- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Krauss-Maffei Pusher Centrifuges презентация

Содержание

- 1. Krauss-Maffei Pusher Centrifuges

- 2. © ANDRITZ 2011 Table of Contents Process

- 3. © ANDRITZ 2011 Process Data & Applications

- 4. © ANDRITZ 2011 Exchangeable solids discharge Layout:

- 5. © ANDRITZ 2011 Layout: Drive Side Overview

- 6. © ANDRITZ 2011 Cross Section Pusher Centrifuge

- 7. © ANDRITZ 2011 Process Basics Pusher Centrifuge

- 8. Double Filtration Technology Traditional Main Filtration

- 9. © ANDRITZ 2011 Process Features Process Housing

- 10. © ANDRITZ 2011 Process Features Bolt distributor

- 11. © ANDRITZ 2011 Process Features Slot Screen

- 12. © ANDRITZ 2011 Process Features Wear Rings

- 13. © ANDRITZ 2011 Mechanical Features Housing Sealing

- 14. © ANDRITZ 2011 Mechanical Features Pusher Shaft

- 15. © ANDRITZ 2011 Mechanical Features Cartridge Features:

- 16. © ANDRITZ 2011 References 80 years of

- 17. ANDRITZ KMPT GmbH Industriestrasse 1-3 D-85256 Vierkirchen Phone: +49 8139 80 299 0 kmpt@andritz.com www.kmpt.com

- 18. © ANDRITZ 2011 Foundation Alternatives Set up

Слайд 2© ANDRITZ 2011

Table of Contents

Process data and applications

Layout

Process basics of pusher

Double filtration technology

Process features

Mechanical features

Controls

References

Optional Features

Слайд 3© ANDRITZ 2011

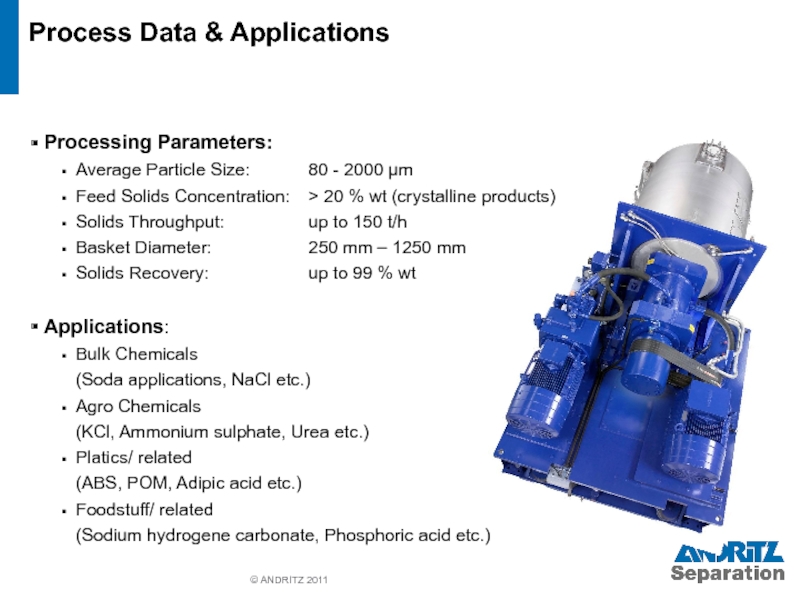

Process Data & Applications

Processing Parameters:

Average Particle Size: 80 - 2000

Feed Solids Concentration: > 20 % wt (crystalline products)

Solids Throughput: up to 150 t/h

Basket Diameter: 250 mm – 1250 mm

Solids Recovery: up to 99 % wt

Applications:

Bulk Chemicals (Soda applications, NaCl etc.)

Agro Chemicals (KCl, Ammonium sulphate, Urea etc.)

Platics/ related (ABS, POM, Adipic acid etc.)

Foodstuff/ related (Sodium hydrogene carbonate, Phosphoric acid etc.)

