- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

MAN Diesel PrimeServ Academy Hydraulic Power Supply, HPS презентация

Содержание

- 1. MAN Diesel PrimeServ Academy Hydraulic Power Supply, HPS

- 2. < > 2) Filter

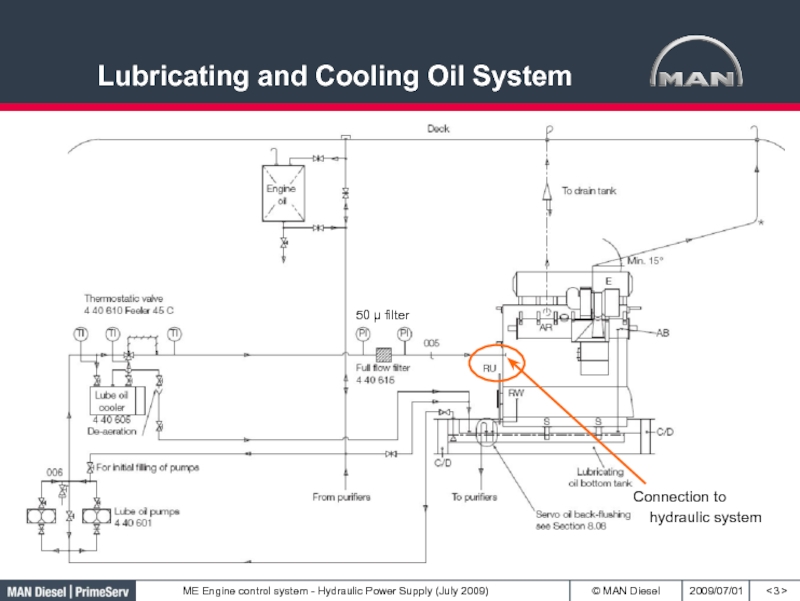

- 3. Lubricating and Cooling Oil System < > Connection to hydraulic system 50 μ filter

