- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

RETAIL INTRODUCTIONAnshuman Duttawww.anshuman-dutta.blogspot.com презентация

Содержание

- 1. RETAIL INTRODUCTIONAnshuman Duttawww.anshuman-dutta.blogspot.com

- 2. Consumer Segmentation Consumers: Persons who consume products

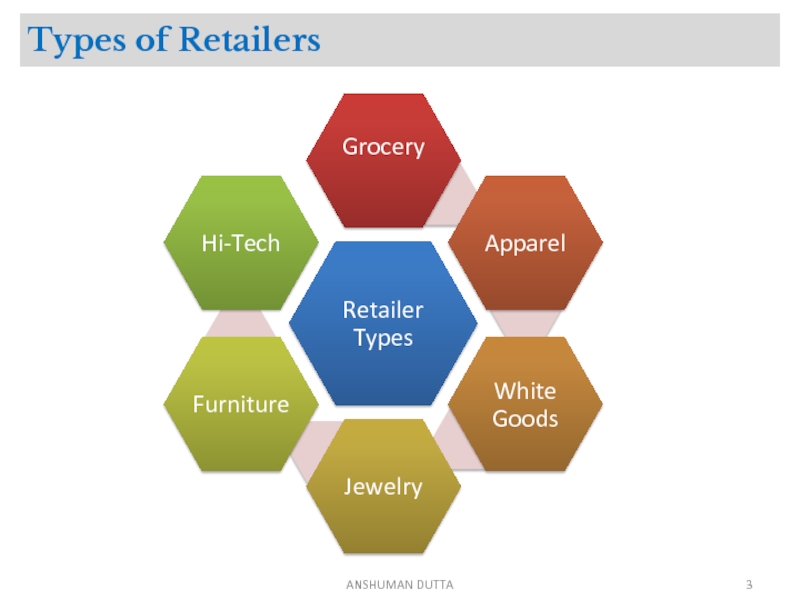

- 3. Types of Retailers ANSHUMAN DUTTA

- 4. Media Formats In store

- 5. Retail Dimensions Organizational Hierarchy Chain Division

- 6. Retailing Processes ANSHUMAN DUTTA

- 7. Value Chain of Retail ANSHUMAN DUTTA Merchandising

- 8. Merchandising ANSHUMAN DUTTA

- 9. Merchandise Merchandise: Goods or services that may

- 10. Width / variety/ breadth of merchandise -

