- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

ML 3 gen training 07( ACD -ICD) презентация

Содержание

- 1. ML 3 gen training 07( ACD -ICD)

- 2. EdGo, MEA 2007-05-3.4 IceDry 3000 internal

- 3. EdGo, MEA 2007-05-3.4 IceDry 3000 separate control panel

- 4. EdGo, MEA 2007-05-3.4 IceDry soft ware Controller

- 5. EdGo, MEA 2007-05-3.4 Differences with standard units

- 6. EdGo, MEA 2007-05-3.4 Reactivation fans. Complete tight

- 7. EdGo, MEA 2007-05-3.4 Enclosure. Unit enclosure completely

- 8. EdGo, MEA 2007-05-3.4 Controls . Control panel

- 9. EdGo, MEA 2007-05-3.4 IceDry 3000 defrost. Defrost

- 10. EdGo, MEA 2007-05-3.4 IceDry installations . See

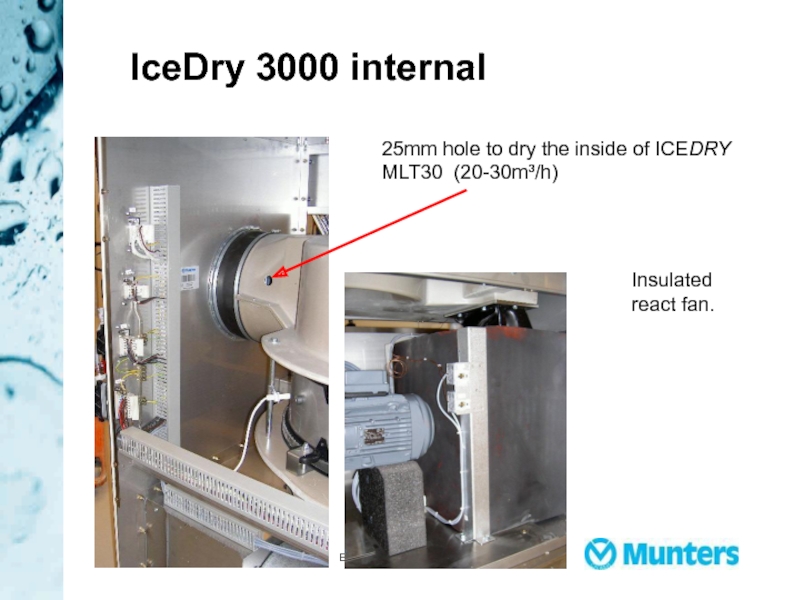

Слайд 2EdGo, MEA 2007-05-3.4

IceDry 3000 internal

25mm hole to dry the inside of

ICEDRY MLT30 (20-30m³/h)

Insulated react fan.