- 4. Hydraulic Power Supply - HPS < >

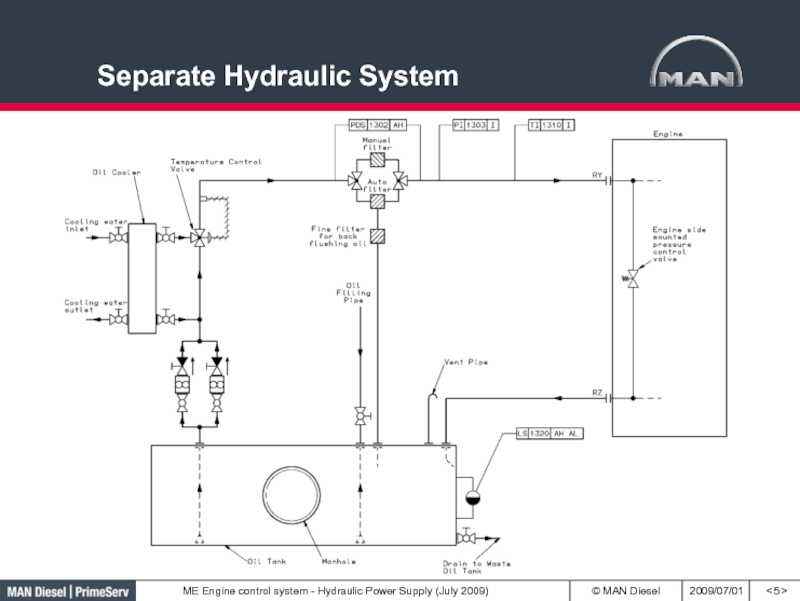

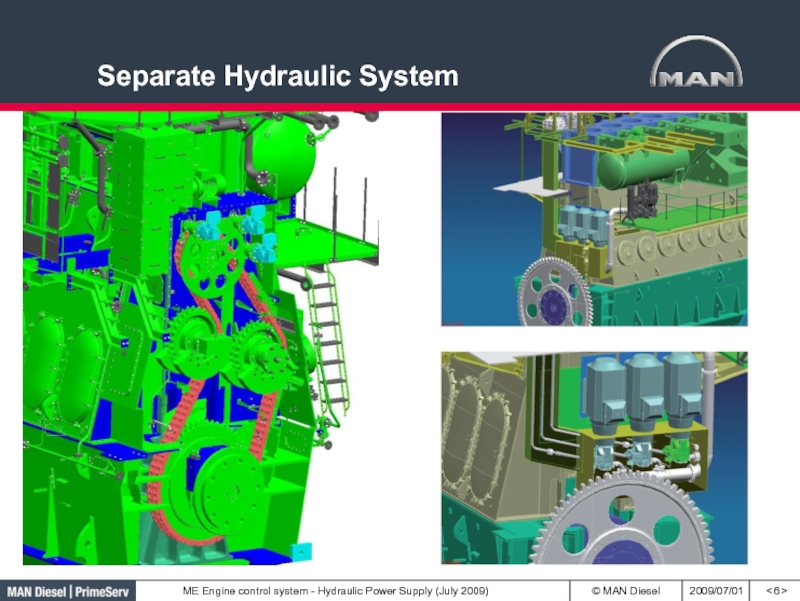

- 5. Separate Hydraulic System < >

- 6. Separate Hydraulic System < >

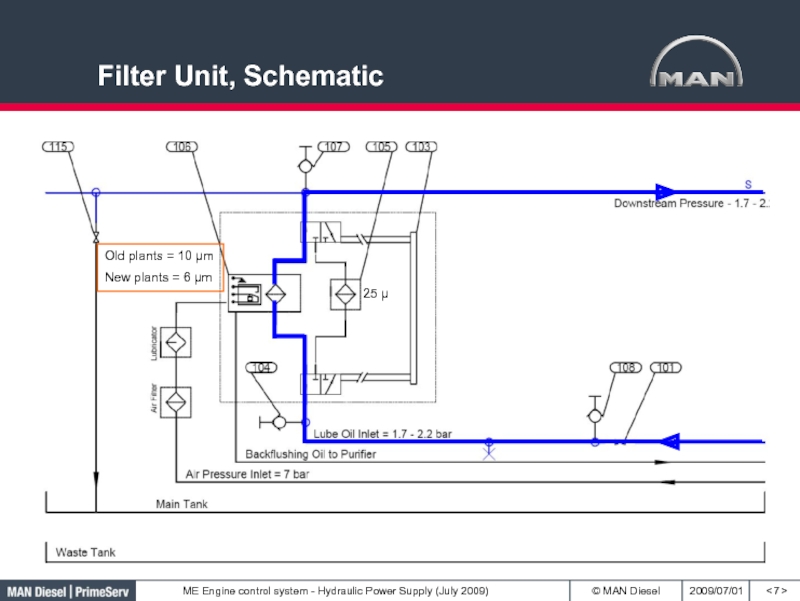

- 7. Filter Unit, Schematic < > Old plants

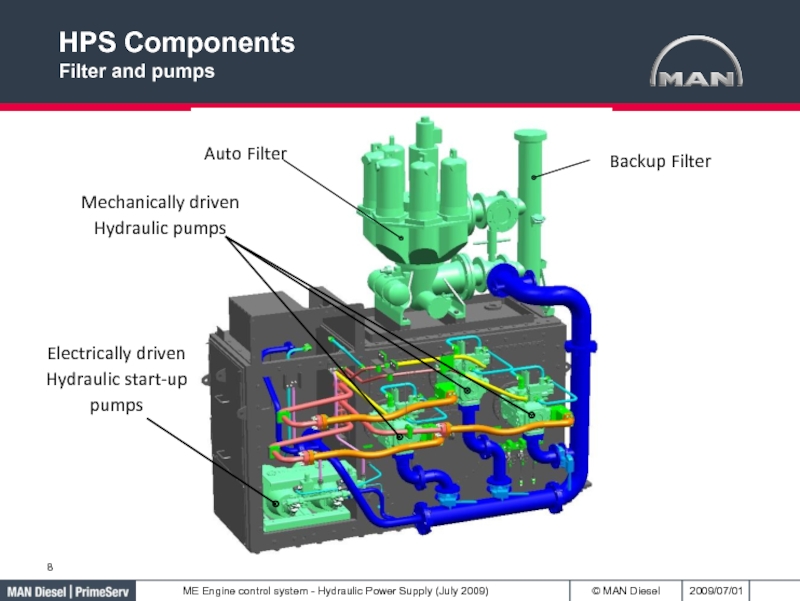

- 8. HPS Components Filter and pumps Auto

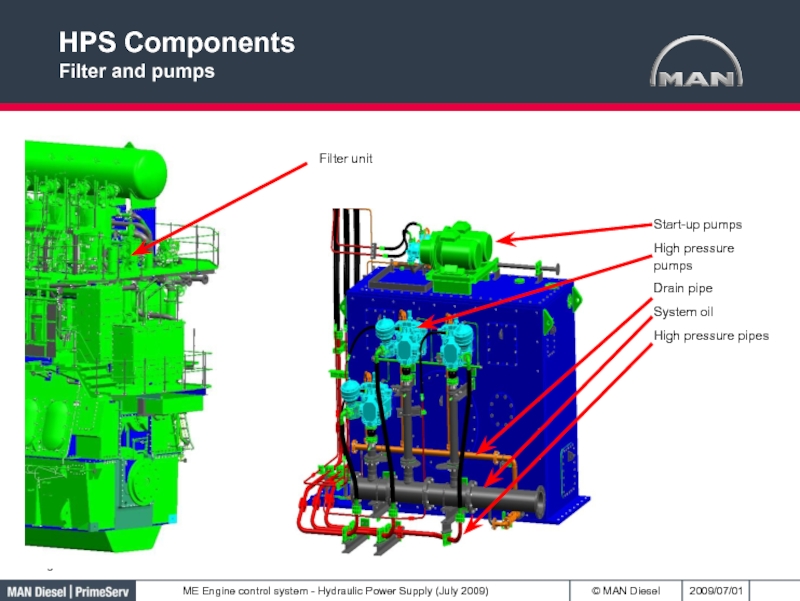

- 9. HPS Components Filter and pumps

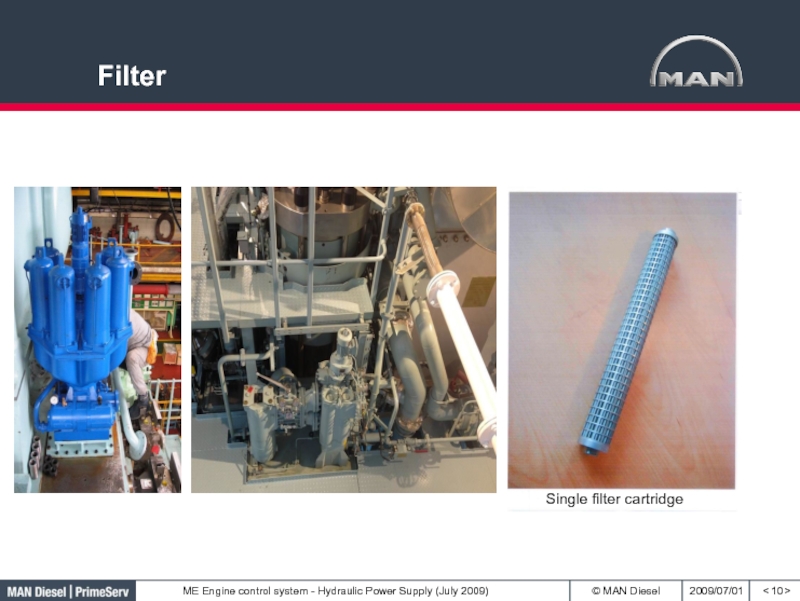

- 10. Filter < > Single filter cartridge

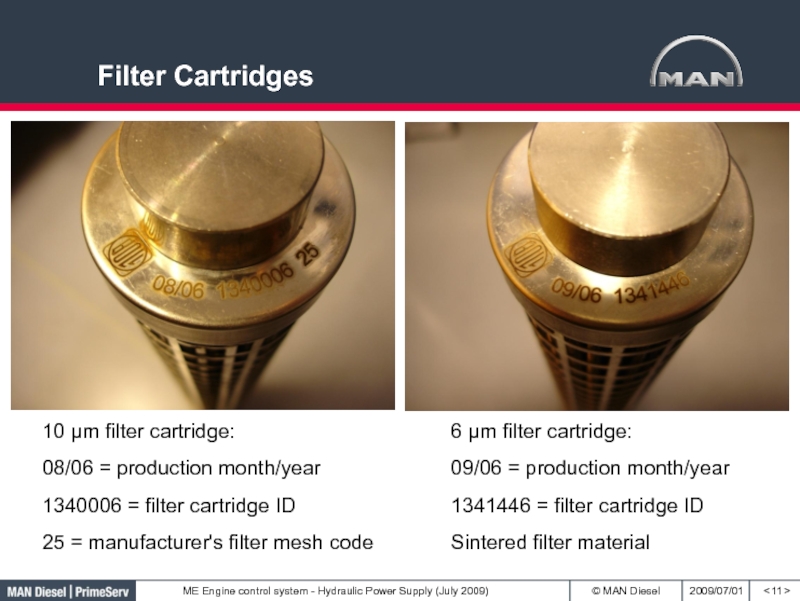

- 11. Filter Cartridges < > 10 µm

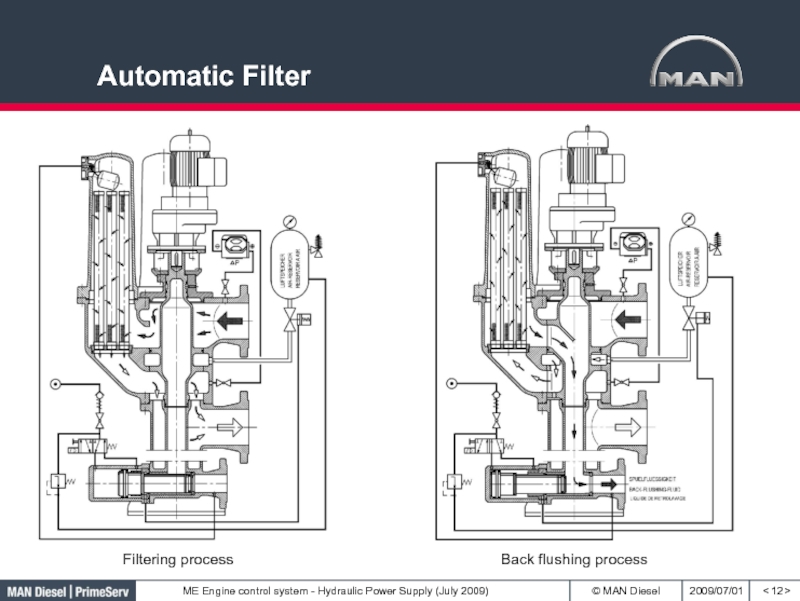

- 12. Automatic Filter < > Filtering process Back flushing process

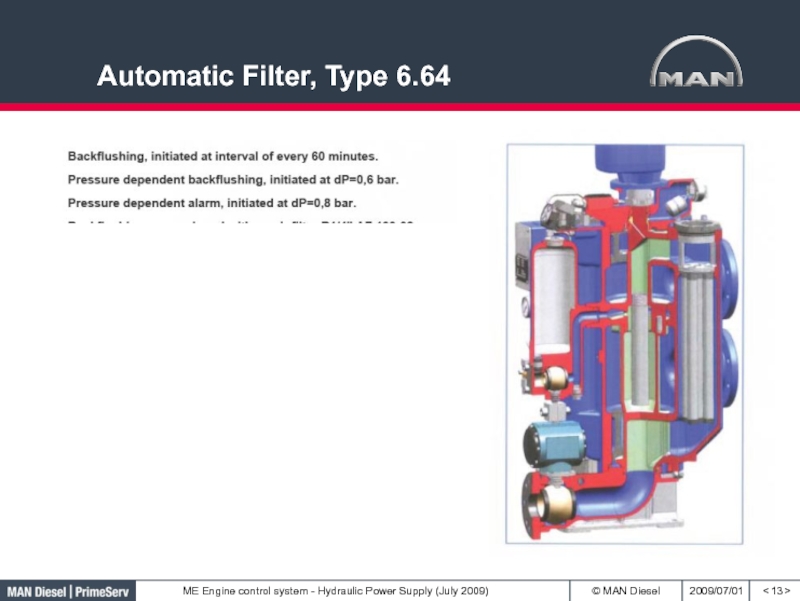

- 13. Automatic Filter, Type 6.64 < >