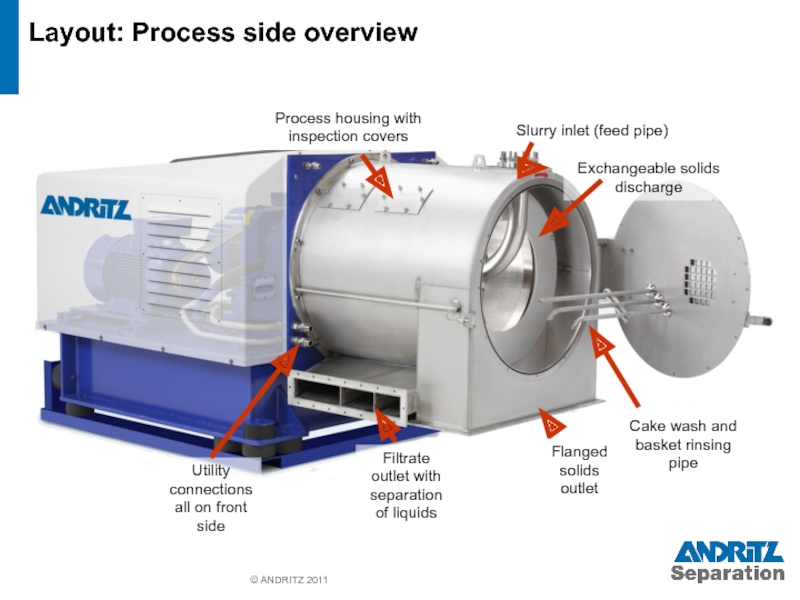

Слайд 4© ANDRITZ 2011

Exchangeable solids discharge

Layout: Process side overview

Filtrate outlet with separation

Slurry inlet (feed pipe)

Flanged solids outlet

Cake wash and basket rinsing pipe

Process housing with inspection covers

Utility connections all on front side

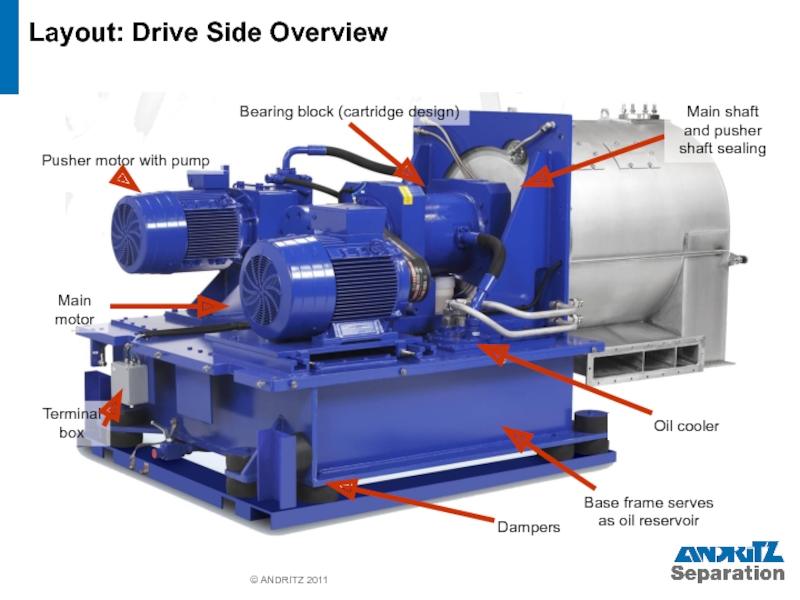

Слайд 5© ANDRITZ 2011

Layout: Drive Side Overview

Pusher motor with pump

Main motor

Dampers

Base frame

Oil cooler

Bearing block (cartridge design)