- 11. Merchandising ANSHUMAN DUTTA Range Planning Range = Width * Depth

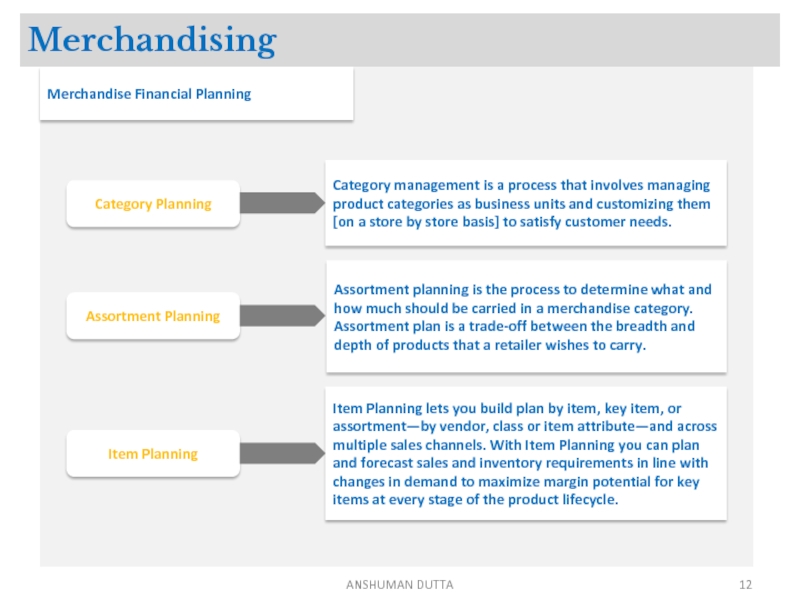

- 12. Merchandising ANSHUMAN DUTTA Merchandise Financial Planning

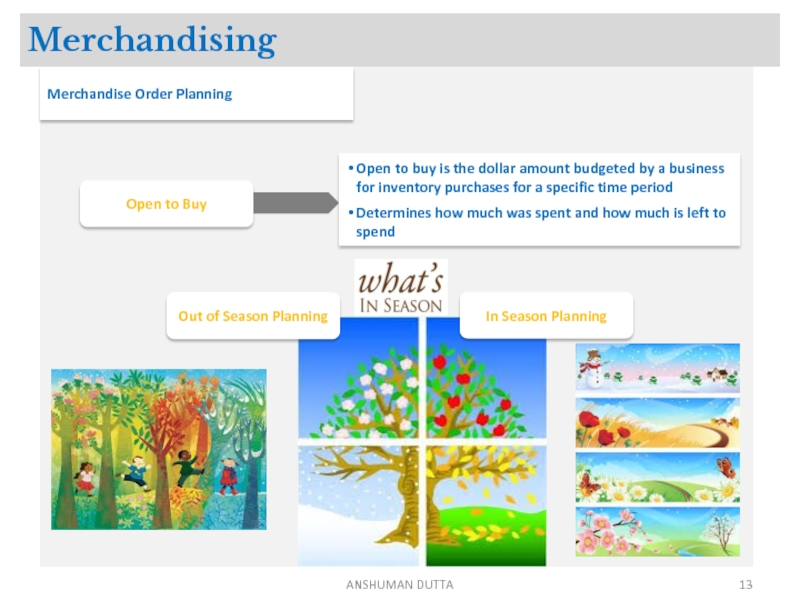

- 13. Merchandising ANSHUMAN DUTTA Merchandise Order

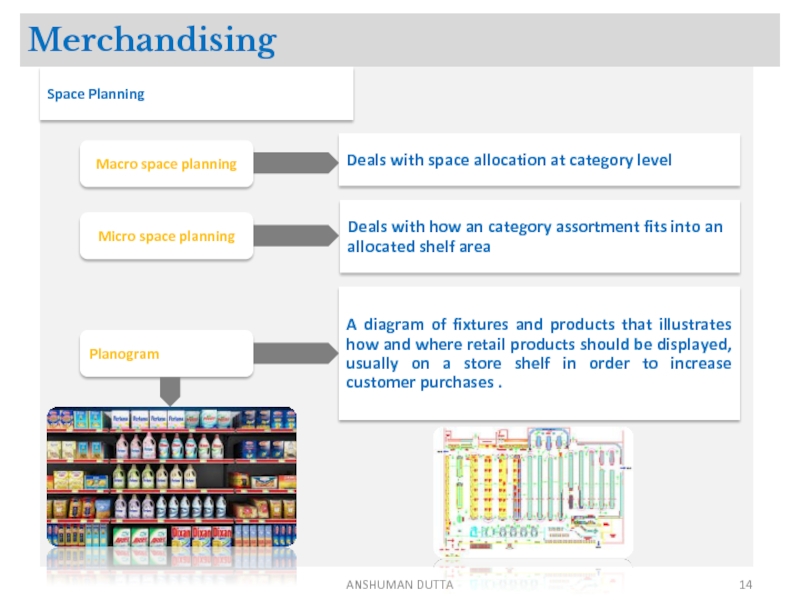

- 14. Merchandising ANSHUMAN DUTTA Space Planning

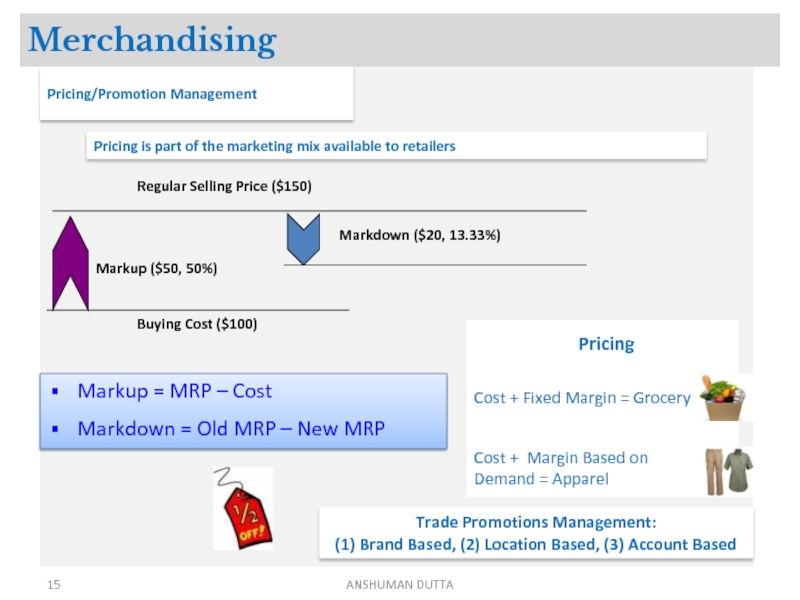

- 15. Merchandising Pricing is part

- 16. Core merchandising: ANSHUMAN DUTTA http://blogs.gartner.com/robert-hetu/retail-marketing-merchandising-must-sing-off-the-same-sheet-music/

- 17. Merchandise Supply Chain and Optimization: ANSHUMAN DUTTA http://blogs.gartner.com/robert-hetu/retail-marketing-merchandising-must-sing-off-the-same-sheet-music/

