- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

JCB 531-70 vs MLT X735 презентация

Содержание

- 1. JCB 531-70 vs MLT X735

- 2. Machines Compared JCB 531-70 - 7m Lift

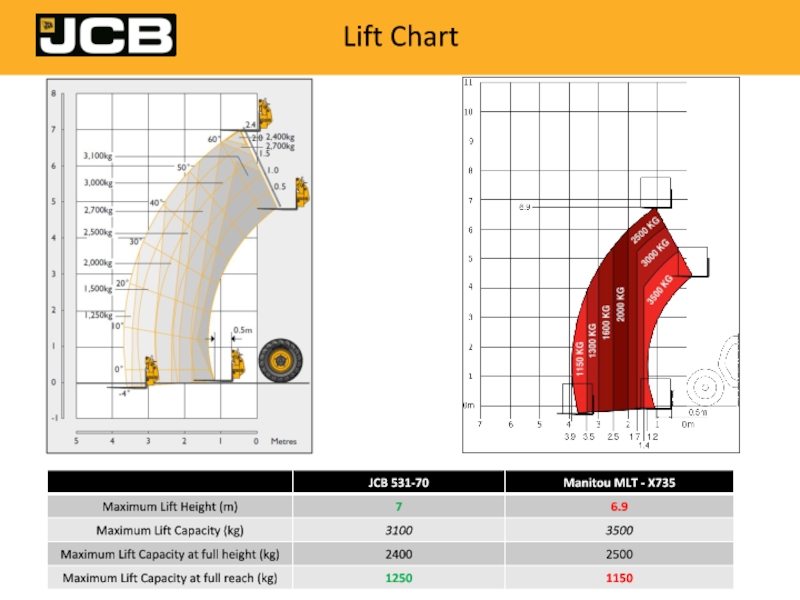

- 3. Lift Chart

- 4. Lift Chart / LMI Higher capacity at

- 5. Boom – Crowd / Dump cylinder Internal

- 6. Boom – Crowd / Dump cylinder Internal

- 7. Boom – QFIT carriage Strong, wide

- 8. Boom – Cylinders Centrally mounted lift cylinder

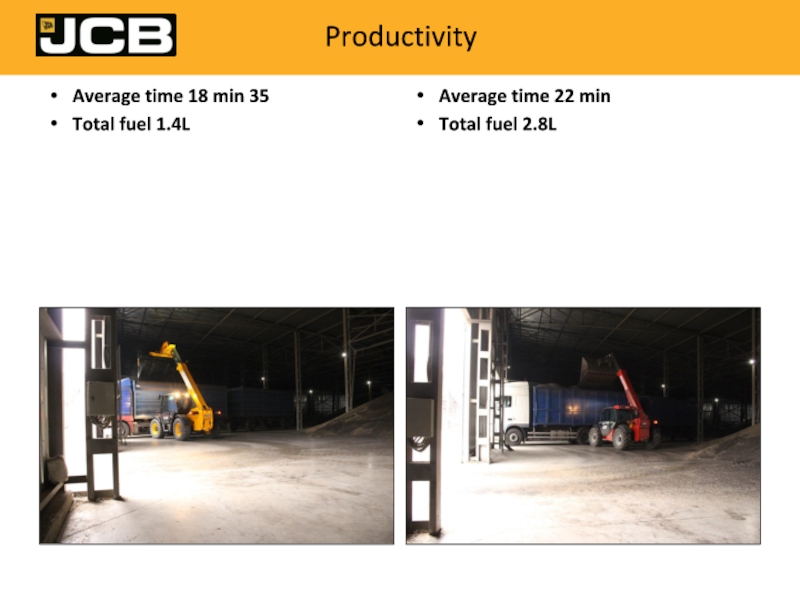

- 9. Productivity Average time 18 min 35 Total

- 10. Boom – Lubrication Dry wax lubricant

- 11. Boom - Construction U shaped pressing

- 12. Boom - Construction Welds do not form

- 13. Drivetrain - Axles Centrally mounted axles Robust

- 14. Drivetrain – Steering joints JCB Manufactured

- 15. Drivetrain - Engine JCB – fully integrated

- 16. Drivetrain - Engine Fold out, easy to

