- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Casing design презентация

Содержание

- 2. Casing Design Akram Miriyev, May 2014

- 3. About Me Studied Petroleum and Natural Gas

- 4. What is Casing ? 10/2/2014 Akram Miriyev

- 5. Key Topics Properties of Casing API specifications

- 6. Properties of Casing Dimensional Properties 10/2/2014 Akram Miriyev

- 7. Properties of casing Drift Diameter Weight

- 8. Properties of casing Material properties. API specifies

- 9. API Specifications Standardization institute Several publications to

- 10. Casing Connections Casing Strings are connected together

- 11. API connection (couplings) Short Thread Connection STC

- 12. Long thread connection Short Thread connection Long

- 13. Casing Connections Long & Short Thread connections

- 14. Casing Connections 10/2/2014 Akram Miriyev Reference : API 5B1 Buttress thread connection

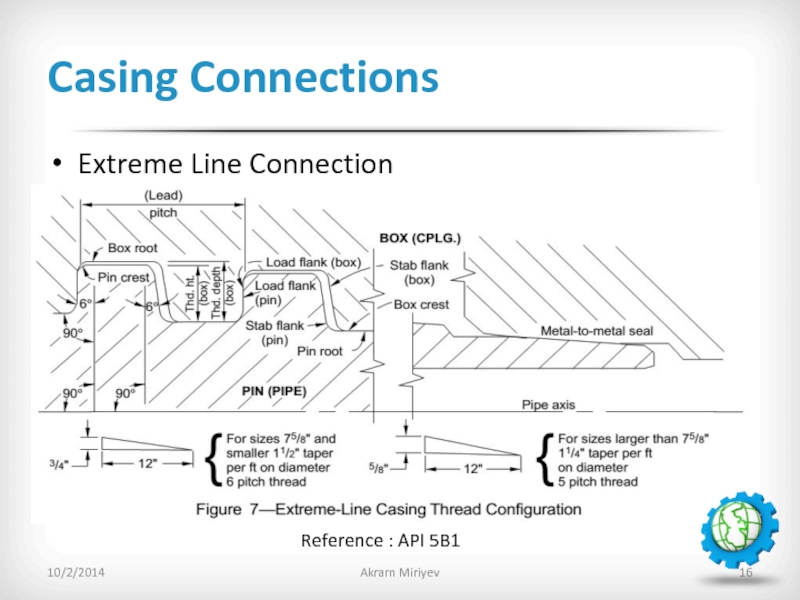

- 15. Casing Connections 10/2/2014 Akram Miriyev Reference : API 5B1 Extreme Line Connection

- 16. Casing Connections 10/2/2014 Akram Miriyev Reference :