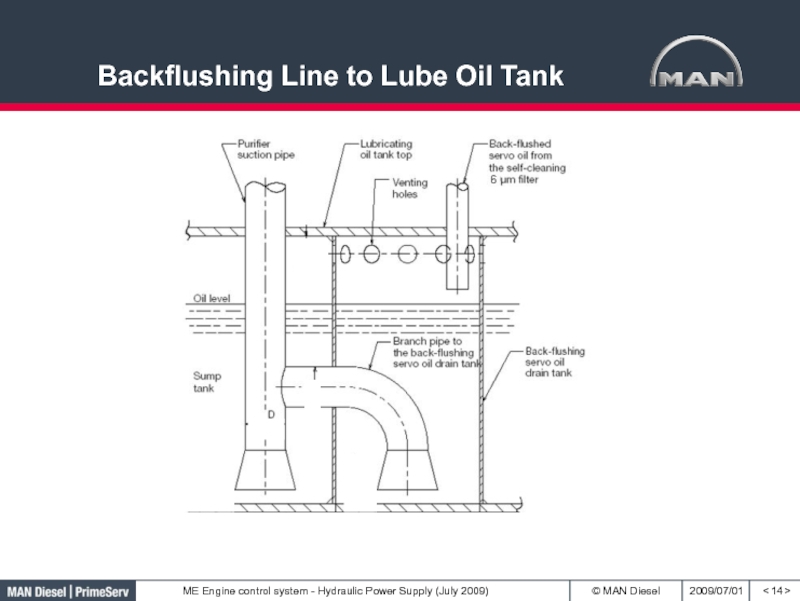

- 14. Backflushing Line to Lube Oil Tank < >

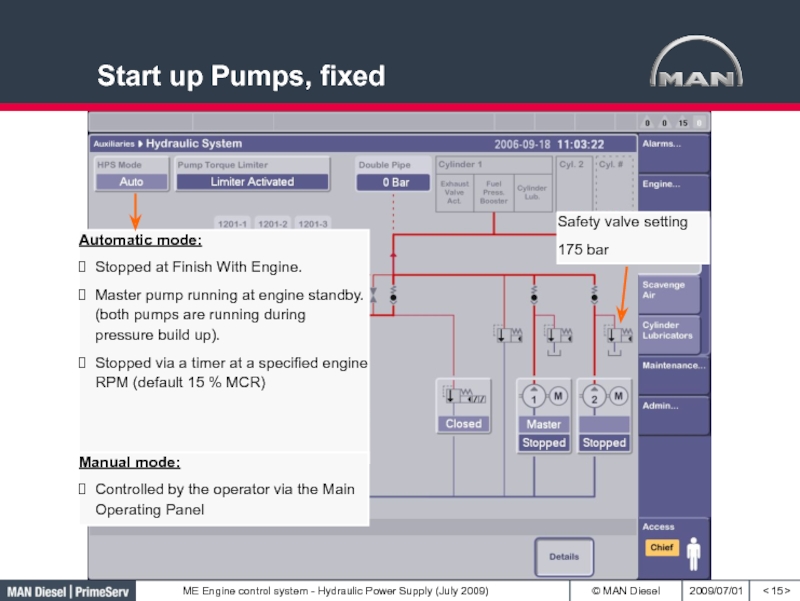

- 15. Start up Pumps, fixed < > Safety valve setting 175 bar

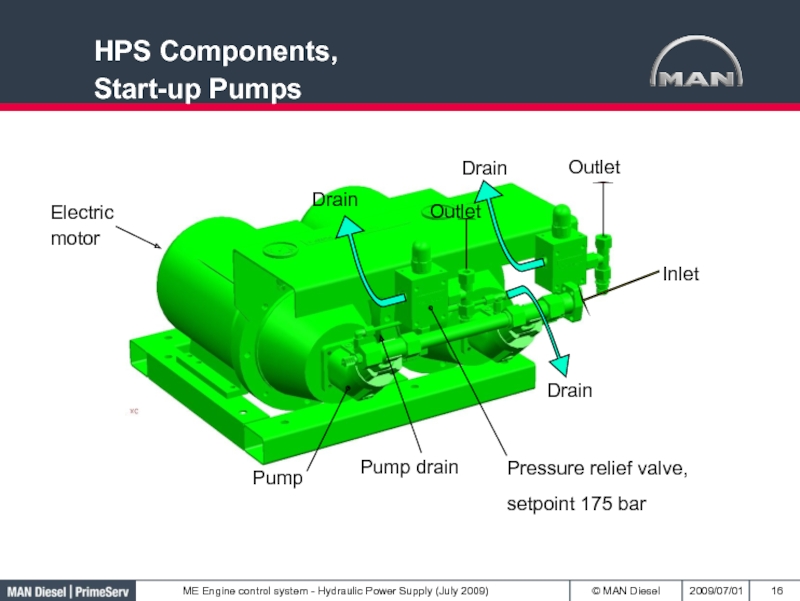

- 16. Electric motor Pump Inlet Drain Pressure relief

- 17. HPS Components, Start-up Pumps Pressure

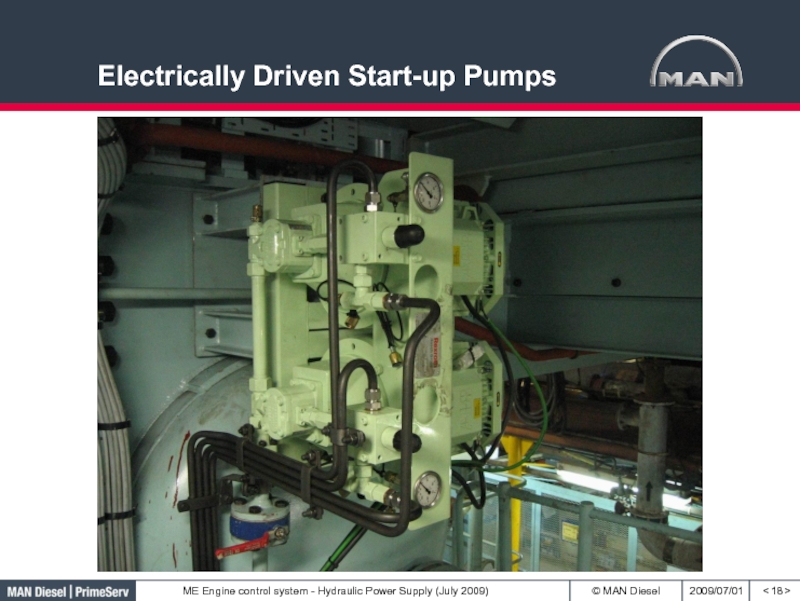

- 18. Electrically Driven Start-up Pumps < >

- 19. Engine Driven Pumps < >

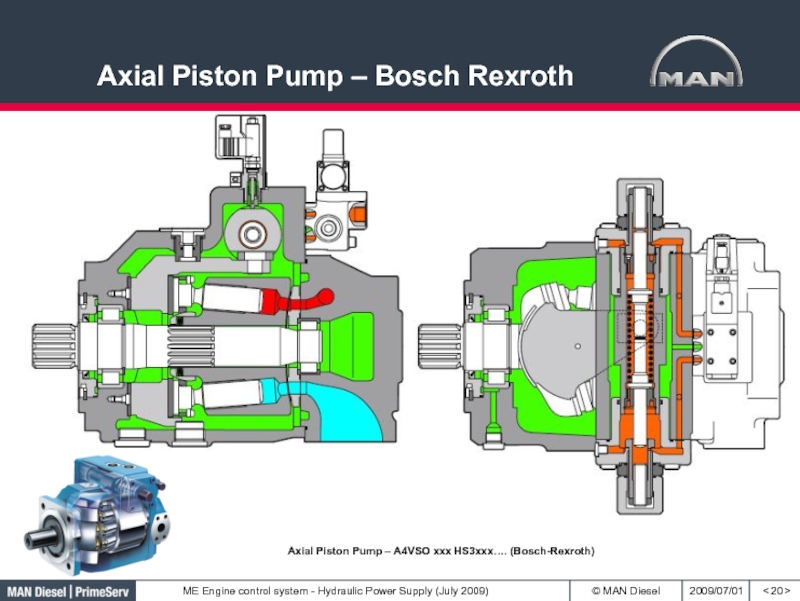

- 20. Axial Piston Pump – Bosch Rexroth

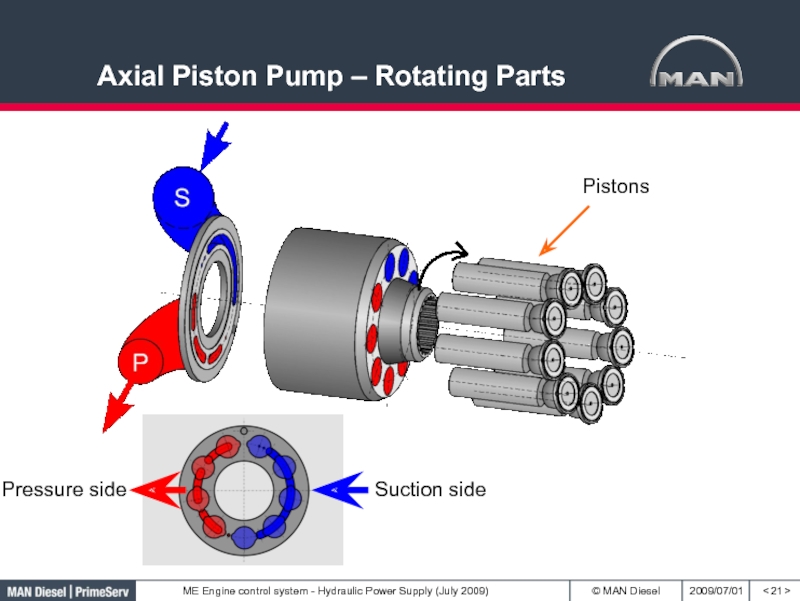

- 21. Axial Piston Pump – Rotating Parts < > Suction side Pressure side Pistons

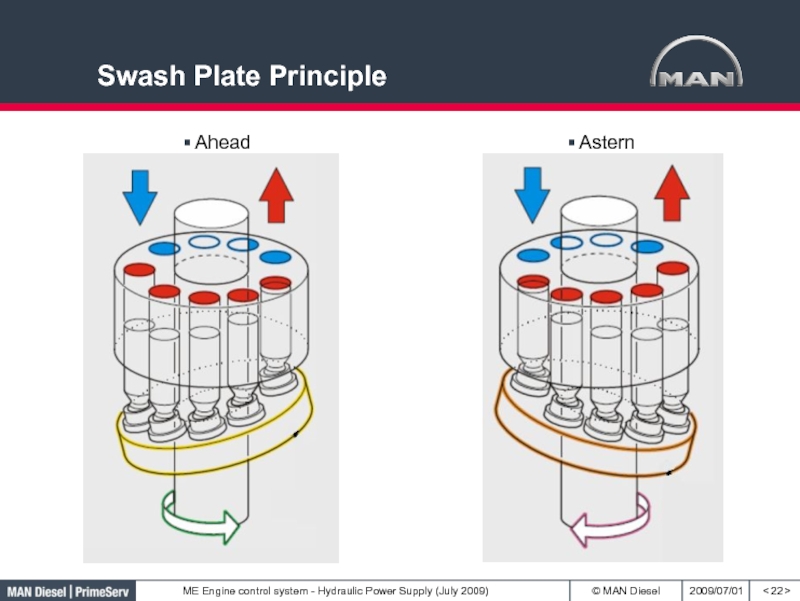

- 22. Swash Plate Principle < > Ahead Astern

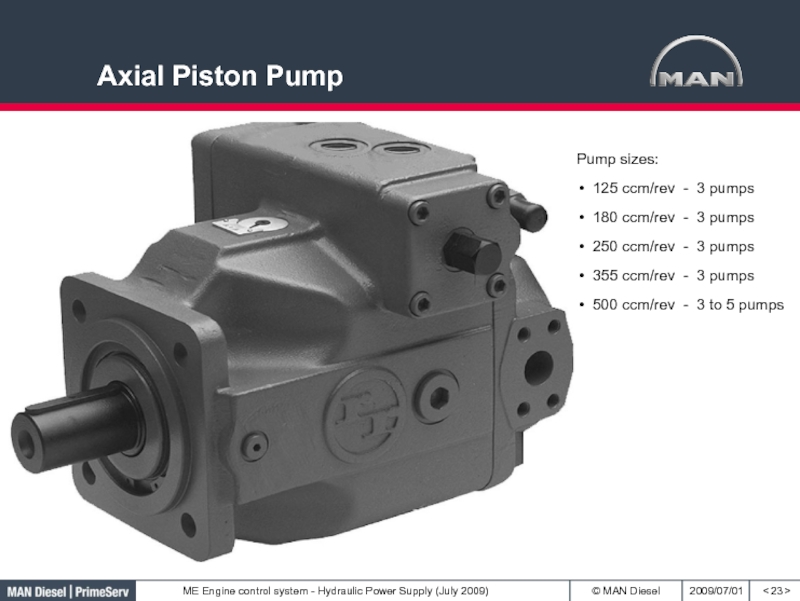

- 23. Axial Piston Pump < > Pump sizes:

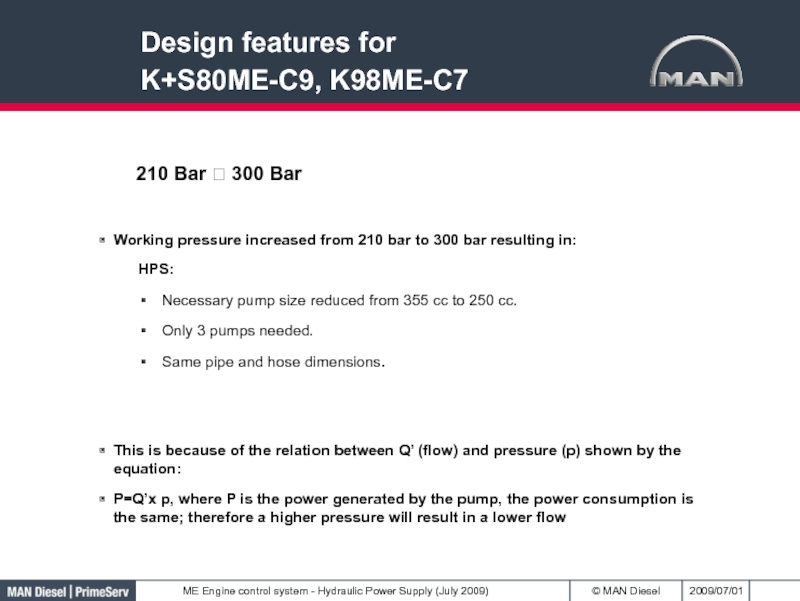

- 24. 210 Bar ? 300 Bar

- 25. 7S50ME-C Hydraulic Power Supply Accumulator Gear Box

- 26. 7S50ME-C Gear Box for HPS Output wheel

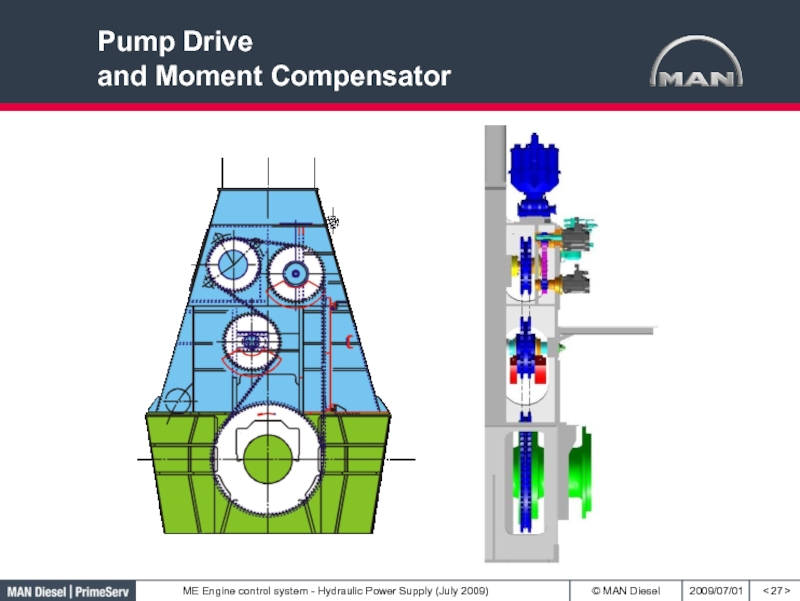

- 27. Pump Drive and Moment Compensator < >

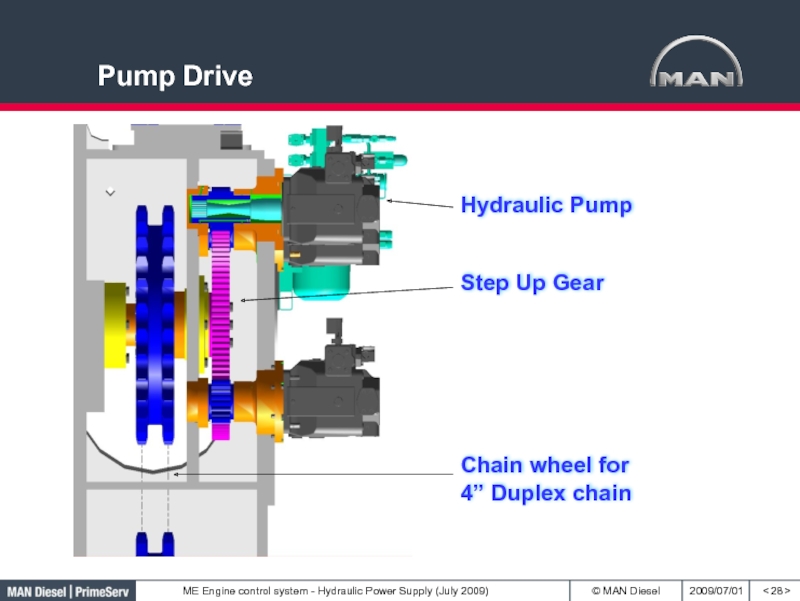

- 28. Pump Drive < >

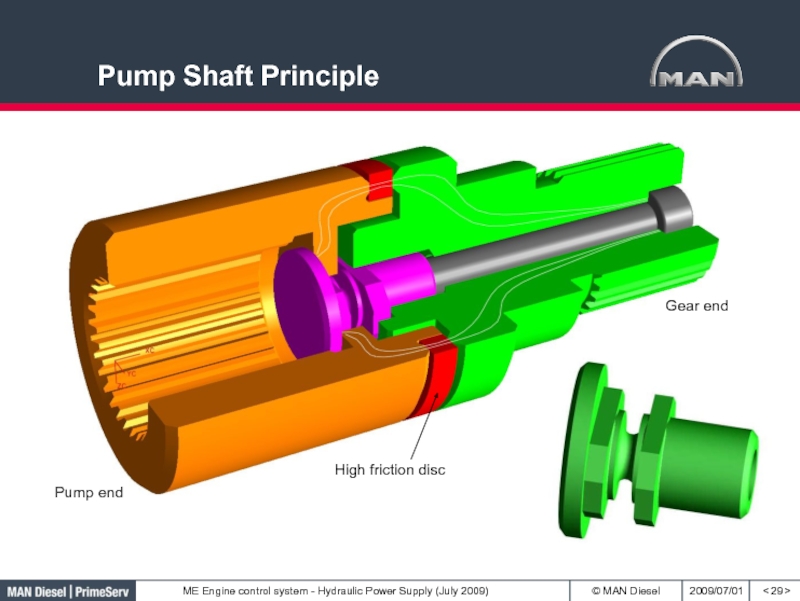

- 29. Pump Shaft Principle < > Pump end Gear end High friction disc

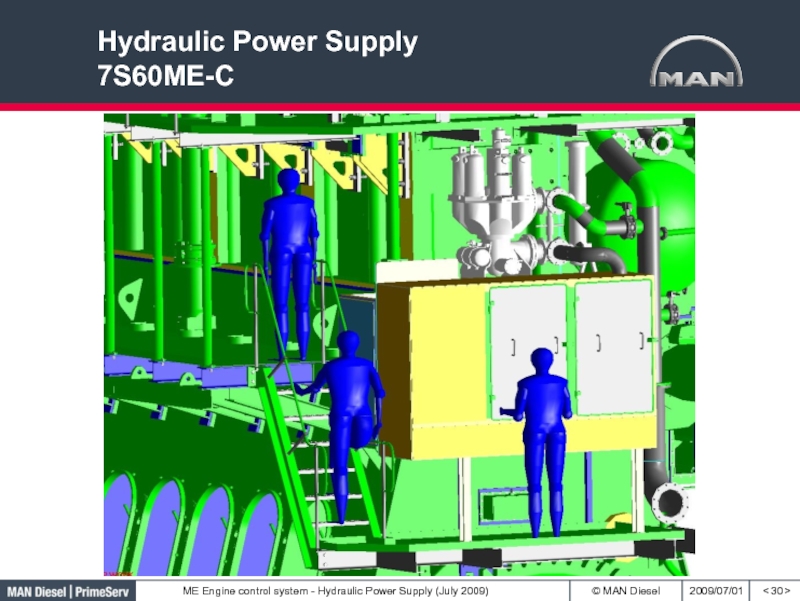

- 30. Hydraulic Power Supply 7S60ME-C < >

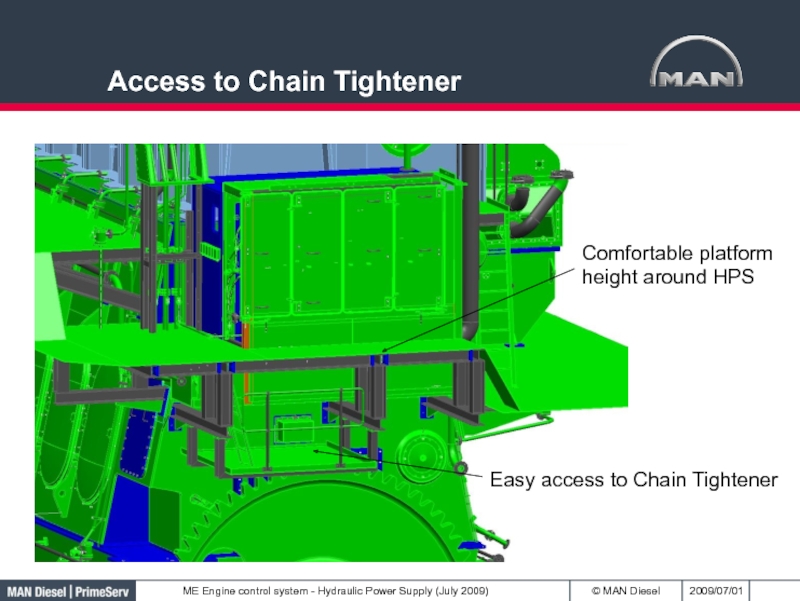

- 31. Comfortable platform height around HPS Easy access to Chain Tightener Access to Chain Tightener

