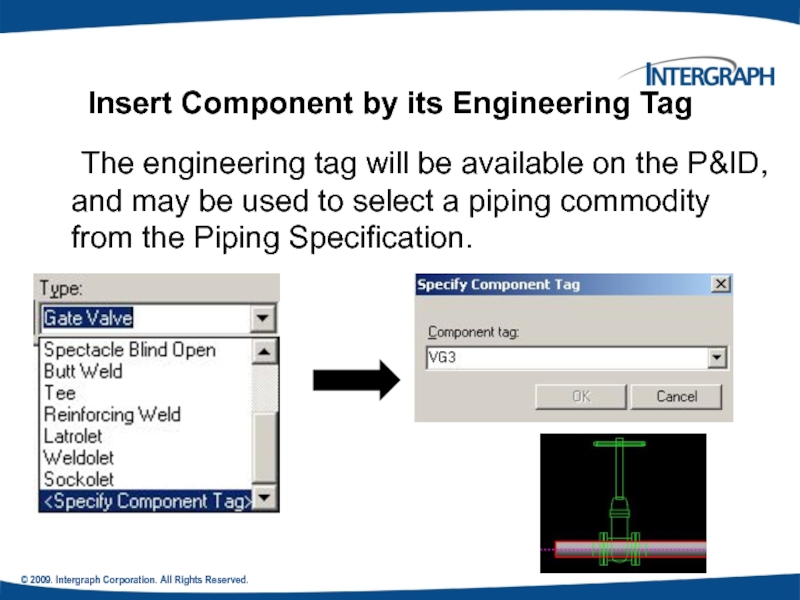

The engineering tag will be

Insert Component by its Engineering Tag

Слайд 50© 2009. Intergraph Corporation. All Rights Reserved.

Instrument & Piping Specialty Placement

We

1. Stock item: Stock items represent those piping items that are purchased from a manufacturer’s catalog, where no real engineering is required other than selecting the correct size, material, etc.

2. Custom-engineered item: custom engineered items are built items according to the process.

Слайд 51© 2009. Intergraph Corporation. All Rights Reserved.

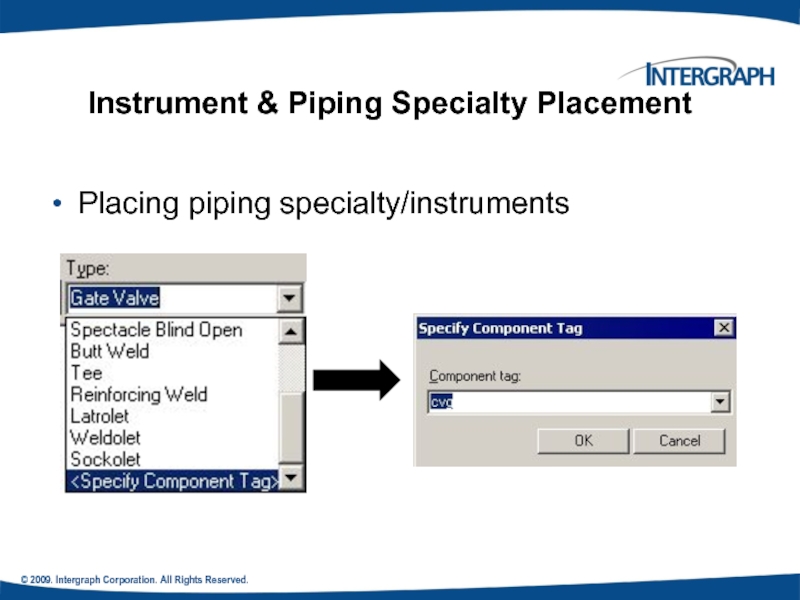

Instrument & Piping Specialty Placement

Placing

Слайд 52© 2009. Intergraph Corporation. All Rights Reserved.

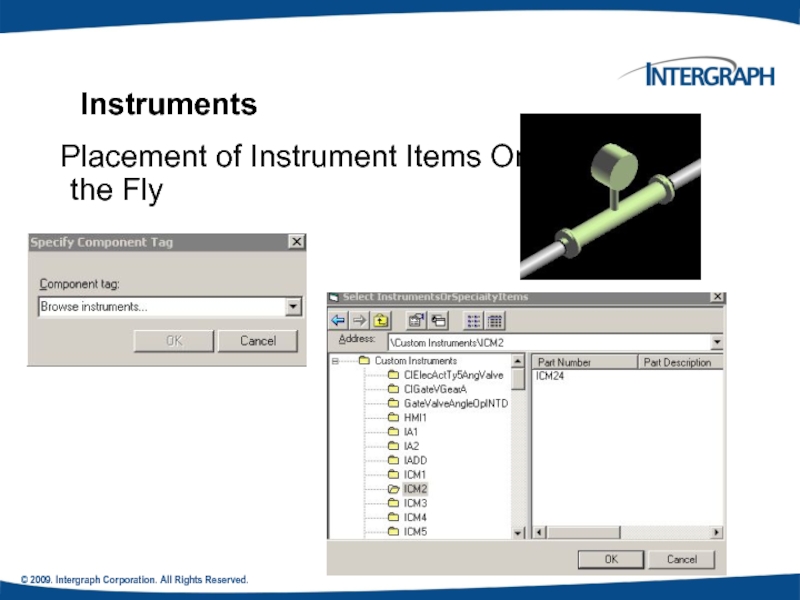

Instruments

Placement of Instrument Items On

Слайд 53© 2009. Intergraph Corporation. All Rights Reserved.

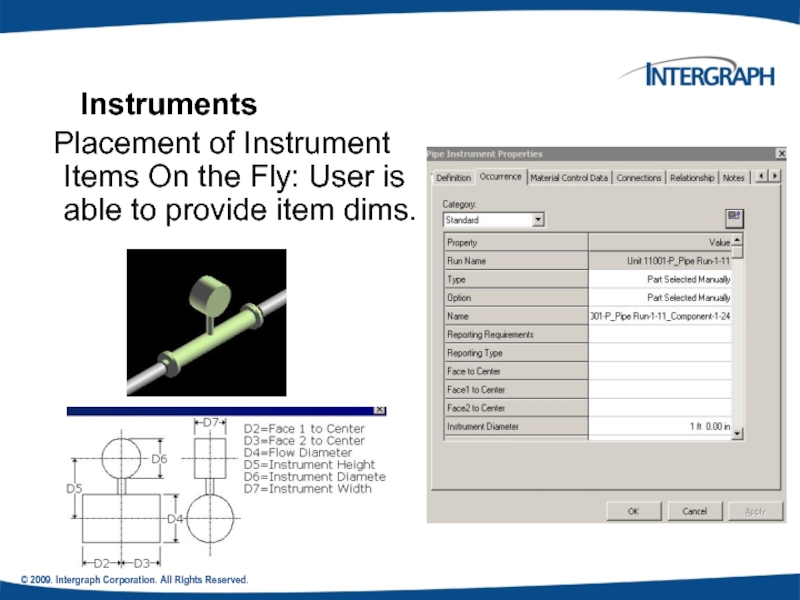

Placement of Instrument Items On

Instruments

Слайд 54© 2009. Intergraph Corporation. All Rights Reserved.