- 17. Ability to drill next hole section while

- 18. Casing Setting Depth Selection 10/2/2014 Akram Miriyev

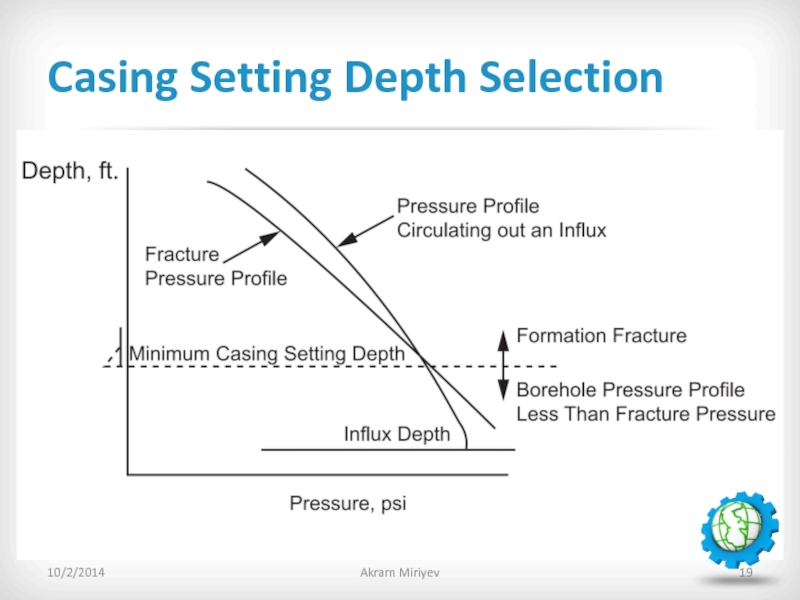

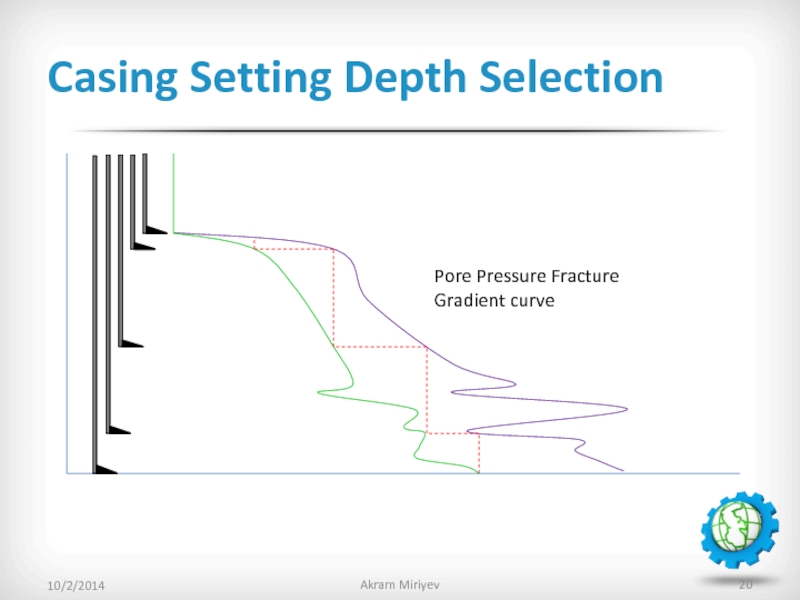

- 19. Casing Setting Depth Selection 10/2/2014 Akram Miriyev Pore Pressure Fracture Gradient curve