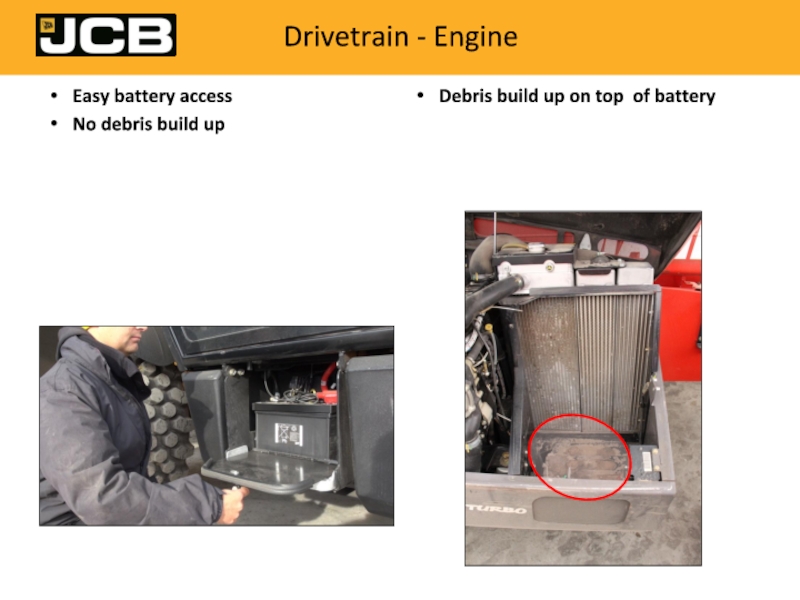

- 17. Drivetrain - Engine Easy battery access No

- 18. Drivetrain - Engine Fan utilised for dust

- 19. Drivetrain - Engine True hydraulically driven reverse

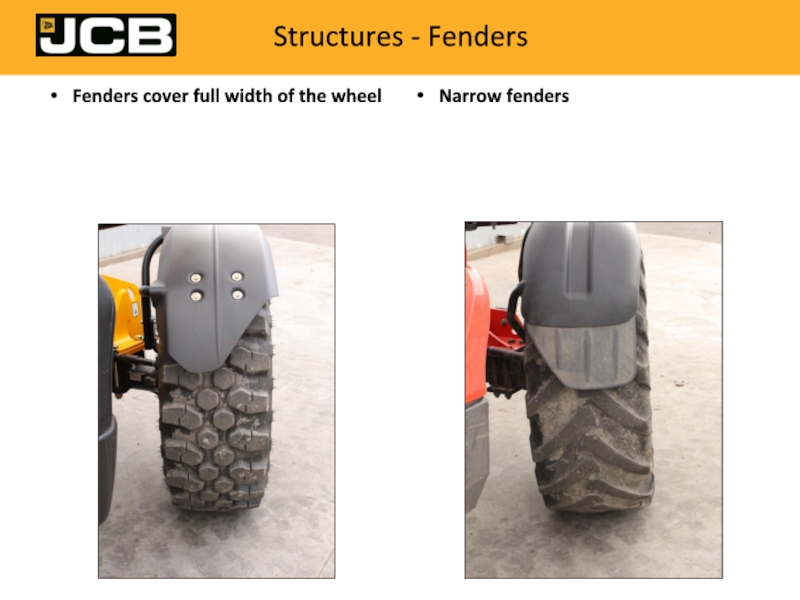

- 20. Structures - Fenders Fenders cover full width of the wheel Narrow fenders

- 21. Structure – Rear lights Adjustable rear lights

- 22. Structure – rear hitch mirror Single, compact

- 23. Service – Fill points Ground level fill Head height fill is more difficult

- 24. Service Grouped daily checks Transmission dipstick under the boom, required to remove cover

- 25. Service Transmission filter ?? hours Easy grouped

- 26. Service Hinged rear access cover Simple operation

- 27. Service Hydraulic tank in the rear Fill

- 28. Service Livelink fuel level warning as standard 3rd party level gauge No livelink fuel guard