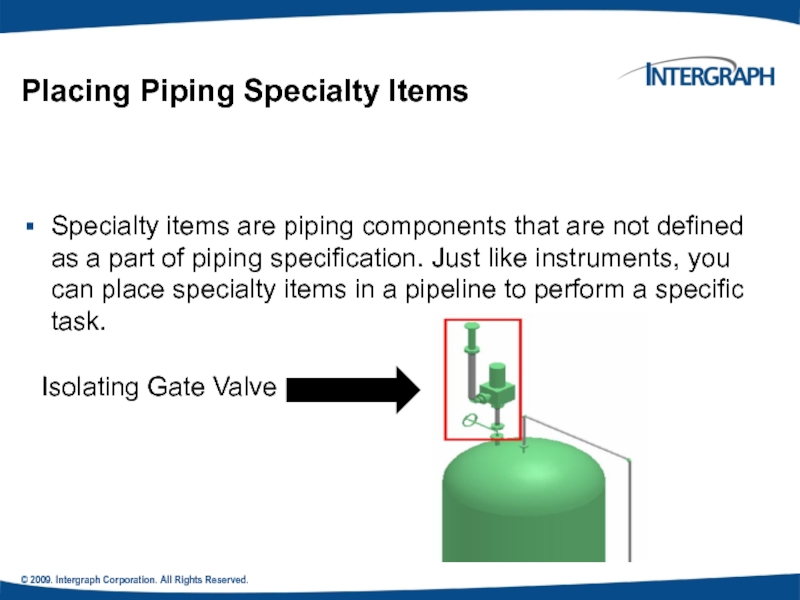

Placing Piping Specialty Items

Specialty items

Isolating Gate Valve

Слайд 55© 2004. Intergraph Corporation. All Rights Reserved.

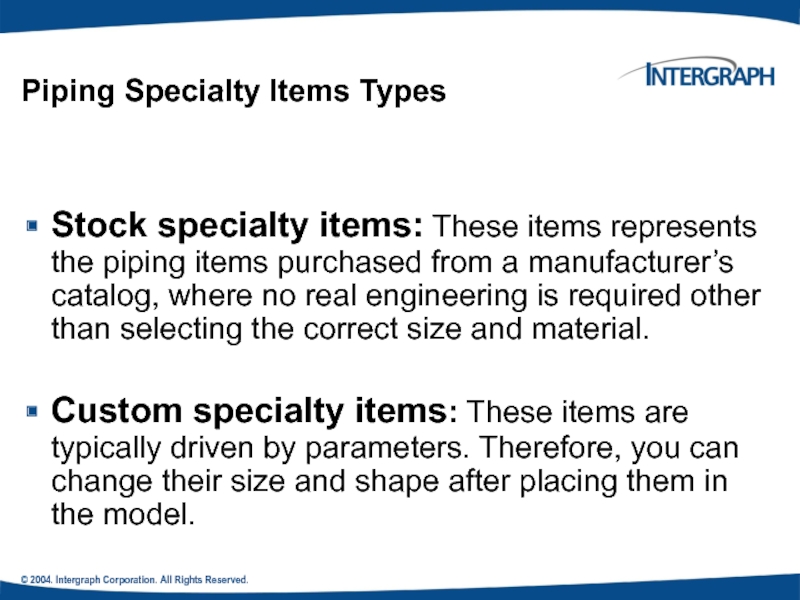

Piping Specialty Items Types

Stock specialty

Custom specialty items: These items are typically driven by parameters. Therefore, you can change their size and shape after placing them in the model.

Слайд 56© 2009. Intergraph Corporation. All Rights Reserved.

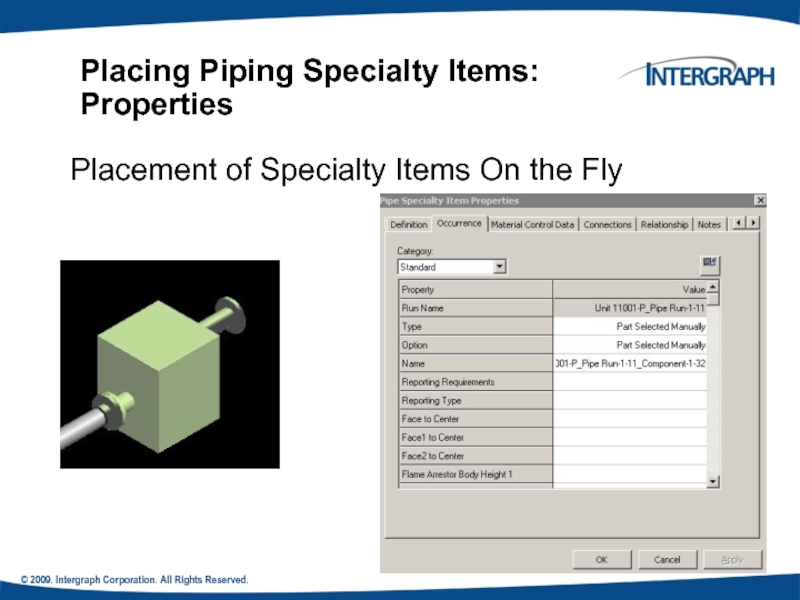

Placing Piping Specialty Items: Properties

Placement

Слайд 57© 2009. Intergraph Corporation. All Rights Reserved.

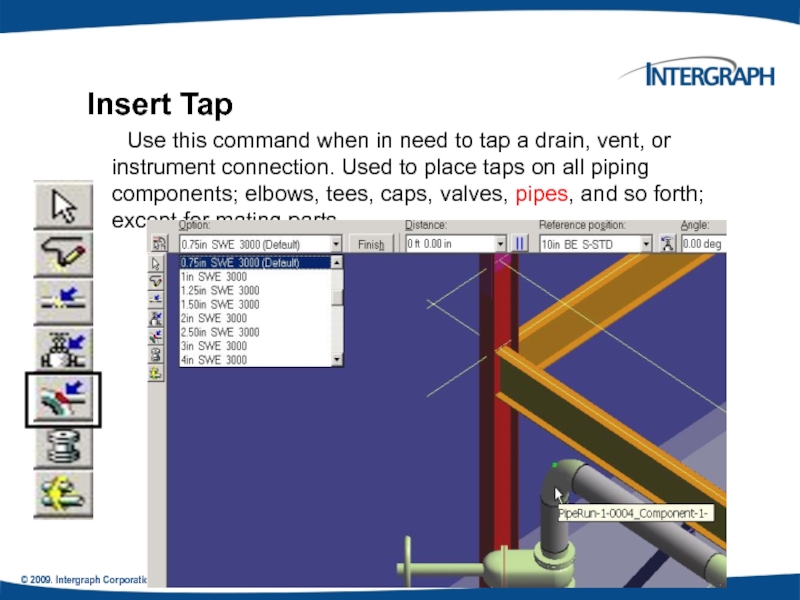

Insert Tap

Use this command when

Слайд 58© 2009. Intergraph Corporation. All Rights Reserved.

