- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

AT - A4AF3. Automatic Transaxle презентация

Содержание

- 1. AT - A4AF3. Automatic Transaxle

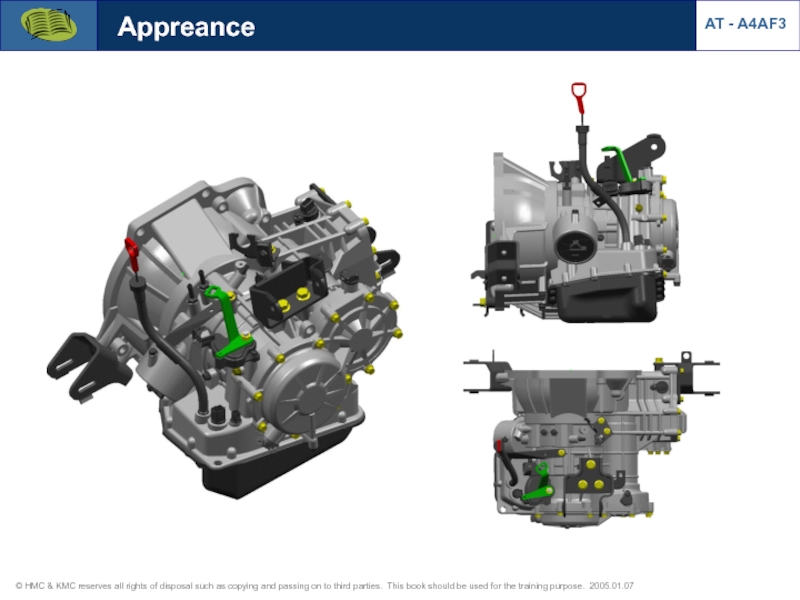

- 2. Appreance AT - A4AF3

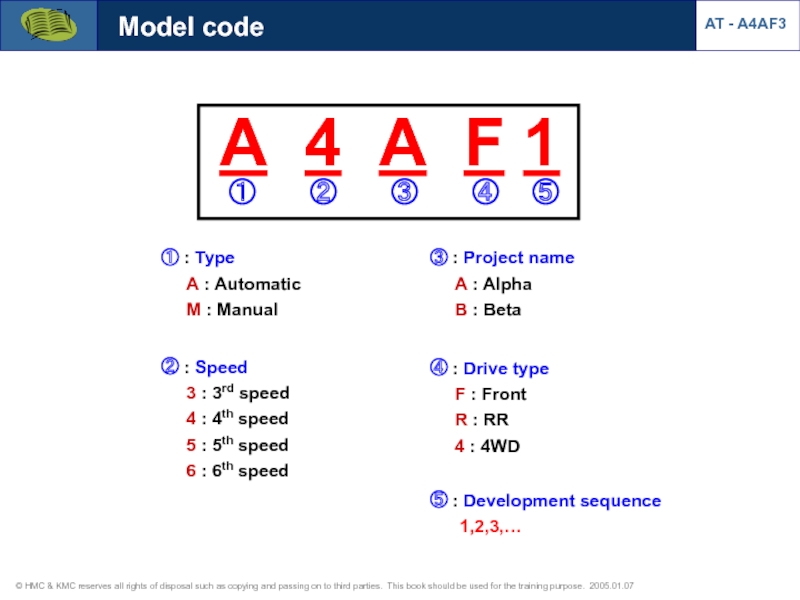

- 3. ③ : Project name

- 4. Location of PCM AT - A4AF3

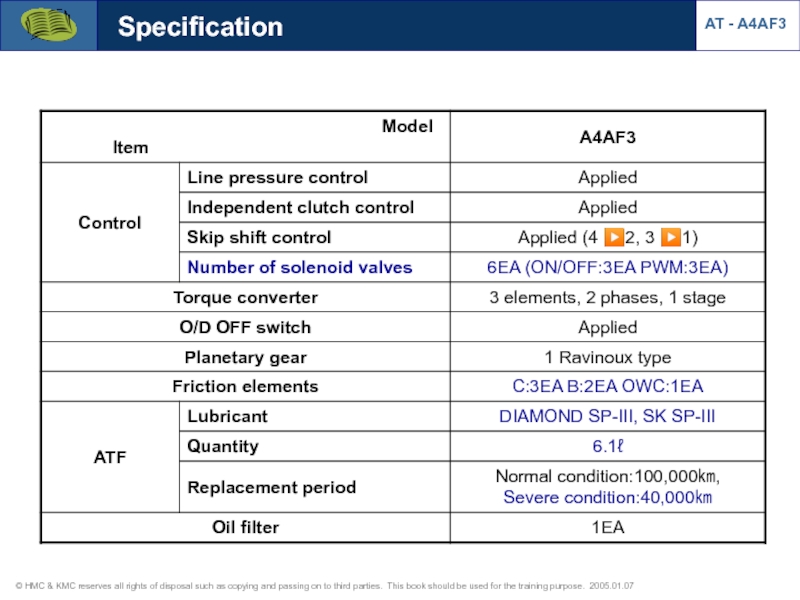

- 5. Specification AT - A4AF3

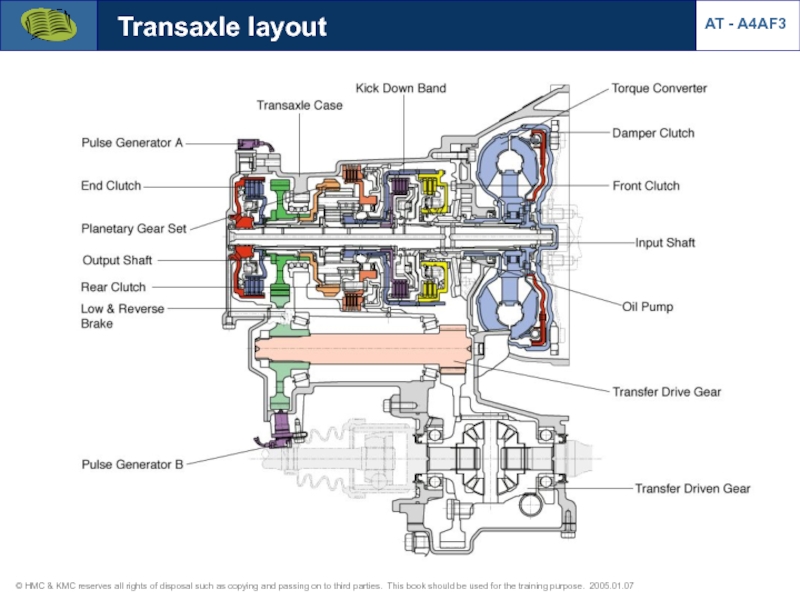

- 6. Transaxle layout AT - A4AF3

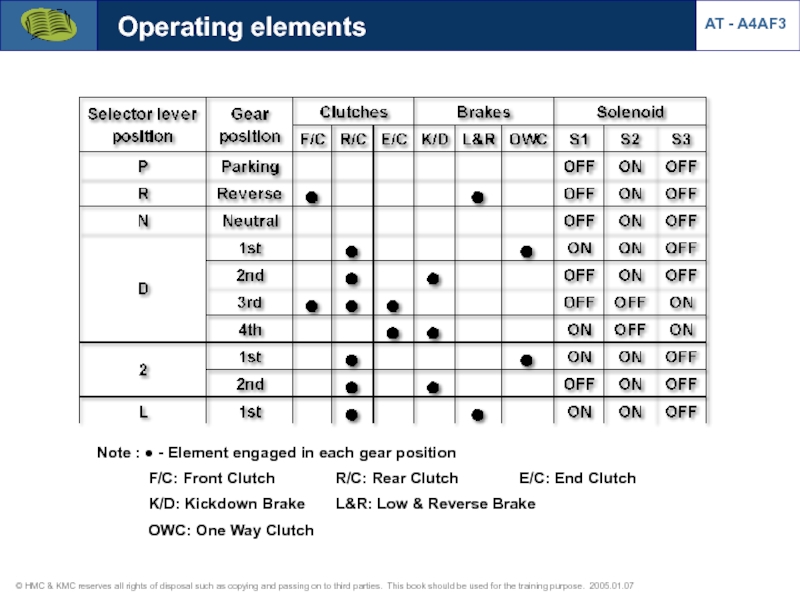

- 7. Note : ● - Element engaged in

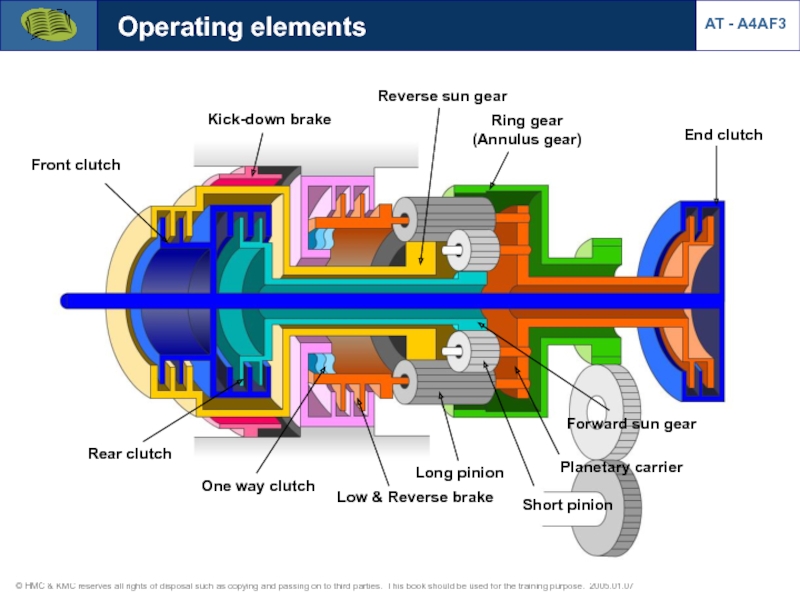

- 8. Short pinion Long pinion Ring gear (Annulus

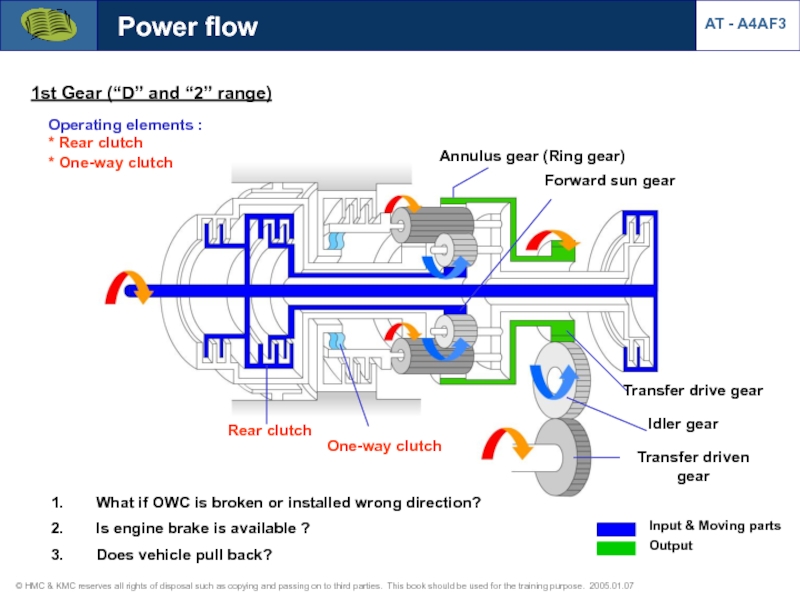

- 9. 1st Gear (“D” and “2” range) Operating

- 10. 1st Gear (“L” range) Operating elements :

- 11. 2nd Gear (“D” and “2” range) Operating

- 12. 3rd Gear (“D” range) Operating elements :

- 13. Does end clutch deliver power ? ?

- 14. 4th Gear (“D” range) Operating elements :

- 15. Reverse range Operating elements : * Front

- 16. AT - A4AF3 Power flow Reverse range

- 17. #1 #2 #13 #12 #11

- 18. Input shaft end play Standard value :

