- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

MAN Diesel PrimeServ Academy Exhaust Valve Design презентация

Содержание

- 1. MAN Diesel PrimeServ Academy Exhaust Valve Design

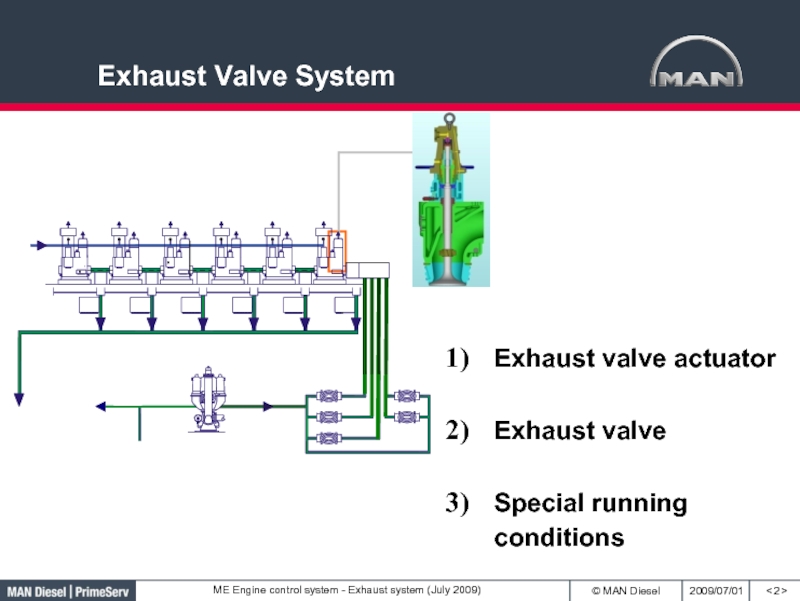

- 2. Exhaust Valve System < > Exhaust valve actuator Exhaust valve Special running conditions