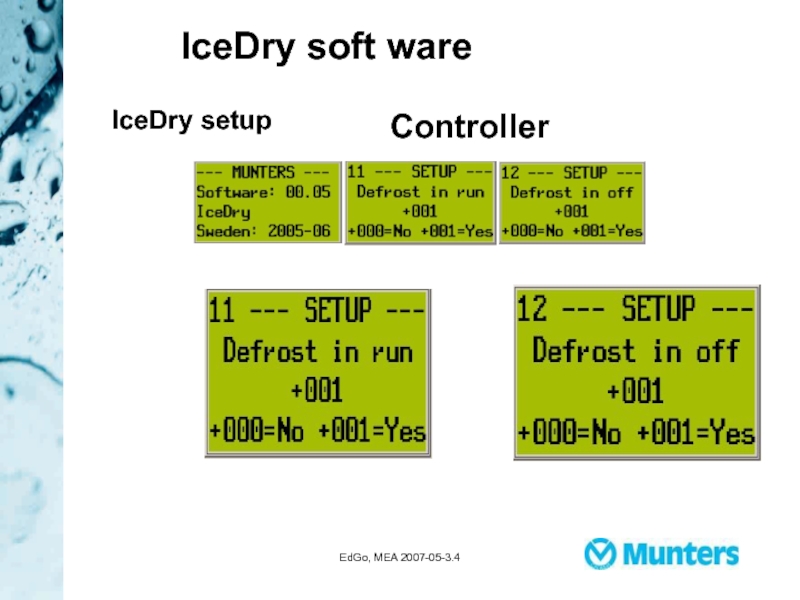

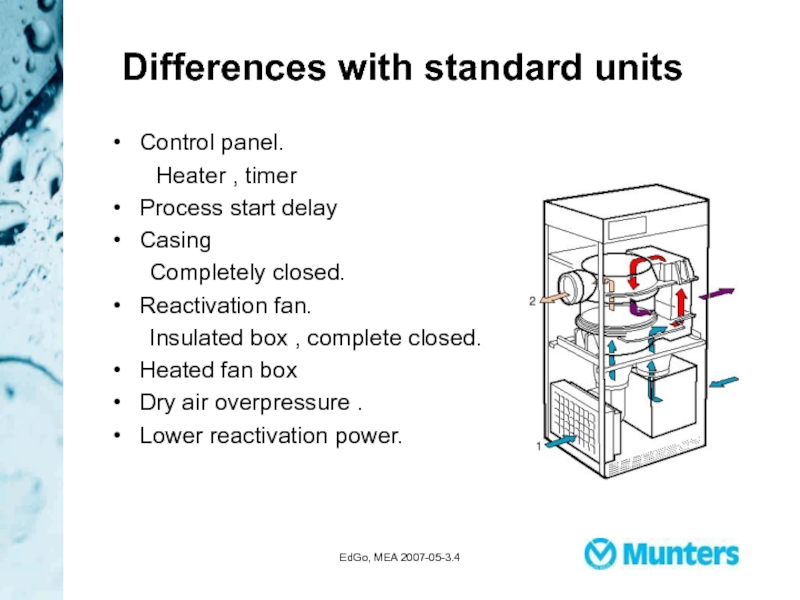

Слайд 5EdGo, MEA 2007-05-3.4

Differences with standard units

Control panel.

Heater , timer

Process start

delay

Casing

Completely closed.

Reactivation fan.

Insulated box , complete closed.

Heated fan box

Dry air overpressure .

Lower reactivation power.

Casing

Completely closed.

Reactivation fan.

Insulated box , complete closed.

Heated fan box

Dry air overpressure .

Lower reactivation power.

Слайд 6EdGo, MEA 2007-05-3.4

Reactivation fans.

Complete tight fan box with external insulation .

Heating

between insulation and box , controlled by thermostats.

Must replaced as a complete item , separate fan is available but NOT advised to replace separately.

Must replaced as a complete item , separate fan is available but NOT advised to replace separately.

Слайд 7EdGo, MEA 2007-05-3.4

Enclosure.

Unit enclosure completely closed.

No seals on panels.

Overpressure dry air

in casing by hole in top cover.

Слайд 8EdGo, MEA 2007-05-3.4

Controls .

Control panel heated , controlled by thermostat.

Delay on

process fan start , only reactivation heater and fan in operation.

No controls are used to start or stop the unit.

Before starting unit 12 hr with power on to heat up reactivation fan compartment.

No controls are used to start or stop the unit.

Before starting unit 12 hr with power on to heat up reactivation fan compartment.

Слайд 9EdGo, MEA 2007-05-3.4

IceDry 3000 defrost.

Defrost will stop process fan and keep

reactivation circuit operational.

Defrost can be set with unit in operation or unit topped.

Defrost can be set with unit in operation or unit topped.

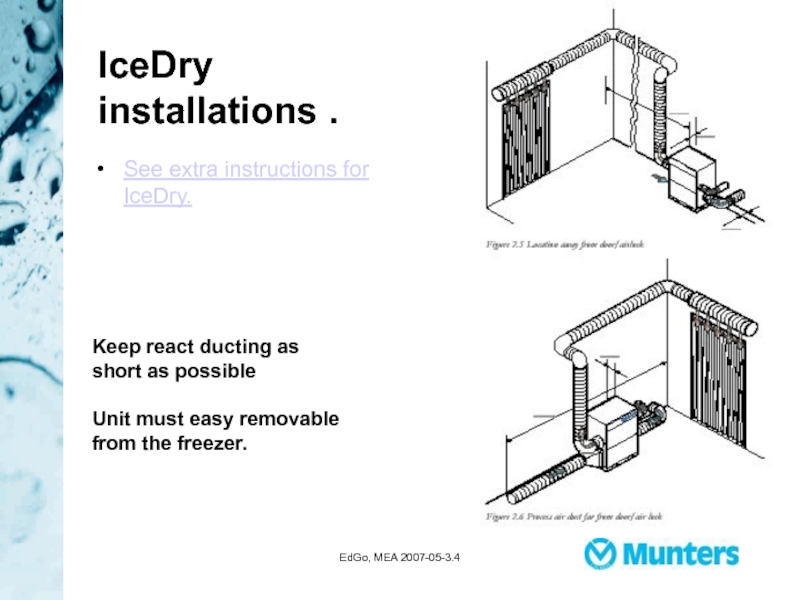

Слайд 10EdGo, MEA 2007-05-3.4

IceDry installations .

See extra instructions for IceDry.

Keep react ducting

as

short as possible

Unit must easy removable

from the freezer.