- 19. Measure the input shaft endplay and select

- 20. #3 thrust race selection

- 21. Front clutch Engaged at D3, R

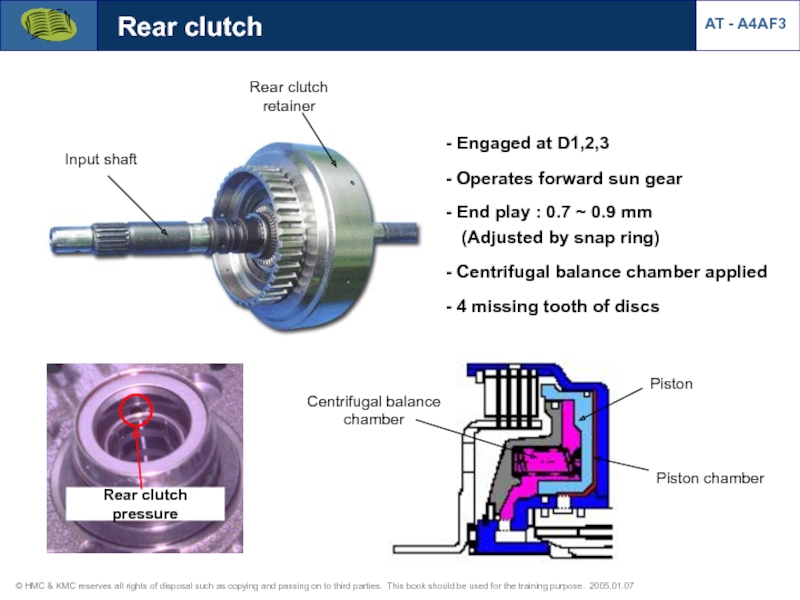

- 22. Input shaft Rear clutch retainer Rear clutch

- 23. End clutch Engaged at D3,4 (powered

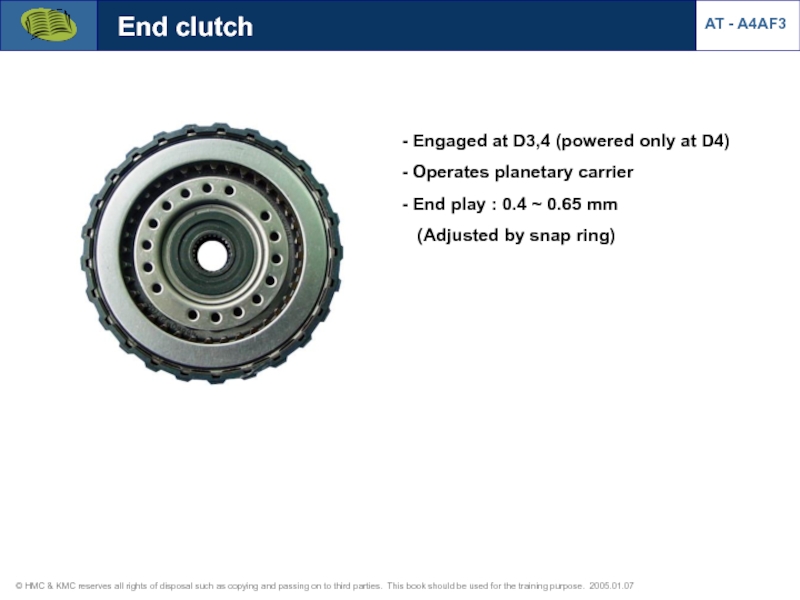

- 24. Kick-down drum Kick-down band Piston rod &

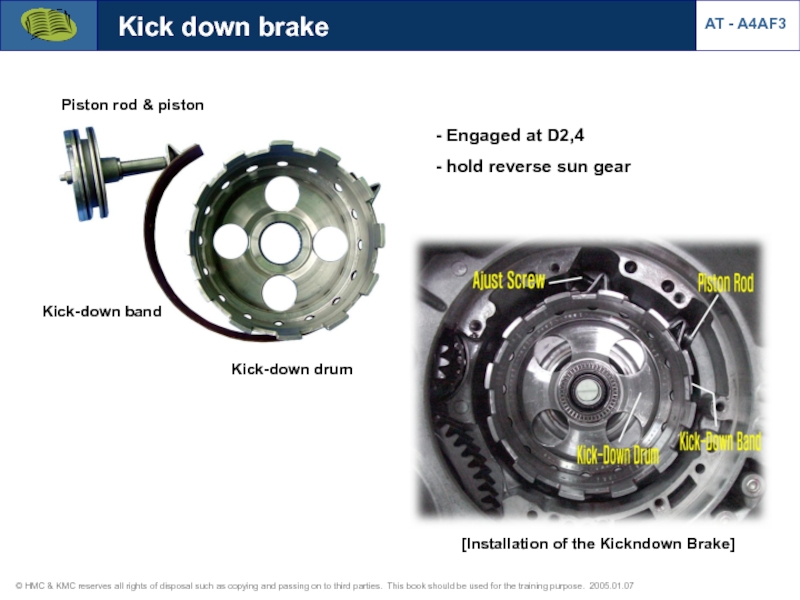

- 25. Kick down brake Kickndown brake servo piston

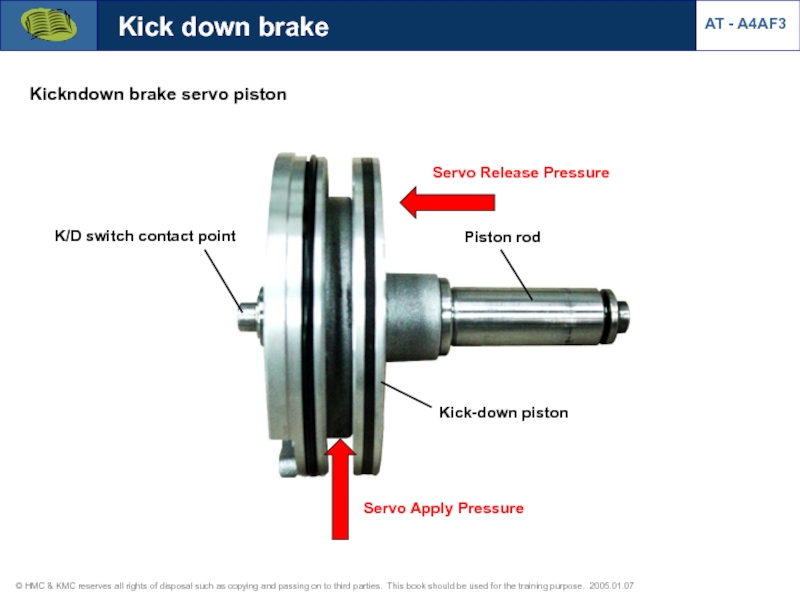

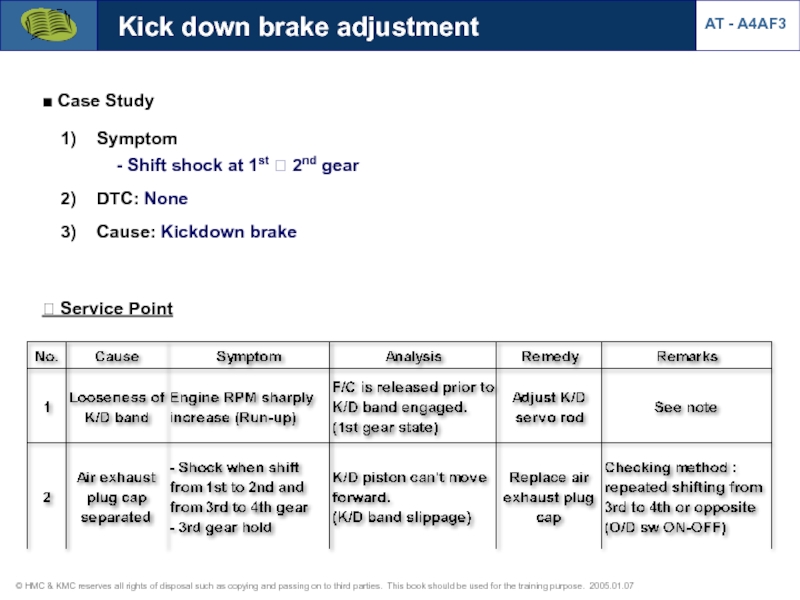

- 26. ? Service Point Symptom

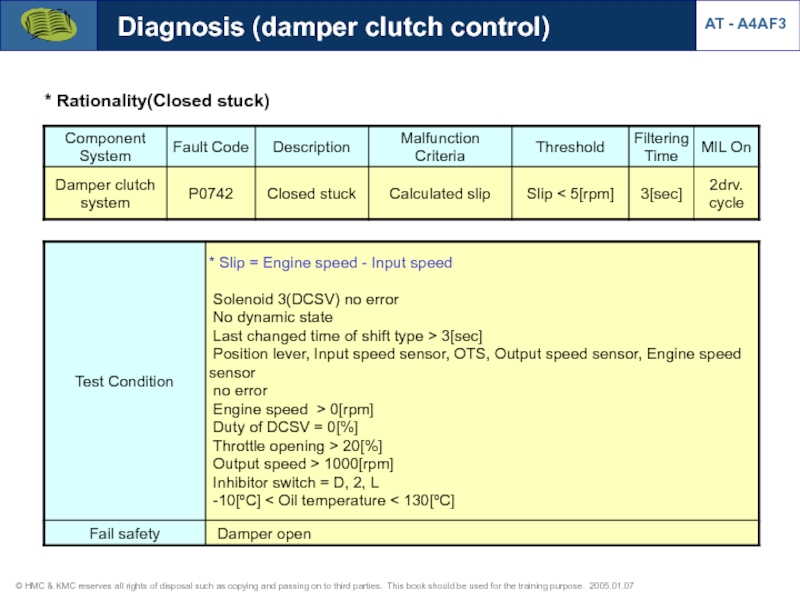

- 27. ① Loosen the adjust screw lock nut

- 28. ③ Tighten the adjust screw (Torque :

- 29. Kick down brake adjustment AT - A4AF3

- 30. Low & Reverse brake Engaged

- 31. Service Point “N”→”R” shift (C1,B2)