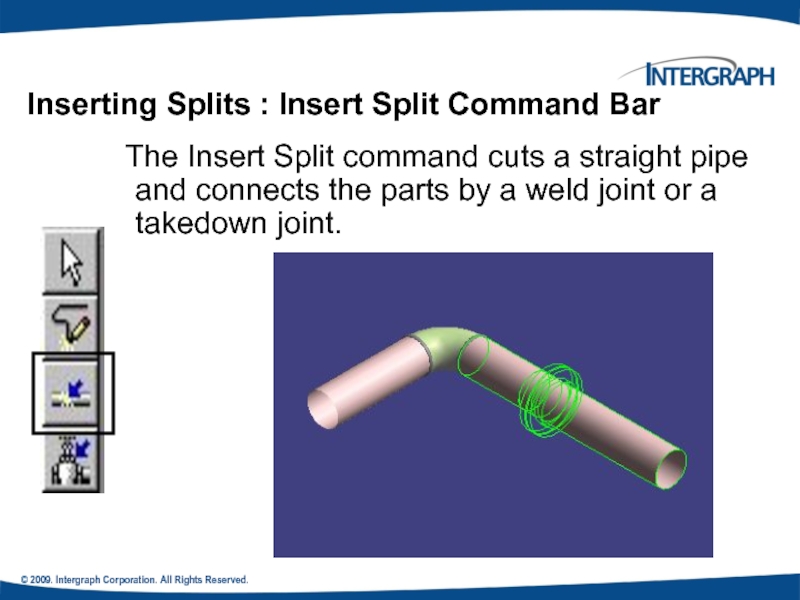

Inserting Splits : Insert Split

The Insert Split command cuts a straight pipe and connects the parts by a weld joint or a takedown joint.

Слайд 59© 2009. Intergraph Corporation. All Rights Reserved.

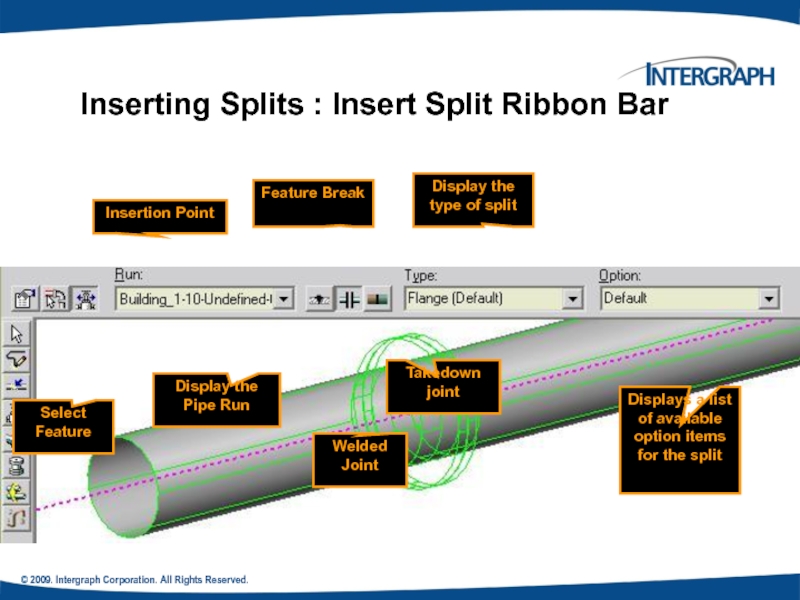

Inserting Splits : Insert Split

Welded Joint

Select Feature

Display the type of split

Insertion Point

Display the Pipe Run

Takedown joint

Displays a list of available option items for the split

Feature Break

Слайд 60© 2009. Intergraph Corporation. All Rights Reserved.

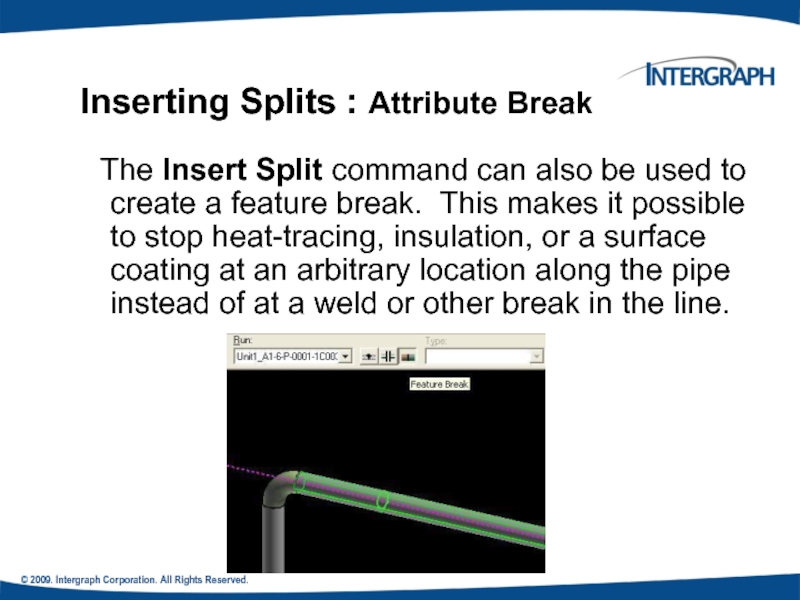

Inserting Splits : Attribute Break

The Insert Split command can also be used to create a feature break. This makes it possible to stop heat-tracing, insulation, or a surface coating at an arbitrary location along the pipe instead of at a weld or other break in the line.

Слайд 61© 2009. Intergraph Corporation. All Rights Reserved.

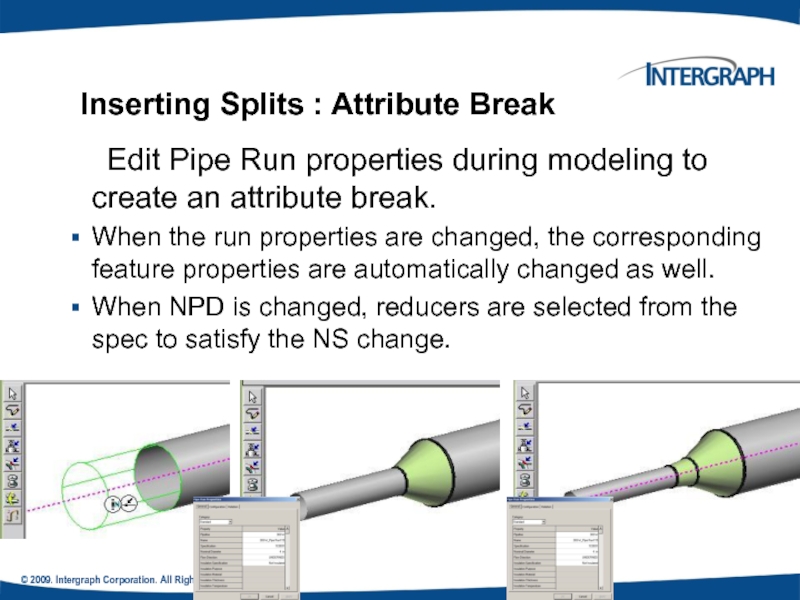

.