- 18. POS in Retail POS data is also

- 19. Travel Merchandising ANSHUMAN DUTTA

- 20. Supply Chain Management ANSHUMAN DUTTA

- 21. Retail Entities Main Entities Manufacturers Retailers Customers

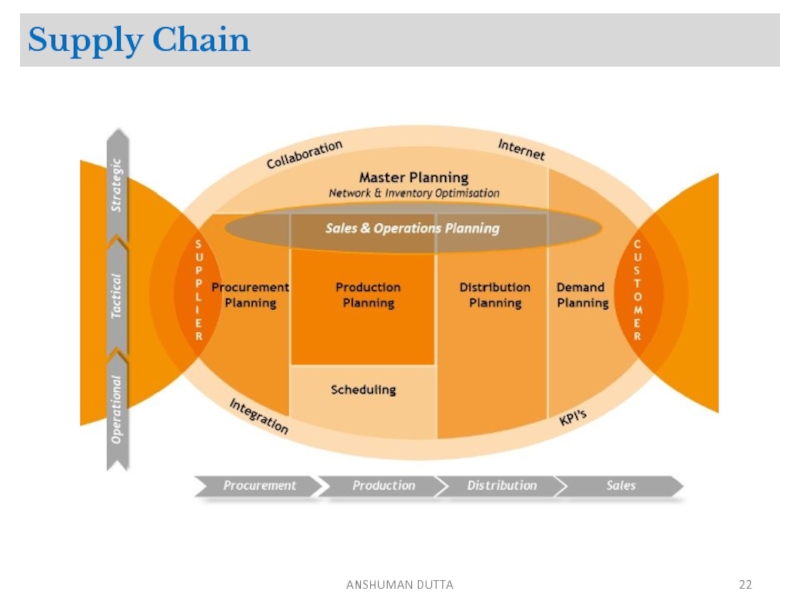

- 22. Supply Chain ANSHUMAN DUTTA

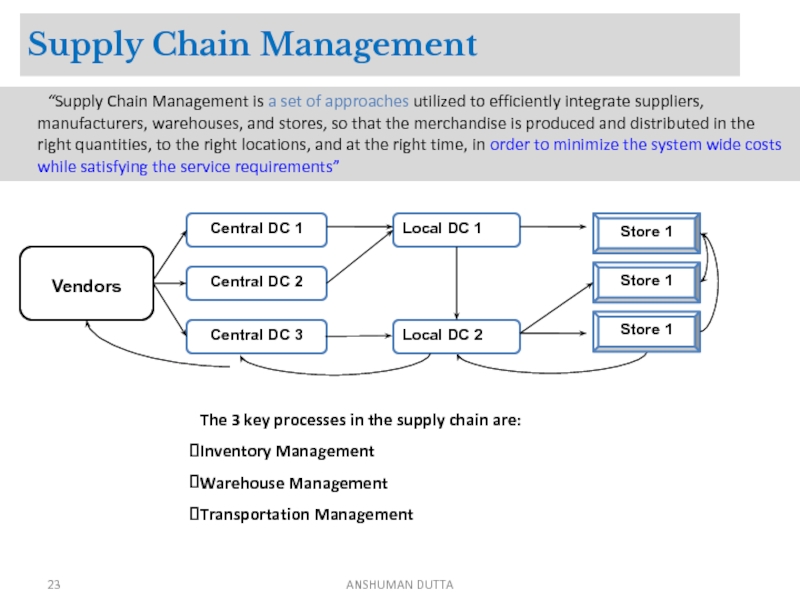

- 23. Supply Chain Management “Supply Chain Management is

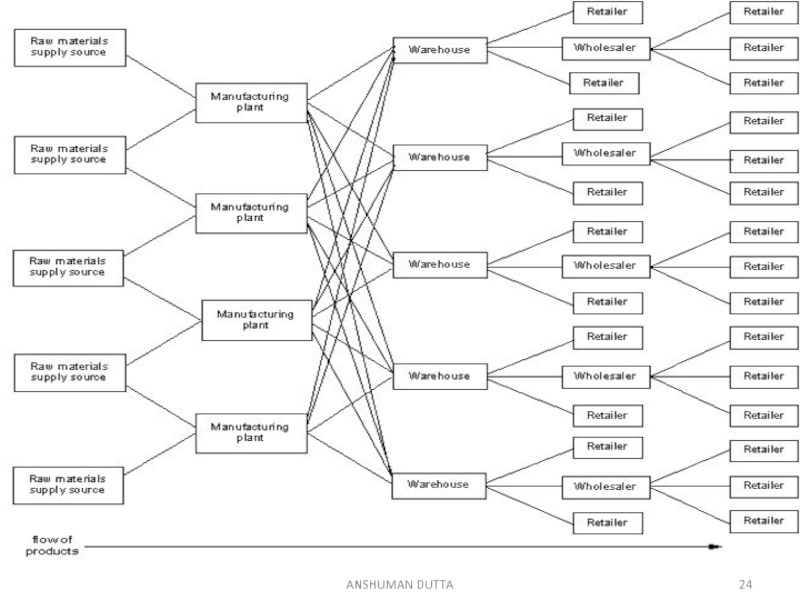

- 24. ANSHUMAN DUTTA

- 25. SCM key processes The Supply Chain

- 26. Warehouse Management Warehouse management aims to enhance