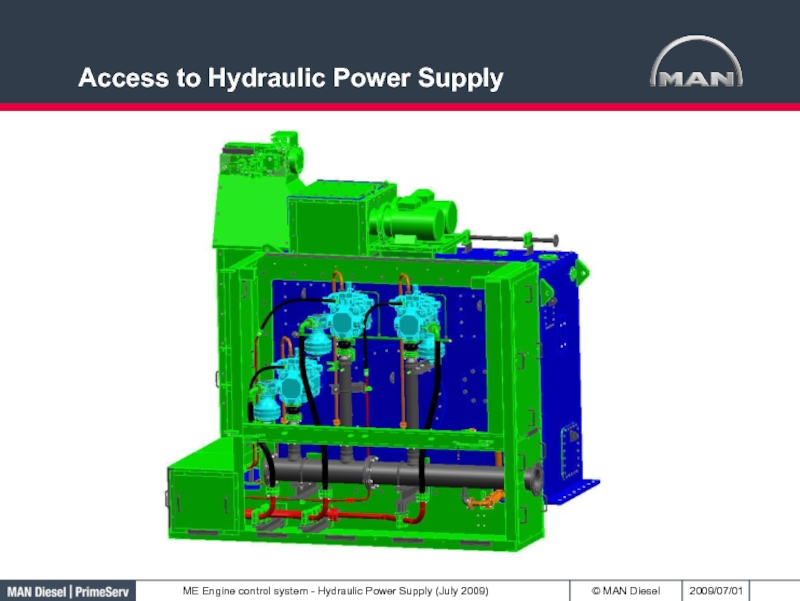

- 32. Access to Hydraulic Power Supply

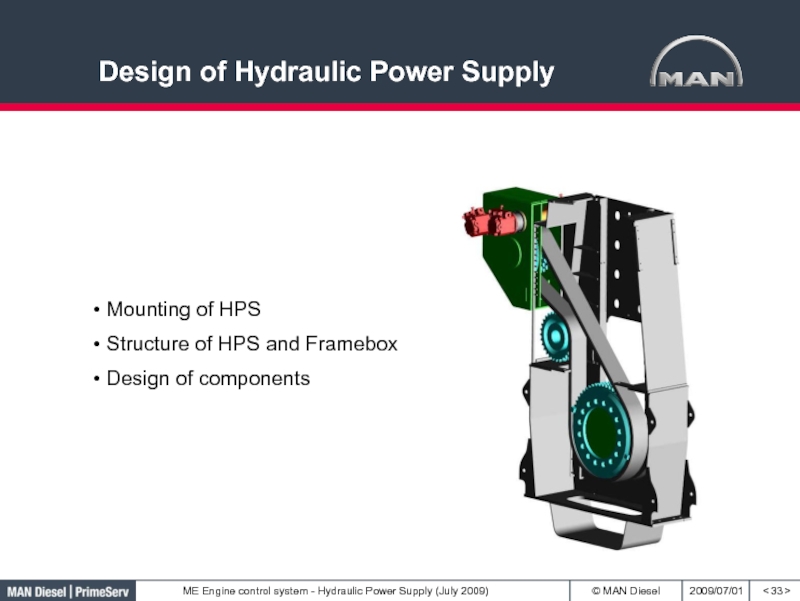

- 33. < > Design of Hydraulic Power Supply

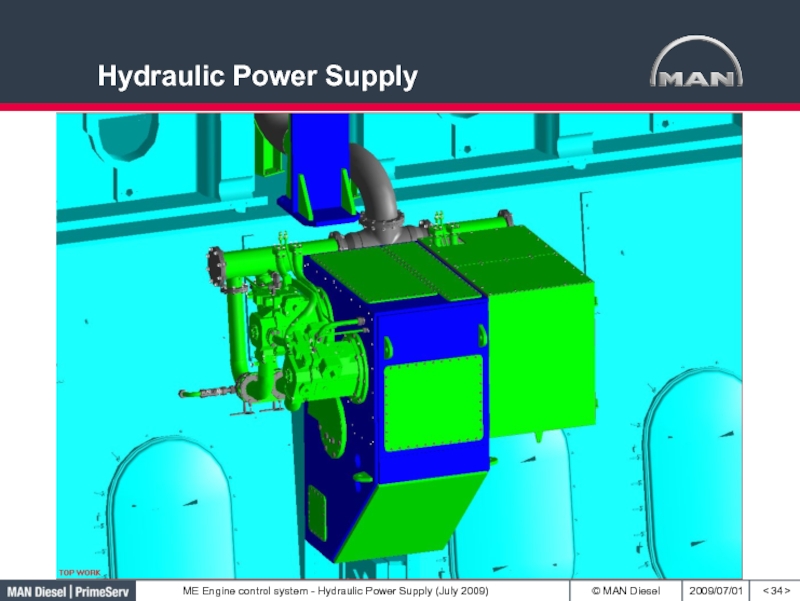

- 34. Hydraulic Power Supply < >

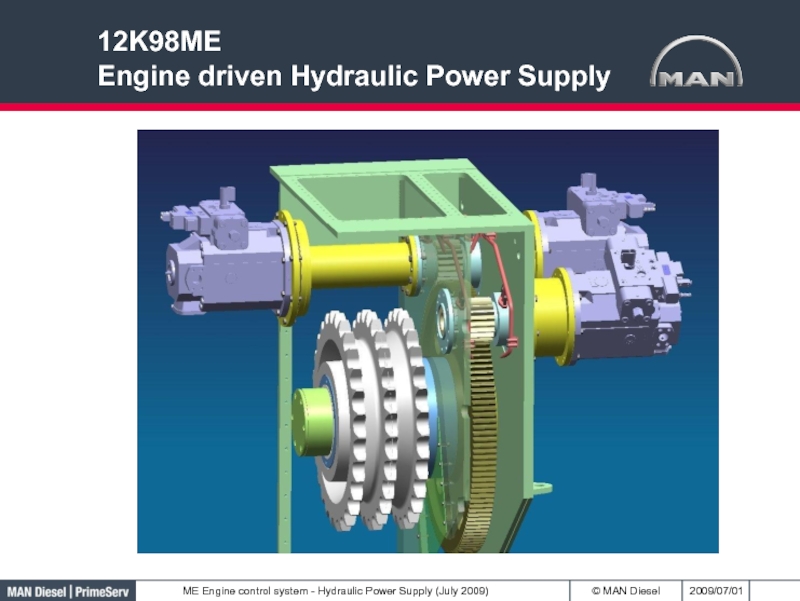

- 35. 12K98ME Engine driven Hydraulic Power Supply

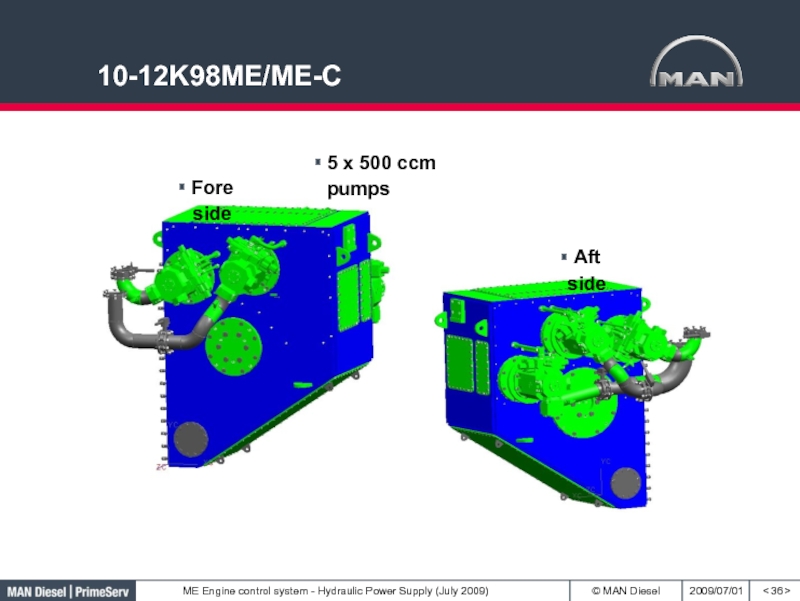

- 36. 10-12K98ME/ME-C < > 5 x 500 ccm pumps Aft side Fore side

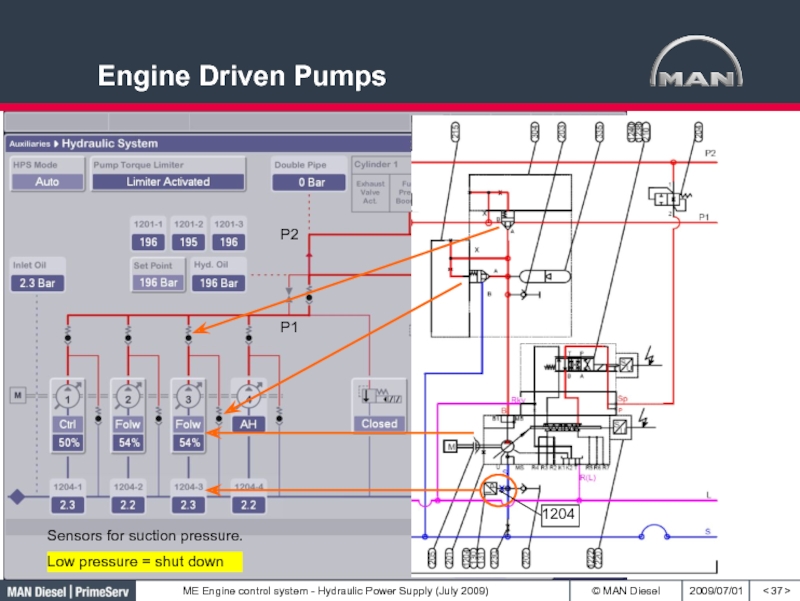

- 37. Engine Driven Pumps < > P1 P2 1204

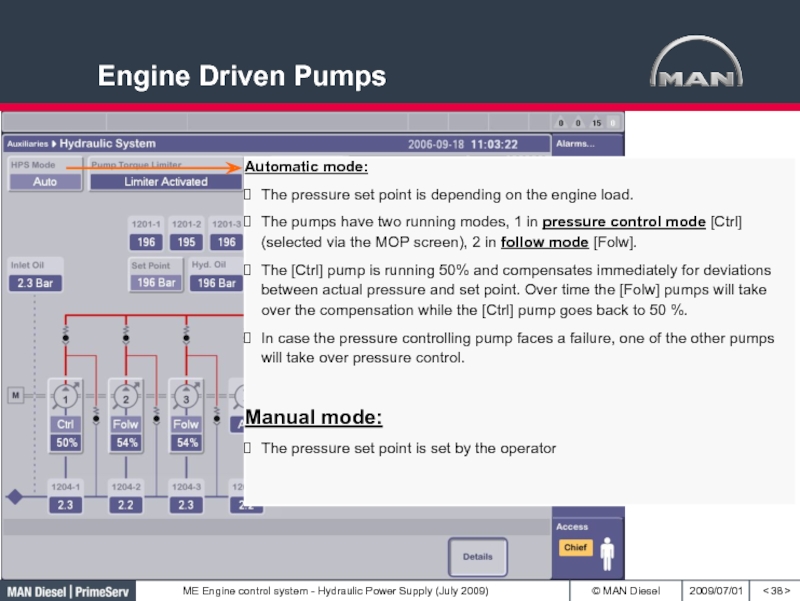

- 38. Engine Driven Pumps < > Automatic mode:

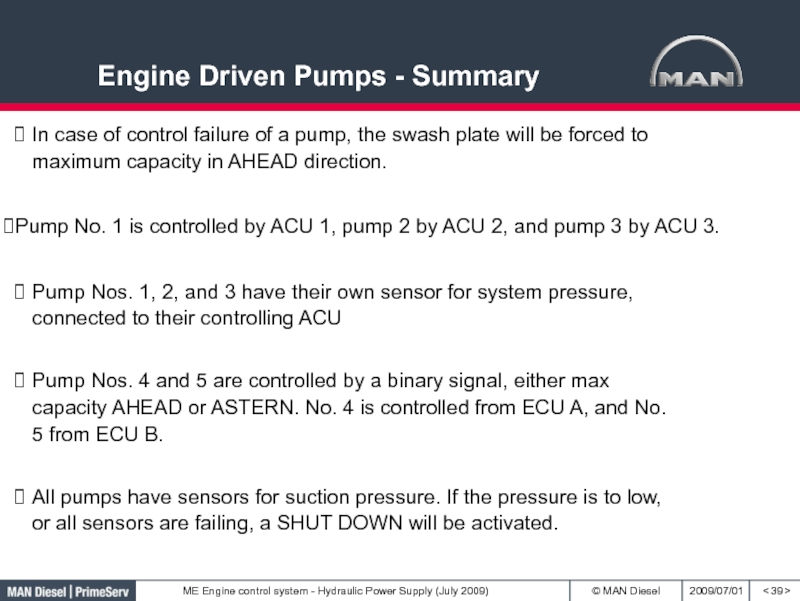

- 39. Engine Driven Pumps - Summary < >

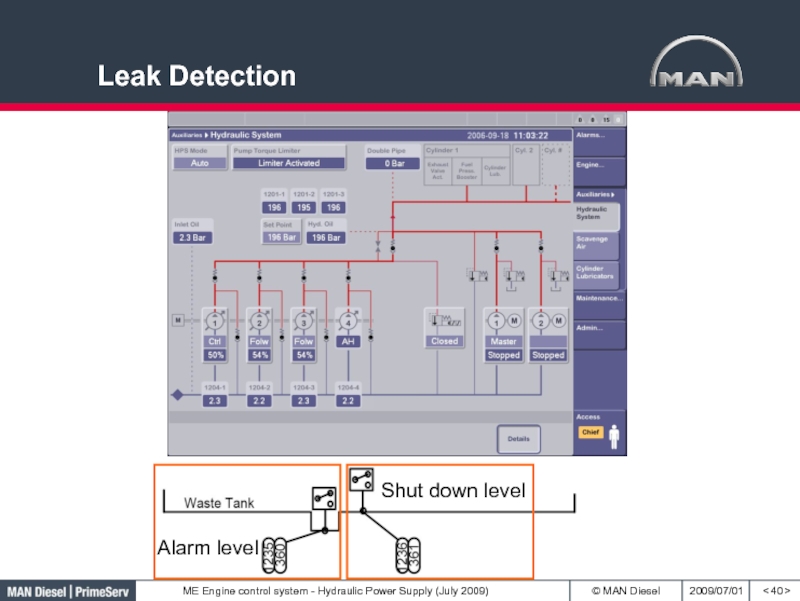

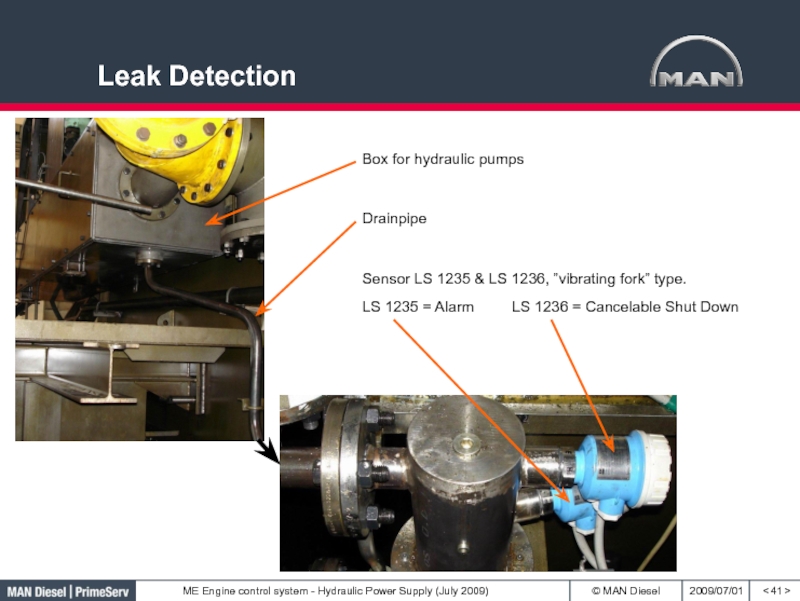

- 40. Leak Detection < > Alarm level Shut down level

- 41. Leak Detection < > Box for hydraulic

- 42. Leak Connections < >

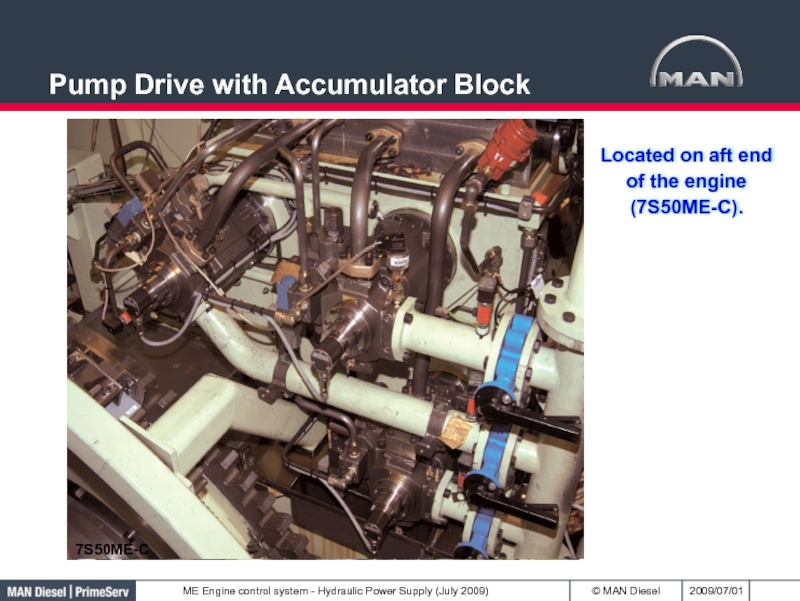

- 43. Pump Drive with Accumulator Block Located on aft end of the engine (7S50ME-C). 7S50ME-C