Edit Pipe Run properties during

When the run properties are changed, the corresponding feature properties are automatically changed as well.

When NPD is changed, reducers are selected from the spec to satisfy the NS change.

Inserting Splits : Attribute Break

Слайд 62© 2009. Intergraph Corporation. All Rights Reserved.

Routing Pipes from P&ID

Placing

Placing Piping Specialty Items

Placing Taps

Placing Splits

Piping Practice Labs

Слайд 63© 2009. Intergraph Corporation. All Rights Reserved.

Piping Manipulation : Edit Straight

Moving a SF moves the entire leg to which the feature is connected.

The move direction is always perpendicular to the axis of the SF.

A branch feature (BF) connected to the moved leg maintains its original angle.

Movement stops when parts on the associated leg overlap, or when they overlap with adjacent parts on connected legs.

Слайд 64© 2009. Intergraph Corporation. All Rights Reserved.

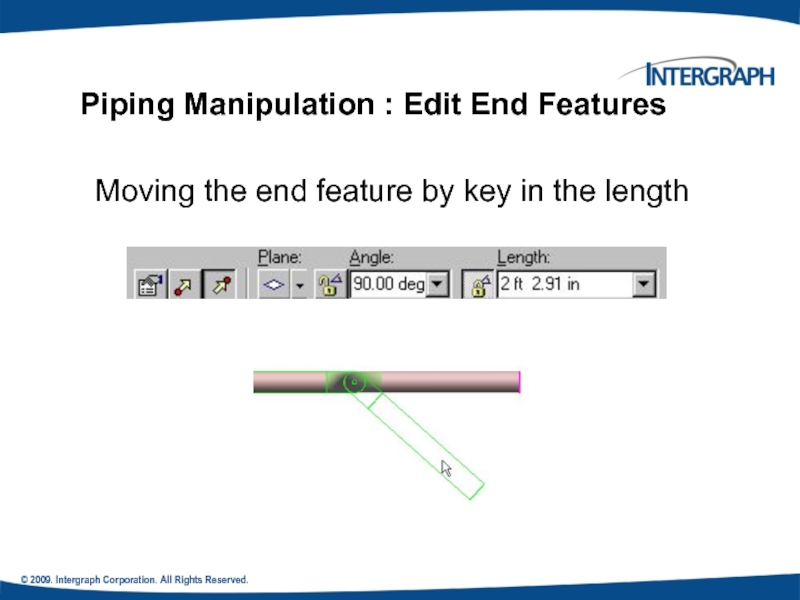

Piping Manipulation : Edit End

Moving the end feature by key in the length

Слайд 65© 2009. Intergraph Corporation. All Rights Reserved.

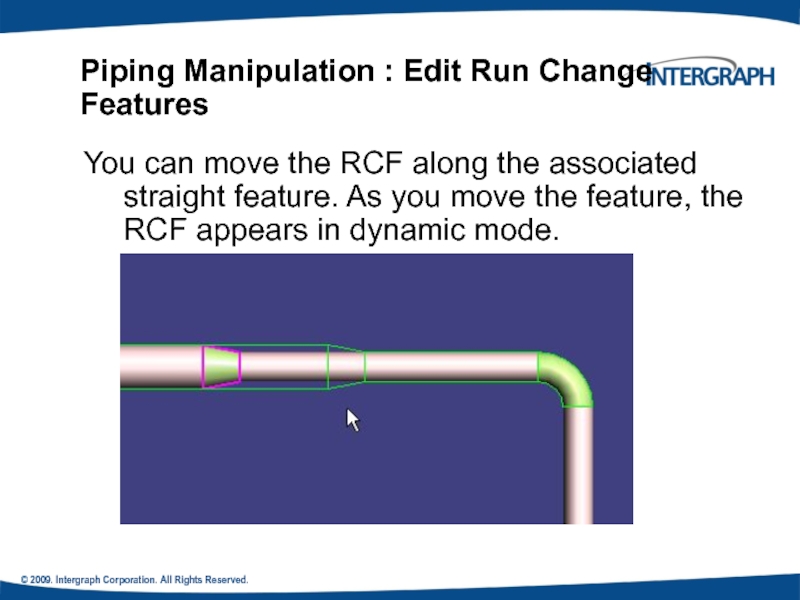

Piping Manipulation : Edit Run

You can move the RCF along the associated straight feature. As you move the feature, the RCF appears in dynamic mode.

Слайд 66© 2004. Intergraph Corporation. All Rights Reserved.

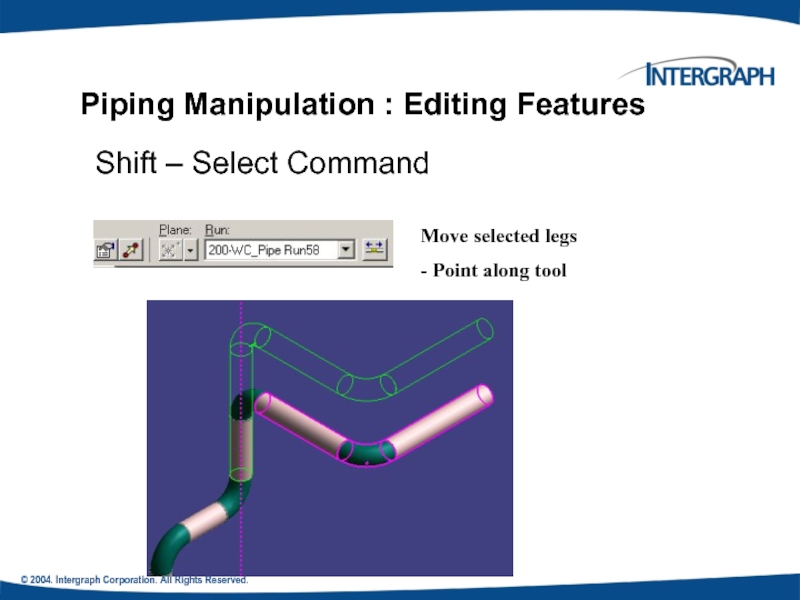

Piping Manipulation : Editing Features

Shift

Move selected legs

- Point along tool

Слайд 67© 2009. Intergraph Corporation. All Rights Reserved.