- 32. Free Lock Outer race

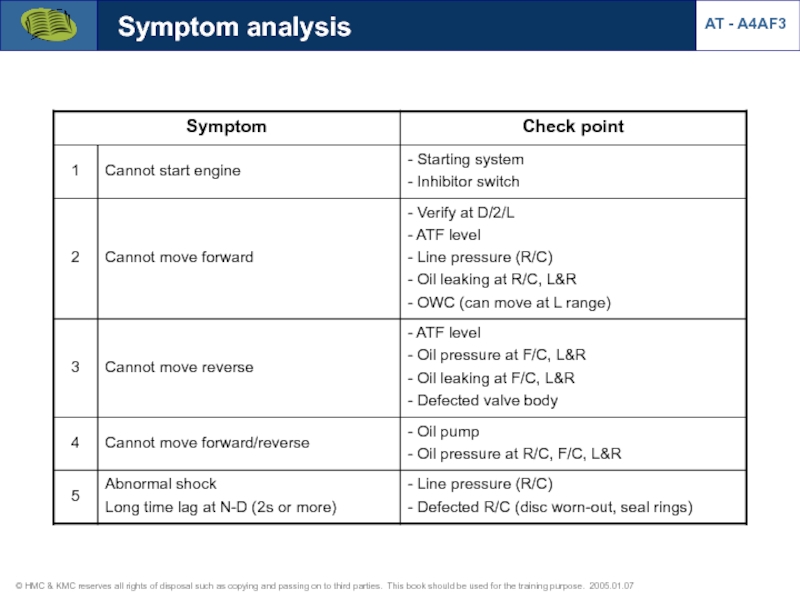

- 33. Pressure check point Reducing pressure Damper Release

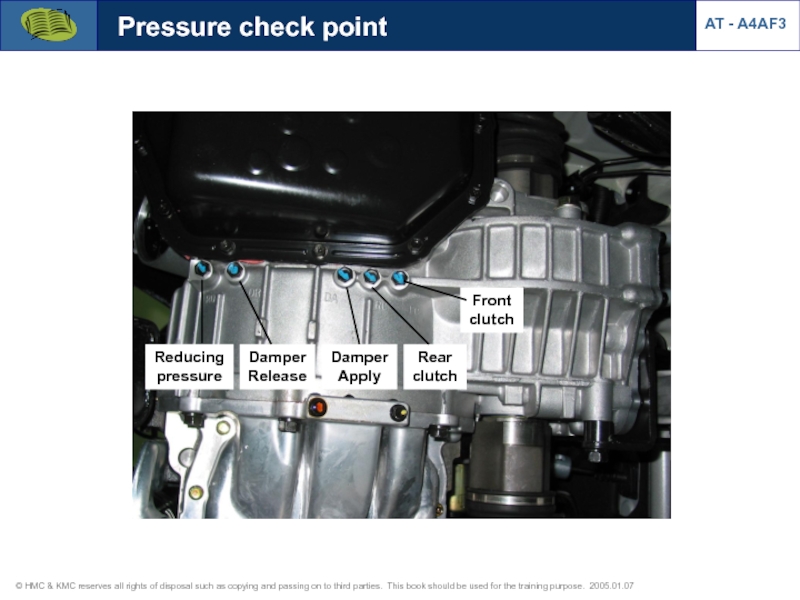

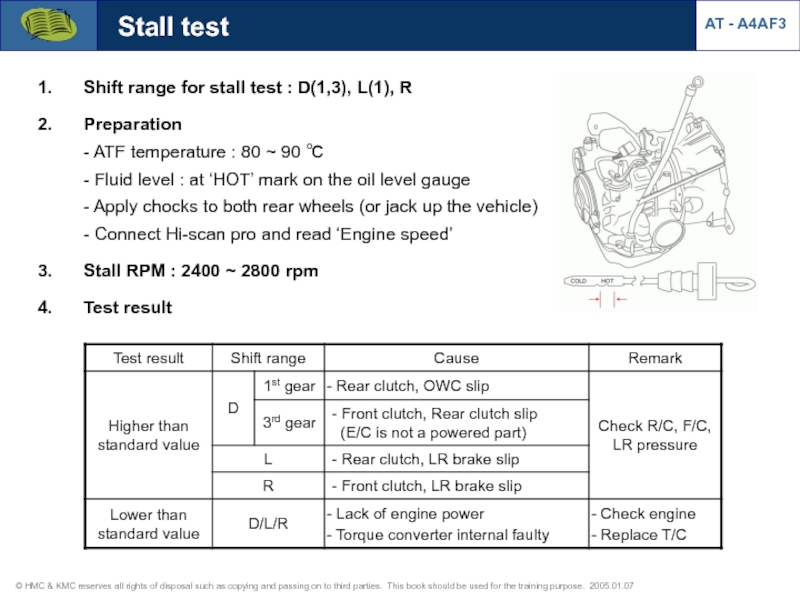

- 34. * Function 1) To reduce the

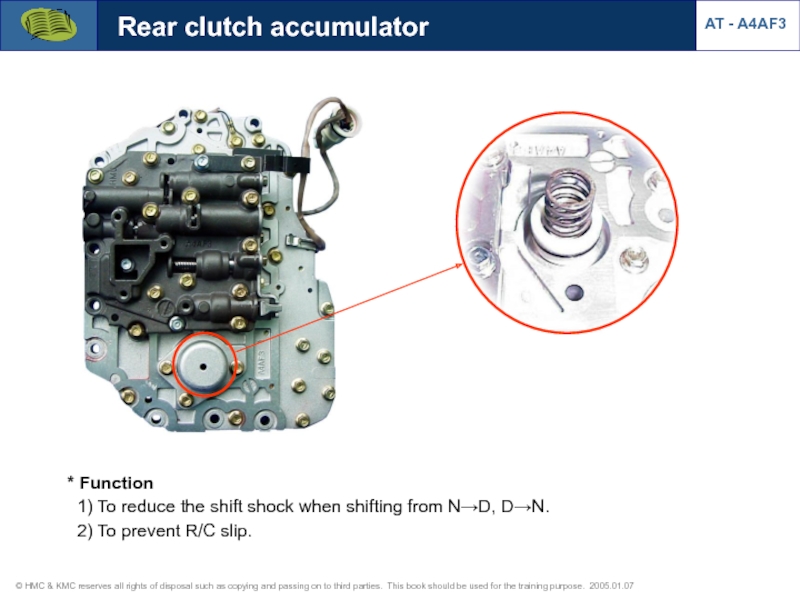

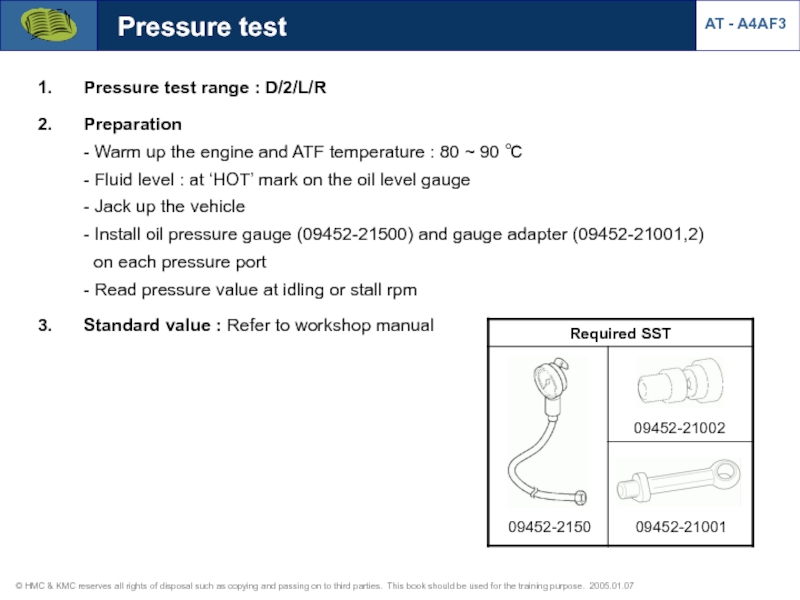

- 35. Outputs Inputs SCSV-A,B,C (ON/OFF) PCSV-A,B

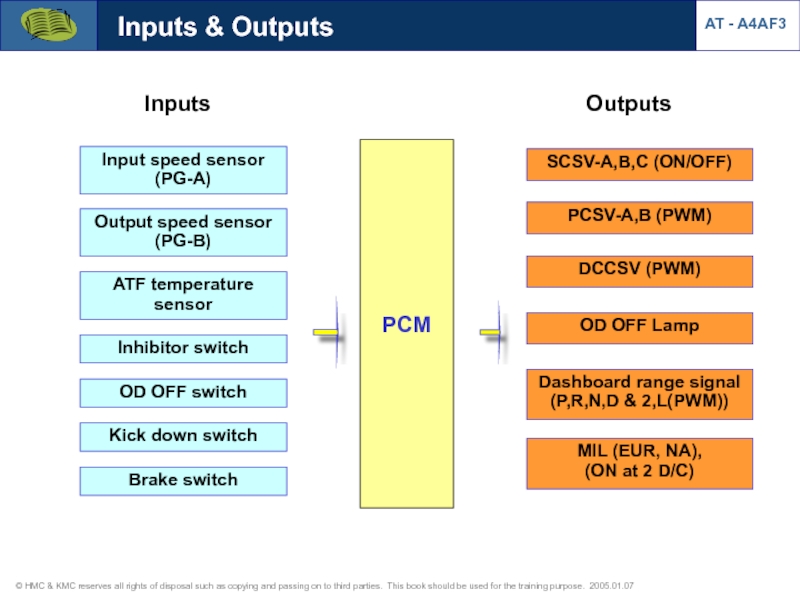

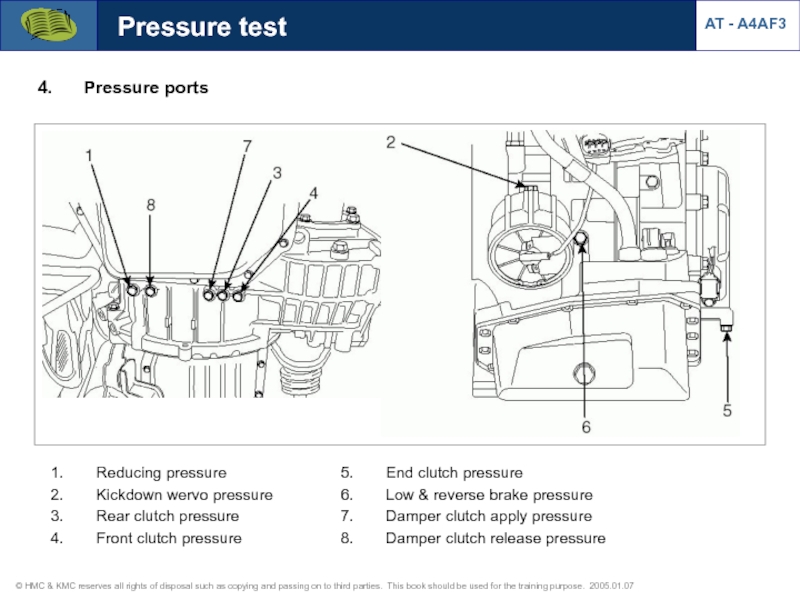

- 36. Input speed sensor (PG-A) PG-A

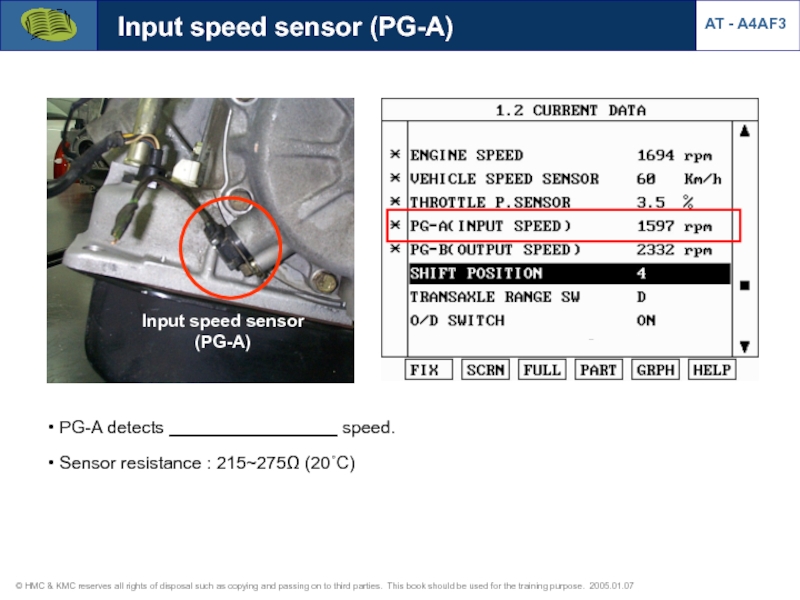

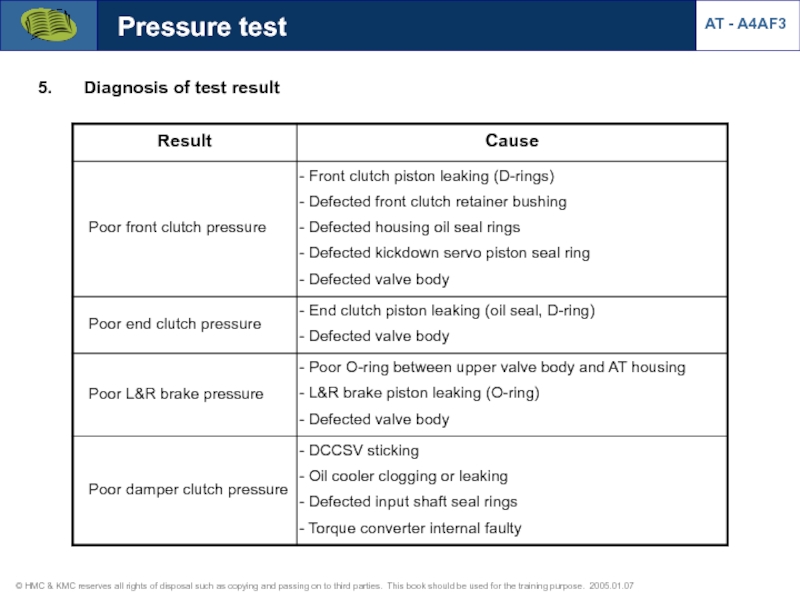

- 37. Output speed sensor (PG-B) Output speed sensor

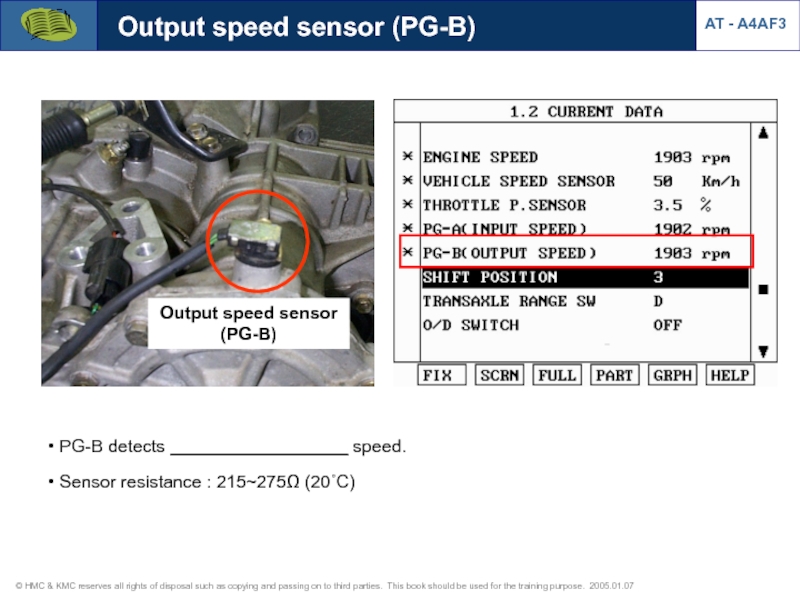

- 38. Output waveform 2.5V 2.5V Input speed sensor

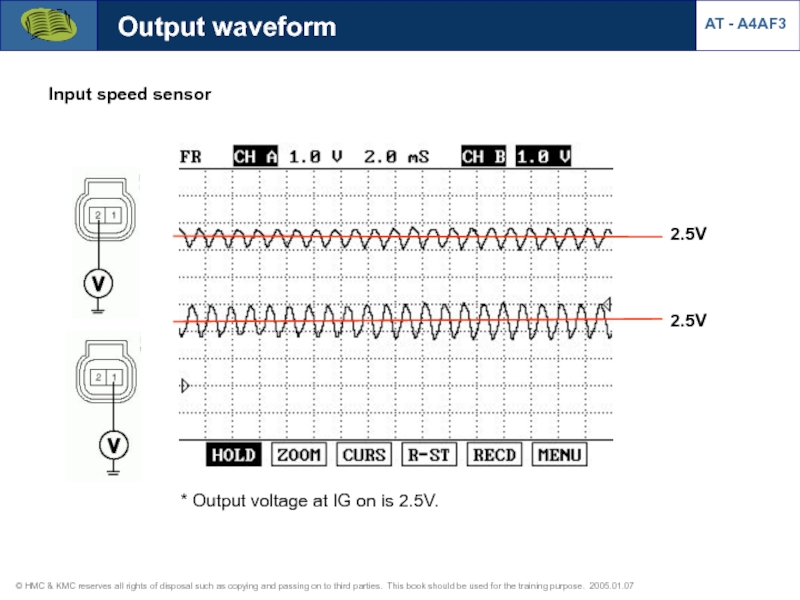

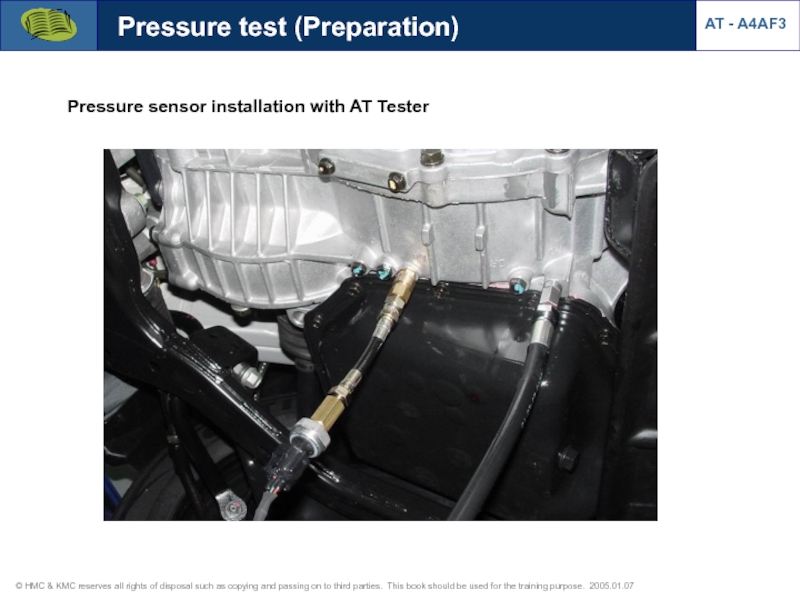

- 39. Diagnosis (input speed sensor) AT - A4AF3 * Rationality

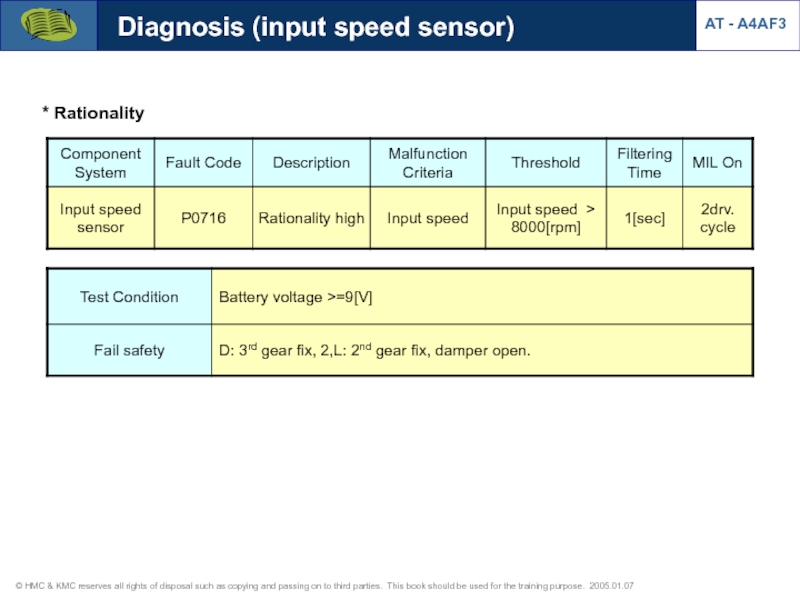

- 40. * Input speed sensor open Diagnosis (input speed sensor) AT - A4AF3

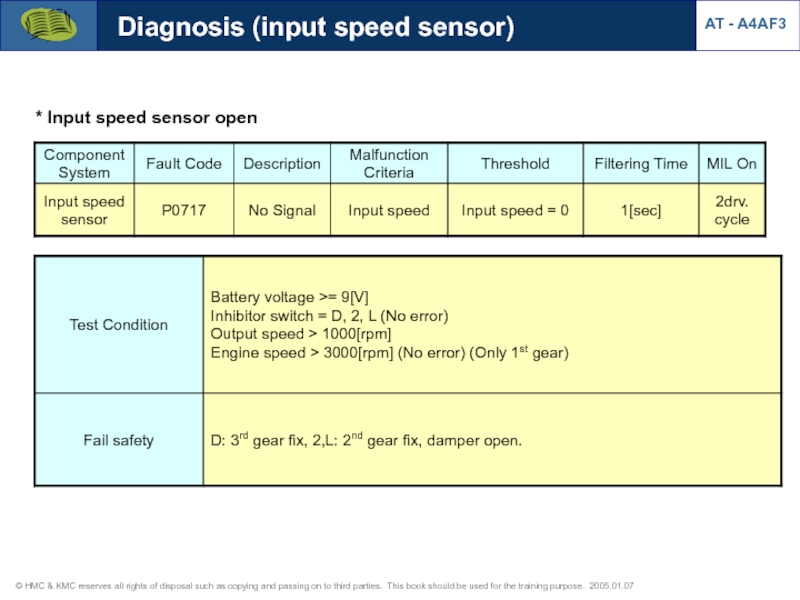

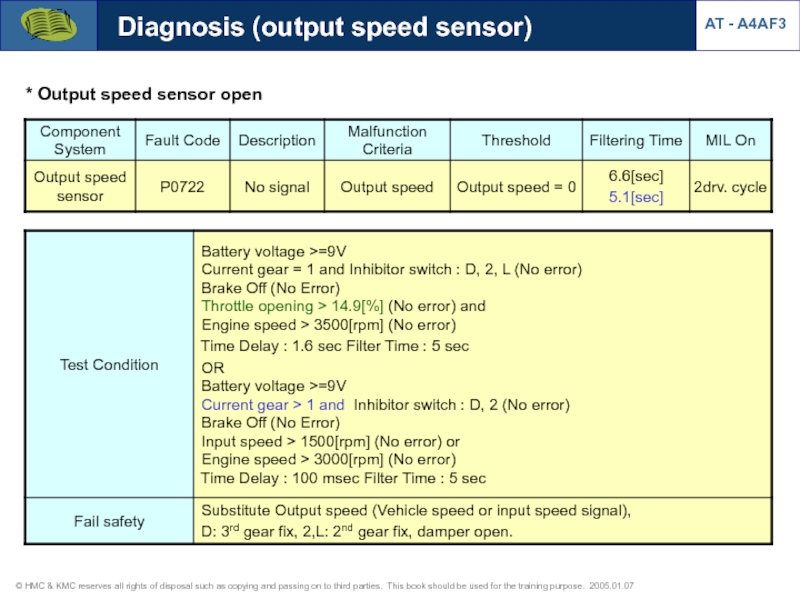

- 41. Diagnosis (output speed sensor) AT - A4AF3 * Output speed sensor open

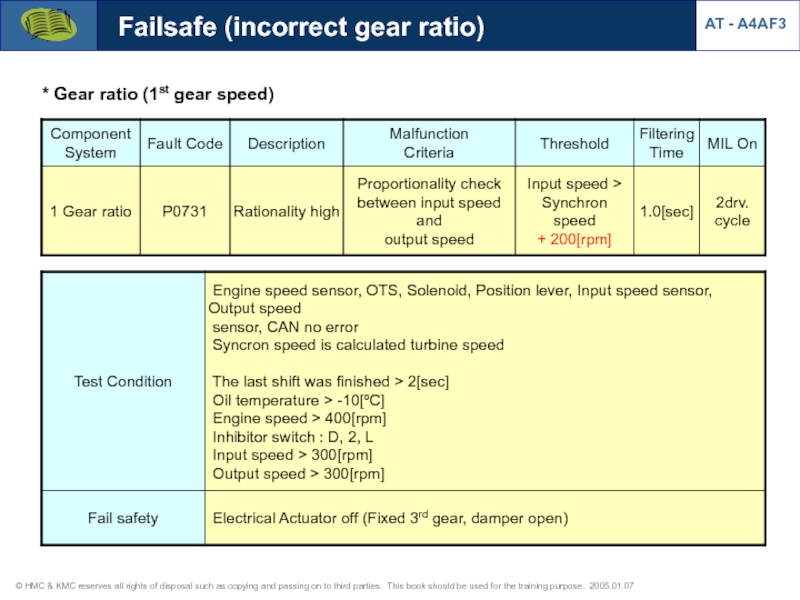

- 42. * Gear ratio (1st gear speed) Failsafe (incorrect gear ratio) AT - A4AF3

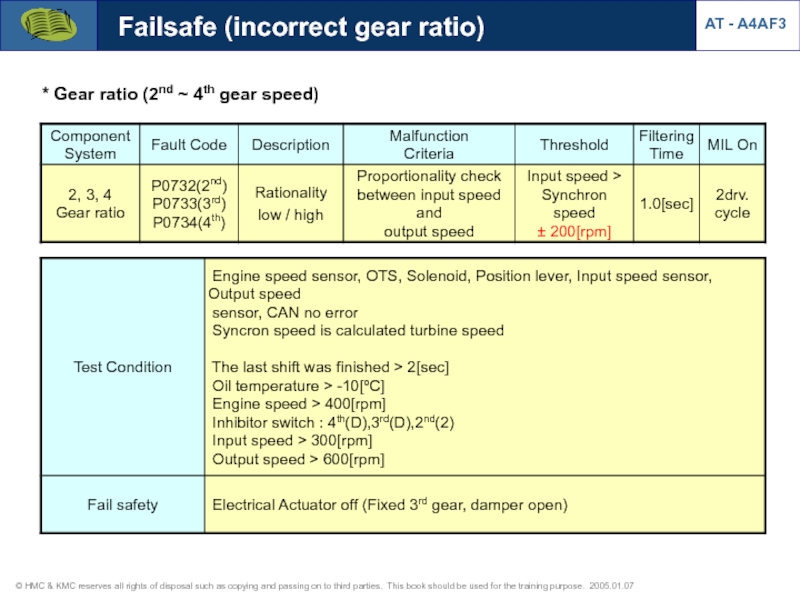

- 43. * Gear ratio (2nd ~ 4th gear speed) Failsafe (incorrect gear ratio) AT - A4AF3