- 29. Service Handbrake lever mechanism covered Exposed handbrake mechanism

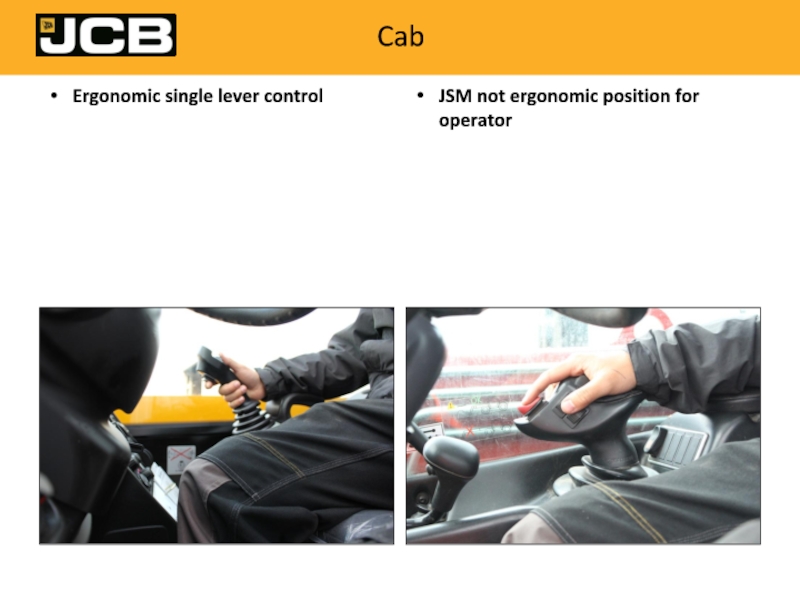

- 30. Cab Ergonomic single lever control JSM not ergonomic position for operator

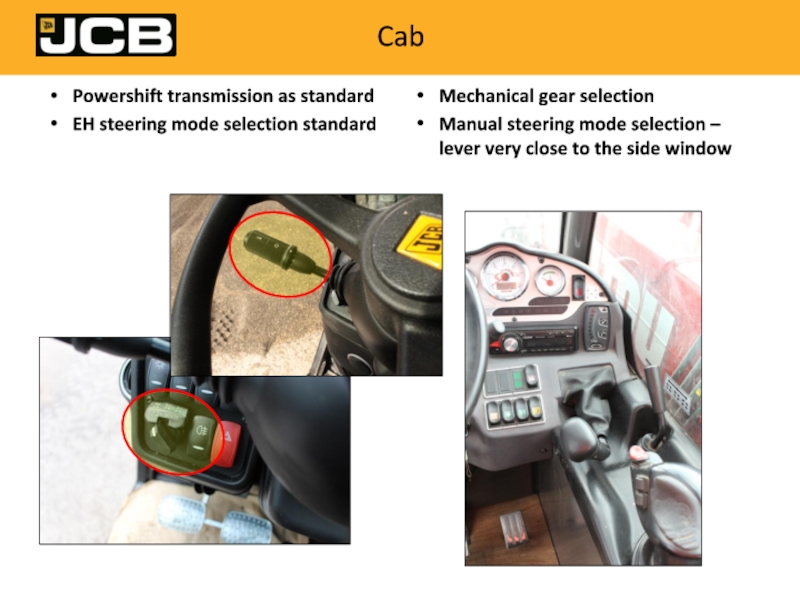

- 31. Cab Powershift transmission as standard EH steering

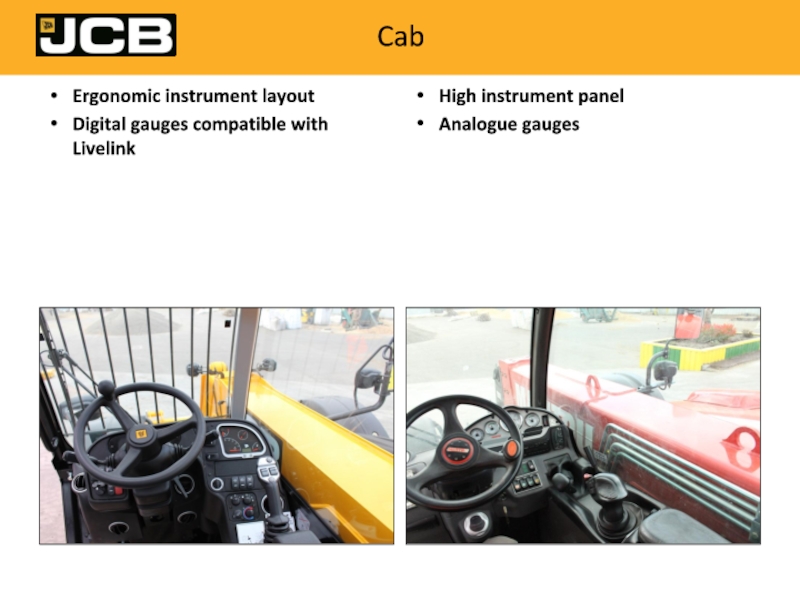