- 20. Class Problem 1. 10/2/2014 Akram Miriyev

- 21. Casing Setting Depth Selection 10/2/2014 Akram Miriyev

- 22. Strength Properties of Casing 10/2/2014 Akram Miriyev

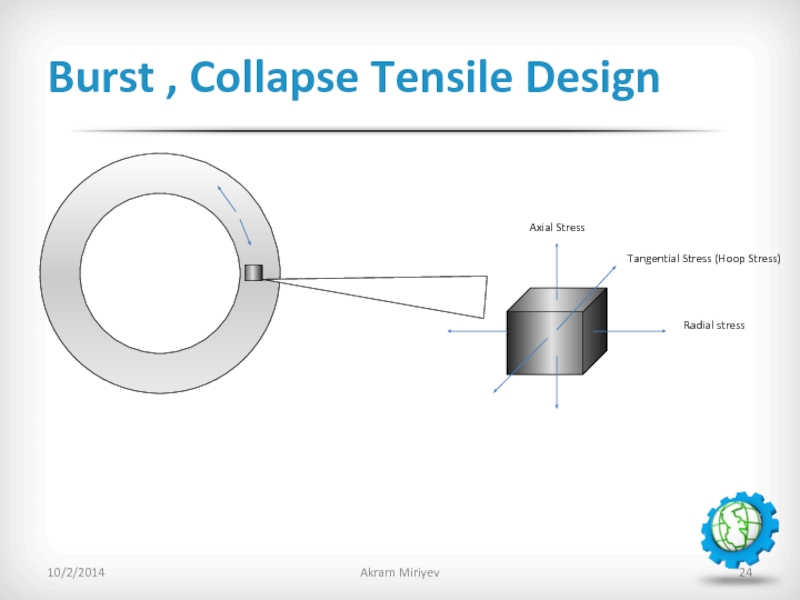

- 23. Burst , Collapse Tensile Design 10/2/2014 Akram Miriyev ID

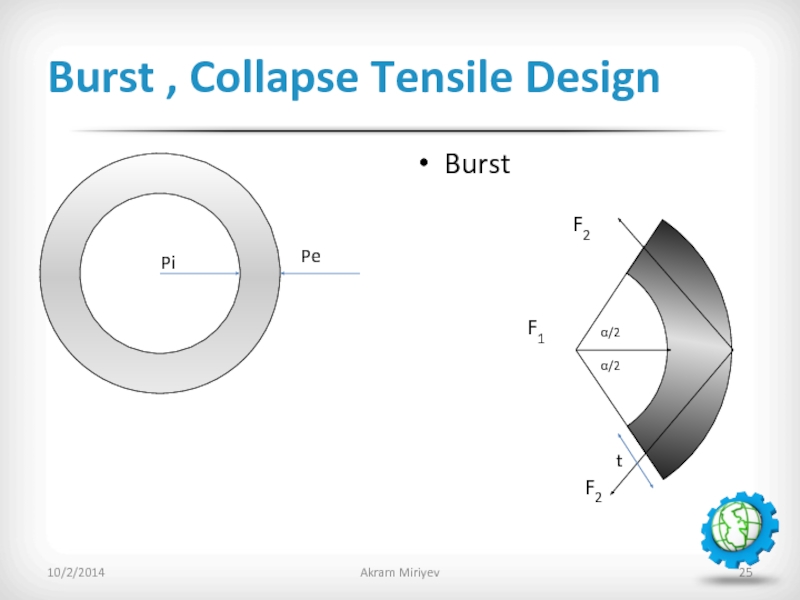

- 24. Burst , Collapse Tensile Design Burst

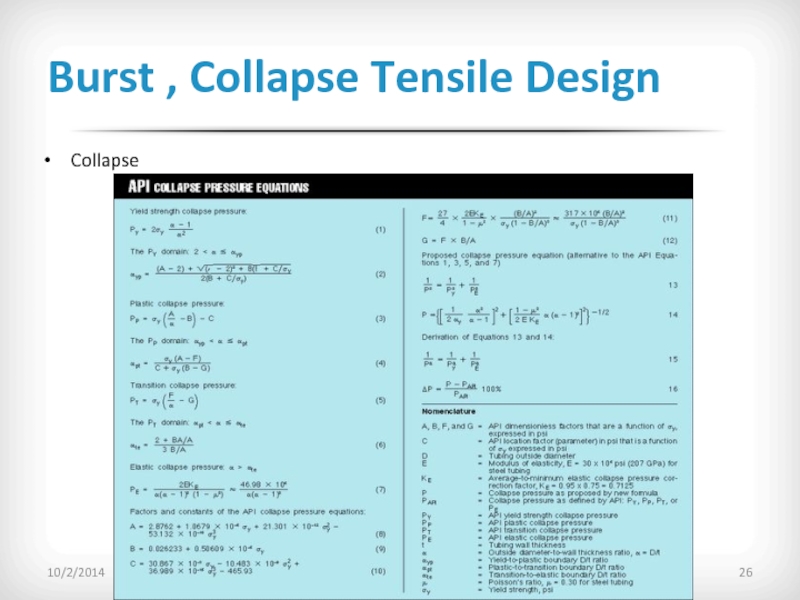

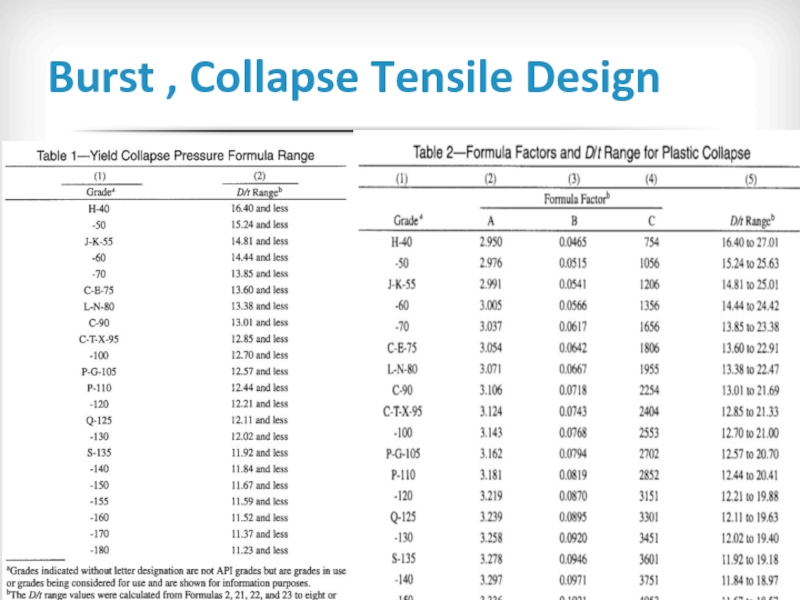

- 25. Burst , Collapse Tensile Design Collapse 10/2/2014 Akram Miriyev