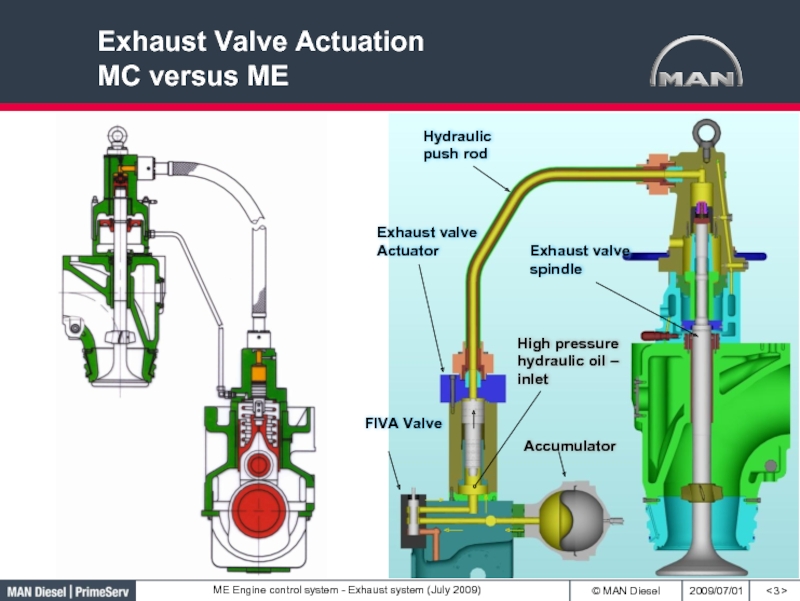

- 3. Exhaust Valve Actuation MC versus ME < >

- 4. Exhaust Valve Pipe Connections < >

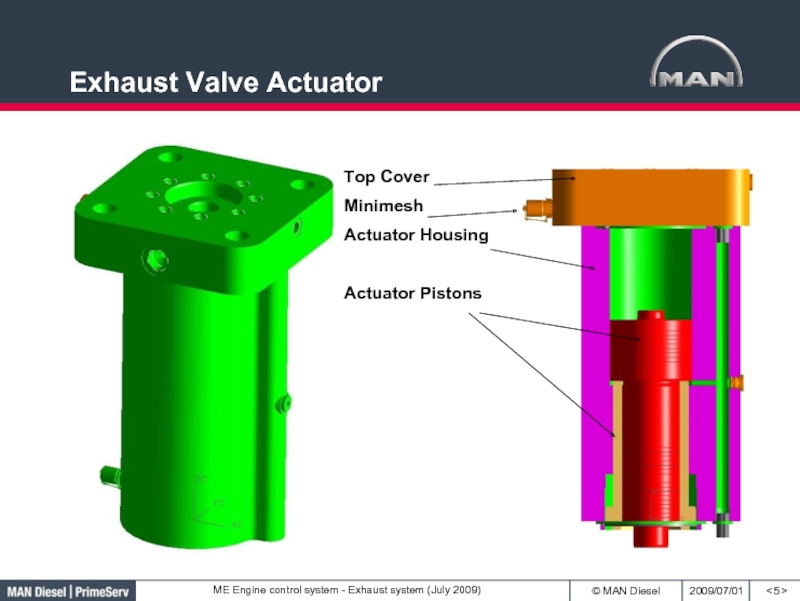

- 5. Exhaust Valve Actuator < > Top