- 32. Cab Ergonomic instrument layout Digital gauges compatible with Livelink High instrument panel Analogue gauges

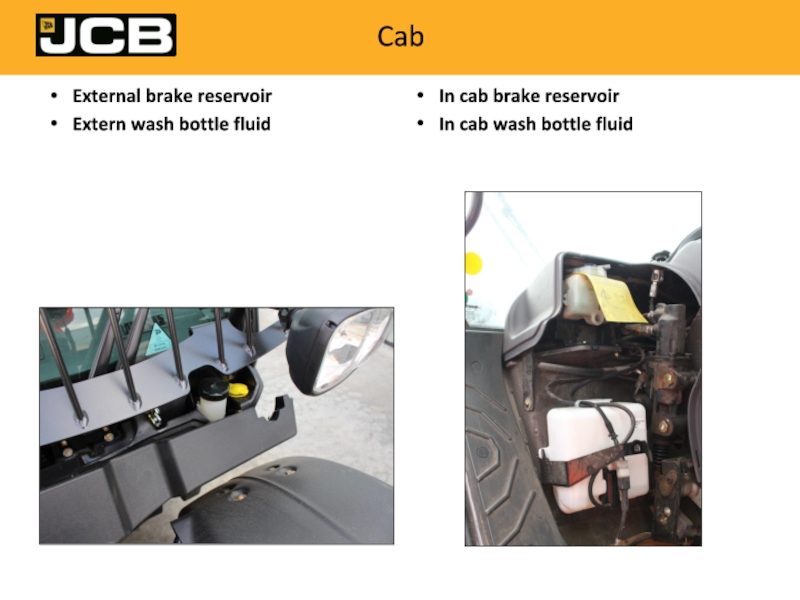

- 33. Cab External brake reservoir Extern wash bottle

- 34. Cab - Visibility Unrivalled visibility Exhaust and air pre filter reduce visibility