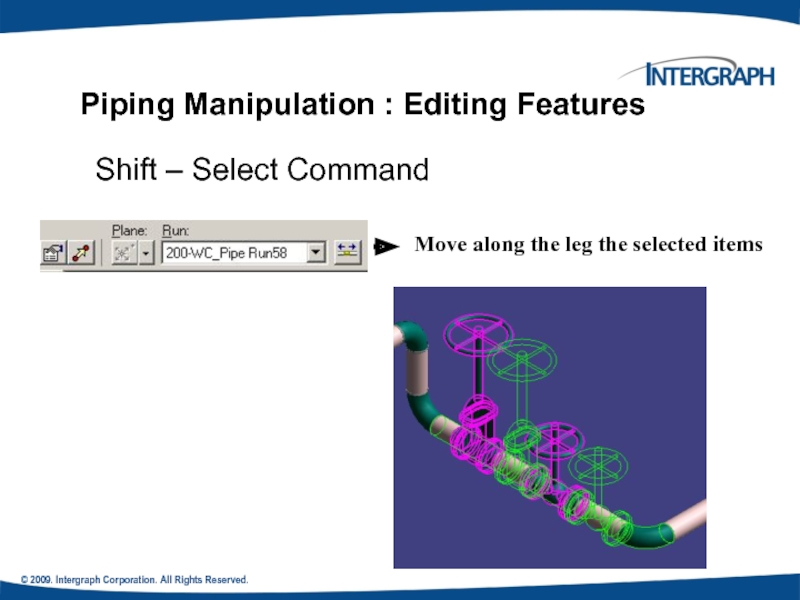

Piping Manipulation : Editing Features

Shift

Move along the leg the selected items

Слайд 68© 2009. Intergraph Corporation. All Rights Reserved.

Piping Manipulation : Editing Features

Shift

Turn off the moving along the leg

Слайд 69© 2009. Intergraph Corporation. All Rights Reserved.

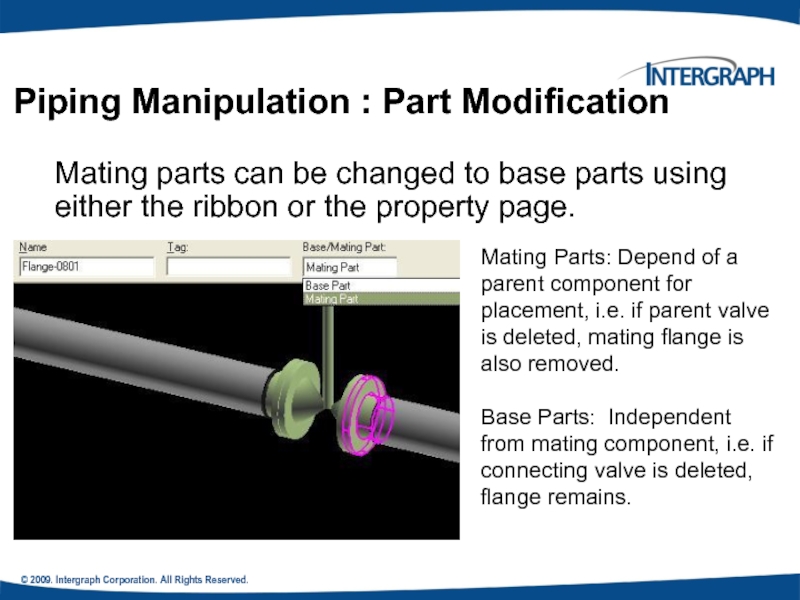

Mating parts can be changed

Piping Manipulation : Part Modification

Mating Parts: Depend of a parent component for placement, i.e. if parent valve is deleted, mating flange is also removed.

Base Parts: Independent from mating component, i.e. if connecting valve is deleted, flange remains.

Слайд 70© 2009. Intergraph Corporation. All Rights Reserved.

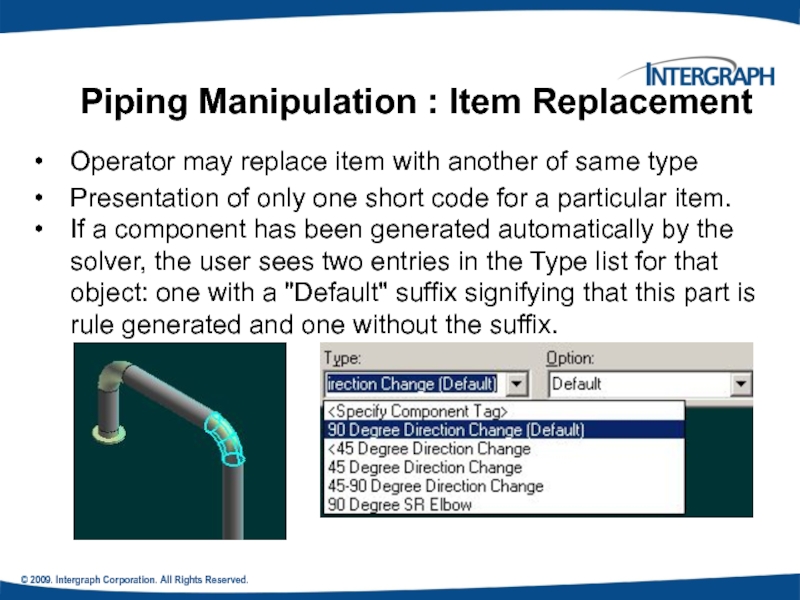

Operator may replace item with

Presentation of only one short code for a particular item.

If a component has been generated automatically by the solver, the user sees two entries in the Type list for that object: one with a "Default" suffix signifying that this part is rule generated and one without the suffix.

Piping Manipulation : Item Replacement

Слайд 71© 2009. Intergraph Corporation. All Rights Reserved.

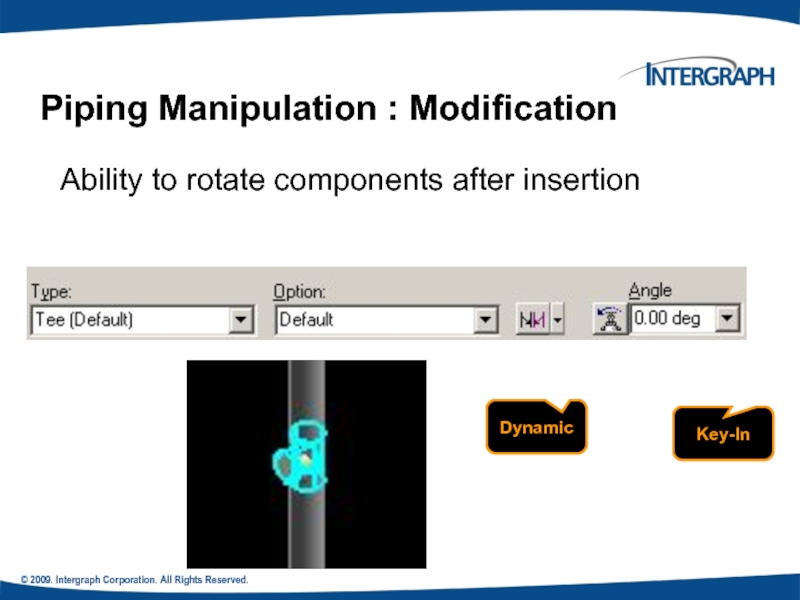

.

New Enhancement in V4

Ability

Key-In

Piping Manipulation : Modification

Dynamic

Слайд 72© 2009. Intergraph Corporation. All Rights Reserved.

New Enhancement in V4

Copy/Paste

Mirror Copy command is available

Creation of a connection (geometry permitting) when multiple objects are moved and placed on another object

Piping Manipulation : Modification

Слайд 73© 2009. Intergraph Corporation. All Rights Reserved.