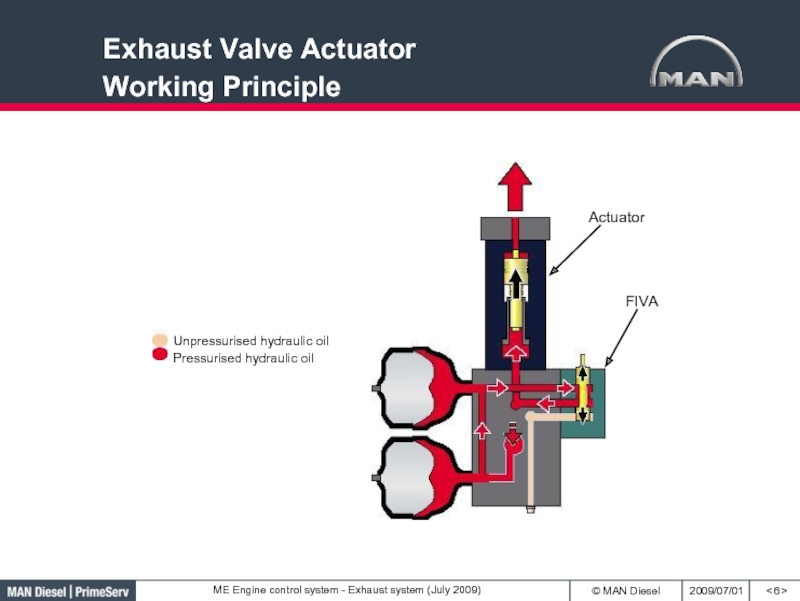

- 6. < > Exhaust Valve Actuator Working Principle

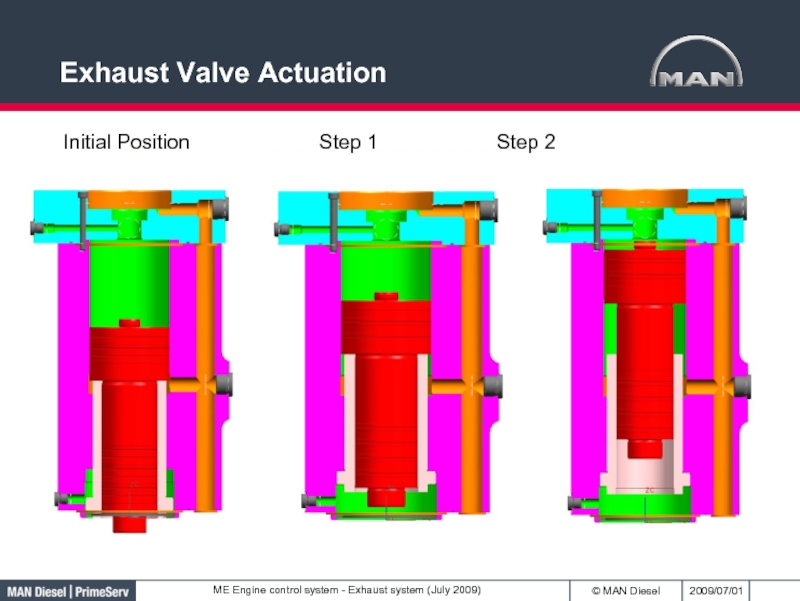

- 7. Exhaust Valve Actuation Initial Position Step 1 Step 2

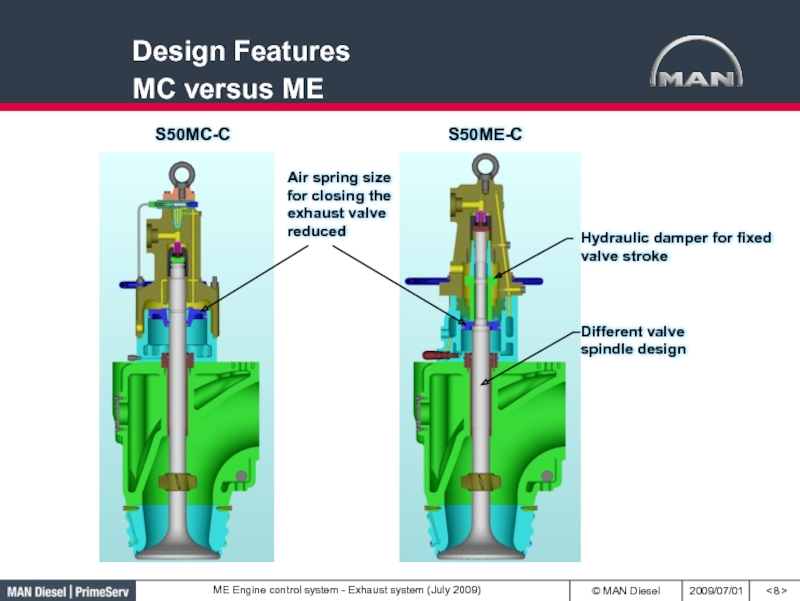