- 44. Sensors for Suction Pressure < >

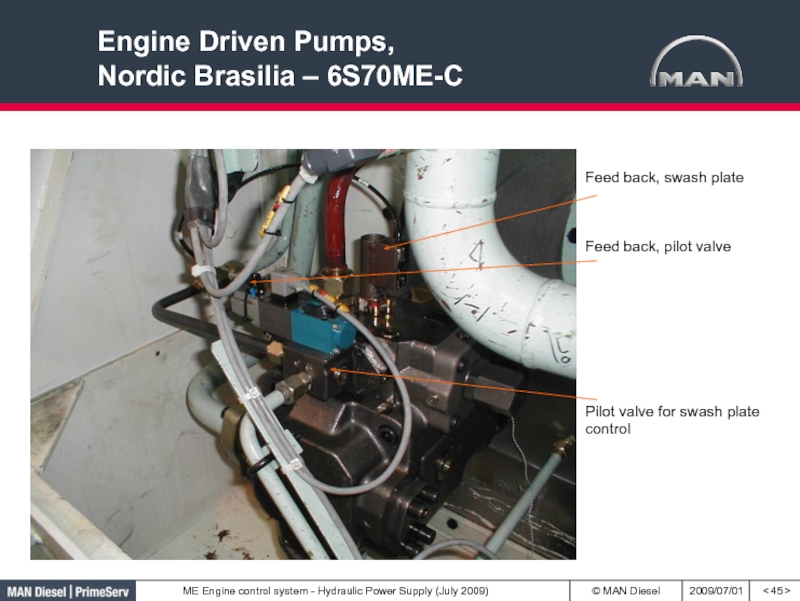

- 45. Engine Driven Pumps, Nordic Brasilia – 6S70ME-C < >

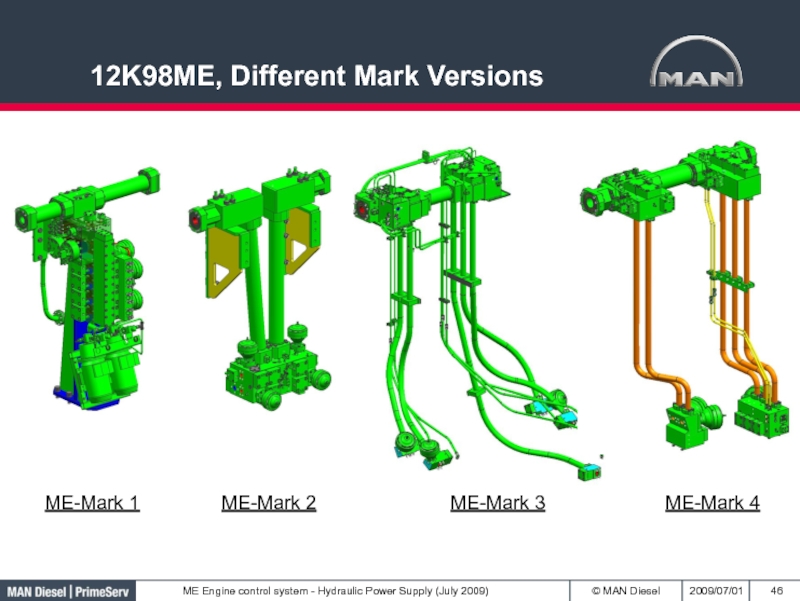

- 46. 12K98ME, Different Mark Versions ME-Mark 3

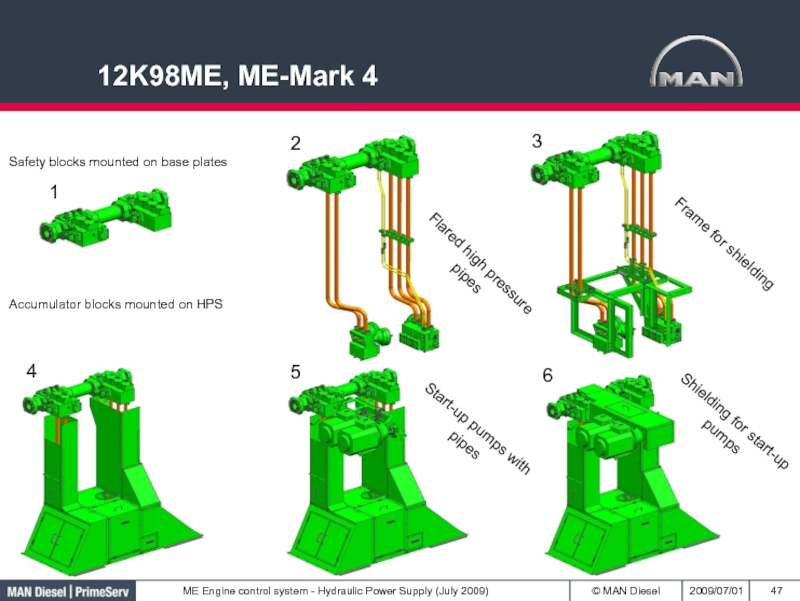

- 47. 12K98ME, ME-Mark 4 Safety blocks mounted on

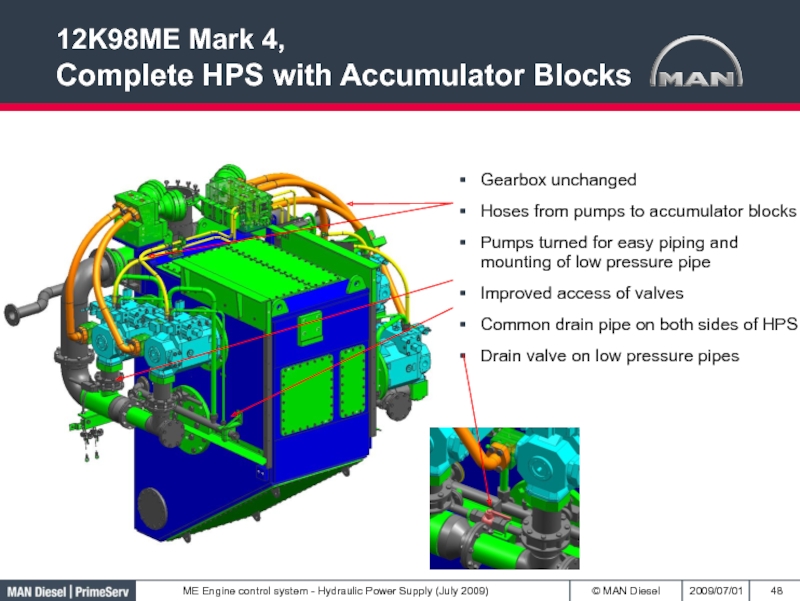

- 48. 12K98ME Mark 4, Complete HPS with

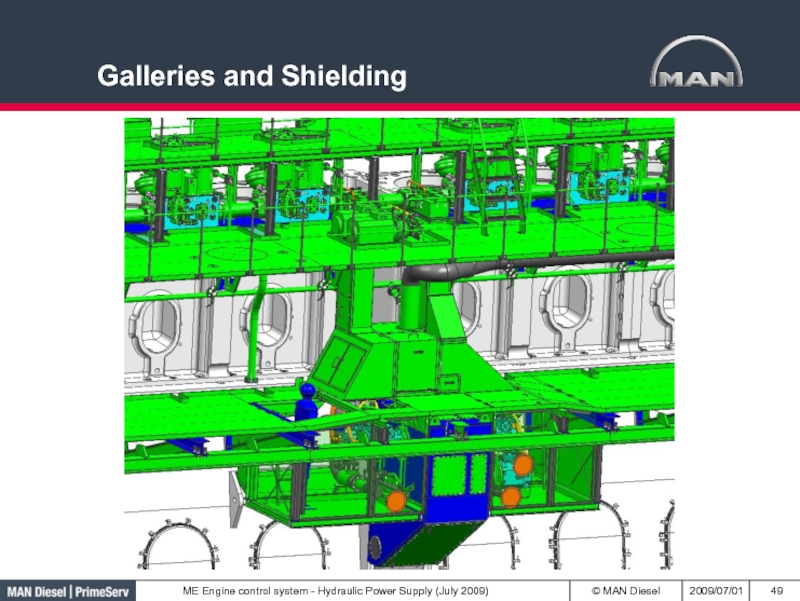

- 49. Galleries and Shielding

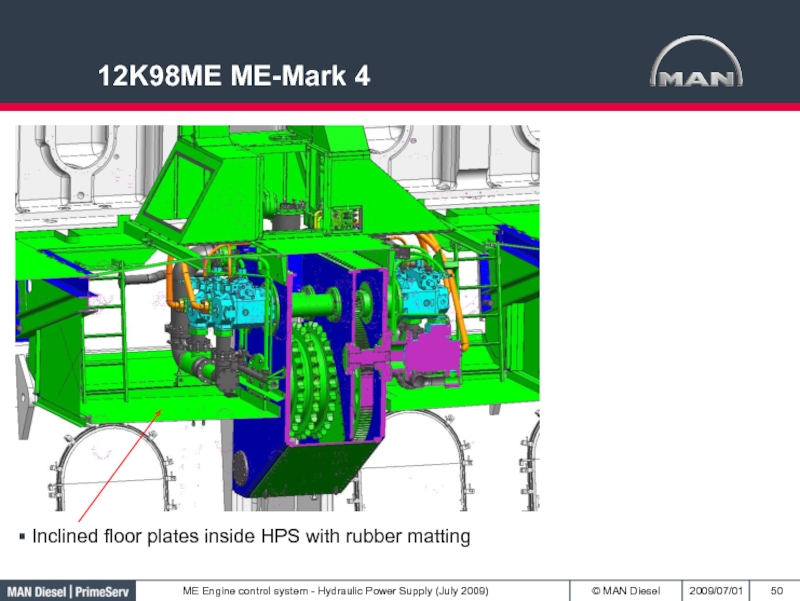

- 50. 12K98ME ME-Mark 4 Inclined floor plates inside HPS with rubber matting

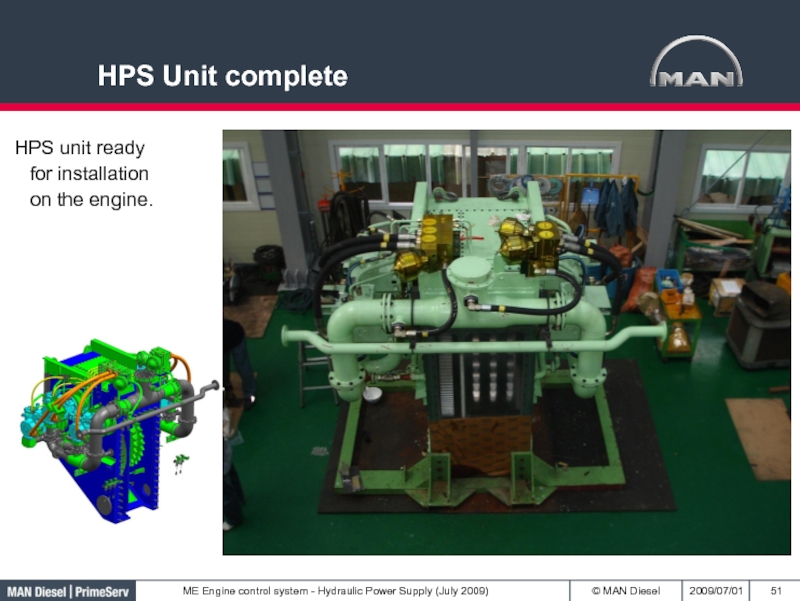

- 51. HPS Unit complete HPS unit ready for installation on the engine.