- 26. Burst , Collapse Tensile Design 10/2/2014 Akram Miriyev

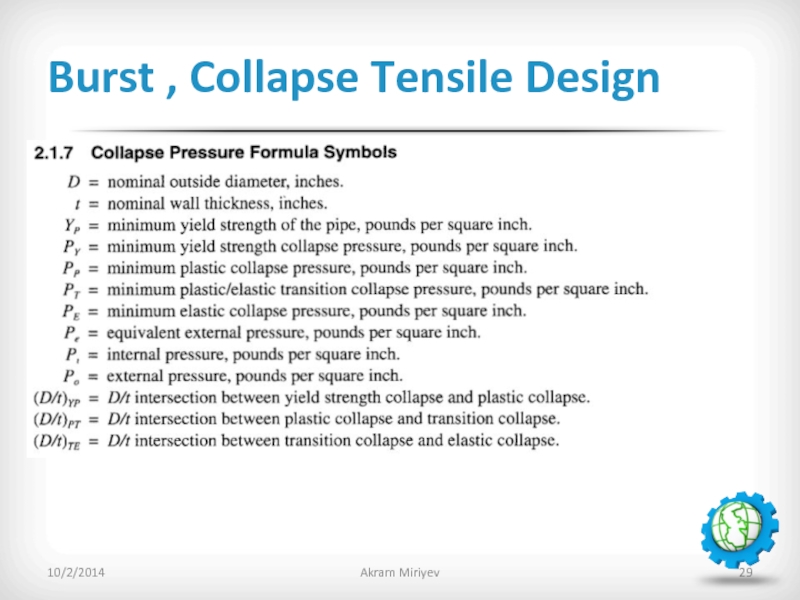

- 27. Burst , Collapse Tensile Design 10/2/2014 Akram Miriyev

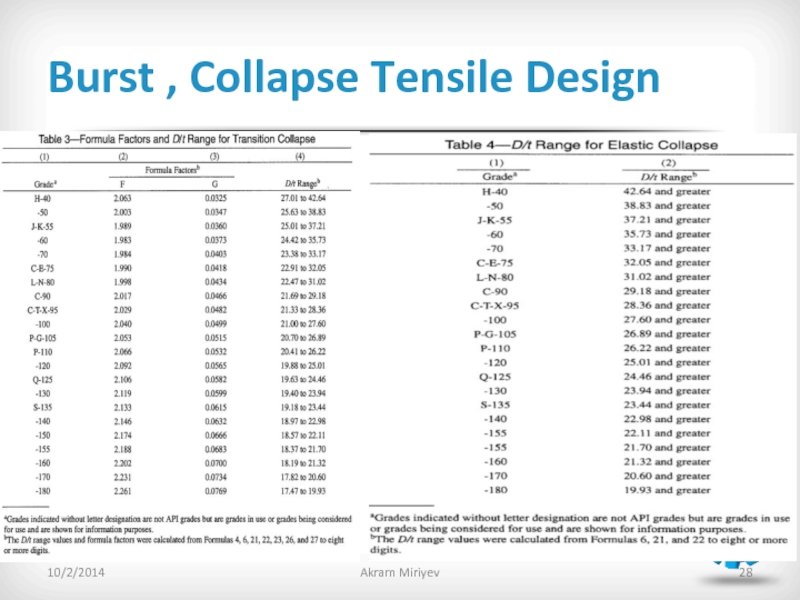

- 28. Burst , Collapse Tensile Design 10/2/2014 Akram Miriyev

- 29. Class Problem 2. Calculate Collapse pressure for

- 30. Burst , Collapse Tensile Design Axial

Слайд 3About Me

Studied Petroleum and Natural Gas Engineering in METU 2006-2011

Working at

10/2/2014

Akram Miriyev

Слайд 4What is Casing ?