- 8. < > S50MC-C S50ME-C Hydraulic damper for

- 9. < > Self-adjusting damper piston Hydraulic

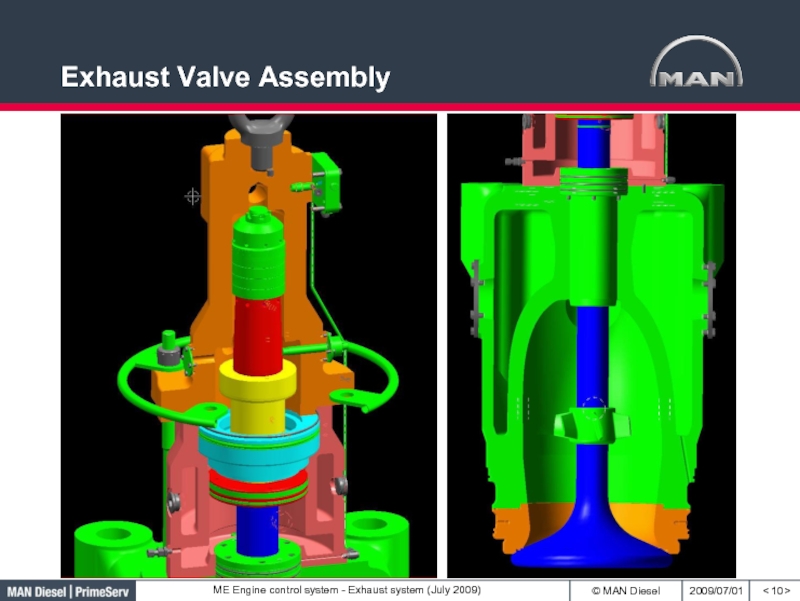

- 10. < > Exhaust Valve Assembly

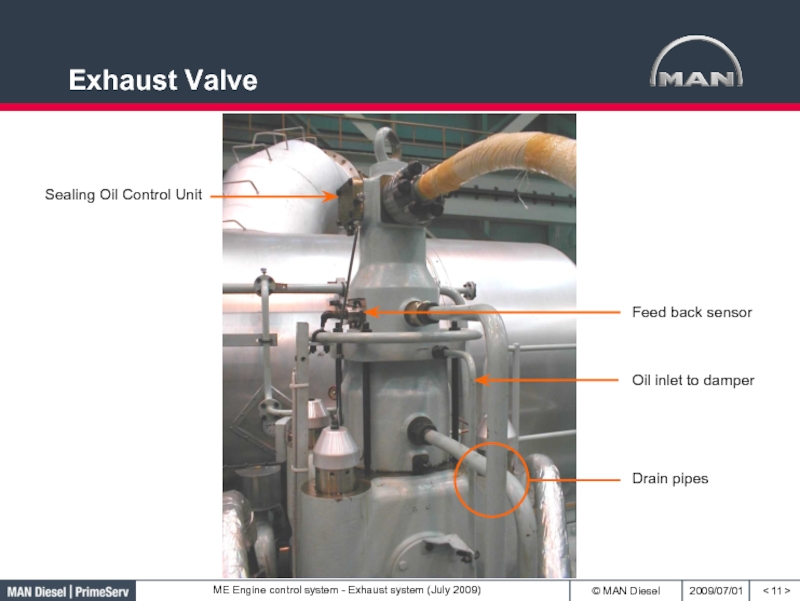

- 11. < > Oil inlet to damper