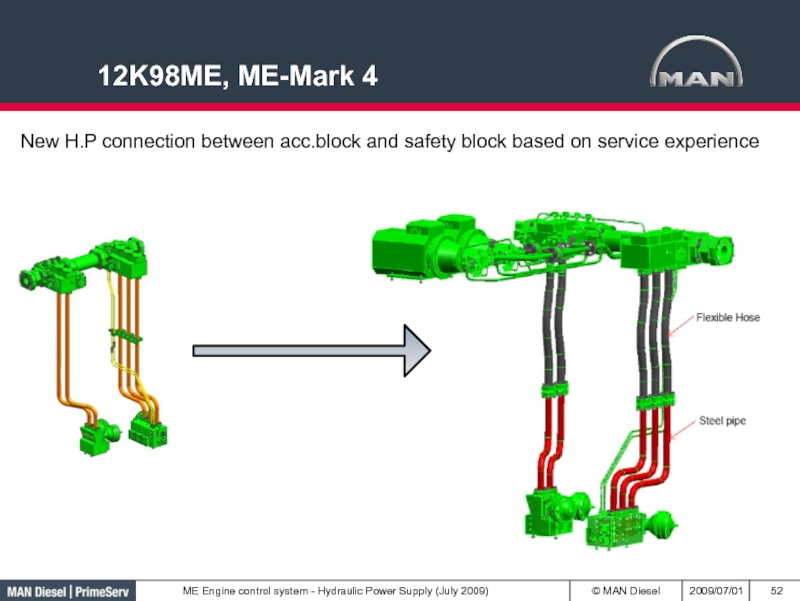

- 52. 12K98ME, ME-Mark 4 New H.P connection

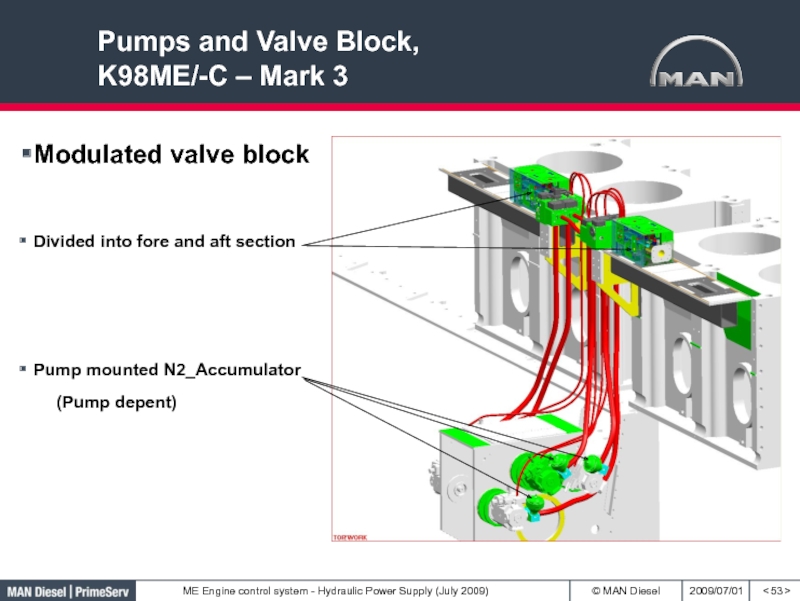

- 53. Pumps and Valve Block, K98ME/-C – Mark

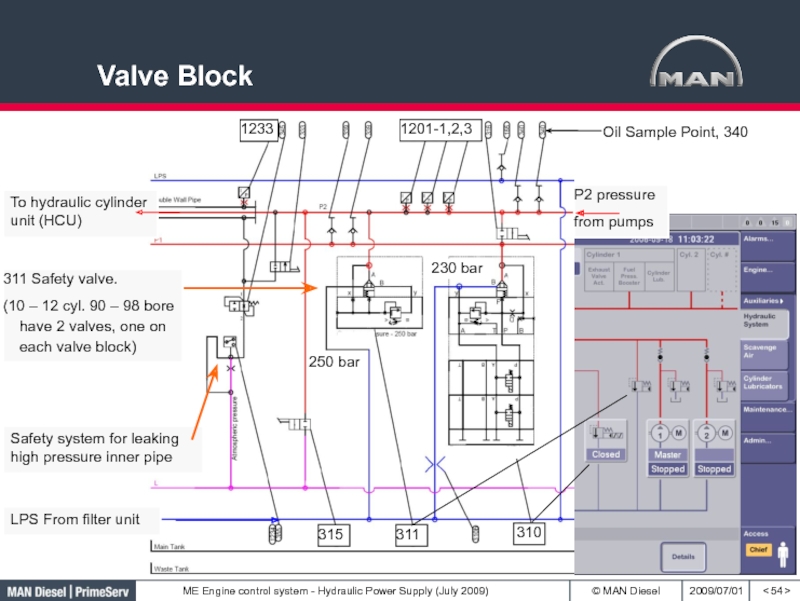

- 54. Valve Block < > 1233 1201-1,2,3 311

- 55. Valve Block K98ME/-C, Mark 3 < >

- 56. Valve Block, Fore Section, Mark 3 <

- 57. Valve Block, Aft Section, Mark 3 <

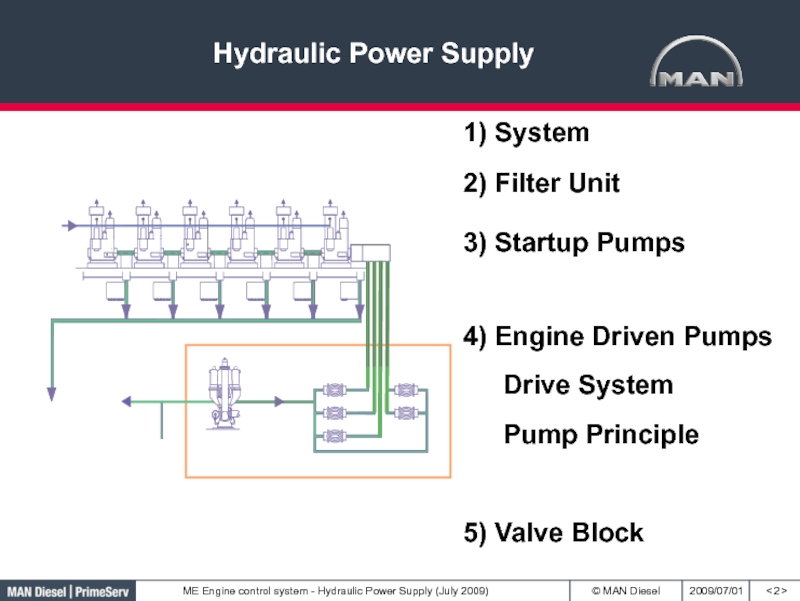

Слайд 2< >

2) Filter Unit

3) Startup Pumps

4) Engine Driven Pumps

Drive System

Pump

5) Valve Block

1) System

Hydraulic Power Supply

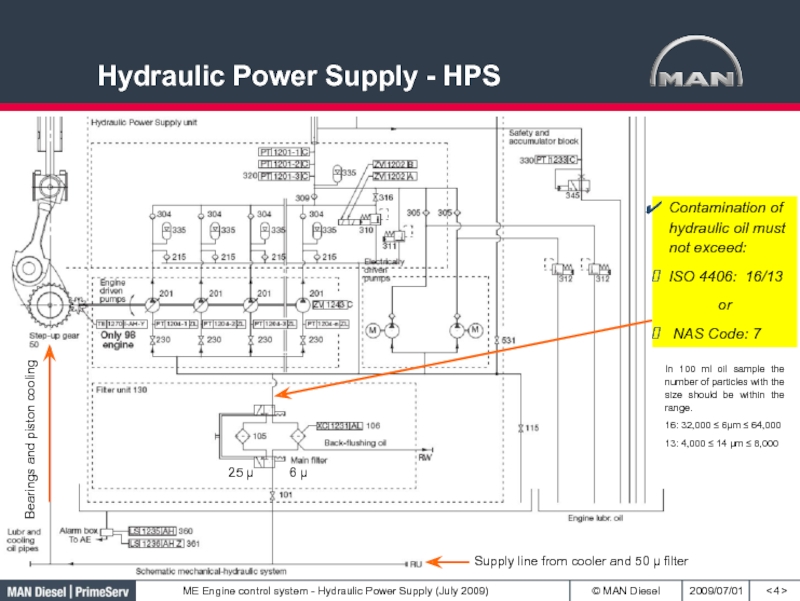

Слайд 4Hydraulic Power Supply - HPS

< >

Supply line from cooler and 50

6 μ

25 μ

Bearings and piston cooling

Contamination of hydraulic oil must not exceed:

ISO 4406: 16/13

or

NAS Code: 7

In 100 ml oil sample the number of particles with the size should be within the range.

16: 32,000 ≤ 6μm ≤ 64,000

13: 4,000 ≤ 14 μm ≤ 8,000

Слайд 8HPS Components

Filter and pumps

Auto Filter

Backup Filter

Electrically driven Hydraulic start-up pumps

Mechanically

Слайд 9HPS Components

Filter and pumps

Start-up pumps

High pressure pumps

Drain pipe

System oil

High pressure pipes

Filter unit

Слайд 11Filter Cartridges

< >

10 µm filter cartridge:

08/06 = production month/year

1340006 =

25 = manufacturer's filter mesh code

6 µm filter cartridge:

09/06 = production month/year

1341446 = filter cartridge ID

Sintered filter material

Слайд 16Electric motor

Pump

Inlet

Drain

Pressure relief valve,

setpoint 175 bar

Pump drain

HPS Components,

Start-up Pumps

Drain

Drain

Outlet

Outlet

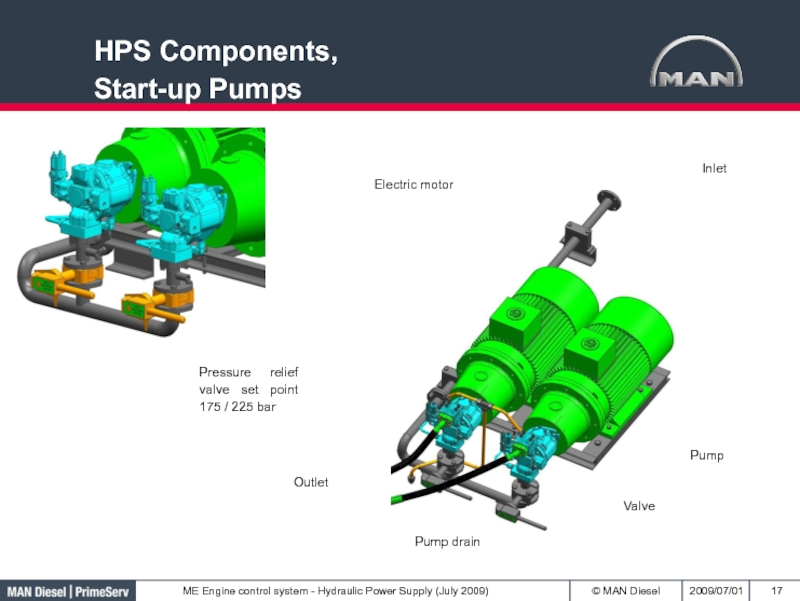

Слайд 17HPS Components,

Start-up Pumps

Pressure relief valve set point 175 / 225

Electric motor

Outlet

Inlet

Pump drain

Valve

Pump

Слайд 23Axial Piston Pump

< >

Pump sizes:

125 ccm/rev - 3 pumps

180 ccm/rev -

250 ccm/rev - 3 pumps

355 ccm/rev - 3 pumps

500 ccm/rev - 3 to 5 pumps

Слайд 24

210 Bar ? 300 Bar

Working pressure increased from 210 bar to

HPS:

Necessary pump size reduced from 355 cc to 250 cc.

Only 3 pumps needed.

Same pipe and hose dimensions.