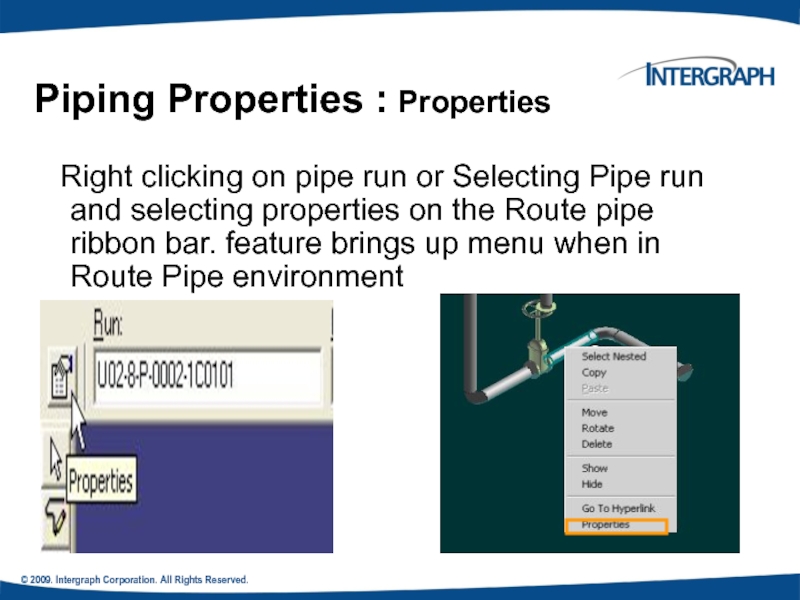

Right clicking on pipe run

Piping Properties : Properties

Слайд 74© 2009. Intergraph Corporation. All Rights Reserved.

.

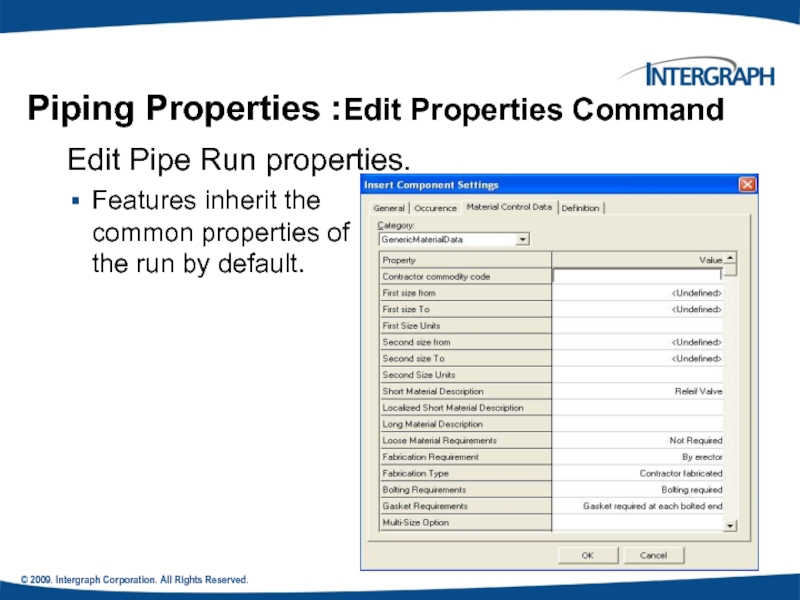

Piping Properties :Edit Properties Command

Edit

Features inherit the common properties of the run by default.

Слайд 75© 2009. Intergraph Corporation. All Rights Reserved.

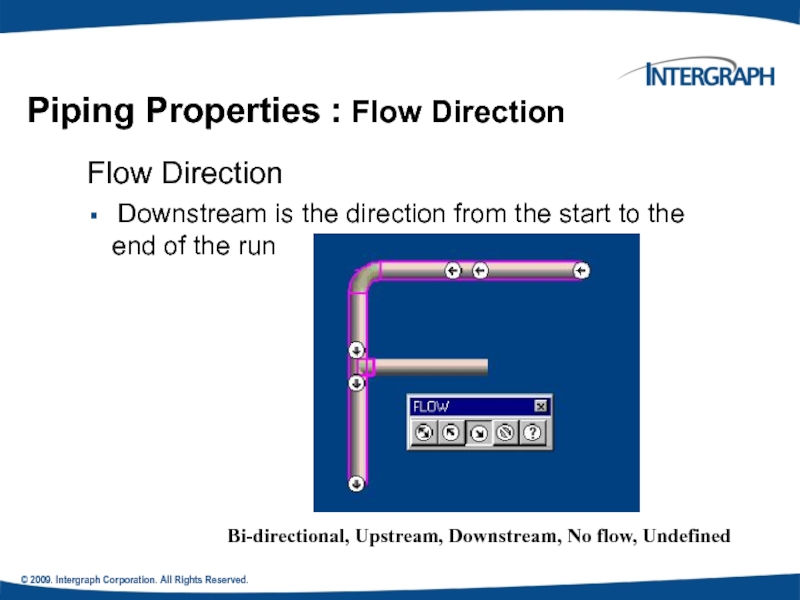

Piping Properties : Flow Direction

Flow

Downstream is the direction from the start to the end of the run

Bi-directional, Upstream, Downstream, No flow, Undefined

Слайд 76© 2009. Intergraph Corporation. All Rights Reserved.

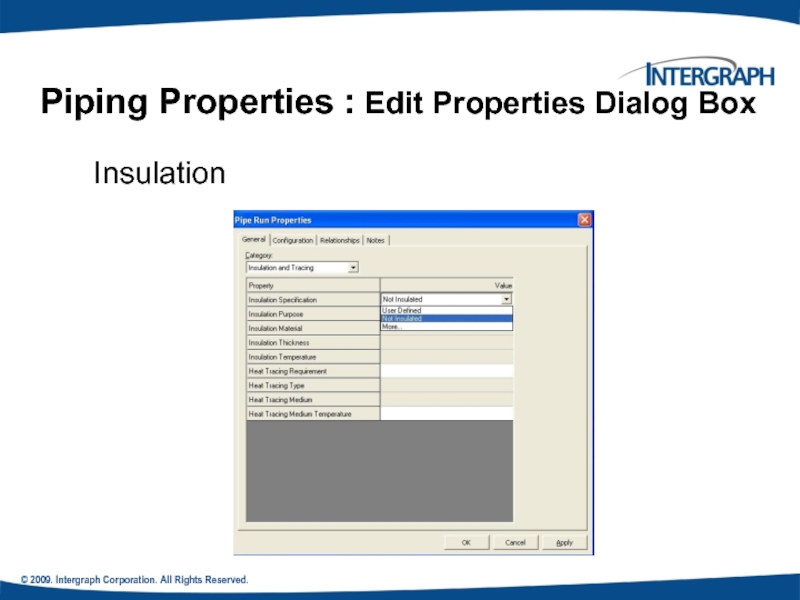

Piping Properties : Edit Properties

Insulation

Слайд 77© 2009. Intergraph Corporation. All Rights Reserved.