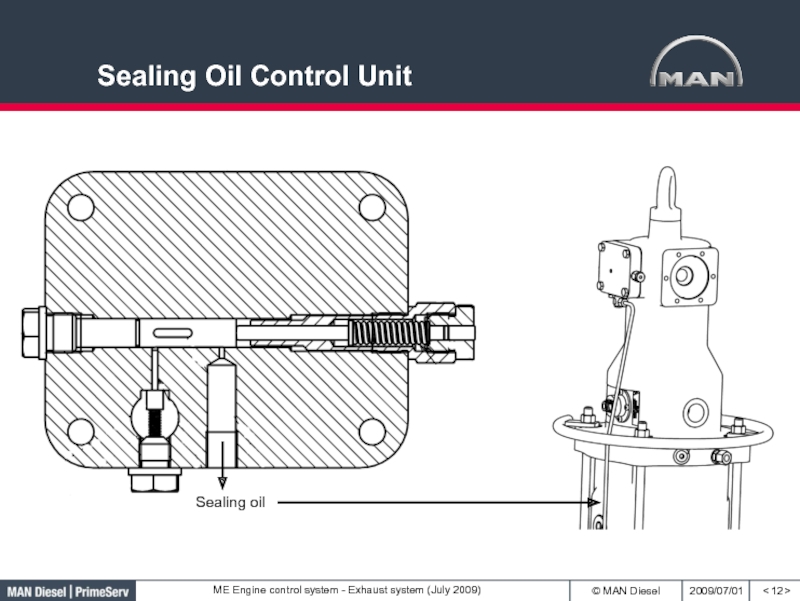

- 12. Sealing Oil Control Unit < > Sealing oil

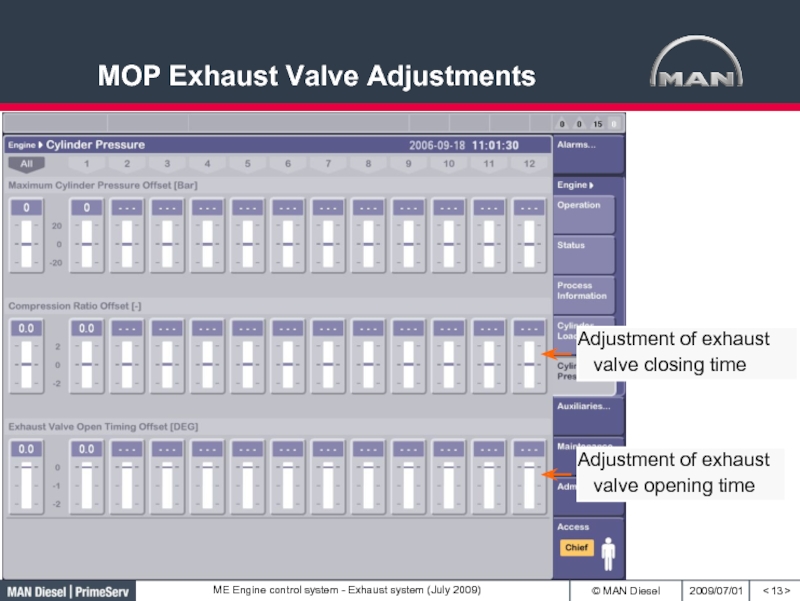

- 13. MOP Exhaust Valve Adjustments < >

- 14. < > Check pressure free at “minimess”