This is because of the relation between Q’ (flow) and pressure (p) shown by the equation:

P=Q’x p, where P is the power generated by the pump, the power consumption is the same; therefore a higher pressure will result in a lower flow

Design features for

K+S80ME-C9, K98ME-C7

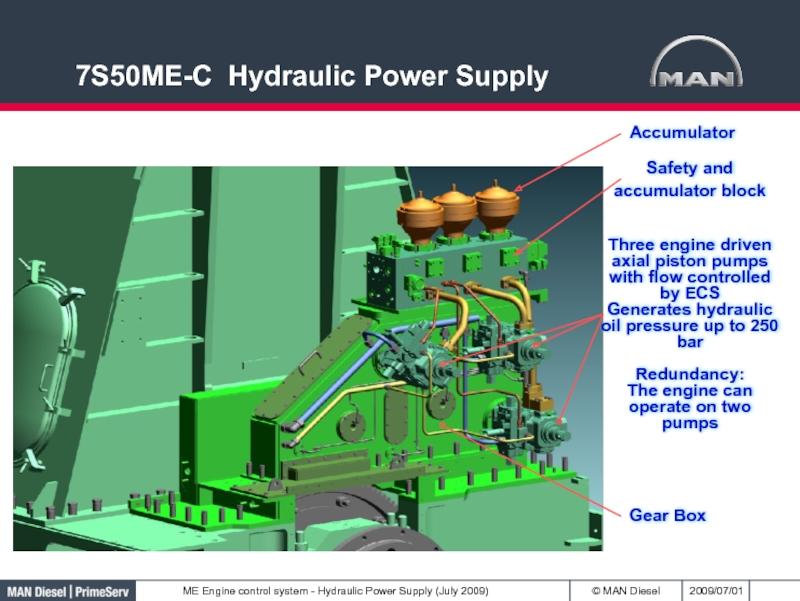

Слайд 257S50ME-C Hydraulic Power Supply

Accumulator

Gear Box

Safety and accumulator block

Three engine driven axial

Generates hydraulic oil pressure up to 250 bar

Redundancy:

The engine can operate on two pumps

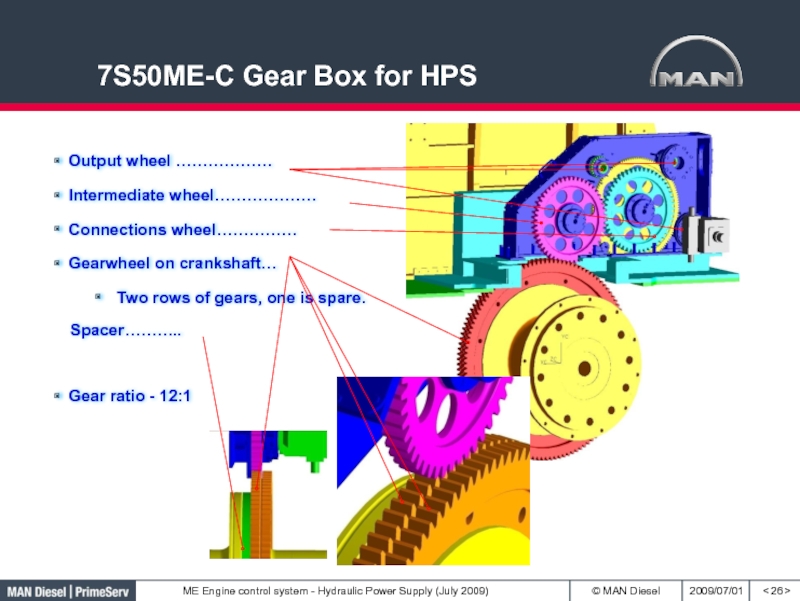

Слайд 267S50ME-C Gear Box for HPS

Output wheel ………………

Intermediate wheel……………….

Connections wheel……………

Gearwheel

Two rows of gears, one is spare.

Spacer………..

Gear ratio - 12:1

< >

Слайд 31Comfortable platform height around HPS

Easy access to Chain Tightener

Access to Chain

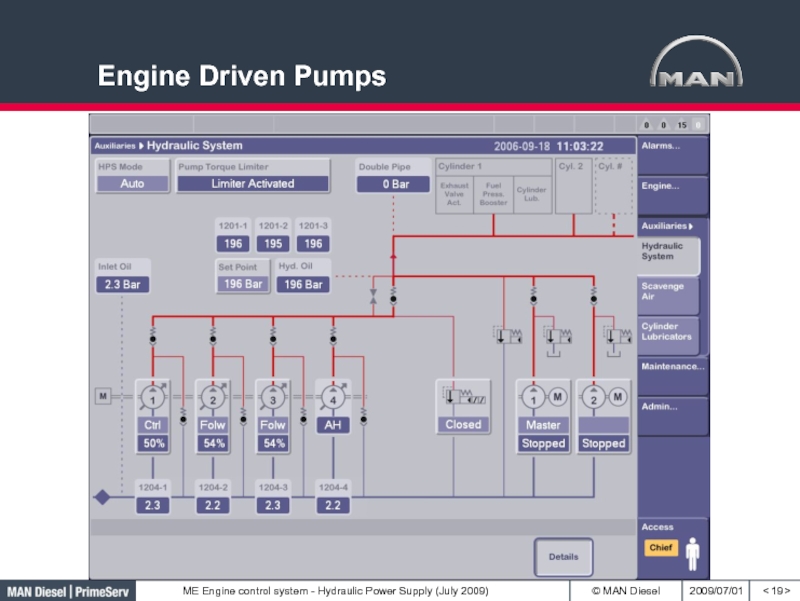

Слайд 38Engine Driven Pumps

< >

Automatic mode:

The pressure set point is depending on

The pumps have two running modes, 1 in pressure control mode [Ctrl] (selected via the MOP screen), 2 in follow mode [Folw].

The [Ctrl] pump is running 50% and compensates immediately for deviations between actual pressure and set point. Over time the [Folw] pumps will take over the compensation while the [Ctrl] pump goes back to 50 %.

In case the pressure controlling pump faces a failure, one of the other pumps will take over pressure control.

Manual mode:

The pressure set point is set by the operator

Слайд 39Engine Driven Pumps - Summary

< >

Pump No. 1 is controlled by

Pump Nos. 4 and 5 are controlled by a binary signal, either max capacity AHEAD or ASTERN. No. 4 is controlled from ECU A, and No. 5 from ECU B.

In case of control failure of a pump, the swash plate will be forced to maximum capacity in AHEAD direction.

Pump Nos. 1, 2, and 3 have their own sensor for system pressure, connected to their controlling ACU

All pumps have sensors for suction pressure. If the pressure is to low, or all sensors are failing, a SHUT DOWN will be activated.

Слайд 41Leak Detection

< >

Box for hydraulic pumps

Drainpipe

Sensor LS 1235 & LS 1236,

LS 1235 = Alarm LS 1236 = Cancelable Shut Down

Слайд 4712K98ME, ME-Mark 4

Safety blocks mounted on base plates

Accumulator blocks mounted

Frame for shielding

Flared high pressure pipes

Start-up pumps with pipes

Shielding for start-up pumps

Слайд 4812K98ME Mark 4,

Complete HPS with Accumulator Blocks

Gearbox unchanged

Hoses from pumps

Pumps turned for easy piping and mounting of low pressure pipe

Improved access of valves

Common drain pipe on both sides of HPS

Drain valve on low pressure pipes

Слайд 5212K98ME, ME-Mark 4

New H.P connection between acc.block and safety block based

Слайд 53Pumps and Valve Block,

K98ME/-C – Mark 3

< >

Modulated valve block

Divided into

Pump mounted N2_Accumulator

(Pump depent)

Слайд 54Valve Block

< >

1233

1201-1,2,3

311

310

315

250 bar

230 bar

To hydraulic cylinder unit (HCU)

Safety system

LPS From filter unit

311 Safety valve.

(10 – 12 cyl. 90 – 98 bore have 2 valves, one on each valve block)

P2 pressure

from pumps

Oil Sample Point, 340

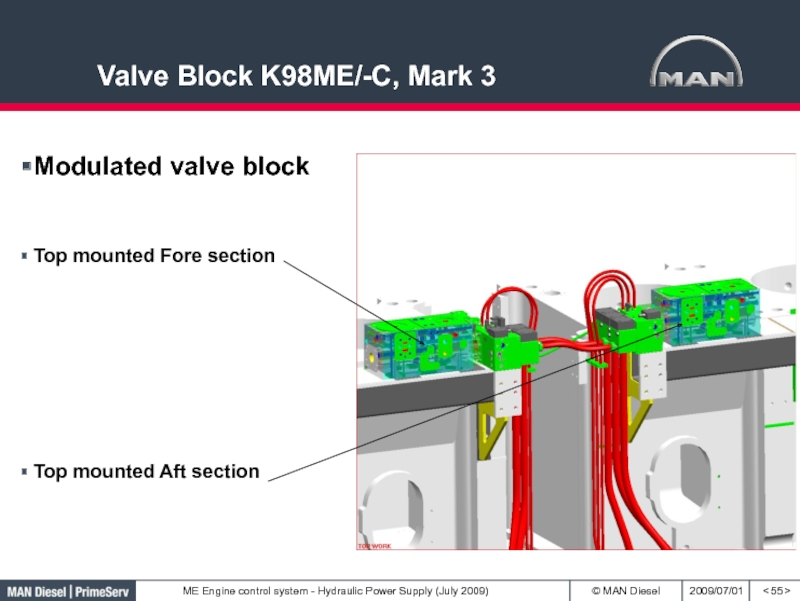

Слайд 55Valve Block K98ME/-C, Mark 3

< >

Modulated valve block

Top mounted Fore section

Top

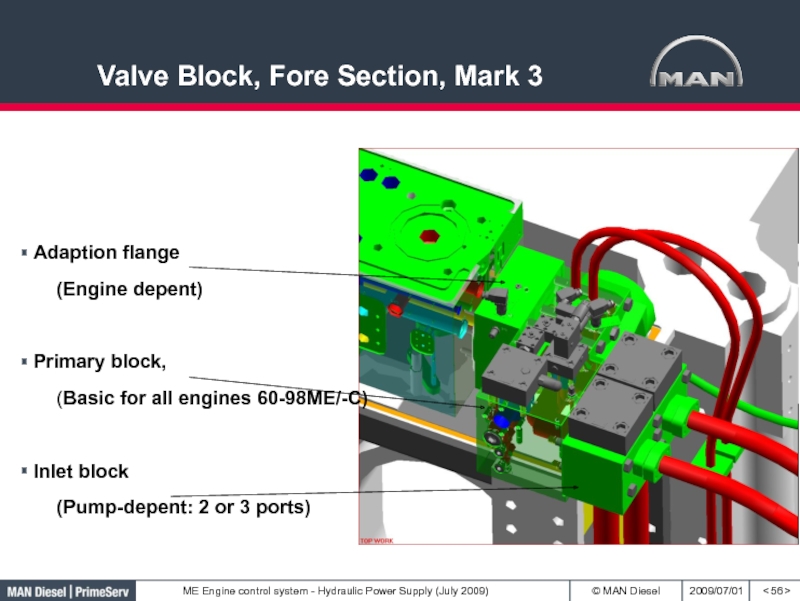

Слайд 56Valve Block, Fore Section, Mark 3

< >

Adaption flange

(Engine depent)

Primary block,

(Basic

Inlet block

(Pump-depent: 2 or 3 ports)

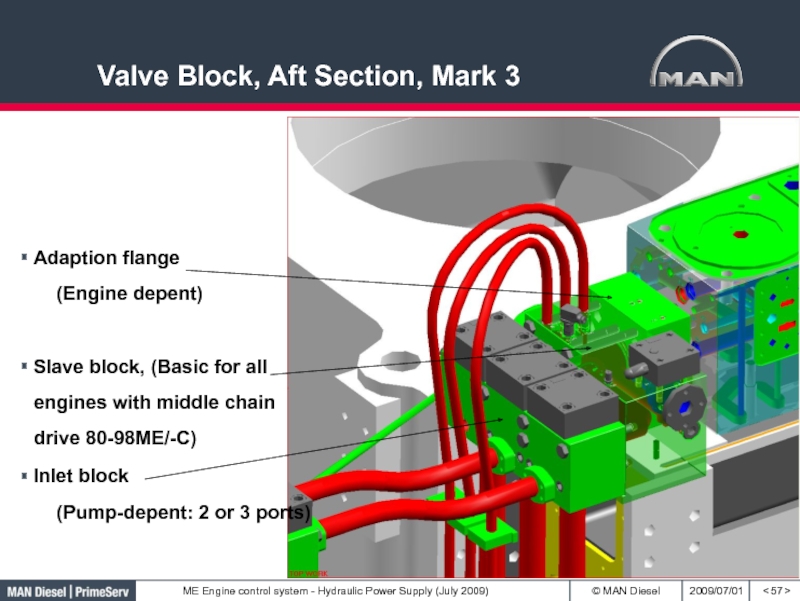

Слайд 57Valve Block, Aft Section, Mark 3

< >

Adaption flange

(Engine depent)

Slave block, (Basic

engines with middle chain

drive 80-98ME/-C)

Inlet block

(Pump-depent: 2 or 3 ports)