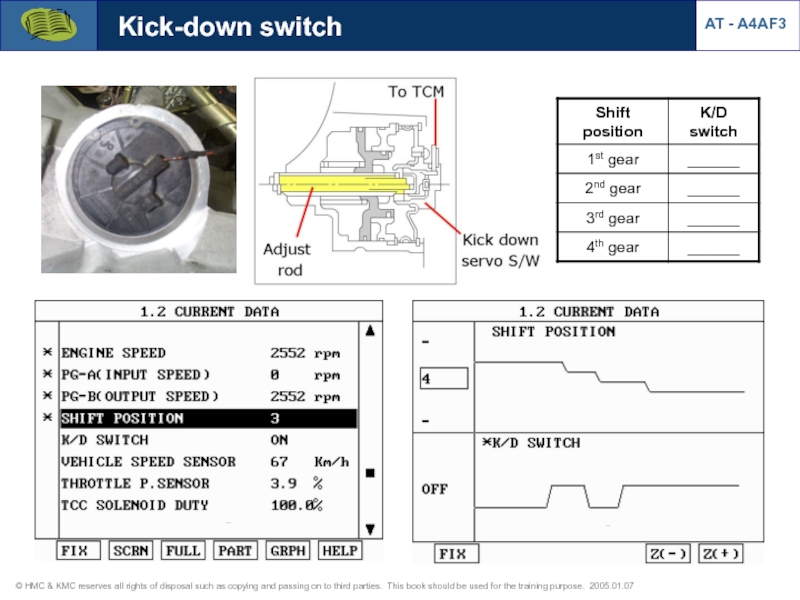

- 44. Kick-down switch AT - A4AF3

- 45. Diagnosis (K/D switch) * K/D switch open

- 46. Brake switch AT - A4AF3 [Brake switch

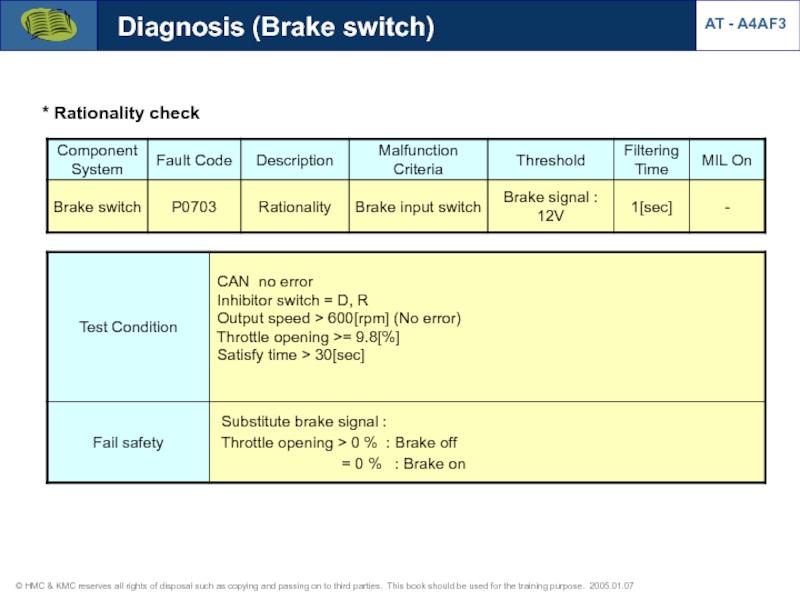

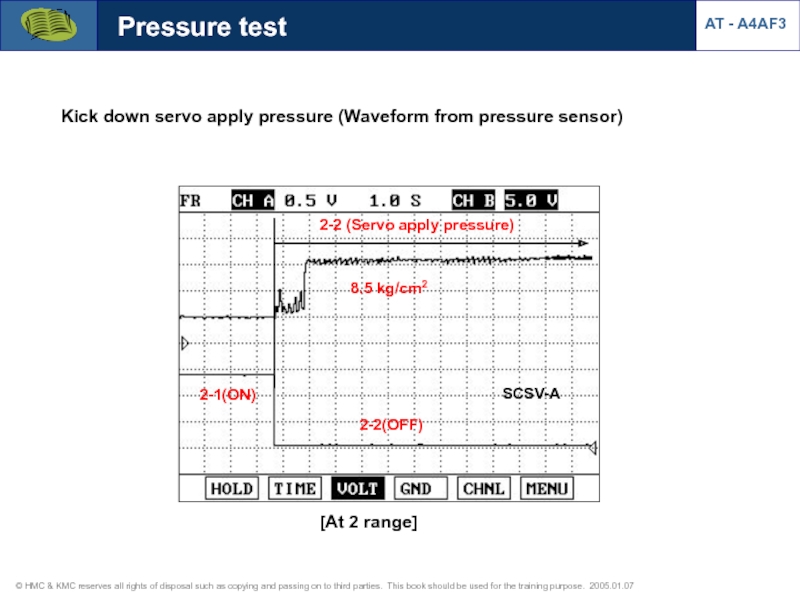

- 47. Diagnosis (Brake switch) AT - A4AF3 * Rationality check

- 48. Oil temperature sensor [Valve body] Oil

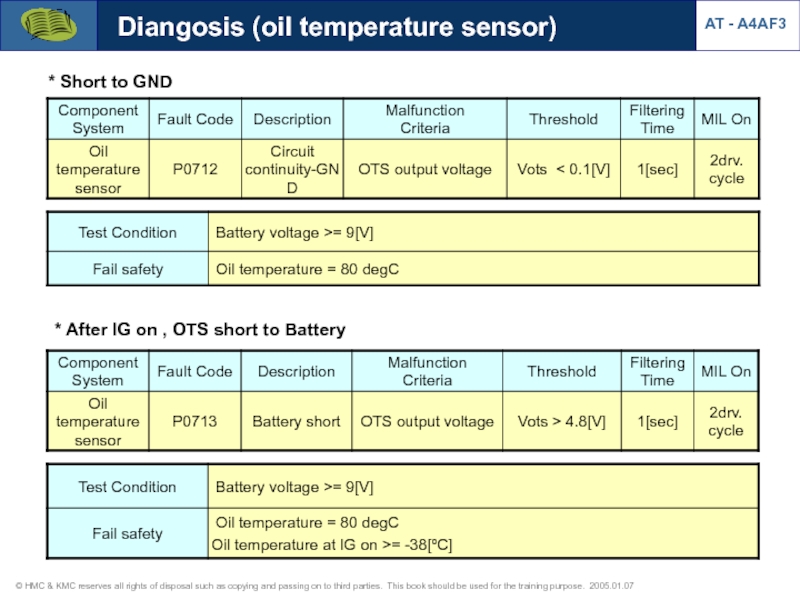

- 49. Diangosis (oil temperature sensor) * Oil temperature

- 50. Diangosis (oil temperature sensor) AT - A4AF3

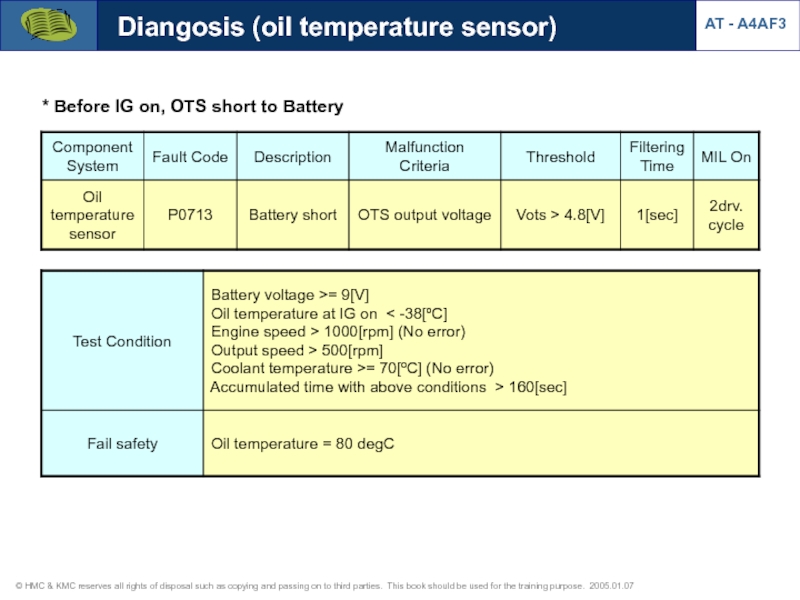

- 51. Diangosis (oil temperature sensor) AT - A4AF3 * Before IG on, OTS short to Battery

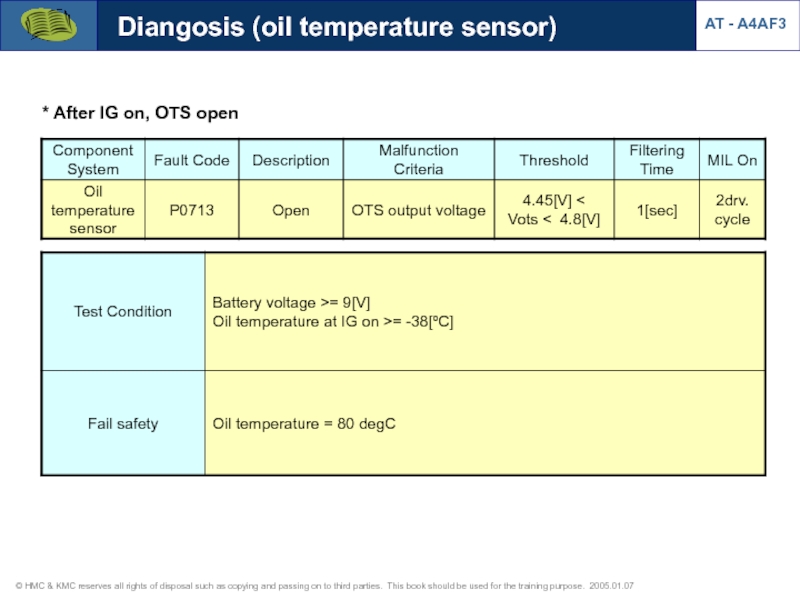

- 52. Diangosis (oil temperature sensor) AT - A4AF3 * After IG on, OTS open

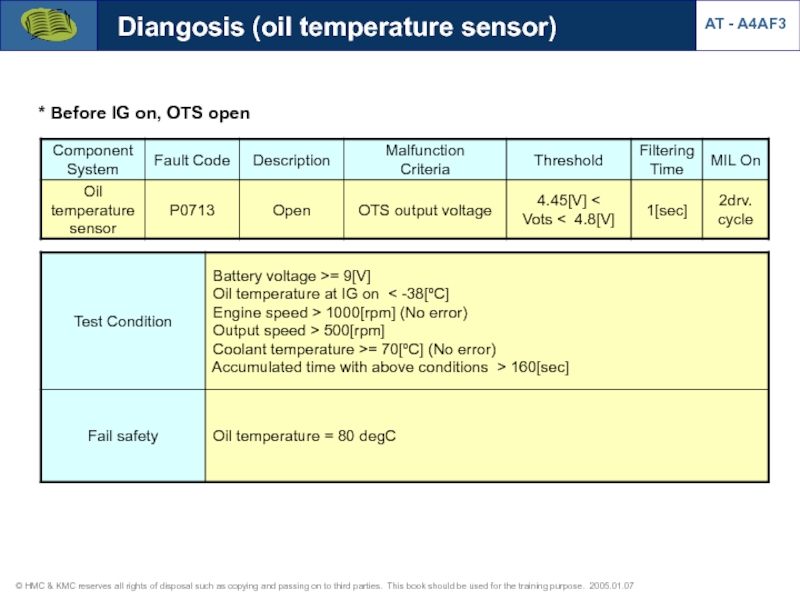

- 53. Diangosis (oil temperature sensor) AT - A4AF3 * Before IG on, OTS open

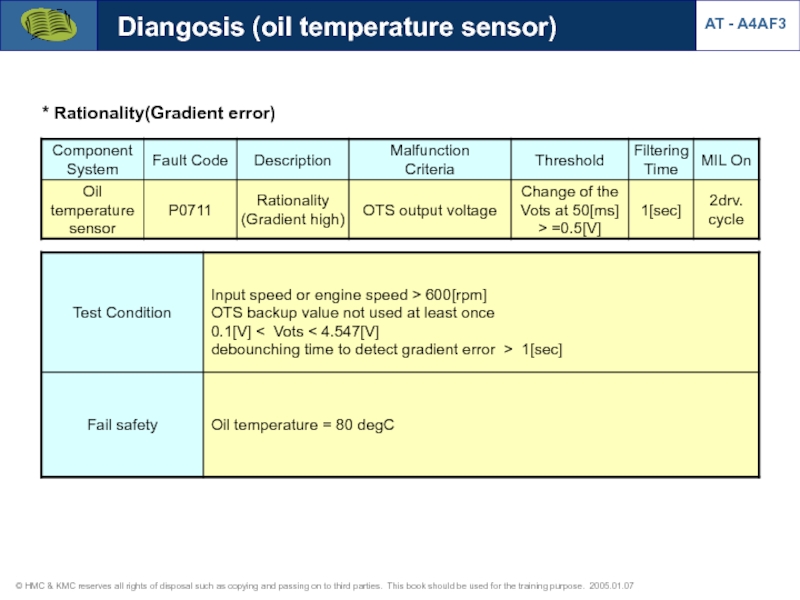

- 54. Diangosis (oil temperature sensor) AT - A4AF3 * Rationality(Gradient error)

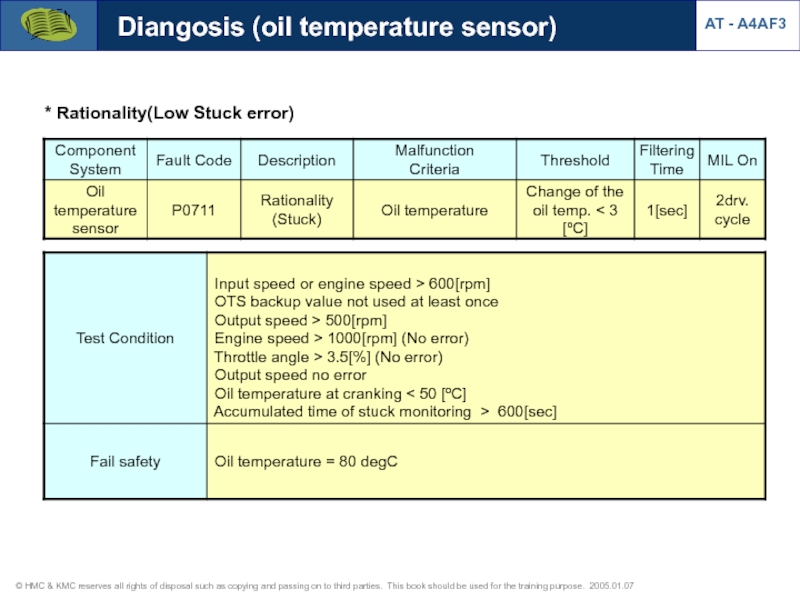

- 55. Diangosis (oil temperature sensor) AT - A4AF3 * Rationality(Low Stuck error)

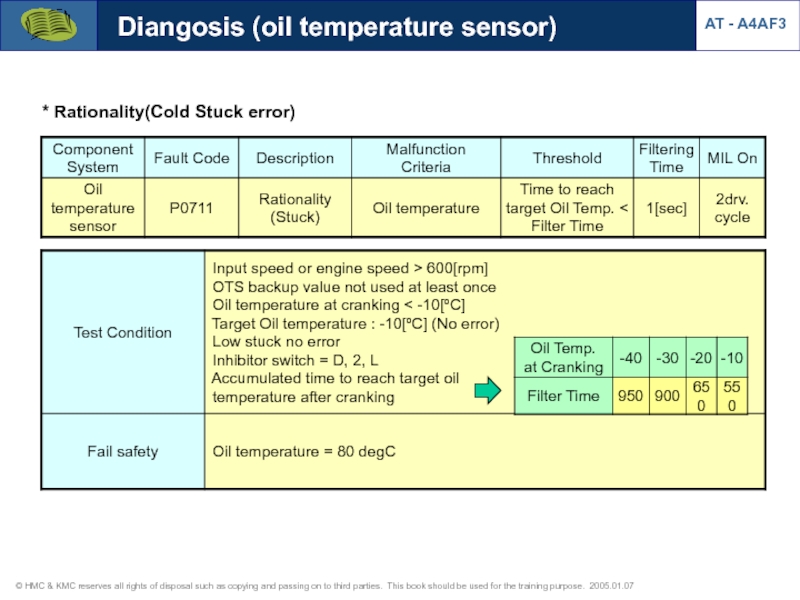

- 56. Diangosis (oil temperature sensor) AT - A4AF3 * Rationality(Cold Stuck error)

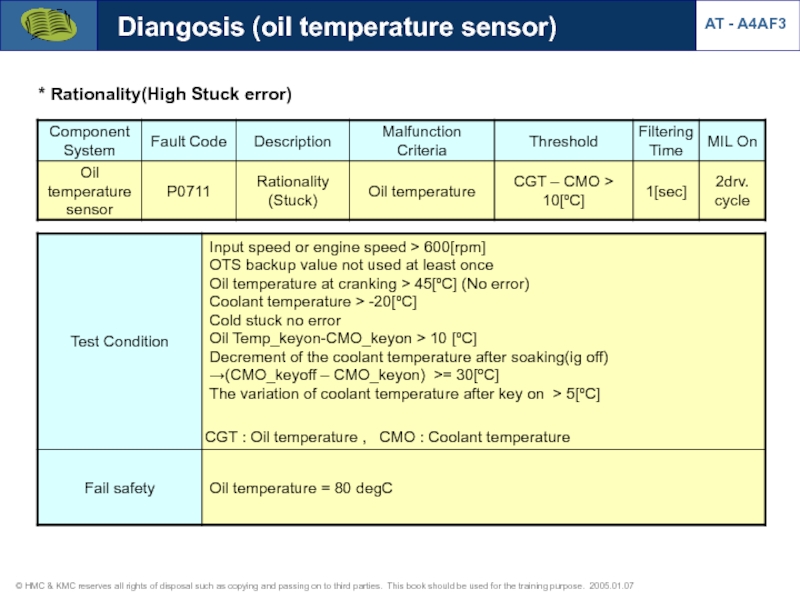

- 57. * Rationality(High Stuck error) Diangosis (oil temperature sensor) AT - A4AF3