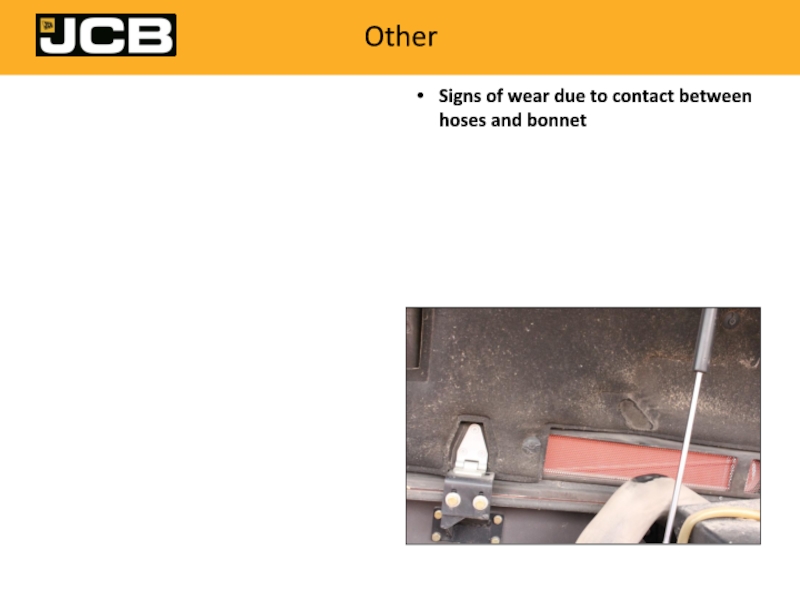

- 35. Other Signs of wear due to contact between hoses and bonnet

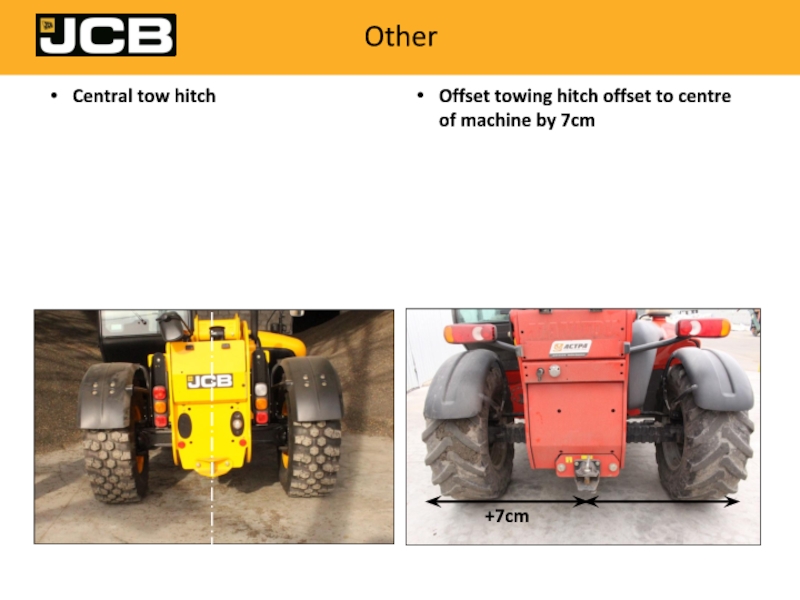

- 36. Other Central tow hitch Offset towing hitch offset to centre of machine by 7cm +7cm