10/2/2014

Akram Miriyev

Main purpose of casing is to sustain

Слайд 5Key Topics

Properties of Casing

API specifications

Casing Connections

Casing Setting Depth Selection

PPFG curve

Class problem

Burst

Load Cases

Class Problem

10/2/2014

Akram Miriyev

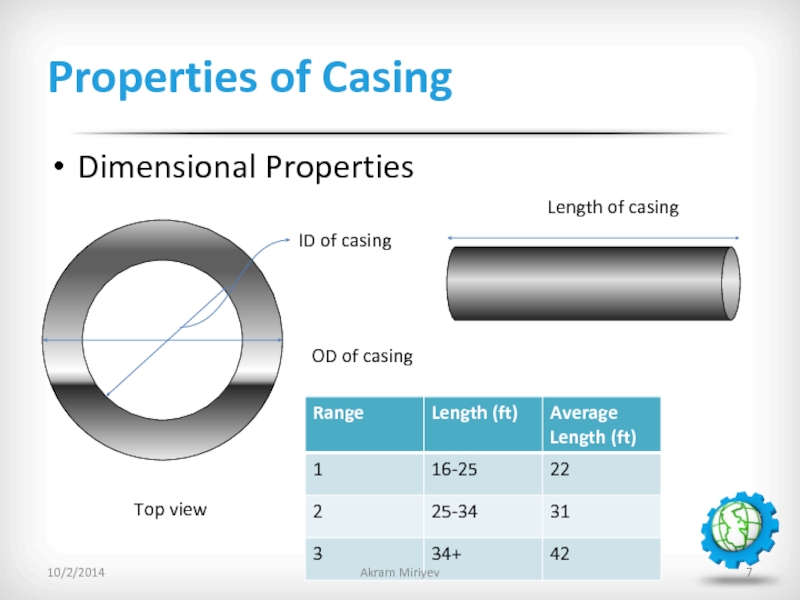

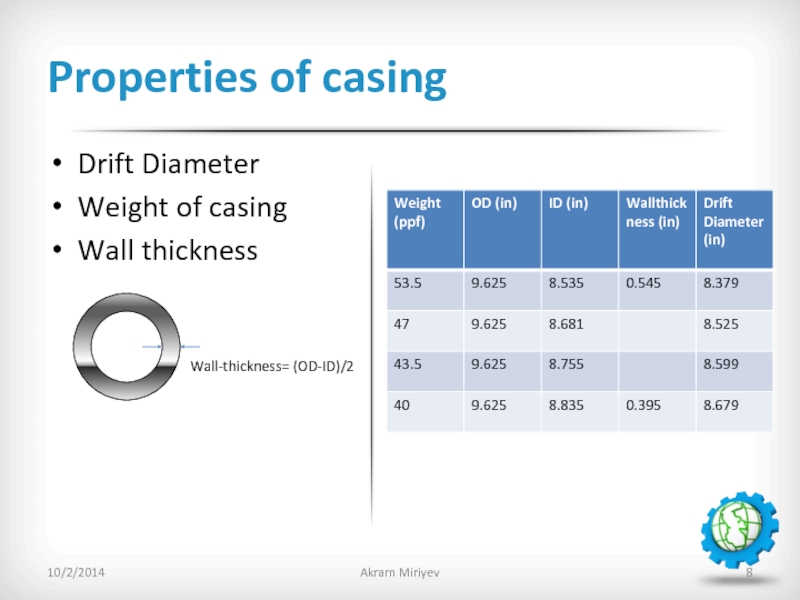

Слайд 7Properties of casing

Drift Diameter

Weight of casing

Wall thickness

Wall-thickness= (OD-ID)/2

10/2/2014

Akram Miriyev

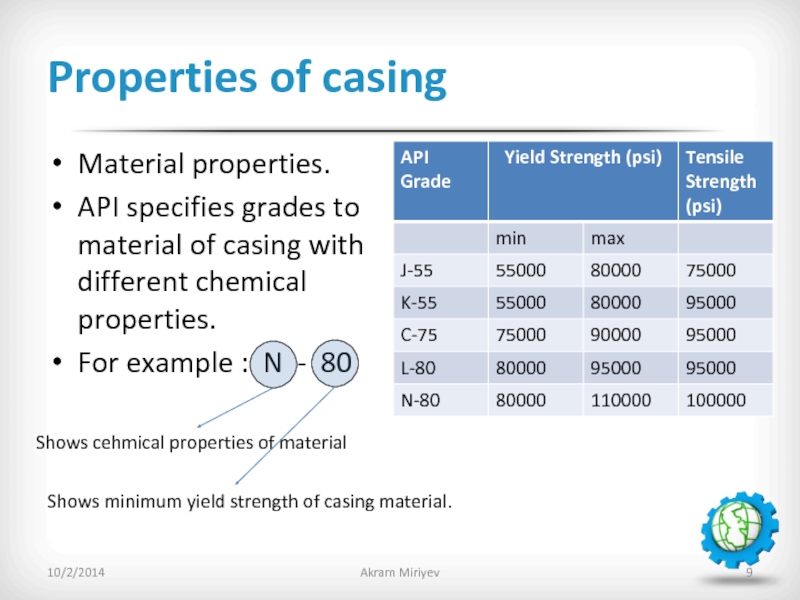

Слайд 8Properties of casing

Material properties.

API specifies grades to material of casing with

For example : N - 80

10/2/2014

Akram Miriyev

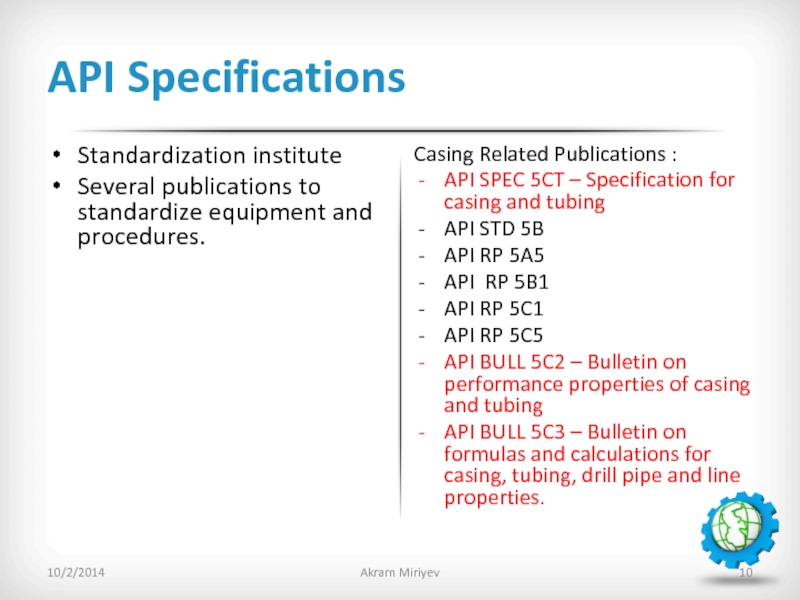

Слайд 9API Specifications

Standardization institute

Several publications to standardize equipment and procedures.