- 58. Dashboard range signal AT - A4AF3 Cluster

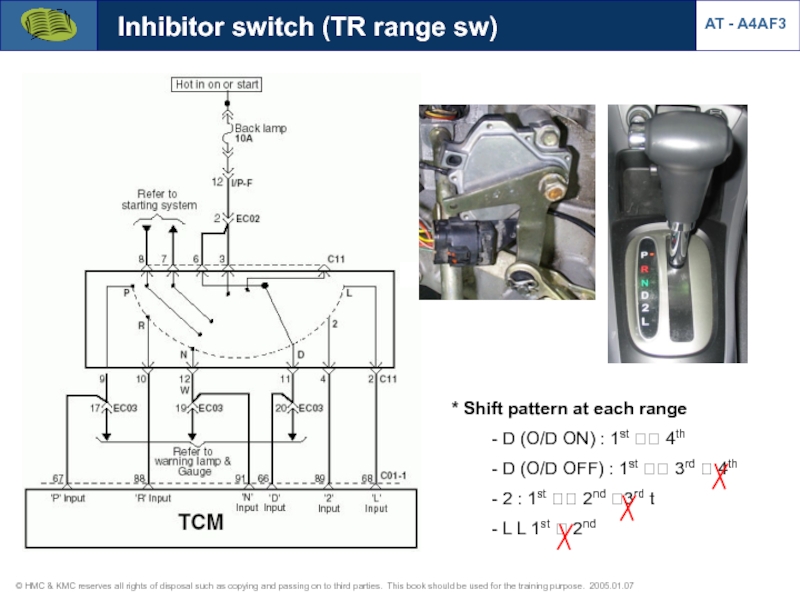

- 59. Inhibitor switch (TR range sw) * Shift

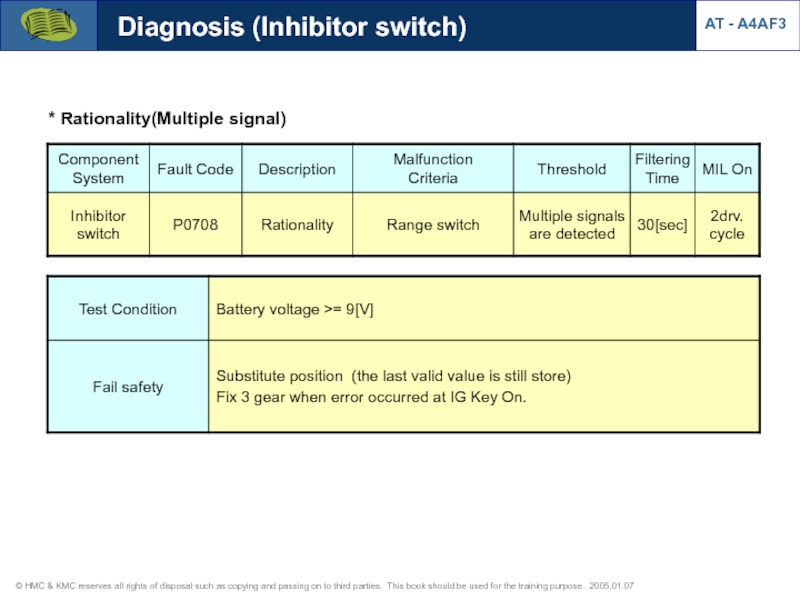

- 60. * Rationality(Multiple signal) Diagnosis (Inhibitor switch) AT - A4AF3

- 61. * Inhibitor switch open Diagnosis (Inhibitor switch) AT - A4AF3

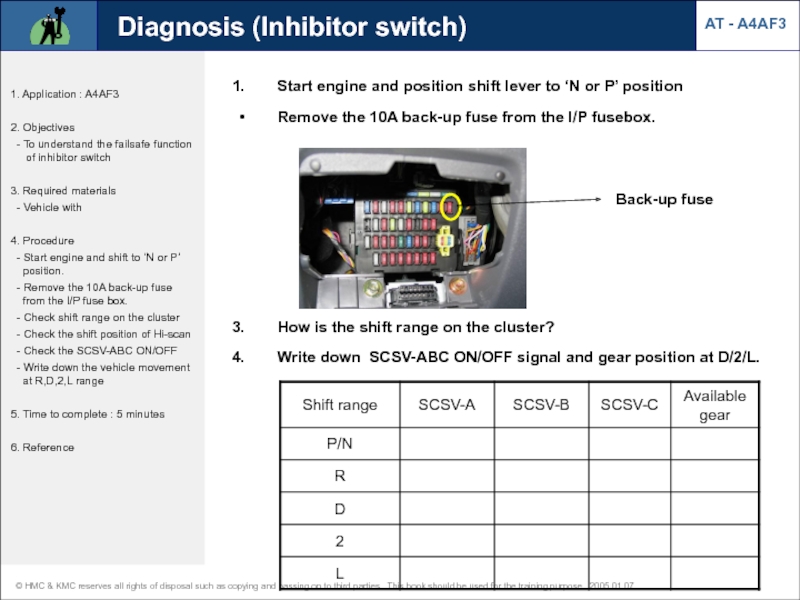

- 62. AT - A4AF3 Diagnosis (Inhibitor switch) 1.

- 63. AT - A4AF3 Diagnosis (Inhibitor switch) 1.

- 64. AT - A4AF3 Diagnosis (Inhibitor switch) 1.

- 65. AT - A4AF3 Diagnosis (Inhibitor switch) 1.

- 66. AT - A4AF3 Diagnosis (Inhibitor switch) 1.

- 67. AT - A4AF3 Diagnosis (Inhibitor switch) 1.

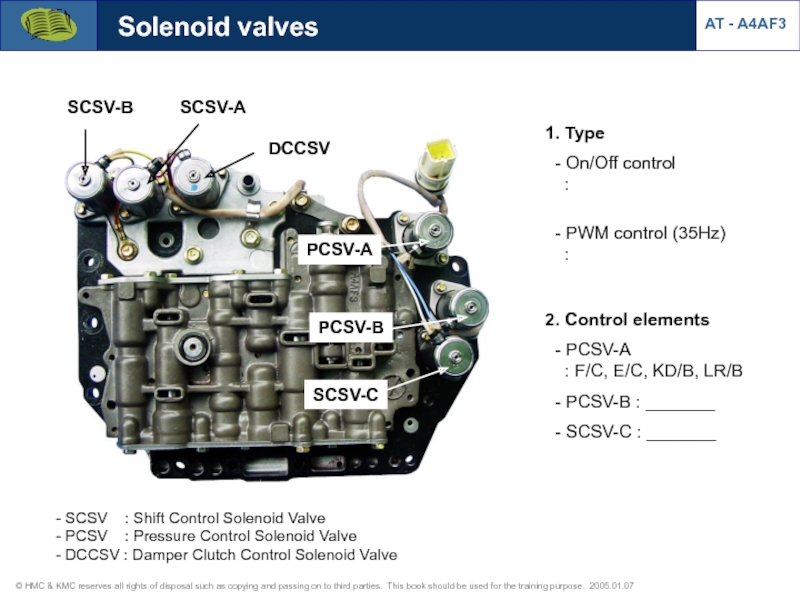

- 68. 1. Type - On/Off control

- 69. Solenoid valves Operation table at D

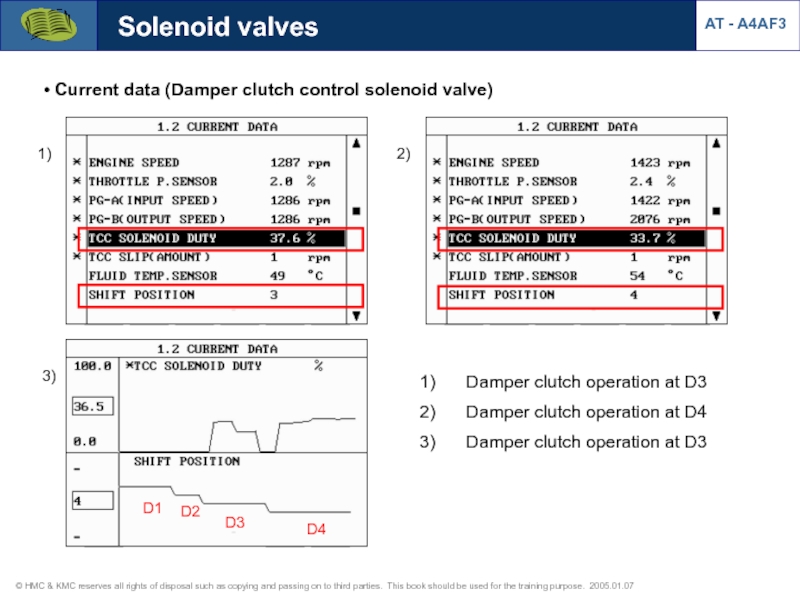

- 70. Solenoid valves Current data (Damper clutch

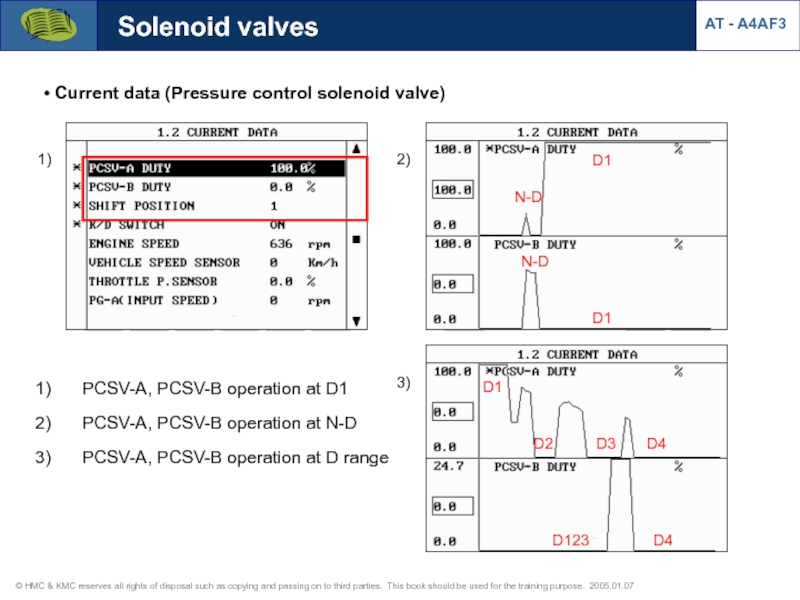

- 71. Solenoid valves Current data (Pressure control

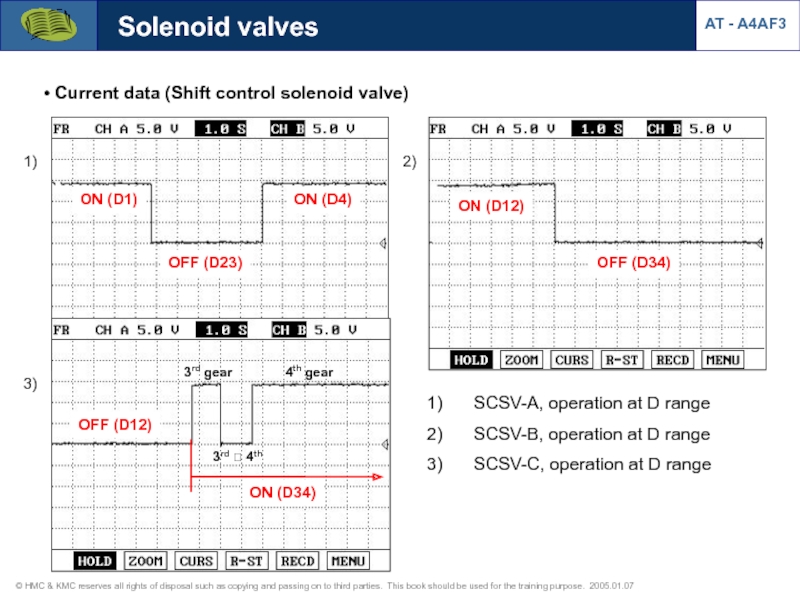

- 72. Solenoid valves Current data (Shift control

- 73. Solenoid valves Circuit diagram [DCCSV duty signal] [PCSV-A duty signal-duty 100%] AT - A4AF3

- 74. Diagnosis (solenoid valves) [Failsafe: 3rd gear hold at D,2,L] AT - A4AF3

- 75. Diagnosis (damper clutch control) AT - A4AF3 * Rationality(Closed stuck)

- 76. Diagnosis (damper clutch control) AT - A4AF3 * Rationality(Open stuck)

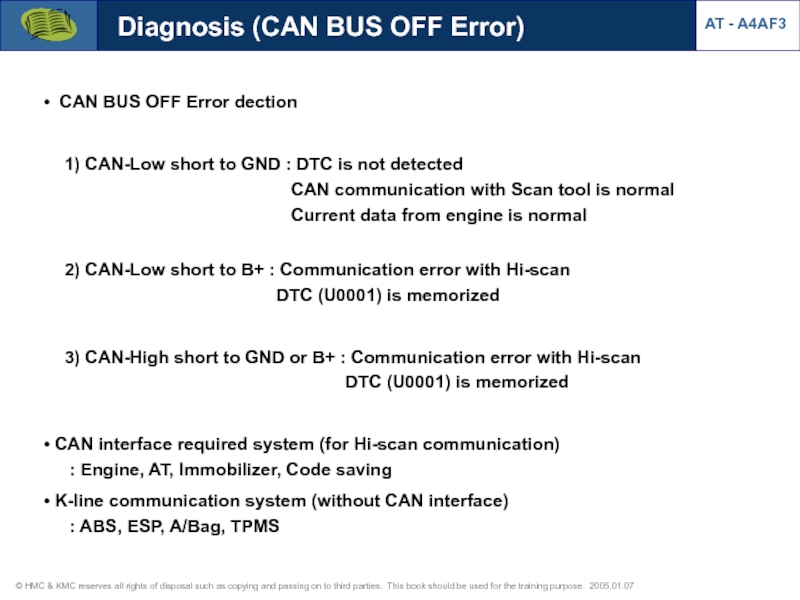

- 77. Diagnosis (CAN BUS OFF Error) AT - A4AF3 * CAN BUS OFF

- 78. Diagnosis (CAN BUS OFF Error) AT -

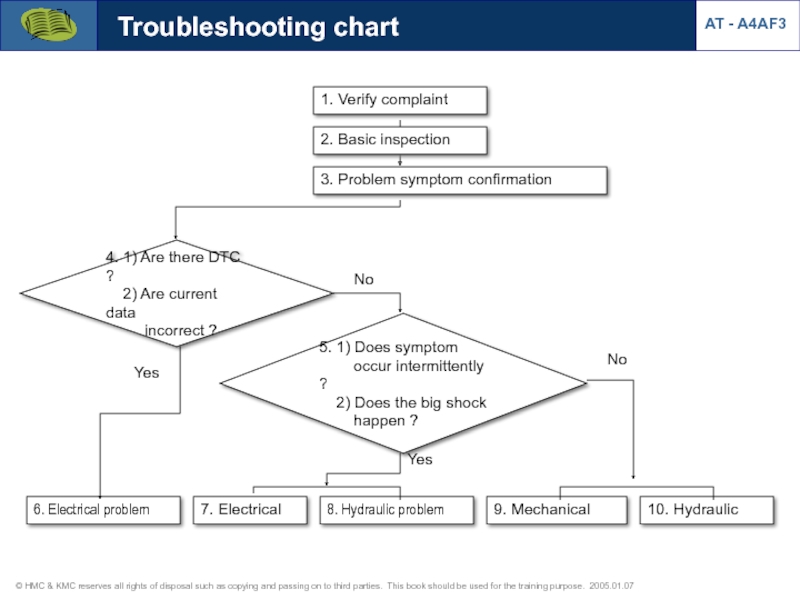

- 79. 1. Verify complaint 3. Problem symptom confirmation

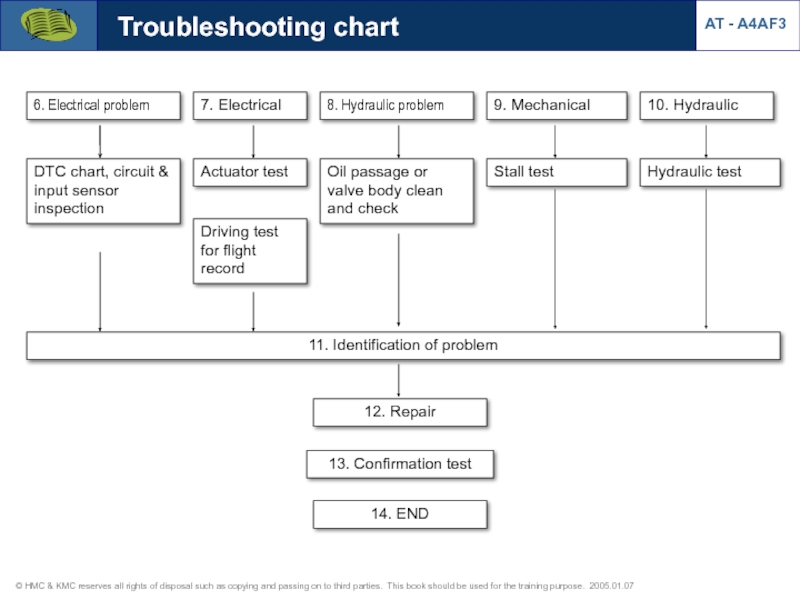

- 80. 6. Electrical problem 7. Electrical 8.