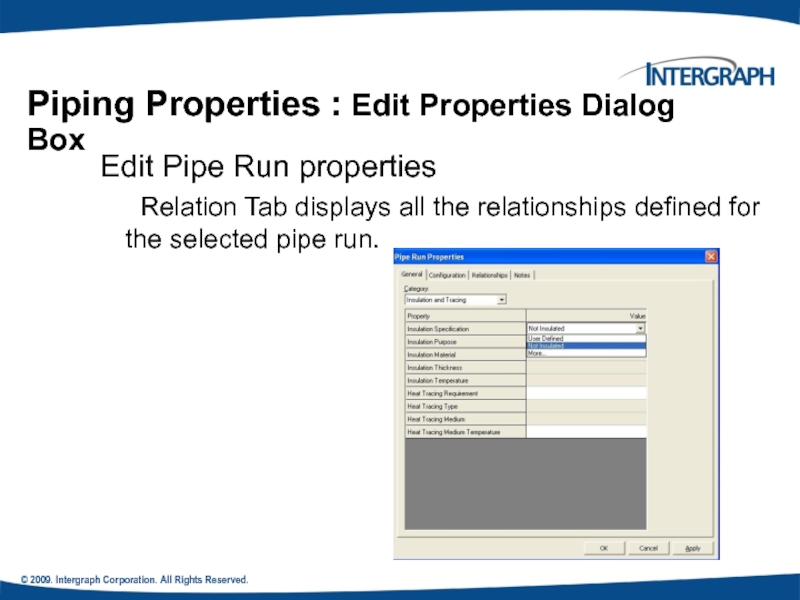

Piping Properties : Edit Properties

Edit Pipe Run properties

Relation Tab displays all the relationships defined for the selected pipe run.

Слайд 78© 2009. Intergraph Corporation. All Rights Reserved.

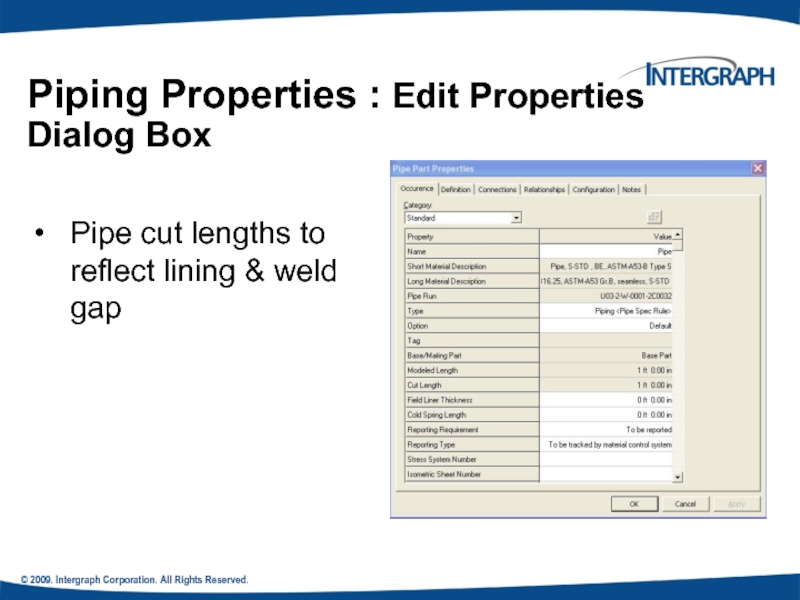

Pipe cut lengths to reflect

Piping Properties : Edit Properties Dialog Box

Слайд 79© 2009. Intergraph Corporation. All Rights Reserved.

Ability to insert notes on

Piping Properties : Inserting notes

Слайд 80© 2009. Intergraph Corporation. All Rights Reserved.

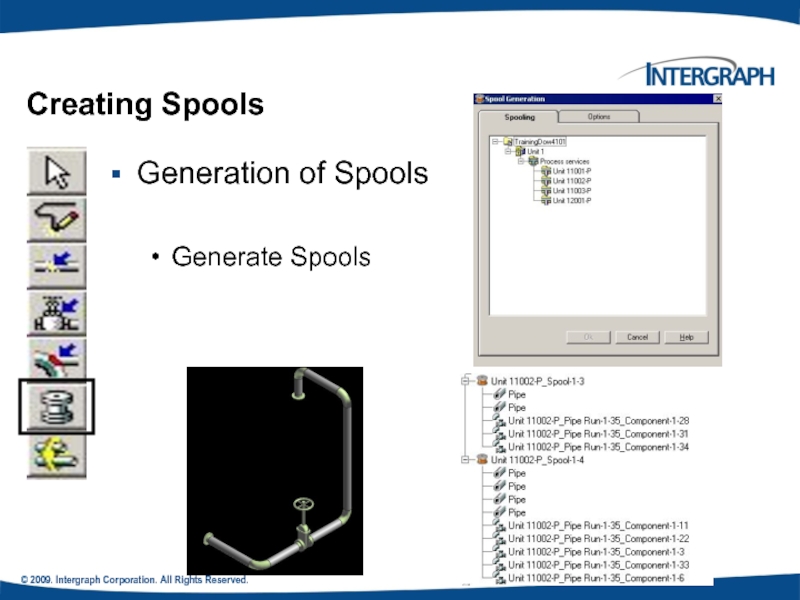

Creating Spools

Generation of Spools

Generate Spools

Слайд 81© 2009. Intergraph Corporation. All Rights Reserved.

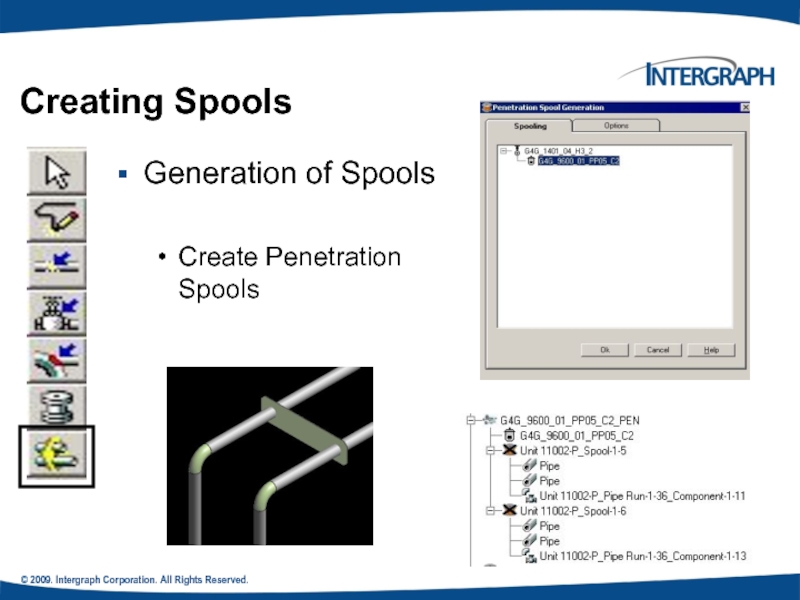

Generation of Spools

Create Penetration

Creating Spools

Слайд 82© 2009. Intergraph Corporation. All Rights Reserved.