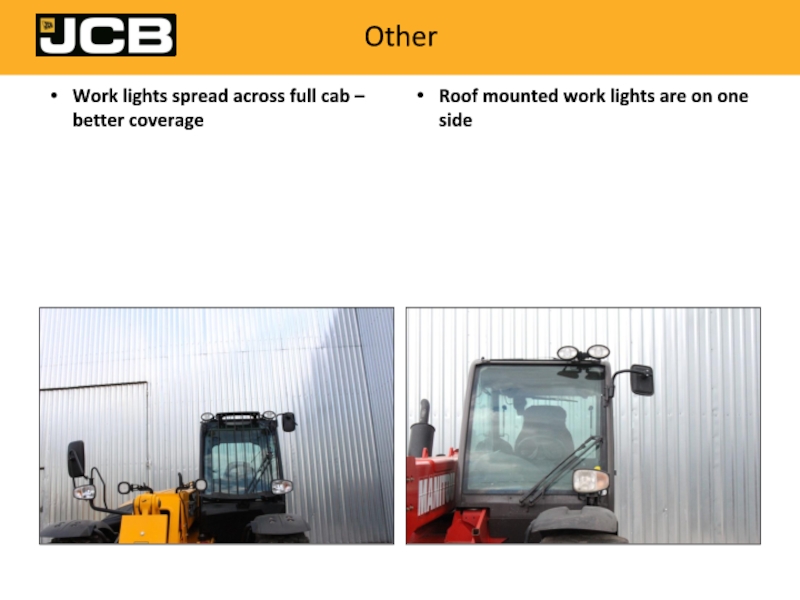

- 37. Other Work lights spread across full cab

- 38. JCB – Superior by design JCB’s proven

Слайд 2Machines Compared

JCB 531-70

- 7m Lift Height

- 3100kg Lift Capacity

- 74kW/100hp JCB

MLT X735

- 7m Lift Height

- 3500kg Lift Capacity

- 74kW/100hp Perkins Engine

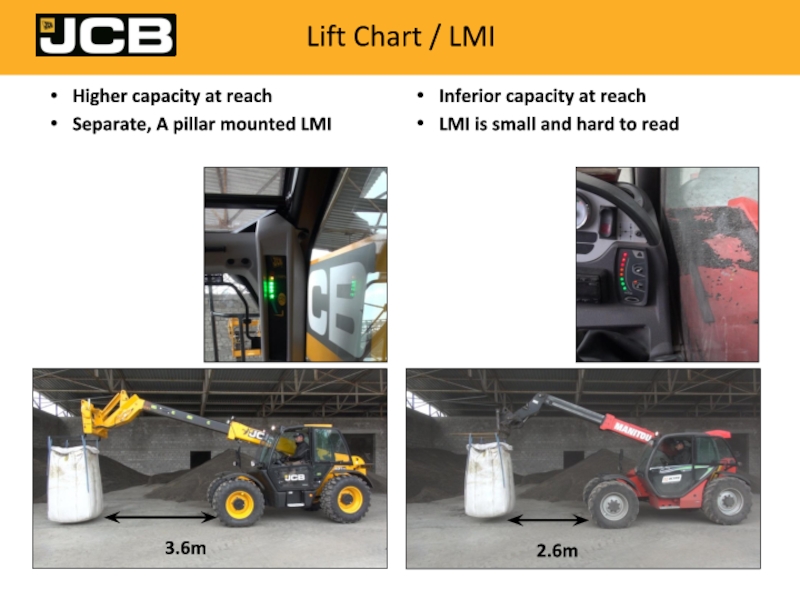

Слайд 4Lift Chart / LMI

Higher capacity at reach

Separate, A pillar mounted LMI

Inferior

LMI is small and hard to read

2.6m

3.6m

Слайд 7Boom – QFIT carriage

Strong, wide construction that adds rigidity to

Over centre locking mechanism – easily converted to hydraulic

Narrow construction

Hooks wear quickly

Manual locking bar – complete headstock replacement to convert to hydraulic

Слайд 8Boom – Cylinders

Centrally mounted lift cylinder

Centrally mounted compensation cylinder

NO TORSION

Offset lift cylinder causes torsion when lifting

Offset compensation cylinder adds to this effect

Слайд 10Boom – Lubrication

Dry wax lubricant – every 500 hours

Less chance

Wet grease lubrication every 50 hours