- 81. Symptom analysis AT - A4AF3

- 82. AT - A4AF3 Stall test Shift range

- 83. Pressure test Pressure test range : D/2/L/R

- 84. Pressure test Pressure ports AT - A4AF3

- 85. Pressure test Diagnosis of test result AT - A4AF3

- 86. AT Tester with adapter cables for AT

- 87. Pressure sensor installation with AT Tester AT

- 88. Pressure test (Preparation) Pressure sensor installation with AT Tester AT - A4AF3

- 89. [R/C pressure & PCSV-B operation at N?D?N]

- 90. AT - A4AF3 Pressure test 1) Rear

- 91. Pressure test Damper clutch pressure (Waveform from

- 92. Damper clutch pressure Pressure test [At D

- 93. Pressure test [At 2 range] [At L

- 94. Pressure test Kick down servo apply pressure

- 95. Kick down servo apply pressure (Waveform from

- 96. L&R brake pressure (Waveform from pressure sensor)

- 97. L&R brake stall pressure Pressure test [R

Слайд 3③ : Project name

A : Alpha

① : Type

A : Automatic

M : Manual

② : Speed

3 : 3rd speed

4 : 4th speed

5 : 5th speed

6 : 6th speed

④ : Drive type

F : Front

R : RR

4 : 4WD

⑤ : Development sequence

1,2,3,…

Model code

AT - A4AF3

Слайд 7Note : ● - Element engaged in each gear position

Operating elements

AT - A4AF3

Слайд 8Short pinion

Long pinion

Ring gear

(Annulus gear)

Forward sun gear

Reverse sun gear

End clutch

Front clutch

Rear

One way clutch

Kick-down brake

Low & Reverse brake

Operating elements

AT - A4AF3

Planetary carrier

Слайд 91st Gear (“D” and “2” range)

Operating elements :

* Rear clutch

* One-way

Forward sun gear

Transfer drive gear

Idler gear

Transfer driven gear

Rear clutch

One-way clutch

Annulus gear (Ring gear)

Power flow

AT - A4AF3

What if OWC is broken or installed wrong direction?

Is engine brake is available ?

Does vehicle pull back?

Input & Moving parts

Output

Слайд 101st Gear (“L” range)

Operating elements :

* Rear clutch

* Low-reverse brake

Short pinion

Carrier

Forward

Rear clutch

Long pinion

Annulus gear

Low-reverse brake

Power flow

AT - A4AF3

Is engine brake is available ?

Does vehicle pull back?

Input & Moving parts

Output

Stationary parts

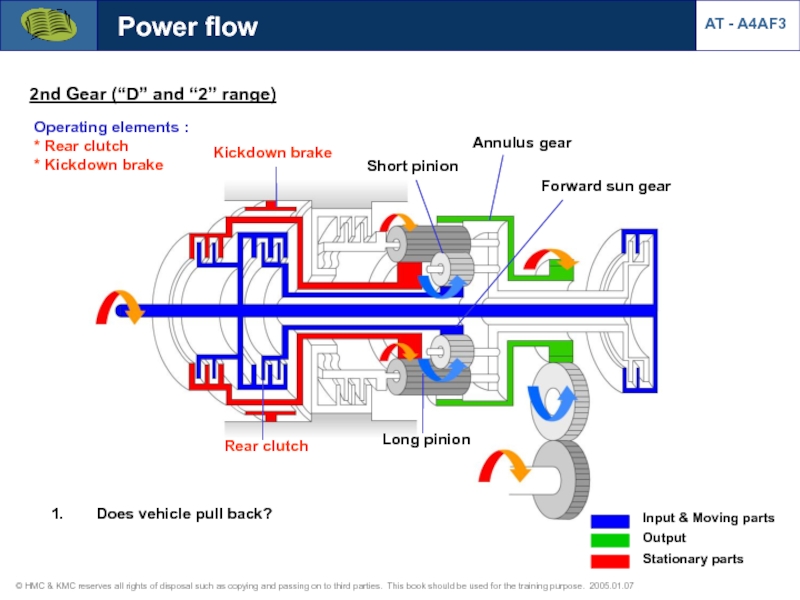

Слайд 112nd Gear (“D” and “2” range)

Operating elements :

* Rear clutch

* Kickdown

Short pinion

Forward sun gear

Kickdown brake

Annulus gear

Rear clutch

Long pinion

Power flow

AT - A4AF3

Does vehicle pull back?

Input & Moving parts

Output

Stationary parts

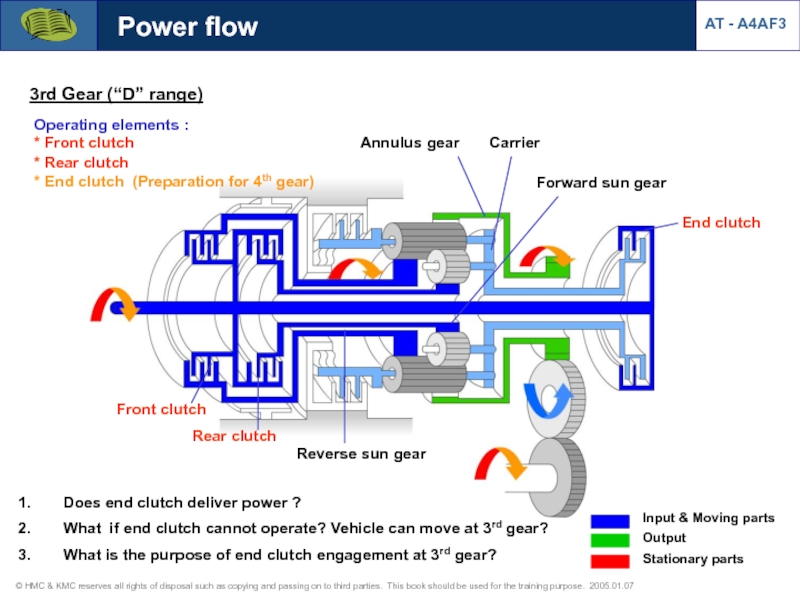

Слайд 123rd Gear (“D” range)

Operating elements :

* Front clutch

* Rear clutch

* End

Forward sun gear

Carrier

End clutch

Annulus gear

Reverse sun gear

Rear clutch

Front clutch

Power flow

AT - A4AF3

Does end clutch deliver power ?

What if end clutch cannot operate? Vehicle can move at 3rd gear?

What is the purpose of end clutch engagement at 3rd gear?

Input & Moving parts

Output

Stationary parts

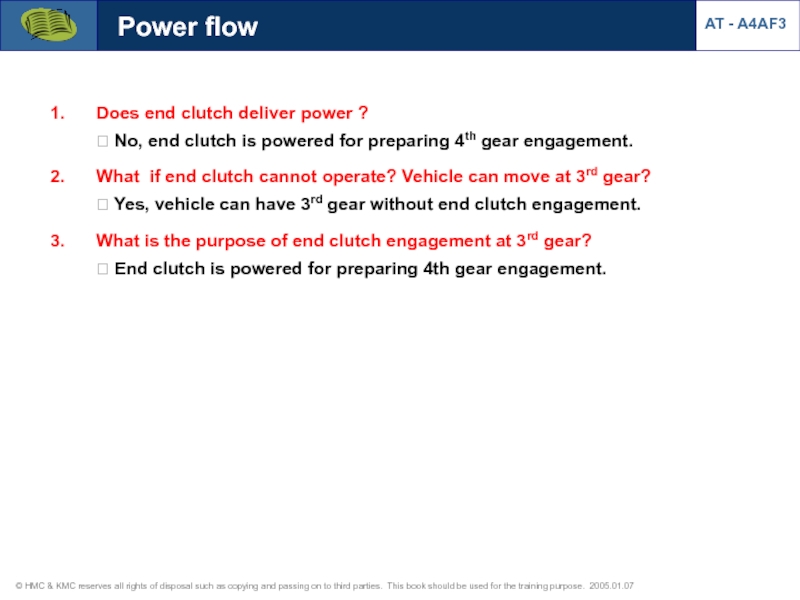

Слайд 13Does end clutch deliver power ? ? No, end clutch is powered

What if end clutch cannot operate? Vehicle can move at 3rd gear? ? Yes, vehicle can have 3rd gear without end clutch engagement.

What is the purpose of end clutch engagement at 3rd gear? ? End clutch is powered for preparing 4th gear engagement.

Power flow

AT - A4AF3

Слайд 144th Gear (“D” range)

Operating elements :

* Kickdown brake

* End clutch

Kickdown brake

End

Long pinion

Carrier

Annulus gear

Reverse sun gear

Power flow

AT - A4AF3

Input & Moving parts

Output

Stationary parts

Слайд 15Reverse range

Operating elements :

* Front clutch

* Low-reverse brake

Low-reverse brake

Front clutch

Reverse sun

Carrier

Annulus gear

Long pinion

Power flow

AT - A4AF3

Input & Moving parts

Output

Stationary parts

Слайд 16AT - A4AF3

Power flow

Reverse range

Operating elements :

* Front clutch

* Low-reverse brake

Input

Locked

Output

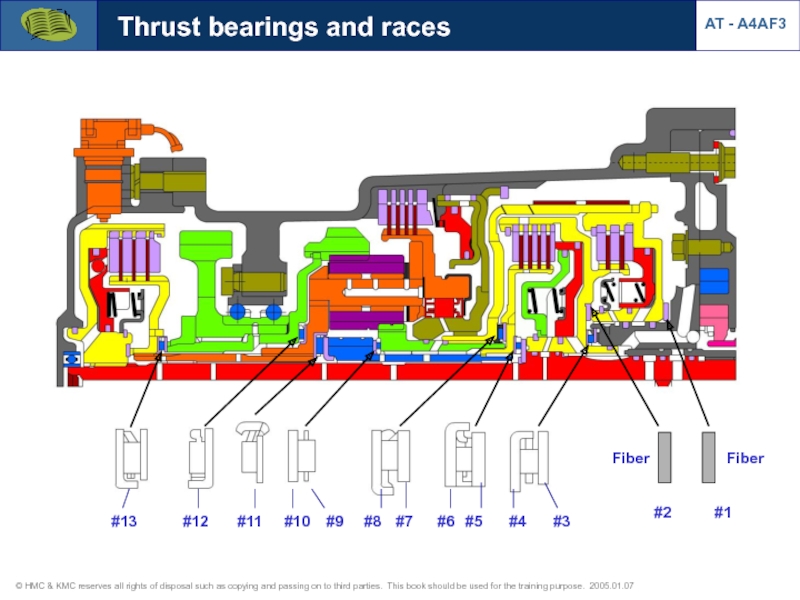

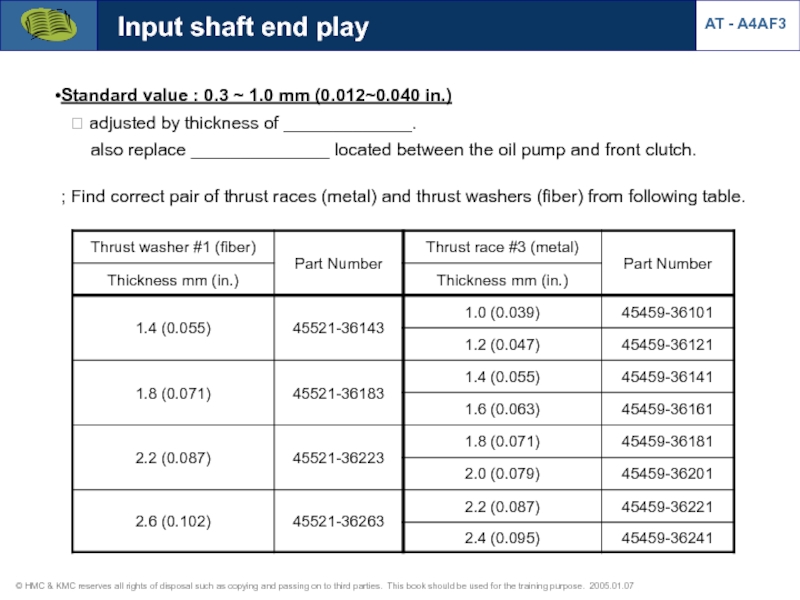

Слайд 18Input shaft end play

Standard value : 0.3 ~ 1.0 mm (0.012~0.040

? adjusted by thickness of _____________. also replace ______________ located between the oil pump and front clutch.

; Find correct pair of thrust races (metal) and thrust washers (fiber) from following table.

AT - A4AF3

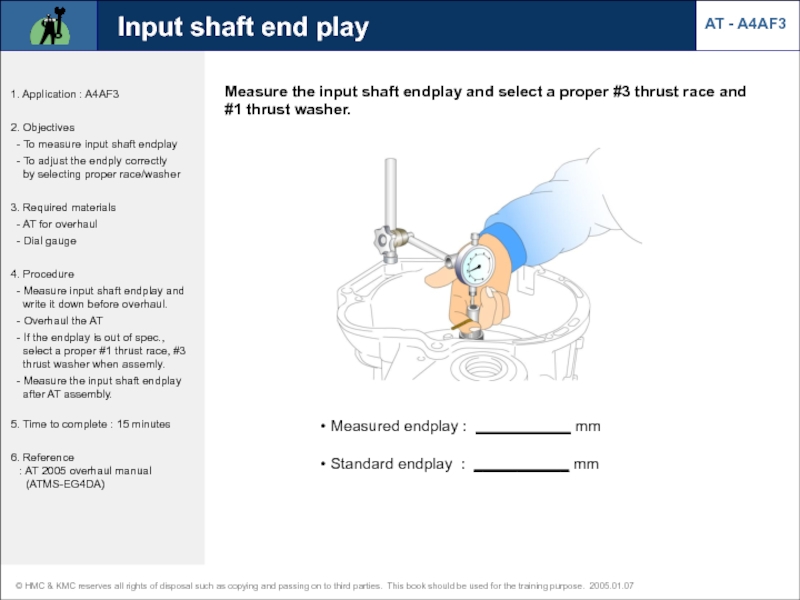

Слайд 19Measure the input shaft endplay and select a proper #3 thrust

Measured endplay : ___________ mm

Standard endplay : ___________ mm

1. Application : A4AF3

2. Objectives

- To measure input shaft endplay

- To adjust the endply correctly

by selecting proper race/washer

3. Required materials

- AT for overhaul

- Dial gauge

4. Procedure

- Measure input shaft endplay and

write it down before overhaul.

- Overhaul the AT

- If the endplay is out of spec.,

select a proper #1 thrust race, #3

thrust washer when assemly.

- Measure the input shaft endplay

after AT assembly.

5. Time to complete : 15 minutes

6. Reference

: AT 2005 overhaul manual

(ATMS-EG4DA)

Input shaft end play

AT - A4AF3

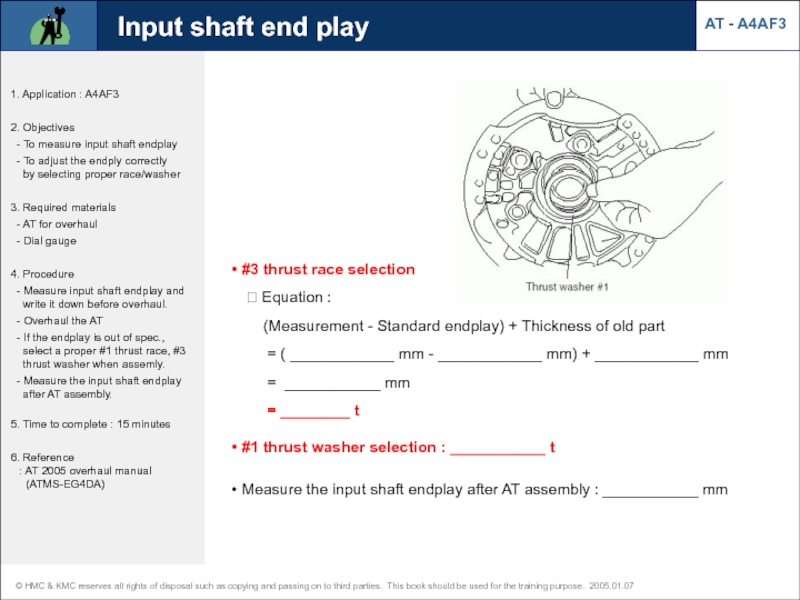

Слайд 20 #3 thrust race selection ? Equation :

#1 thrust washer selection : ___________ t

Input shaft end play

AT - A4AF3

Measure the input shaft endplay after AT assembly : ___________ mm

1. Application : A4AF3

2. Objectives

- To measure input shaft endplay

- To adjust the endply correctly

by selecting proper race/washer

3. Required materials

- AT for overhaul

- Dial gauge

4. Procedure

- Measure input shaft endplay and

write it down before overhaul.