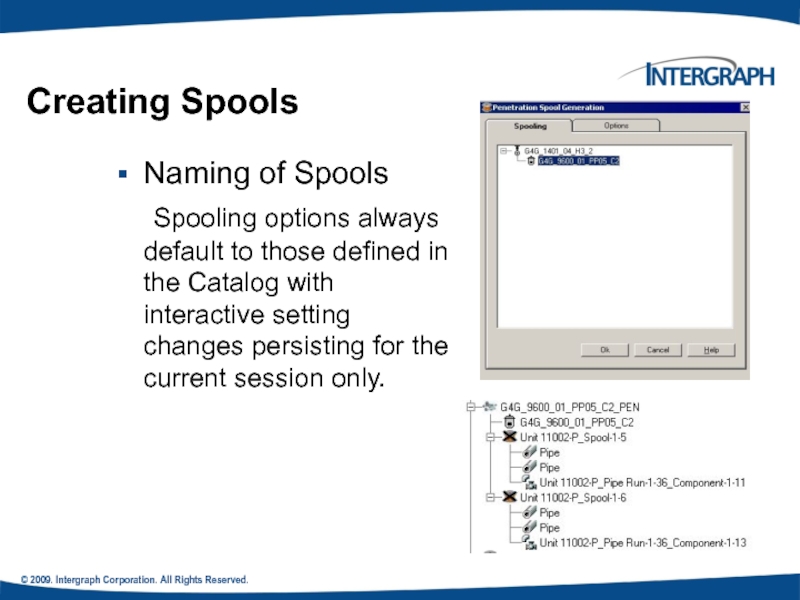

Naming of Spools

Spooling options

Creating Spools

Слайд 83© 2009. Intergraph Corporation. All Rights Reserved.

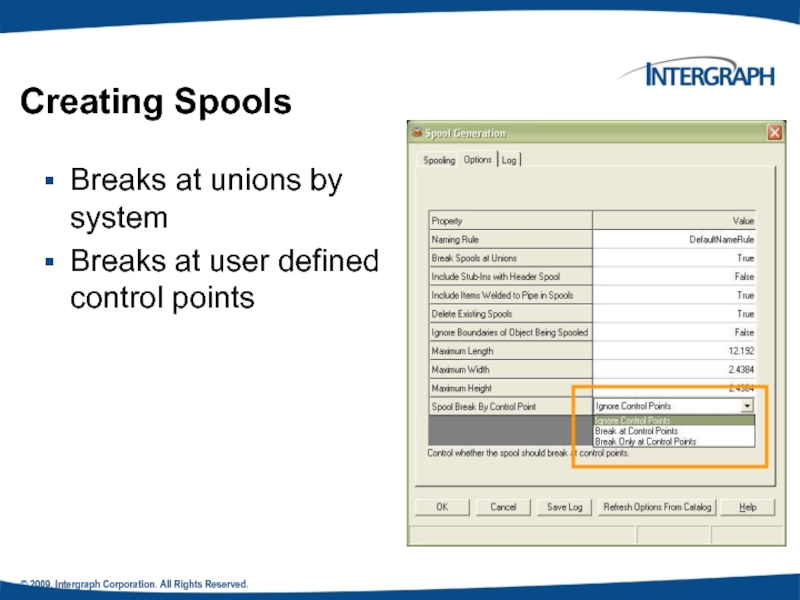

Breaks at unions by system

Breaks

Creating Spools

Слайд 84© 2009. Intergraph Corporation. All Rights Reserved.

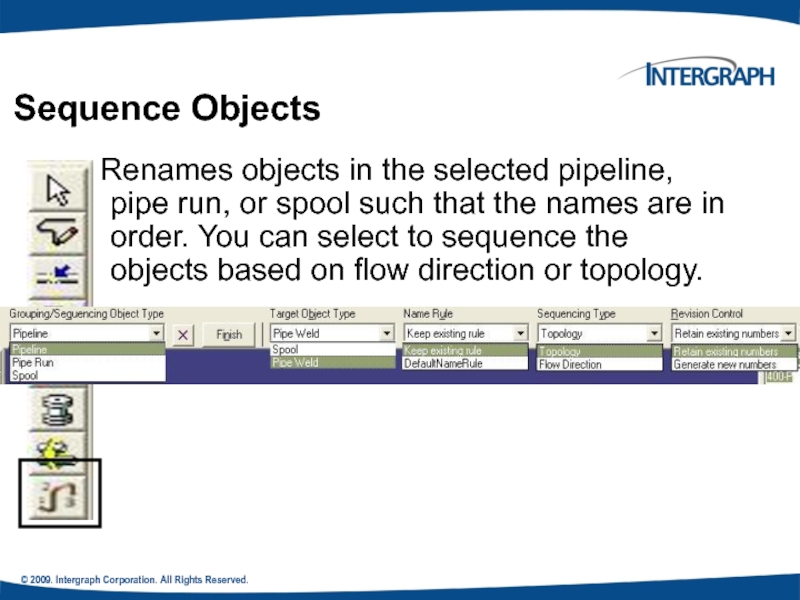

.

Sequence Objects

Renames objects in the

Слайд 85© 2004. Intergraph Corporation. All Rights Reserved.

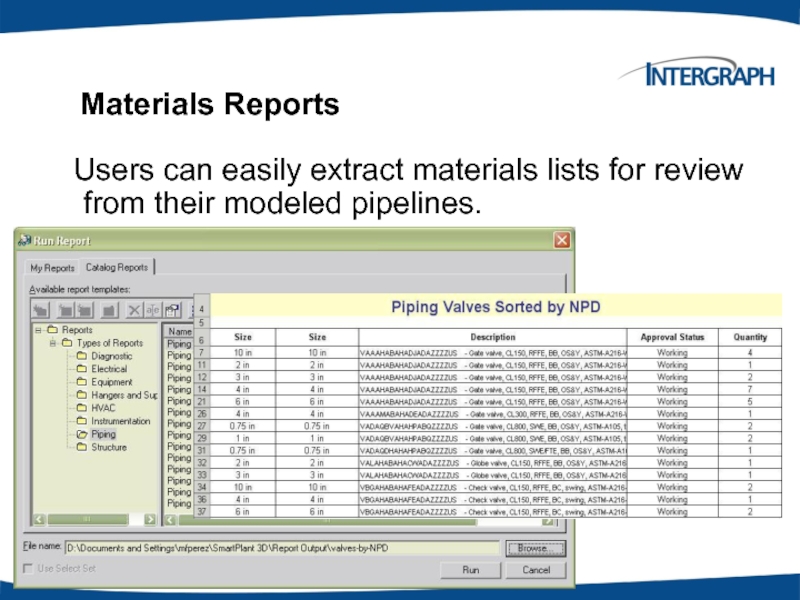

Materials Reports

Users can easily extract

Слайд 86© 2004. Intergraph Corporation. All Rights Reserved.

Manipulating Piping Objects

Creating Spools

Sequencing Objects

Creating

Piping Practice Labs