Casing Related Publications

API SPEC 5CT – Specification for casing and tubing

API STD 5B

API RP 5A5

API RP 5B1

API RP 5C1

API RP 5C5

API BULL 5C2 – Bulletin on performance properties of casing and tubing

API BULL 5C3 – Bulletin on formulas and calculations for casing, tubing, drill pipe and line properties.

10/2/2014

Akram Miriyev

Слайд 10Casing Connections

Casing Strings are connected together by connections

API

Premium

Gastight

Metal-to-Metal seal

10/2/2014

Akram Miriyev

Слайд 11API connection (couplings)

Short Thread Connection STC

Long Thread Connection LTC

Buttress Thread

Extreme

10/2/2014

Akram Miriyev

Casing Connections

Слайд 12Long thread connection

Short Thread connection

Long thread connection has better sealing capacity.

Short thread connection has 8 thread per inch

10/2/2014

Akram Miriyev

Casing Connections

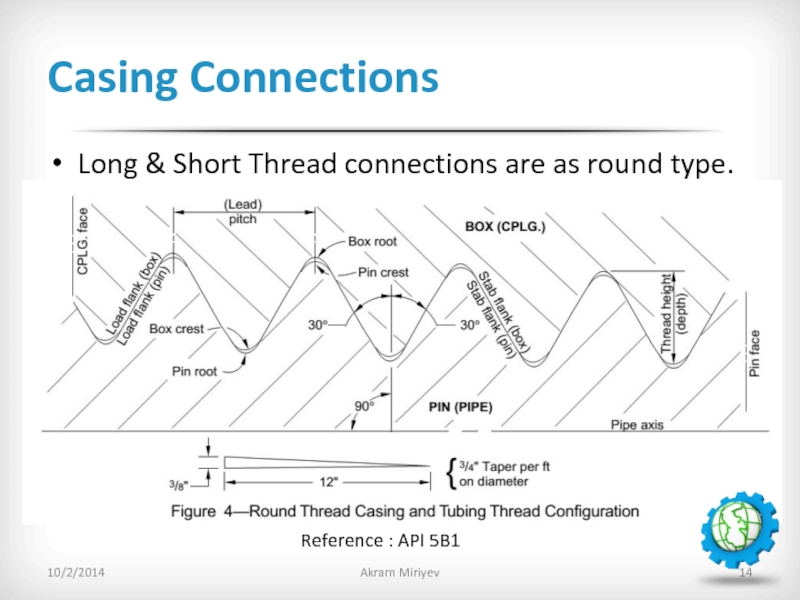

Слайд 13Casing Connections

Long & Short Thread connections are as round type.