- Overhaul the AT

- If the endplay is out of spec.,

select a proper #1 thrust race, #3

thrust washer when assemly.

- Measure the input shaft endplay

after AT assembly.

5. Time to complete : 15 minutes

6. Reference

: AT 2005 overhaul manual

(ATMS-EG4DA)

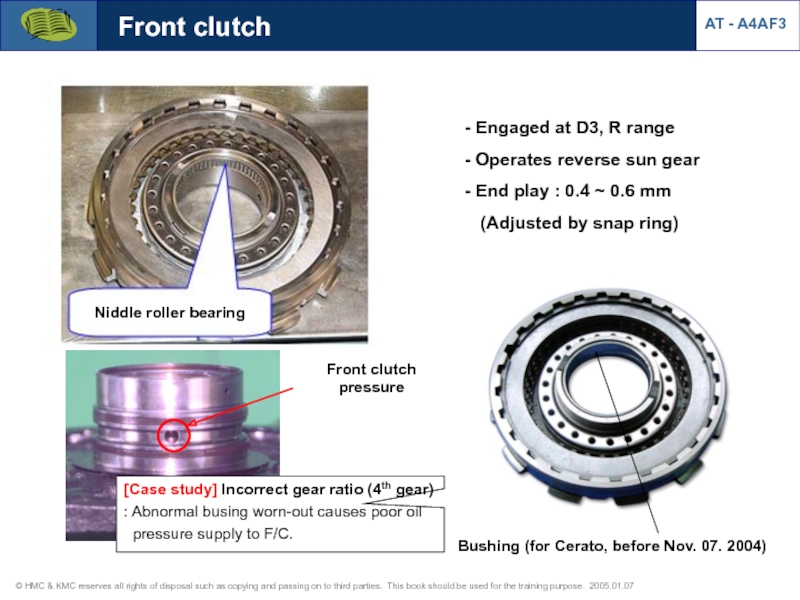

Слайд 21Front clutch

Engaged at D3, R range

Operates reverse sun gear

Bushing (for Cerato, before Nov. 07. 2004)

AT - A4AF3

Niddle roller bearing

[Case study] Incorrect gear ratio (4th gear)

: Abnormal busing worn-out causes poor oil

pressure supply to F/C.

Front clutch pressure

Слайд 22Input shaft

Rear clutch retainer

Rear clutch

Engaged at D1,2,3

Operates forward sun

End play : 0.7 ~ 0.9 mm (Adjusted by snap ring)

Centrifugal balance chamber applied

4 missing tooth of discs

Centrifugal balance chamber

Piston

Piston chamber

AT - A4AF3

Rear clutch pressure

Слайд 23End clutch

Engaged at D3,4 (powered only at D4)

Operates planetary

End play : 0.4 ~ 0.65 mm (Adjusted by snap ring)

AT - A4AF3

Слайд 24Kick-down drum

Kick-down band

Piston rod & piston

Kick down brake

Engaged at D2,4

hold reverse sun gear

[Installation of the Kickndown Brake]

AT - A4AF3

Слайд 25Kick down brake

Kickndown brake servo piston

Servo Release Pressure

Servo Apply Pressure

K/D switch

AT - A4AF3

Kick-down piston

Piston rod

Слайд 26? Service Point

Symptom

- Shift shock at

DTC: None

Cause: Kickdown brake

■ Case Study

Kick down brake adjustment

AT - A4AF3

Слайд 27① Loosen the adjust screw lock nut

Kick down brake adjustment

② Tighten

AT - A4AF3

* Adjustment procedure

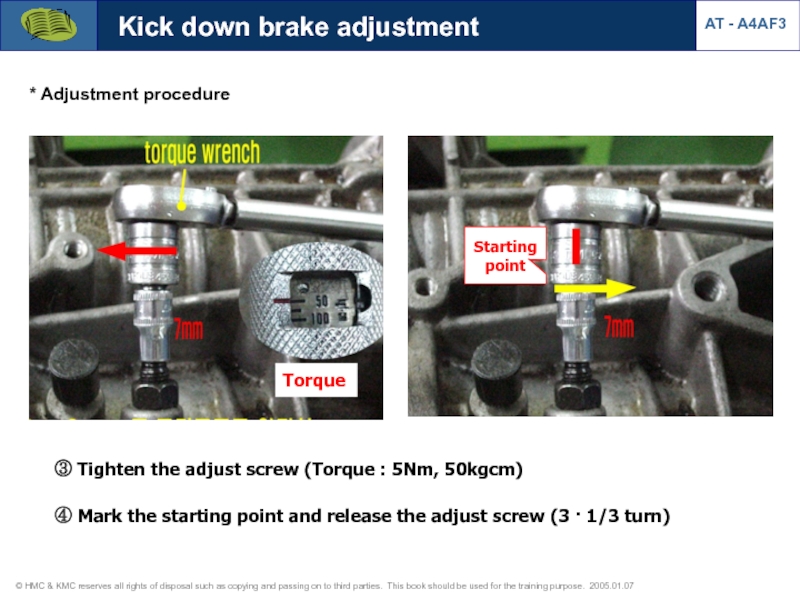

Слайд 28③ Tighten the adjust screw (Torque : 5Nm, 50kgcm)

Torque

④ Mark

Starting point

Kick down brake adjustment

AT - A4AF3

* Adjustment procedure

Слайд 29Kick down brake adjustment

AT - A4AF3

* Adjustment procedure

⑤ Tighten the lock

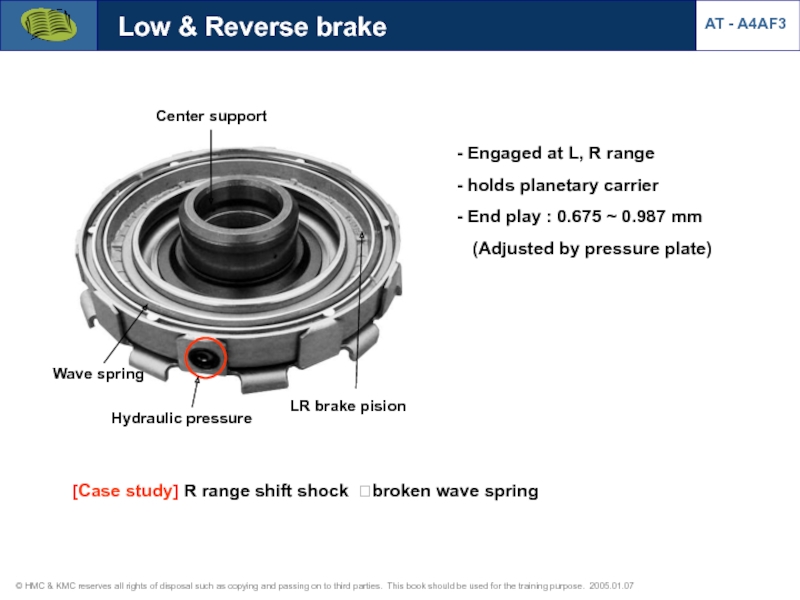

Слайд 30Low & Reverse brake

Engaged at L, R range

holds planetary

End play : 0.675 ~ 0.987 mm (Adjusted by pressure plate)

Hydraulic pressure

LR brake pision

Center support

Wave spring

[Case study] R range shift shock ?broken wave spring

AT - A4AF3

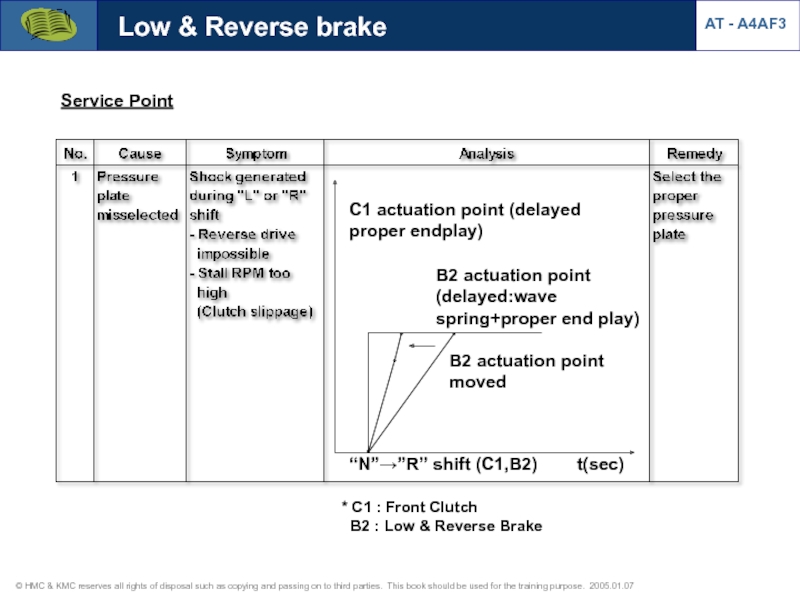

Слайд 31Service Point

“N”→”R” shift (C1,B2) t(sec)

B2 actuation point moved

C1

B2 actuation point (delayed:wave spring+proper end play)

* C1 : Front Clutch

B2 : Low & Reverse Brake

Low & Reverse brake

AT - A4AF3

Слайд 32

Free

Lock

Outer race

(planetary gear carrier)

Inner race

(Center support)

Sprag

Annulus gear

Short pinion

Long pinion

Forward

Carrier

One way clutch

Service Point

AT - A4AF3

Слайд 33Pressure check point

Reducing pressure

Damper Release

Damper Apply

Rear clutch

Front clutch

AT - A4AF3

Слайд 34* Function

1) To reduce the shift shock when shifting from

2) To prevent R/C slip.

Rear clutch accumulator

AT - A4AF3

Слайд 35

Outputs

Inputs

SCSV-A,B,C (ON/OFF)

PCSV-A,B (PWM)

DCCSV (PWM)

Input speed sensor (PG-A)

Output speed sensor

(PG-B)

ATF temperature sensor

Inhibitor

OD OFF switch

Kick down switch

Brake switch

PCM

Inputs & Outputs

AT - A4AF3

OD OFF Lamp

Dashboard range signal

(P,R,N,D & 2,L(PWM))

MIL (EUR, NA),

(ON at 2 D/C)

Слайд 36

Input speed sensor (PG-A)

PG-A detects _________________ speed.

Sensor resistance :

Input speed sensor

(PG-A)

AT - A4AF3

Слайд 37Output speed sensor (PG-B)

Output speed sensor

(PG-B)

PG-B detects __________________

Sensor resistance : 215~275Ω (20˚C)

AT - A4AF3

Слайд 46Brake switch

AT - A4AF3

[Brake switch signal]

Brake applied

High :12V

Low : 0V

Purpose

Damper

Output speed sensor failure detection (stall test detection)

Слайд 48Oil temperature sensor

[Valve body]

Oil temperature sensor

Pressure control

: PCSV

Damper clutch control : damper clutch On/Off control according to ATF temperature

High temperature control : performs different shift pattern when ATF temperature is too high (115 ℃)

AT - A4AF3

Слайд 49Diangosis (oil temperature sensor)

* Oil temperature sensor

AT - A4AF3

[Oil temperature-circuit open]

[DTC-circuit

[Oil temperature-failsafe]

Слайд 50Diangosis (oil temperature sensor)

AT - A4AF3

* Short to GND

* After IG

Слайд 58Dashboard range signal

AT - A4AF3

Cluster

Inhibitor switch

P

R

N

D

PCM

2

L

Dashboard range signal

(2, L, PWM)

[Trip computer

Duty at 2 range : 75 %

Duty at L range : 87 %

Слайд 59Inhibitor switch (TR range sw)

* Shift pattern at each range

- D

AT - A4AF3

Слайд 62AT - A4AF3

Diagnosis (Inhibitor switch)

1. Application : A4AF3

2. Objectives

- To

3. Required materials

- Vehicle with

4. Procedure

- Start engine and shift to ‘N or P’ position.

- Remove the 10A back-up fuse from the I/P fuse box.

- Check shift range on the cluster

- Check the shift position of Hi-scan

- Check the SCSV-ABC ON/OFF

- Write down the vehicle movement at R,D,2,L range

5. Time to complete : 5 minutes

6. Reference

Start engine and position shift lever to ‘N or P’ position

Remove the 10A back-up fuse from the I/P fusebox.

Back-up fuse

How is the shift range on the cluster?

Write down SCSV-ABC ON/OFF signal and gear position at D/2/L.

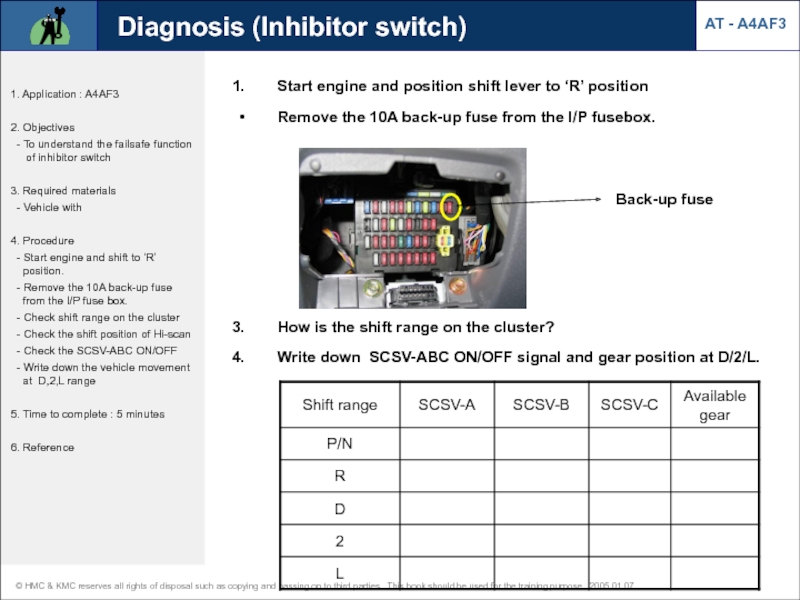

Слайд 63AT - A4AF3

Diagnosis (Inhibitor switch)

1. Application : A4AF3

2. Objectives

- To

3. Required materials

- Vehicle with

4. Procedure

- Start engine and shift to ‘R’ position.

- Remove the 10A back-up fuse from the I/P fuse box.

- Check shift range on the cluster

- Check the shift position of Hi-scan

- Check the SCSV-ABC ON/OFF

- Write down the vehicle movement at D,2,L range

5. Time to complete : 5 minutes

6. Reference

Start engine and position shift lever to ‘R’ position

Remove the 10A back-up fuse from the I/P fusebox.

Back-up fuse

How is the shift range on the cluster?

Write down SCSV-ABC ON/OFF signal and gear position at D/2/L.

Слайд 64AT - A4AF3

Diagnosis (Inhibitor switch)

1. Application : A4AF3

2. Objectives

- To

3. Required materials

- Vehicle with

4. Procedure

- Start engine and shift to 'D’ position.

- Remove the 10A back-up fuse from the I/P fuse box.

- Check shift range on the cluster

- Check the shift position of Hi-scan

- Check the SCSV-ABC ON/OFF

- Write down the vehicle movement at R,2,L range

5. Time to complete : 5 minutes

6. Reference

Start engine and position shift lever to ‘D’ position

Remove the 10A back-up fuse from the I/P fusebox.

Back-up fuse

How is the shift range on the cluster?

Write down SCSV-ABC ON/OFF signal and gear shifting at R/D/2/L.