- 15. < > Connect the mini-mesh hose between

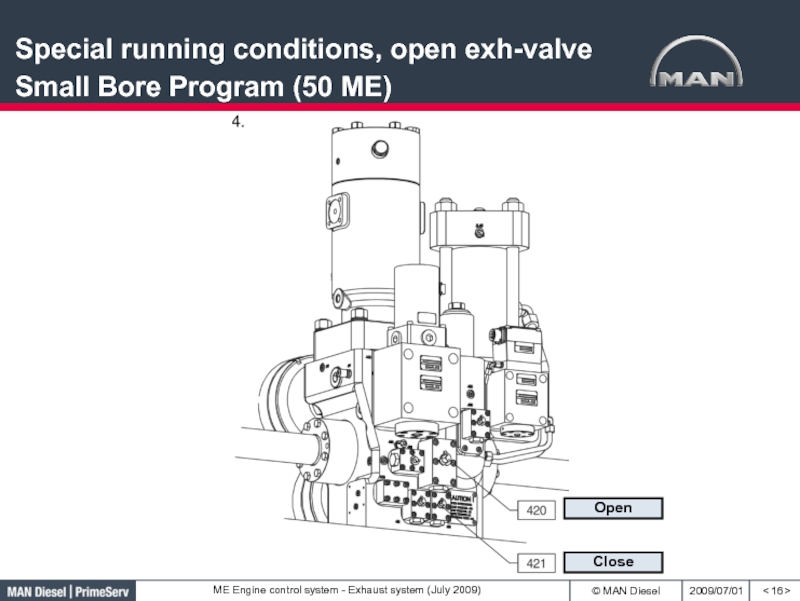

- 16. < > Close Open Special running

- 17. < > Check pressure free at

- 18. < > Close valve 531 to shut

- 19. < > Drain off air pressure from

- 20. < > Remove plug screw and mount

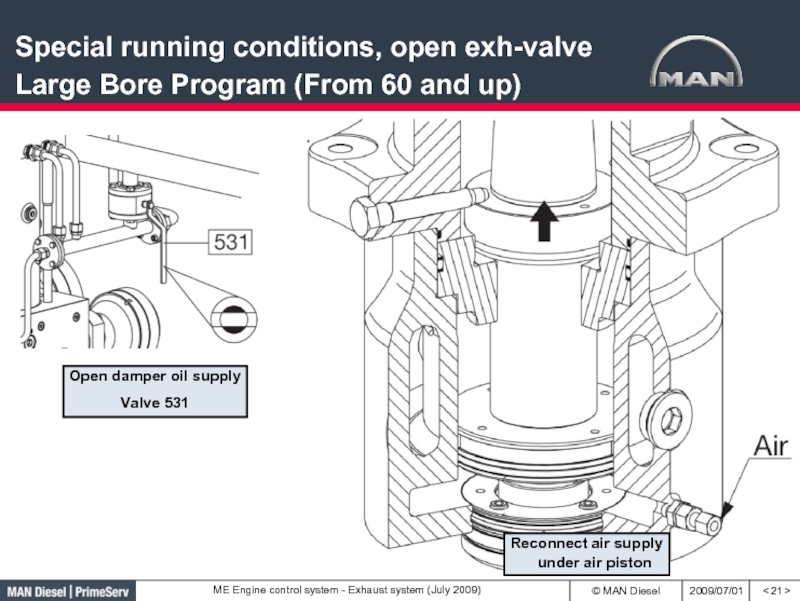

- 21. < > Reconnect air supply under air

Слайд 8< >

S50MC-C

S50ME-C

Hydraulic damper for fixed valve stroke

Air spring size for closing

Different valve spindle design

Design Features

MC versus ME

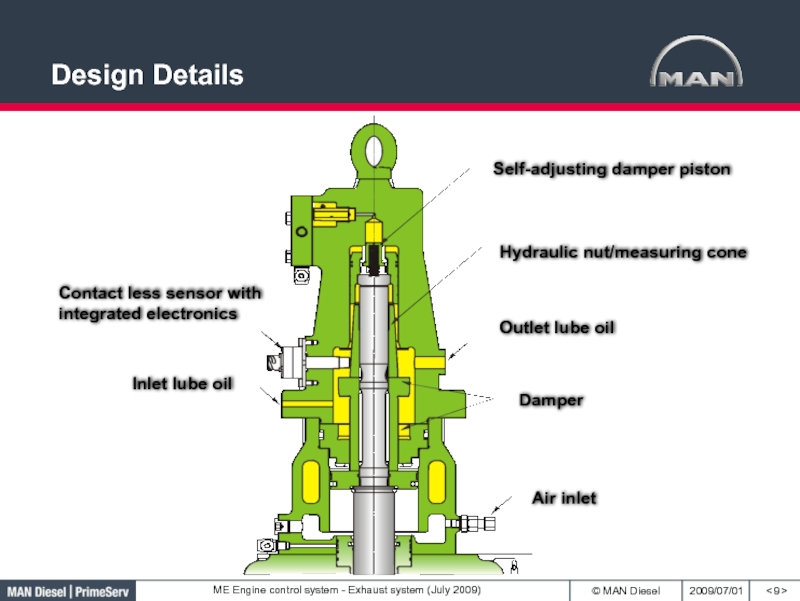

Слайд 9< >

Self-adjusting damper piston

Hydraulic nut/measuring cone

Outlet lube oil