Material can stick / combine to create an abrasive paste and accelerate wear

Debris build up forced into rear of the boom

Слайд 11

Boom - Construction

U shaped pressing and closing plate

More robust

Two piece welded

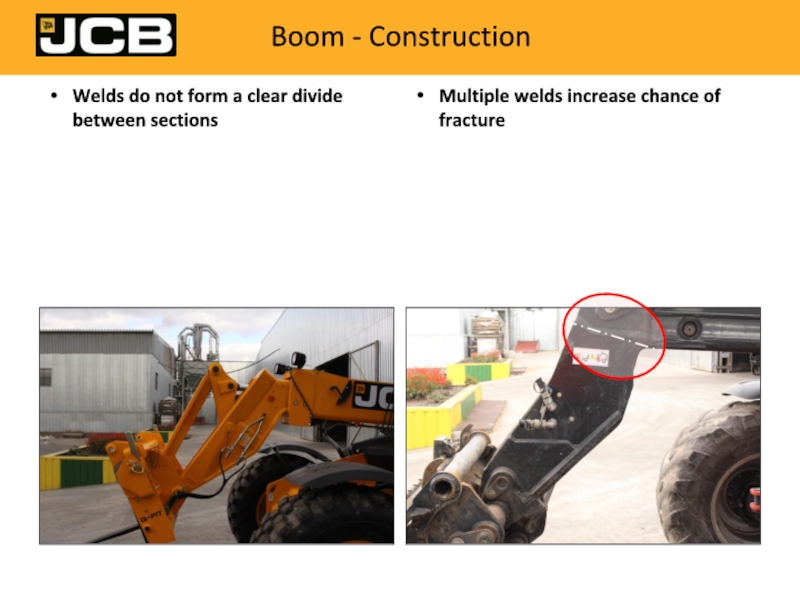

Слайд 12Boom - Construction

Welds do not form a clear divide between sections

Multiple

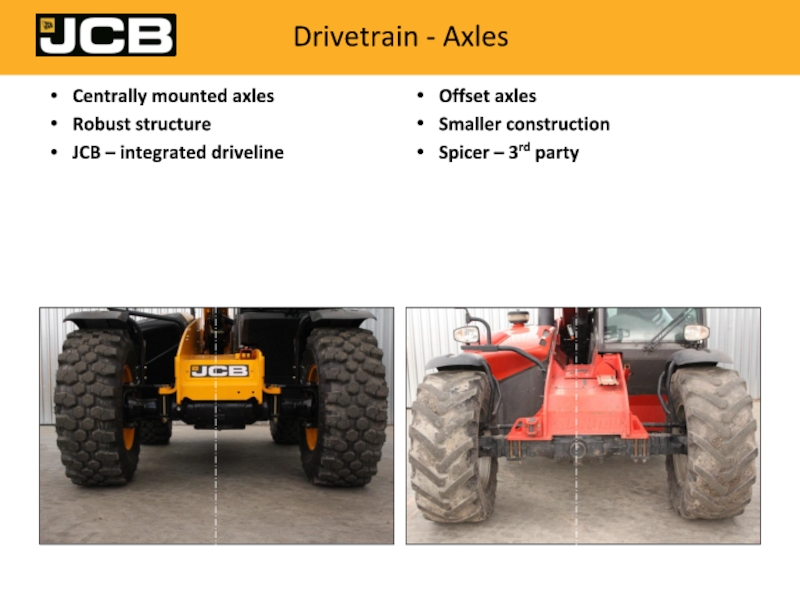

Слайд 13Drivetrain - Axles

Centrally mounted axles

Robust structure

JCB – integrated driveline

Offset axles

Smaller construction

Spicer

Слайд 14Drivetrain – Steering joints

JCB Manufactured axle steering system pivoted at

Easy to remove

Low maintenance and long life

Manitou Dana Spicer axle steering system pivoted at the hub with ball joint

Not simple to change with specialist tooling required

Low life high maintenance

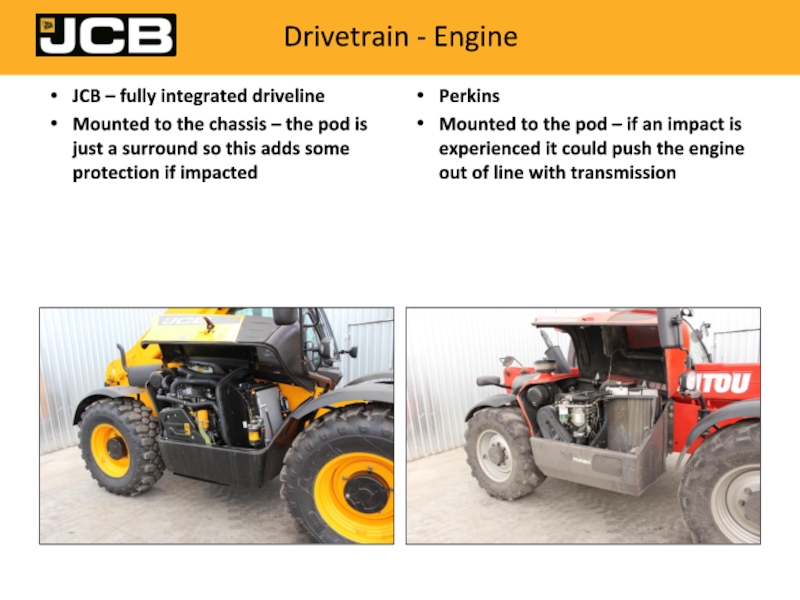

Слайд 15Drivetrain - Engine

JCB – fully integrated driveline

Mounted to the chassis –

Perkins

Mounted to the pod – if an impact is experienced it could push the engine out of line with transmission