- 27. Warehouse Layout/ Movements & Activities Inbound

- 28. Bullwhip Effect ANSHUMAN DUTTA What is the

- 29. ANALYTICS IN SUPPLY CHAIN RISK MANAGEMENT

- 30. 15 Key Innovations in supply chain strategy

- 31. 15 Key Innovations in Supply Chain Strategy 1998

- 32. Supply Chain Myths ANSHUMAN DUTTA 1. Reduce

- 33. Supply Chain Service ANSHUMAN DUTTA

- 34. Store Front ANSHUMAN DUTTA

- 35. Store Operations What all are needed for

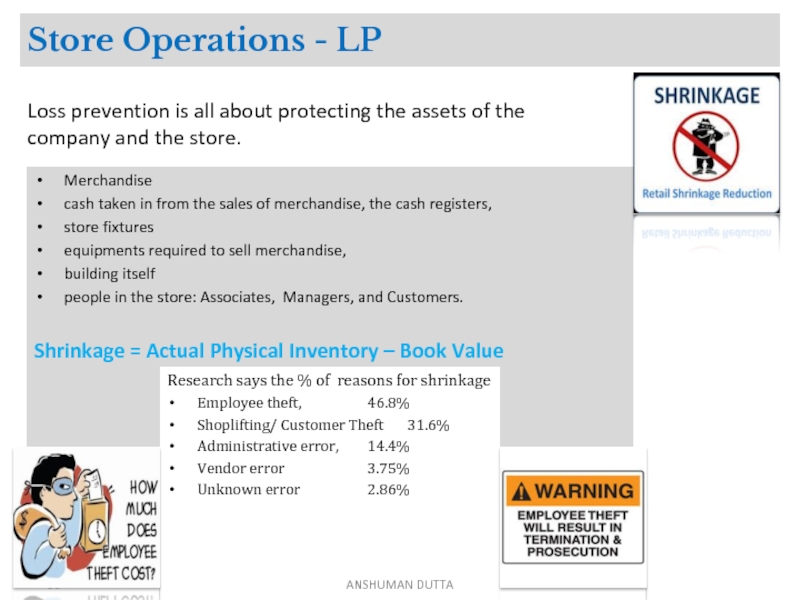