Damper

Air inlet

Inlet lube oil

Contact

Design Details

Слайд 14< >

Check pressure free at “minimess” point 455

Close

Open

Special running conditions, open

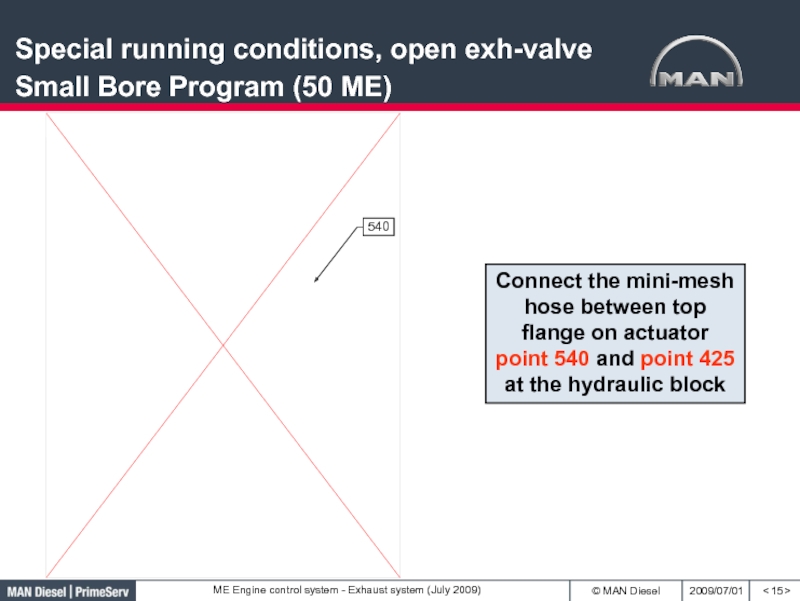

Слайд 15< >

Connect the mini-mesh hose between top flange on actuator point

Special running conditions, open exh-valve Small Bore Program (50 ME)

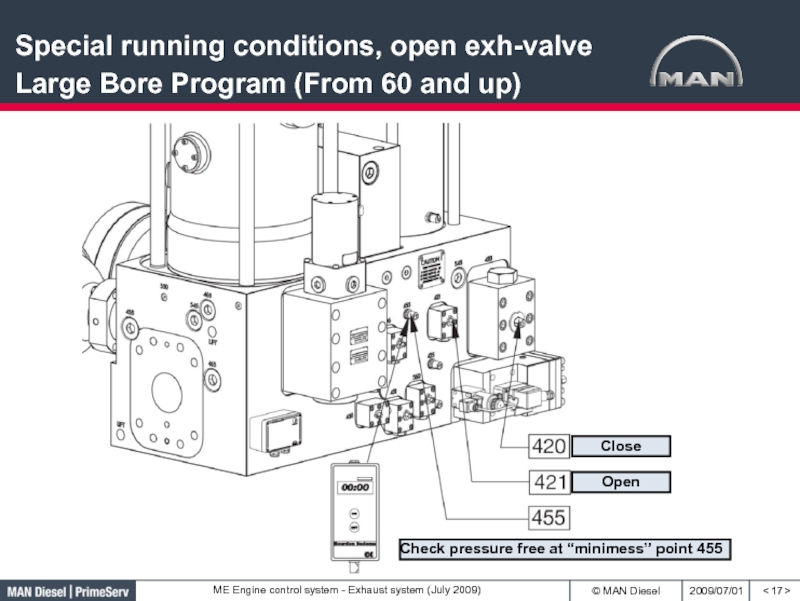

Слайд 17< >

Check pressure free at “minimess” point 455

Close

Open

Special running conditions, open

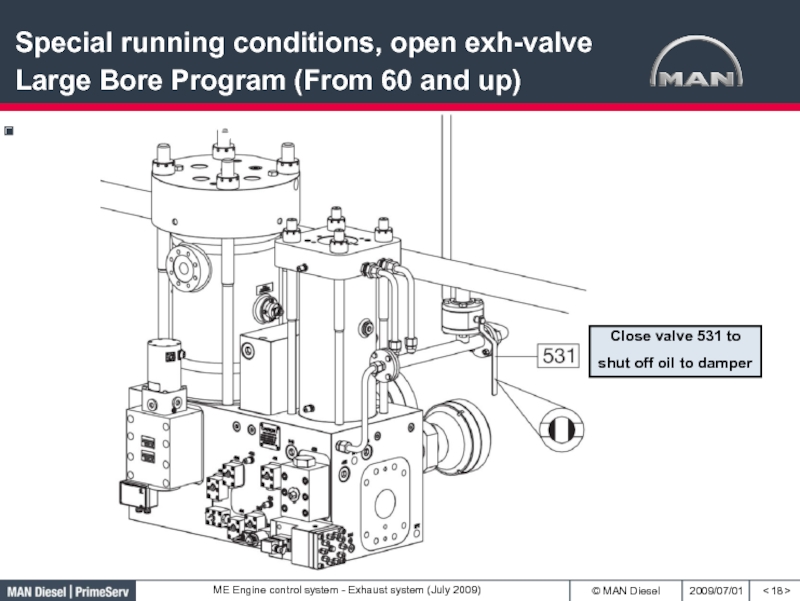

Слайд 18< >

Close valve 531 to

shut off oil to damper

Special running conditions,

(From 60 and up)