Main shaft and pusher shaft sealing

Terminal box

Слайд 6© ANDRITZ 2011

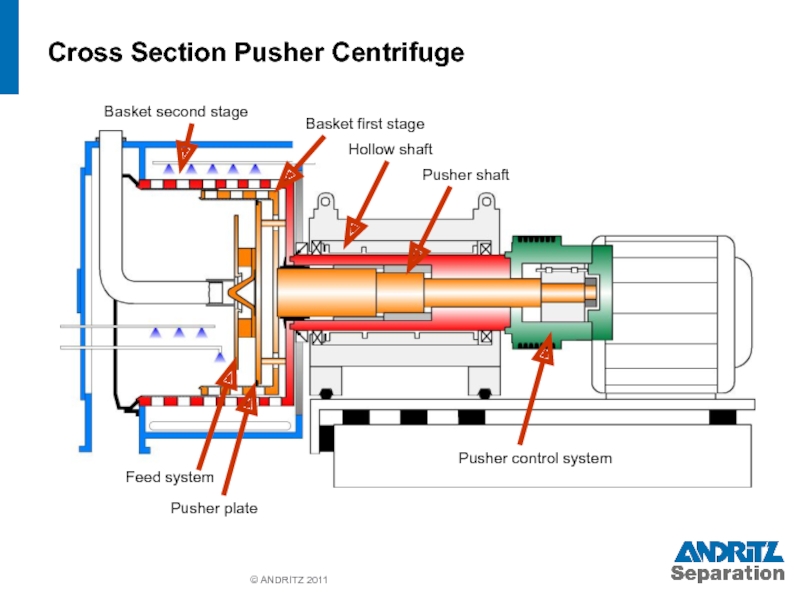

Cross Section Pusher Centrifuge

Basket second stage

Basket first stage

Pusher plate

Feed

Hollow shaft

Pusher shaft

Pusher control system

Слайд 7© ANDRITZ 2011

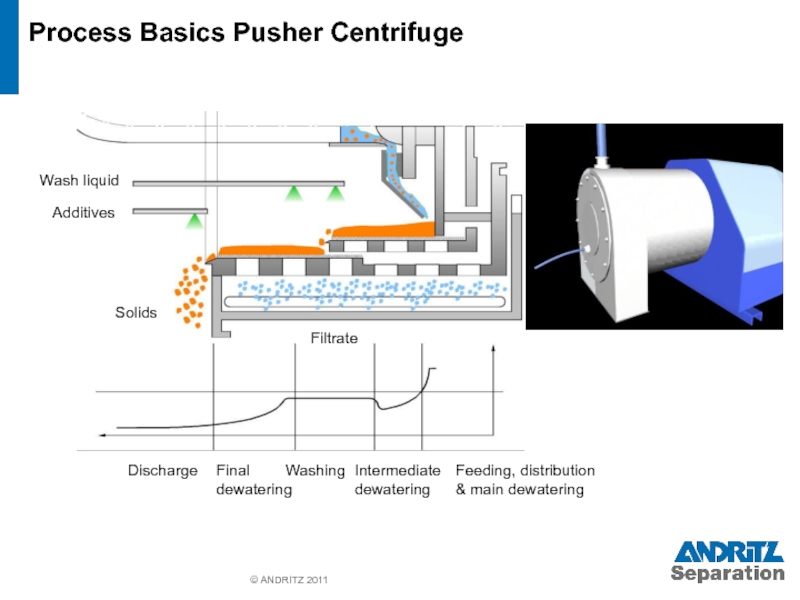

Process Basics Pusher Centrifuge

Feeding, distribution & main dewatering

Discharge

Washing

Intermediate

dewatering

Final

dewatering

Additives

Wash liquid

Solids

Filtrate

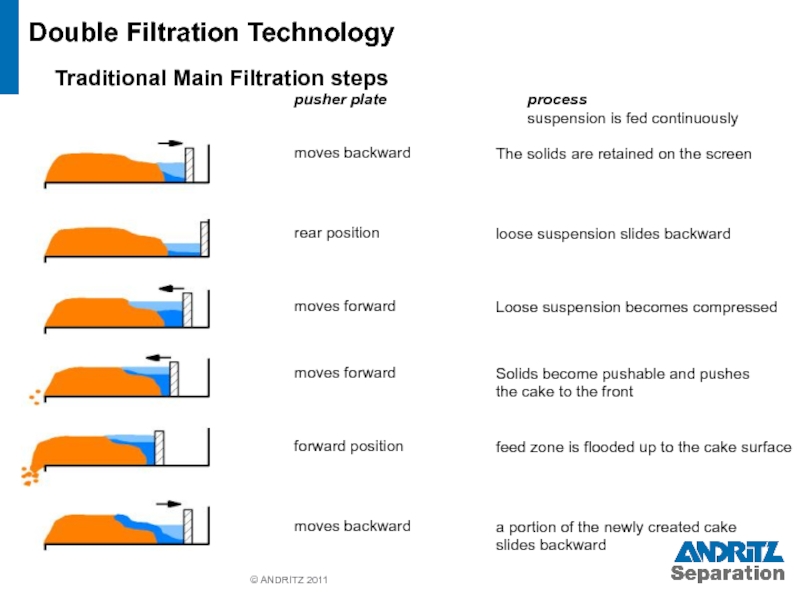

Слайд 8Double Filtration Technology

Traditional Main Filtration steps

pusher plate

process

suspension is fed continuously