10/2/2014

Akram Miriyev

Reference

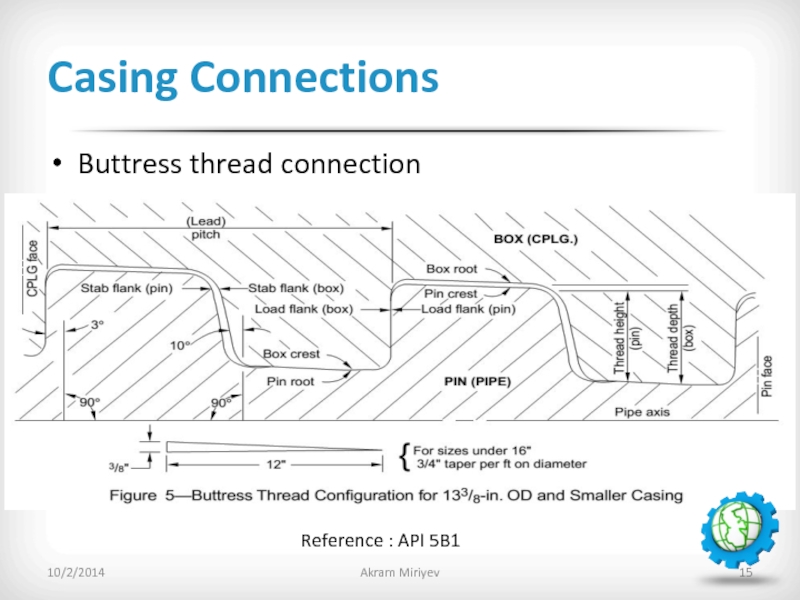

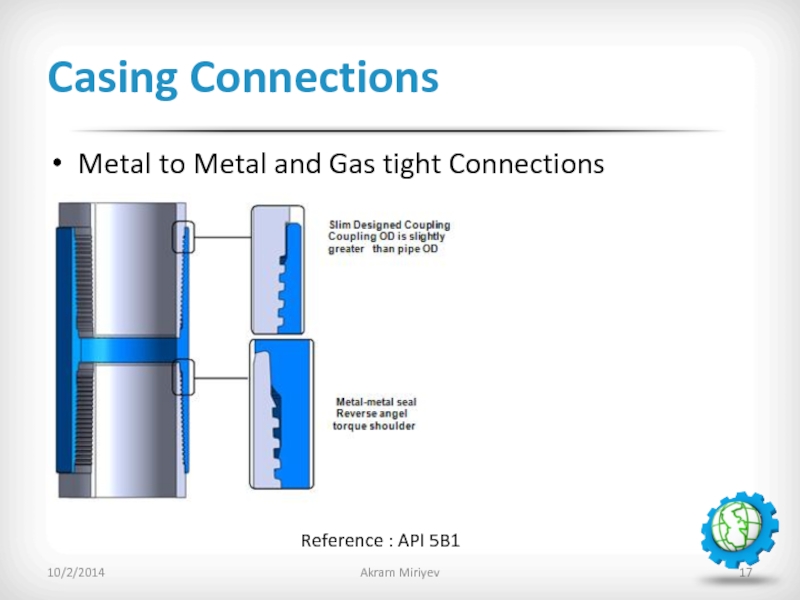

Слайд 16Casing Connections

10/2/2014

Akram Miriyev

Reference : API 5B1

Metal to Metal and Gas tight

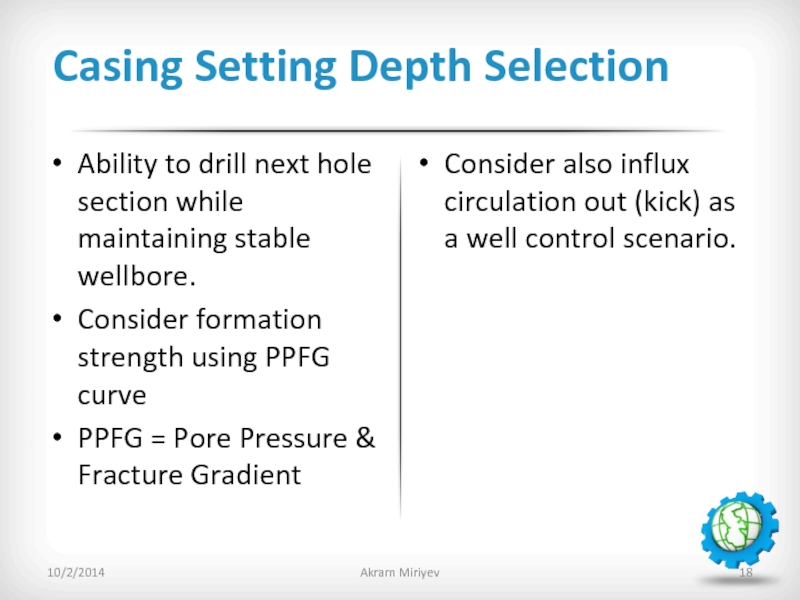

Слайд 17Ability to drill next hole section while maintaining stable wellbore.

Consider formation

PPFG = Pore Pressure & Fracture Gradient

Consider also influx circulation out (kick) as a well control scenario.

10/2/2014

Akram Miriyev

Casing Setting Depth Selection

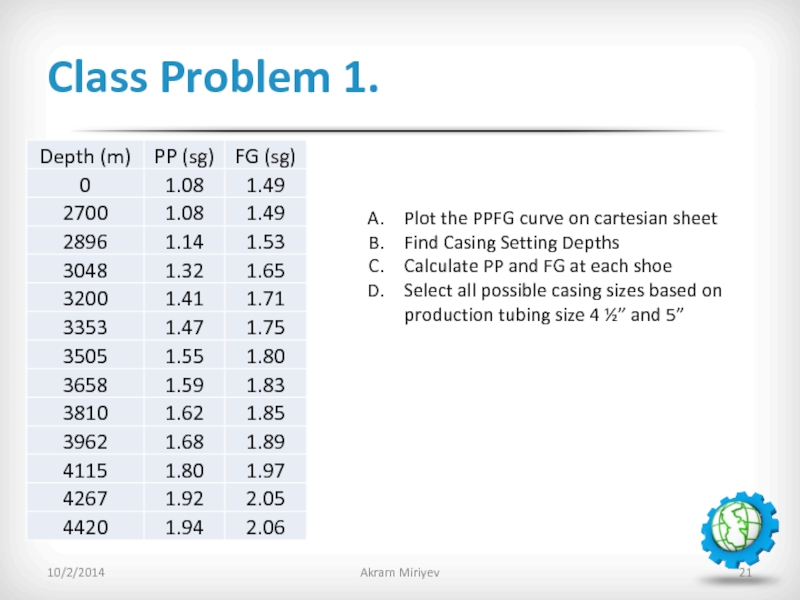

Слайд 20Class Problem 1.