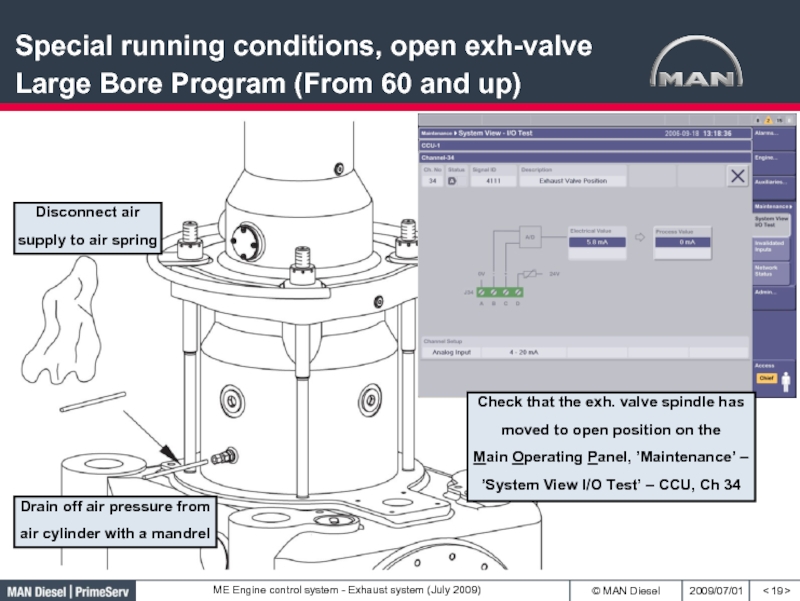

Слайд 19< >

Drain off air pressure from

air cylinder with a mandrel

Disconnect

supply to air spring

Check that the exh. valve spindle has

moved to open position on the

Main Operating Panel, ’Maintenance’ –

’System View I/O Test’ – CCU, Ch 34

Special running conditions, open exh-valve Large Bore Program (From 60 and up)

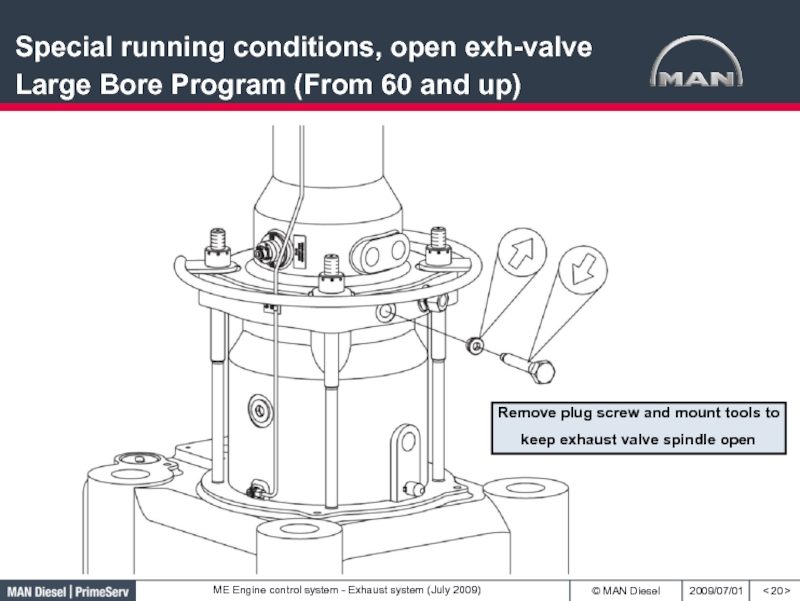

Слайд 20< >

Remove plug screw and mount tools to

keep exhaust valve spindle

Special running conditions, open exh-valve Large Bore Program (From 60 and up)