moves

The solids are retained on the screen

rear position

loose suspension slides backward

moves forward

Loose suspension becomes compressed

moves forward

Solids become pushable and pushes

the cake to the front

forward position

feed zone is flooded up to the cake surface

moves backward

a portion of the newly created cake

slides backward

© ANDRITZ 2011

Слайд 9© ANDRITZ 2011

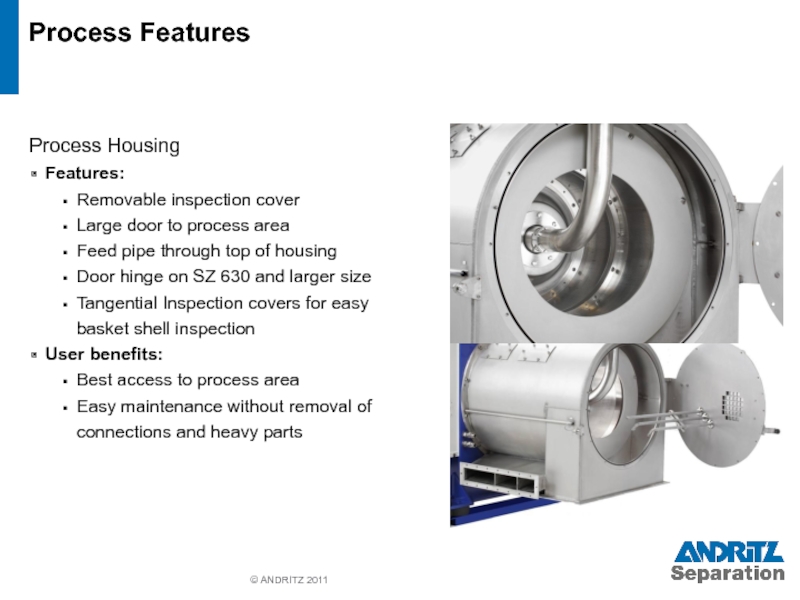

Process Features

Process Housing

Features:

Removable inspection cover

Large door to process area

Feed

Door hinge on SZ 630 and larger size

Tangential Inspection covers for easy basket shell inspection

User benefits:

Best access to process area

Easy maintenance without removal of connections and heavy parts

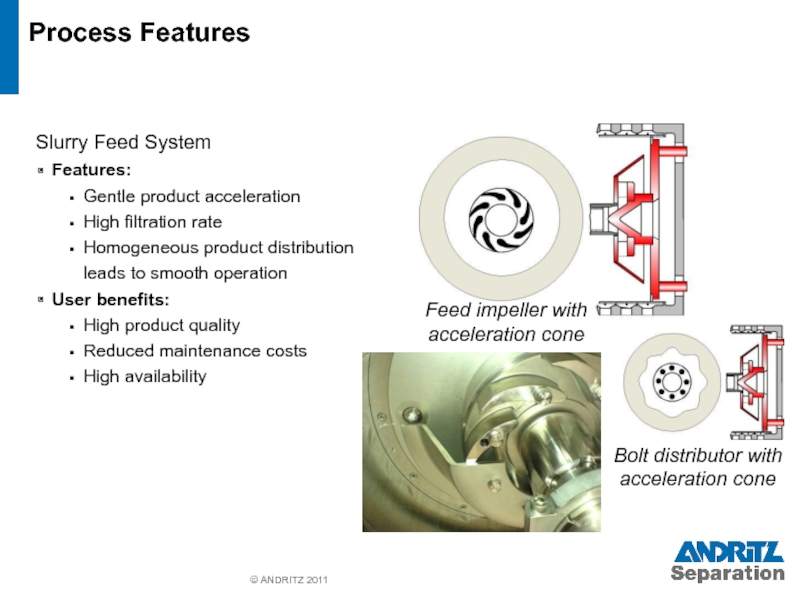

Слайд 10© ANDRITZ 2011

Process Features

Bolt distributor with

acceleration cone

Feed impeller with

acceleration cone

Slurry Feed

Features:

Gentle product acceleration

High filtration rate

Homogeneous product distribution leads to smooth operation

User benefits:

High product quality

Reduced maintenance costs

High availability

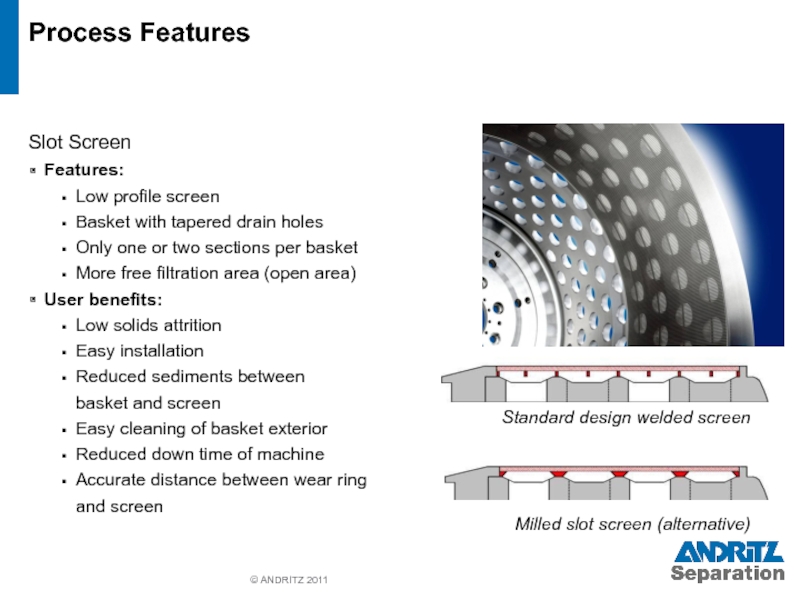

Слайд 11© ANDRITZ 2011

Process Features

Slot Screen

Features:

Low profile screen

Basket with tapered drain holes

Only

More free filtration area (open area)

User benefits:

Low solids attrition

Easy installation

Reduced sediments between basket and screen

Easy cleaning of basket exterior

Reduced down time of machine

Accurate distance between wear ring and screen

Standard design welded screen

Milled slot screen (alternative)

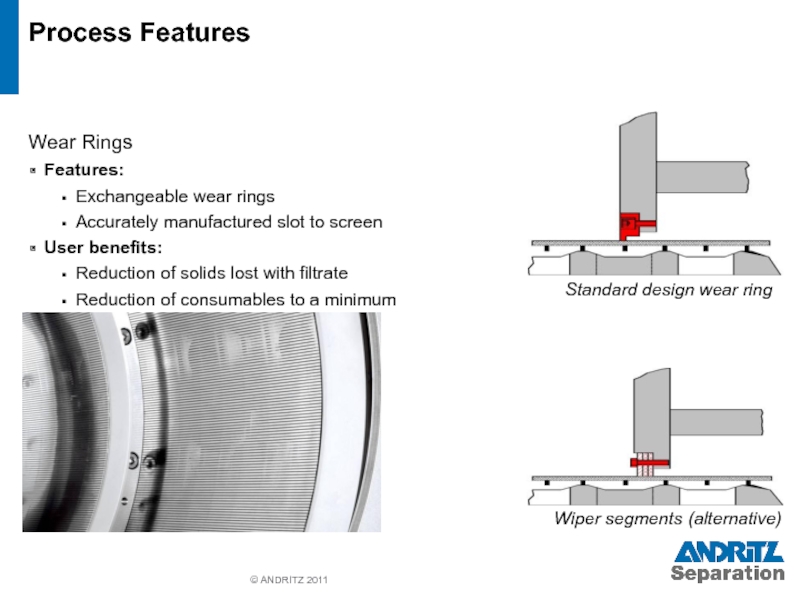

Слайд 12© ANDRITZ 2011

Process Features

Wear Rings

Features:

Exchangeable wear rings

Accurately manufactured slot to screen

User

Reduction of solids lost with filtrate

Reduction of consumables to a minimum

Standard design wear ring

Wiper segments (alternative)

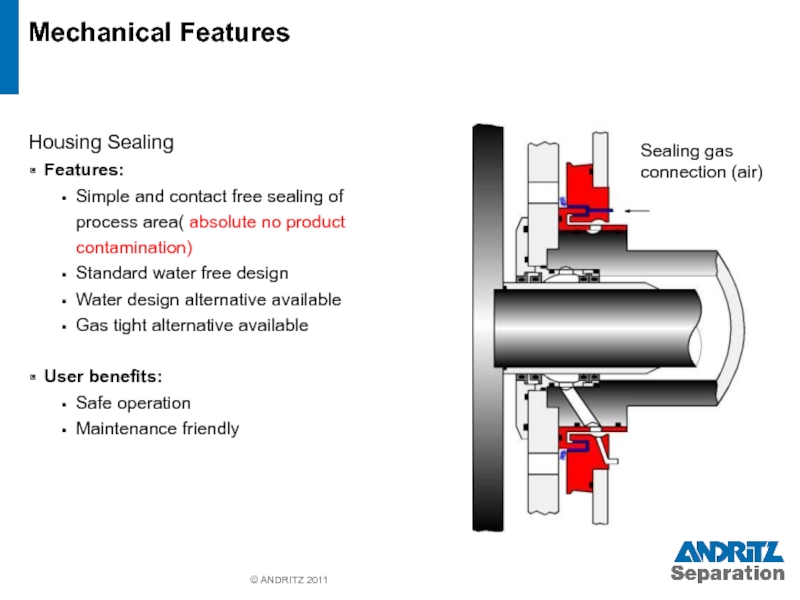

Слайд 13© ANDRITZ 2011

Mechanical Features

Housing Sealing

Features:

Simple and contact free sealing of process

Standard water free design

Water design alternative available

Gas tight alternative available

User benefits:

Safe operation

Maintenance friendly

Sealing gas

connection (air)

Слайд 14© ANDRITZ 2011

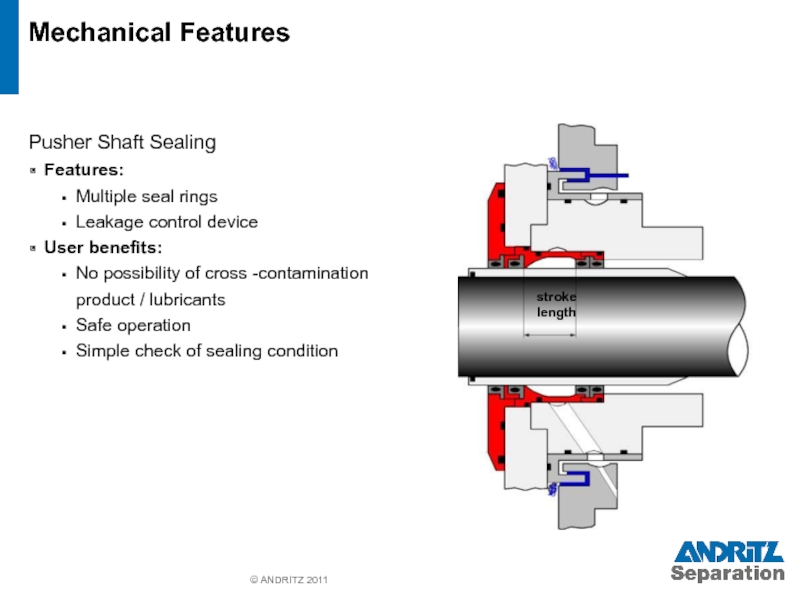

Mechanical Features

Pusher Shaft Sealing

Features:

Multiple seal rings

Leakage control device

User benefits:

No

Safe operation

Simple check of sealing condition

stroke

length

Слайд 15© ANDRITZ 2011

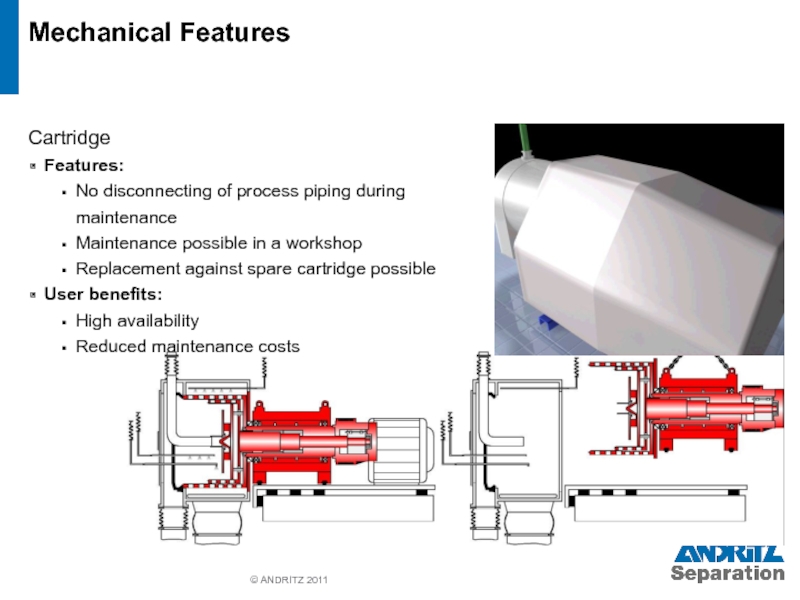

Mechanical Features

Cartridge

Features:

No disconnecting of process piping during maintenance

Maintenance possible

Replacement against spare cartridge possible

User benefits:

High availability

Reduced maintenance costs

Слайд 16© ANDRITZ 2011

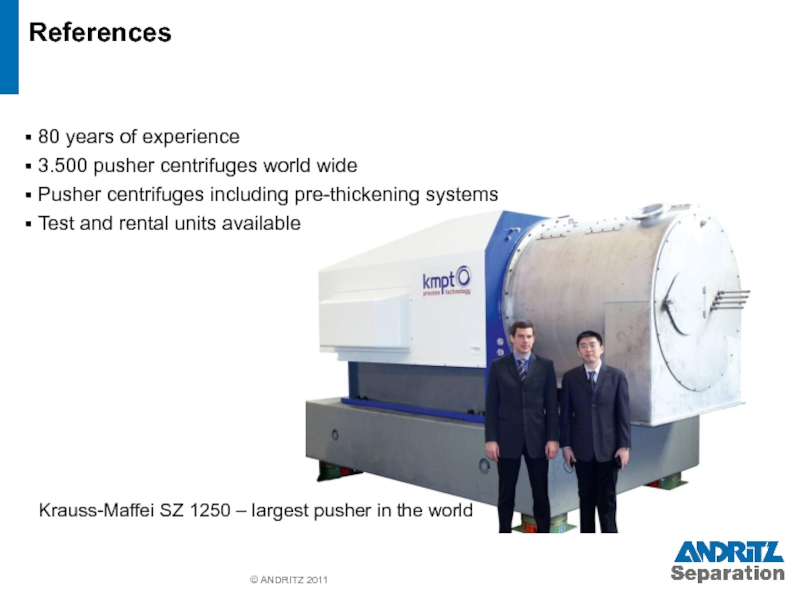

References

80 years of experience

3.500 pusher centrifuges world wide

Pusher centrifuges

Test and rental units available

Krauss-Maffei SZ 1250 – largest pusher in the world