- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

CoDeSys CNC functionality презентация

Содержание

- 1. CoDeSys CNC functionality

- 2. General CNC (Computerized Numerical Control) is an

- 3. G-Code In order to provide an easy

- 4. Fundamental of CNC-Technology 2D 2-D-control: Allows machining

- 5. Fundamental of CNC-Technology 2,5D 2,5-D-control: Allows linear

- 6. Fundamental of CNC-Technology 3D 3-D-control: Allows linear

- 7. Features 3 axis for transformation additional

Слайд 2General

CNC (Computerized Numerical Control) is an electronic method for control and

regulation of machine (CNC machines), or the equipment used (controller, computer).

The set-up and the numerical address of the sending control information is described in DIN 66025/ISO 6983, usually referred to DIN / ISO programming. DIN A program can run on any CNC machine. However, for almost all machine specific commands, such as cycles, which can only be interpreted by these machines. Cycles are global programs, with parameters / variables that can be used where "pockets" (square contours or similar bags) or describe holes etc.. This makes the programming cycles and increase the clarity.

The set-up and the numerical address of the sending control information is described in DIN 66025/ISO 6983, usually referred to DIN / ISO programming. DIN A program can run on any CNC machine. However, for almost all machine specific commands, such as cycles, which can only be interpreted by these machines. Cycles are global programs, with parameters / variables that can be used where "pockets" (square contours or similar bags) or describe holes etc.. This makes the programming cycles and increase the clarity.

Слайд 3G-Code

In order to provide an easy way for programming geometric motion

profiles SoftMotion supports parts of the CNC language DIN66025. Since the whole SoftMotion concept is embedded in the much more powerful language IEC61131, only those parts of DIN66025 are supported, which serve to create a path.

Prescribed structure of a CNC program:

N G

Example:

% MyExample

N10 G01 X100 Y100 E100 F100 E-200

N20 G01 Z40 F20

N30 G03 X-100 R200 F100

Prescribed structure of a CNC program:

N

Example:

% MyExample

N10 G01 X100 Y100 E100 F100 E-200

N20 G01 Z40 F20

N30 G03 X-100 R200 F100

Слайд 4Fundamental of CNC-Technology 2D

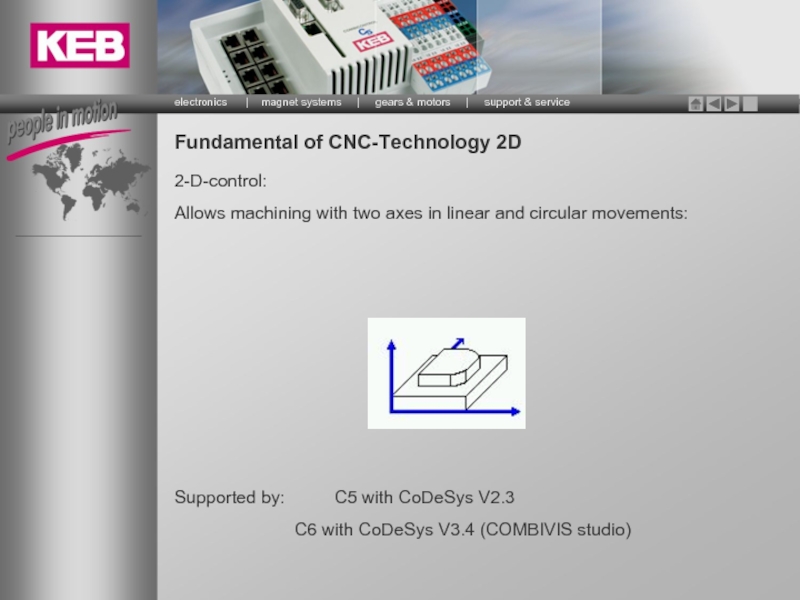

2-D-control:

Allows machining with two axes in linear and

circular movements:

Supported by: C5 with CoDeSys V2.3

C6 with CoDeSys V3.4 (COMBIVIS studio)

Supported by: C5 with CoDeSys V2.3

C6 with CoDeSys V3.4 (COMBIVIS studio)

Слайд 5Fundamental of CNC-Technology 2,5D

2,5-D-control:

Allows linear and circular movements of tool or

workpiece in several

Working planes. However you can coordinate not more then two axis

In their movements at the same time.

Supported by: C5 with CoDeSys V2.3

C6 with CoDeSys V3.4 (COMBIVIS studio)

Working planes. However you can coordinate not more then two axis

In their movements at the same time.

Supported by: C5 with CoDeSys V2.3

C6 with CoDeSys V3.4 (COMBIVIS studio)

Слайд 6Fundamental of CNC-Technology 3D

3-D-control:

Allows linear and circular special movements of tool

or workpiece. All

three axis have a functional interpolation.

Supported by: C6 with CoDeSys V3.4 (COMBIVIS studio)

three axis have a functional interpolation.

Supported by: C6 with CoDeSys V3.4 (COMBIVIS studio)

Слайд 7Features

3 axis for transformation

additional axis can not transformation (only straight

no curves)

manual generation of contours by g-code and by graphical editor

import of DXF-files possible

read NC program as txt-files

change of the driving speed and direction during runtime

change of curve coordinates by variable coordinates in the g-code

different modules for translation to the kinematics

comfortable visualisation elements

manual generation of contours by g-code and by graphical editor

import of DXF-files possible

read NC program as txt-files

change of the driving speed and direction during runtime

change of curve coordinates by variable coordinates in the g-code

different modules for translation to the kinematics

comfortable visualisation elements