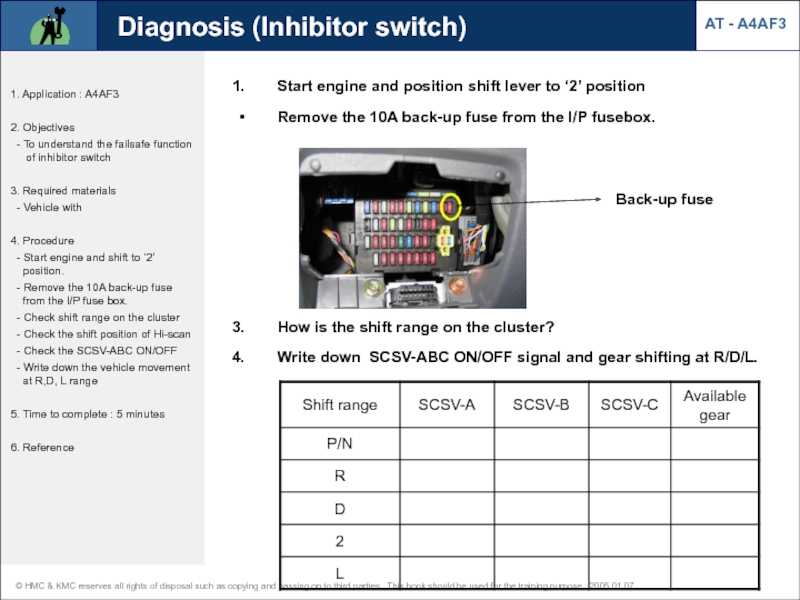

Слайд 65AT - A4AF3

Diagnosis (Inhibitor switch)

1. Application : A4AF3

2. Objectives

- To

3. Required materials

- Vehicle with

4. Procedure

- Start engine and shift to ‘2’ position.

- Remove the 10A back-up fuse from the I/P fuse box.

- Check shift range on the cluster

- Check the shift position of Hi-scan

- Check the SCSV-ABC ON/OFF

- Write down the vehicle movement at R,D, L range

5. Time to complete : 5 minutes

6. Reference

Start engine and position shift lever to ‘2’ position

Remove the 10A back-up fuse from the I/P fusebox.

Back-up fuse

How is the shift range on the cluster?

Write down SCSV-ABC ON/OFF signal and gear shifting at R/D/L.

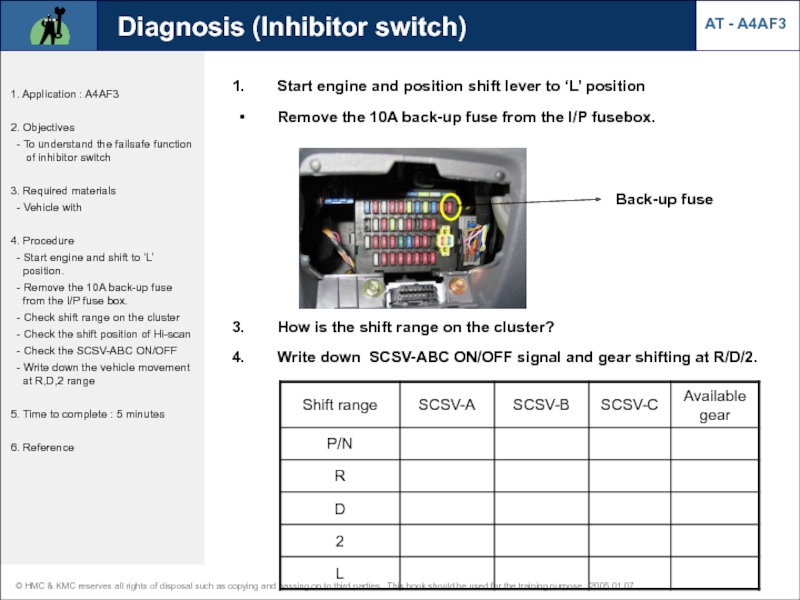

Слайд 66AT - A4AF3

Diagnosis (Inhibitor switch)

1. Application : A4AF3

2. Objectives

- To

3. Required materials

- Vehicle with

4. Procedure

- Start engine and shift to ‘L’ position.

- Remove the 10A back-up fuse from the I/P fuse box.

- Check shift range on the cluster

- Check the shift position of Hi-scan

- Check the SCSV-ABC ON/OFF

- Write down the vehicle movement at R,D,2 range

5. Time to complete : 5 minutes

6. Reference

Start engine and position shift lever to ‘L’ position

Remove the 10A back-up fuse from the I/P fusebox.

Back-up fuse

How is the shift range on the cluster?

Write down SCSV-ABC ON/OFF signal and gear shifting at R/D/2.

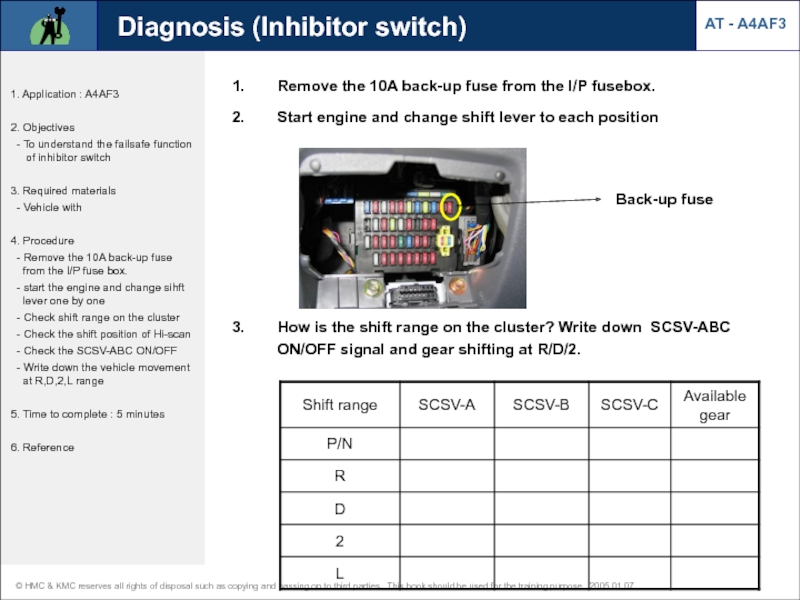

Слайд 67AT - A4AF3

Diagnosis (Inhibitor switch)

1. Application : A4AF3

2. Objectives

- To

3. Required materials

- Vehicle with

4. Procedure

- Remove the 10A back-up fuse from the I/P fuse box.

- start the engine and change sihft lever one by one

- Check shift range on the cluster

- Check the shift position of Hi-scan

- Check the SCSV-ABC ON/OFF

- Write down the vehicle movement at R,D,2,L range

5. Time to complete : 5 minutes

6. Reference

Back-up fuse

How is the shift range on the cluster? Write down SCSV-ABC ON/OFF signal and gear shifting at R/D/2.

Remove the 10A back-up fuse from the I/P fusebox.

Start engine and change shift lever to each position

Слайд 681. Type

- On/Off control

:

- PWM control

- PCSV-A : F/C, E/C, KD/B, LR/B

- PCSV-B : _______

- SCSV-C : _______

DCCSV

SCSV-B

SCSV-A

PCSV-A

PCSV-B

SCSV-C

Solenoid valves

SCSV : Shift Control Solenoid Valve

PCSV : Pressure Control Solenoid Valve

DCCSV : Damper Clutch Control Solenoid Valve

AT - A4AF3

Слайд 69Solenoid valves

Operation table at D range (SCSV-A,B,C)

Solenoid resistance

DCCSV

SCSV-B

SCSV-A

PCSV-A

PCSV-B

SCSV-C

AT - A4AF3

Слайд 70Solenoid valves

Current data (Damper clutch control solenoid valve)

D1

D2

D3

D4

Damper clutch operation

Damper clutch operation at D4

Damper clutch operation at D3

1)

2)

3)

AT - A4AF3

Слайд 71Solenoid valves

Current data (Pressure control solenoid valve)

N-D

D1

D1

N-D

D1

D2

D3

D4

D4

D123

1)

2)

PCSV-A, PCSV-B operation at

PCSV-A, PCSV-B operation at N-D

PCSV-A, PCSV-B operation at D range

3)

AT - A4AF3

Слайд 72Solenoid valves

Current data (Shift control solenoid valve)

SCSV-A, operation at D

SCSV-B, operation at D range

SCSV-C, operation at D range

1)

2)

3)

AT - A4AF3

ON (D12)

OFF (D34)

ON (D1)

ON (D4)

OFF (D23)

OFF (D12)

ON (D34)

3rd gear

4th gear

3rd ? 4th

Слайд 78Diagnosis (CAN BUS OFF Error)

AT - A4AF3

CAN BUS OFF Error

1) CAN-Low short to GND : DTC is not detected CAN communication with Scan tool is normal Current data from engine is normal

2) CAN-Low short to B+ : Communication error with Hi-scan DTC (U0001) is memorized

3) CAN-High short to GND or B+ : Communication error with Hi-scan DTC (U0001) is memorized

CAN interface required system (for Hi-scan communication) : Engine, AT, Immobilizer, Code saving

K-line communication system (without CAN interface) : ABS, ESP, A/Bag, TPMS

Слайд 791. Verify complaint

3. Problem symptom confirmation

4. 1) Are there DTC ?

incorrect ?

5. 1) Does symptom

occur intermittently ?

2) Does the big shock

happen ?

6. Electrical problem

7. Electrical

8. Hydraulic problem

9. Mechanical

10. Hydraulic

2. Basic inspection

No

Yes

No

Yes

Troubleshooting chart

AT - A4AF3

Слайд 806. Electrical problem

7. Electrical

8. Hydraulic problem

9. Mechanical

10. Hydraulic

DTC chart,

Actuator test

Driving test for flight record

Oil passage or valve body clean and check

Stall test

Hydraulic test

11. Identification of problem

12. Repair

13. Confirmation test

14. END

Troubleshooting chart

AT - A4AF3

Слайд 82AT - A4AF3

Stall test

Shift range for stall test : D(1,3), L(1),

Preparation - ATF temperature : 80 ~ 90 ℃ - Fluid level : at ‘HOT’ mark on the oil level gauge - Apply chocks to both rear wheels (or jack up the vehicle) - Connect Hi-scan pro and read ‘Engine speed’

Stall RPM : 2400 ~ 2800 rpm

Test result

Слайд 83Pressure test

Pressure test range : D/2/L/R

Preparation

- Warm up the engine and

Standard value : Refer to workshop manual

AT - A4AF3

09452-2150

09452-21001

09452-21002

Слайд 84Pressure test

Pressure ports

AT - A4AF3

Reducing pressure

Kickdown wervo pressure

Rear clutch pressure

Front clutch

End clutch pressure

Low & reverse brake pressure

Damper clutch apply pressure

Damper clutch release pressure

Слайд 86AT Tester with adapter cables for AT (F4A**, F4EL-K, AISIN)

Pressure test

AT - A4AF3

Слайд 87Pressure sensor installation with AT Tester

AT - A4AF3

[AT Tester]

[Pressure control box]

[Pressure

Pressure test (Preparation)

Слайд 89[R/C pressure & PCSV-B operation at N?D?N]

Pressure test

1) Rear clutch pressure

Rear

N?D

D?N

Duty controlled

2.7V = 8.2kg/cm2

[R/C pressure & SCSV-A operation at N?D?N]

N?D

D?N

OFF

ON

AT - A4AF3

Слайд 90AT - A4AF3

Pressure test

1) Rear clutch pressure

N?D?2

L range, idle

[R/C pressure at

[R/C pressure at L]

R/C pressure at L

PCSV-A duty control

Слайд 91Pressure test

Damper clutch pressure (Waveform from pressure sensor)

[At P,N range]

[At R

D/R pressure (1.1V=4.5kg/cm2)

D/A pressure (0.95V = 3.5kg/cm2)

D/A: Damper clutch apply

D/R: Damper clutch release

D/R pressure

D/A pressure

During acceleration

AT - A4AF3

Слайд 92Damper clutch pressure

Pressure test

[At D range]

Damper clutch pressure (Waveform from pressure

D/R pressure

D/A pressure

a

b

c

d

* a : D 1,2,3 gear

b: D 3 gear with damper clutch engaged (lock-up)

c: D3-4 up shift (no lock-up)

d: D4 gear with lock-up

d

a

b

c

2~3.5 kg/cm2

AT - A4AF3

Слайд 93Pressure test

[At 2 range]

[At L range]

Damper clutch pressure (Waveform from pressure

D/R pressure

D/A pressure

a

b

D/R pressure

D/A pressure

* a : 2 range 1,2 gear

b: 2 range 2 gear with lock-up

2~3.5 kg/cm2

AT - A4AF3

Слайд 94Pressure test

Kick down servo apply pressure (Waveform from pressure sensor)

[At N-D

D range

N range

[At D range]

Servo apply pressure

D1

6.5 kg/cm2

D4

D3

8.5 kg/cm2

7 kg/cm2

SCSV-A

D1(ON)

D23(OFF)

D4(ON)

D2

AT - A4AF3

Слайд 95Kick down servo apply pressure (Waveform from pressure sensor)

Pressure test

2-2 (Servo

8.5 kg/cm2

SCSV-A

2-1(ON)

2-2(OFF)

[At 2 range]

AT - A4AF3

Слайд 96L&R brake pressure (Waveform from pressure sensor)

Pressure test

[At R range]

N?R

[At L

12 kg/cm2

a: PCSV-A duty control

b: PCSV-A duty 0% (accleration)

a

b

Acceleration

17 kg/cm2

2 ? L

4~6 kg/cm2

Acceleration

PCSV-A duty control (32%)

AT - A4AF3

Слайд 97L&R brake stall pressure

Pressure test

[R range stall pressure]

[At L range stall

N?R

20 kg/cm2

a

a: Stall test range

4~6 kg/cm2

a

AT - A4AF3

![Brake switchAT - A4AF3[Brake switch signal]Brake appliedHigh :12VLow : 0VPurpose Damper cltuch operation (brake applied](/img/tmb/6/513692/01f25eedaa89ab91f46dc4b54210c49c-800x.jpg)

![Oil temperature sensor[Valve body]Oil temperature sensor Pressure control : PCSV duty changes according to](/img/tmb/6/513692/5e671f21512d53dcbb1c875932b60cbc-800x.jpg)

![Diangosis (oil temperature sensor)* Oil temperature sensorAT - A4AF3[Oil temperature-circuit open][DTC-circuit open][Oil temperature-failsafe]](/img/tmb/6/513692/fbb490ca30de5bf8eadccb828e43bac2-800x.jpg)

![Dashboard range signalAT - A4AF3ClusterInhibitor switchPRNDPCM2LDashboard range signal(2, L, PWM)[Trip computer display on the clutster]](/img/tmb/6/513692/9495041aec65b269d77359c1fa1b6b15-800x.jpg)

![Solenoid valves Circuit diagram[DCCSV duty signal][PCSV-A duty signal-duty 100%]AT - A4AF3](/img/tmb/6/513692/559e4f084b2678b8cb5a9135ff16b3f2-800x.jpg)

![Diagnosis (solenoid valves)[Failsafe: 3rd gear hold at D,2,L]AT - A4AF3](/img/tmb/6/513692/f8b8b79bf99b08ce44286378b40661c4-800x.jpg)

![Pressure sensor installation with AT TesterAT - A4AF3[AT Tester][Pressure control box][Pressure sensor & adapter]Pressure test (Preparation)](/img/tmb/6/513692/8e6adfb47373e1be466aa35cfa09a40f-800x.jpg)

![[R/C pressure & PCSV-B operation at N?D?N]Pressure test1) Rear clutch pressureRear clutch pressureN?DD?NDuty controlled2.7V =](/img/tmb/6/513692/6db4fb7c6ed9013b95df95e238a98427-800x.jpg)

![AT - A4AF3Pressure test1) Rear clutch pressureN?D?2L range, idle[R/C pressure at N?D?2?L][R/C pressure at L]R/C](/img/tmb/6/513692/f9eb1741f53cfdb9c679f8ba544f5409-800x.jpg)

![Pressure testDamper clutch pressure (Waveform from pressure sensor)[At P,N range][At R range]D/R pressure (1.1V=4.5kg/cm2)D/A pressure](/img/tmb/6/513692/88488cc238c16ec79a9ad9fd39d3728b-800x.jpg)

![Damper clutch pressurePressure test[At D range]Damper clutch pressure (Waveform from pressure sensor)D/R pressureD/A pressureabcd* a](/img/tmb/6/513692/345a275f7bbafb6f419d50b220678000-800x.jpg)

![Pressure test[At 2 range][At L range]Damper clutch pressure (Waveform from pressure sensor)D/R pressureD/A pressureabD/R pressureD/A](/img/tmb/6/513692/92ef4b794bb69ee3191d46a86a94aec9-800x.jpg)

![Pressure testKick down servo apply pressure (Waveform from pressure sensor)[At N-D control]D rangeN range[At D](/img/tmb/6/513692/cb589671de208a82c7e4b5b85e408183-800x.jpg)

![L&R brake pressure (Waveform from pressure sensor)Pressure test[At R range]N?R[At L range]12 kg/cm2a: PCSV-A duty](/img/tmb/6/513692/40ca799b36218535789d7773f8633437-800x.jpg)

![L&R brake stall pressurePressure test[R range stall pressure][At L range stall pressure]N?R20 kg/cm2aa: Stall test](/img/tmb/6/513692/6f35d5244d1387ce37902817fad0a453-800x.jpg)