10/2/2014

Akram Miriyev

Plot the PPFG curve on cartesian sheet

Find Casing

Calculate PP and FG at each shoe

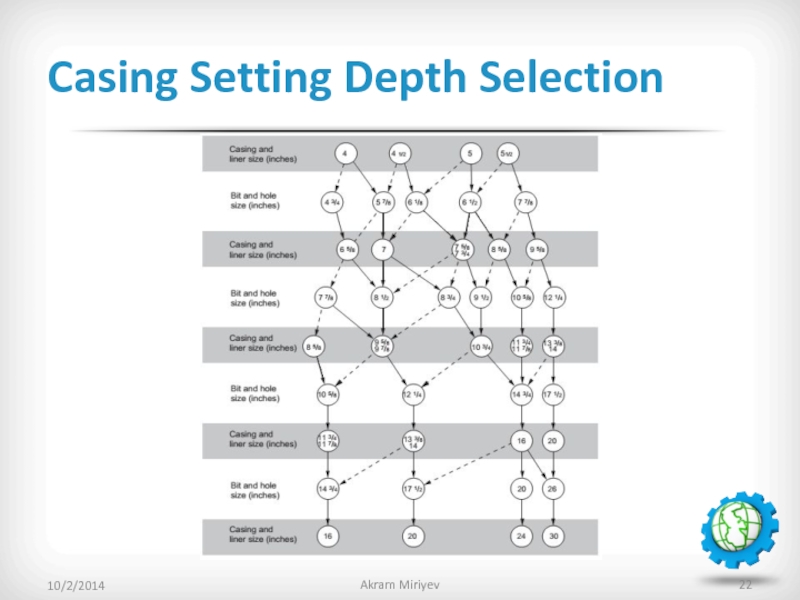

Select all possible casing sizes based on production tubing size 4 ½” and 5”

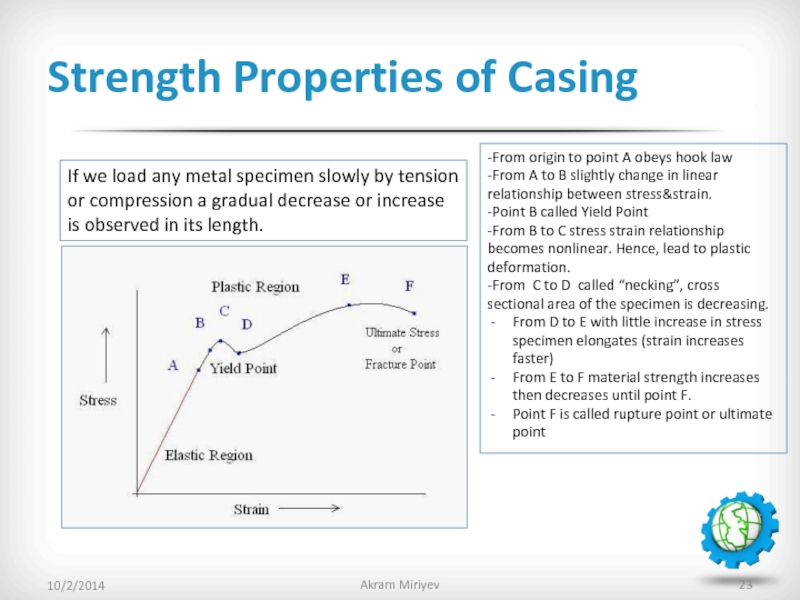

Слайд 22Strength Properties of Casing

10/2/2014

Akram Miriyev

If we load any metal specimen slowly

-From origin to point A obeys hook law

-From A to B slightly change in linear relationship between stress&strain.

-Point B called Yield Point

-From B to C stress strain relationship becomes nonlinear. Hence, lead to plastic deformation.

-From C to D called “necking”, cross sectional area of the specimen is decreasing.

From D to E with little increase in stress specimen elongates (strain increases faster)

From E to F material strength increases then decreases until point F.

Point F is called rupture point or ultimate point

Слайд 29Class Problem 2.

Calculate Collapse pressure for pipe :

OD=7”

Weight = 26

Wall Thickness = 0.362”

P-110

10/2/2014

Akram Miriyev

Слайд 30Burst , Collapse Tensile Design

Axial Tension

Faxial tension = σyield

10/2/2014

Akram Miriyev