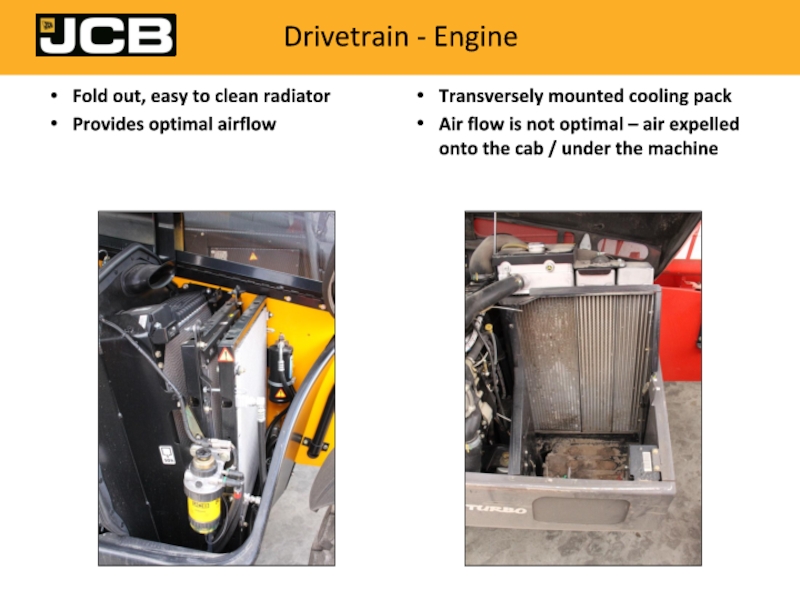

Слайд 16Drivetrain - Engine

Fold out, easy to clean radiator

Provides optimal airflow

Transversely mounted

Air flow is not optimal – air expelled onto the cab / under the machine

Слайд 18Drivetrain - Engine

Fan utilised for dust extraction from the air filter

Pre

Extra maintenance

Reduces visibility

Слайд 19Drivetrain - Engine

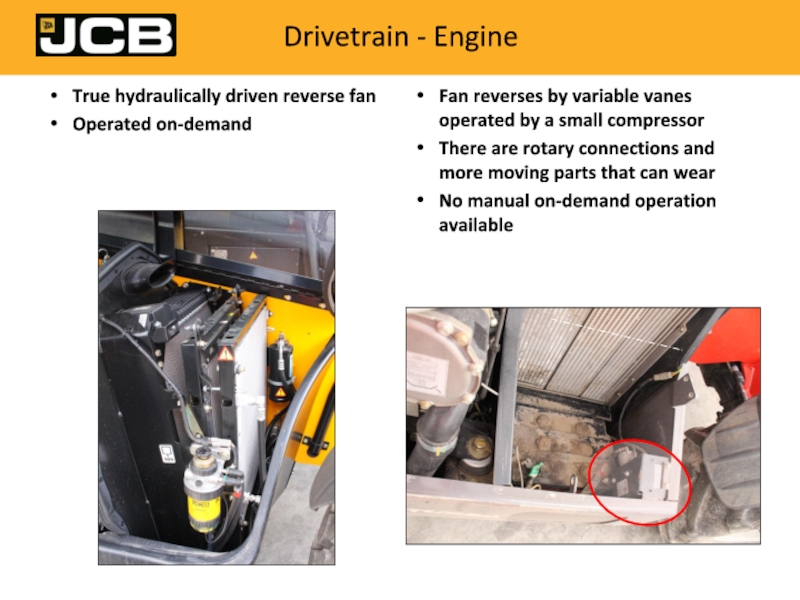

True hydraulically driven reverse fan

Operated on-demand

Fan reverses by variable

There are rotary connections and more moving parts that can wear

No manual on-demand operation available

Слайд 21Structure – Rear lights

Adjustable rear lights as standard

Reduced damage potential

Increased protection

Fixed rear lights

Exposed to damage permanently

No protection to lighting unit increasing cost of ownership

Слайд 22Structure – rear hitch mirror

Single, compact and robust support

Brackets fixed to

Слайд 25Service

Transmission filter ?? hours

Easy grouped service access

Transmission filter ?? hours

Panel removal

Replacement seal on cap 1000 hours

Слайд 26Service

Hinged rear access cover

Simple operation to access

Dedicated ‘T’ bar locking

Fixed rear access plate restricting access

4 bolts require removing to access

Universal fixtures increase the possibility of external access to the machine

Слайд 27Service

Hydraulic tank in the rear

Fill point at ground level

Hydraulic tank under

Fill point at height with restricted access

Слайд 31Cab

Powershift transmission as standard

EH steering mode selection standard

Mechanical gear selection

Manual steering

Слайд 32Cab

Ergonomic instrument layout

Digital gauges compatible with Livelink

High instrument panel

Analogue gauges

Слайд 33Cab

External brake reservoir

Extern wash bottle fluid

In cab brake reservoir

In cab wash

Слайд 37Other

Work lights spread across full cab – better coverage

Roof mounted work

Слайд 38JCB – Superior by design

JCB’s proven 10 year design life

In house

Structural integrity and durability built in

Higher Residual Values

Minimal daily checks

Simple control layout for safe and productive operation

Increased visibility for high productivity and increased safety