- 36. Store Operations - LP Merchandise cash taken

- 37. Why are Retailers use Multiple Channels Customer

- 38. Why Multichannel Retailing Increasing Online sales Increasing

- 39. Merchandizing : Out of Stock leading to

- 40. Thanks ANSHUMAN DUTTA

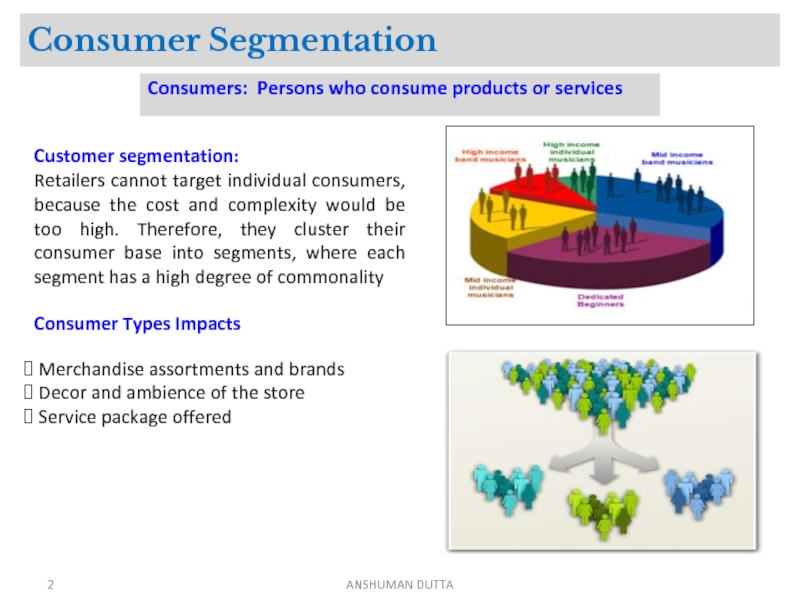

Слайд 2Consumer Segmentation

Consumers: Persons who consume products or services

Customer segmentation:

Retailers

Consumer Types Impacts

Merchandise assortments and brands

Decor and ambience of the store

Service package offered

ANSHUMAN DUTTA

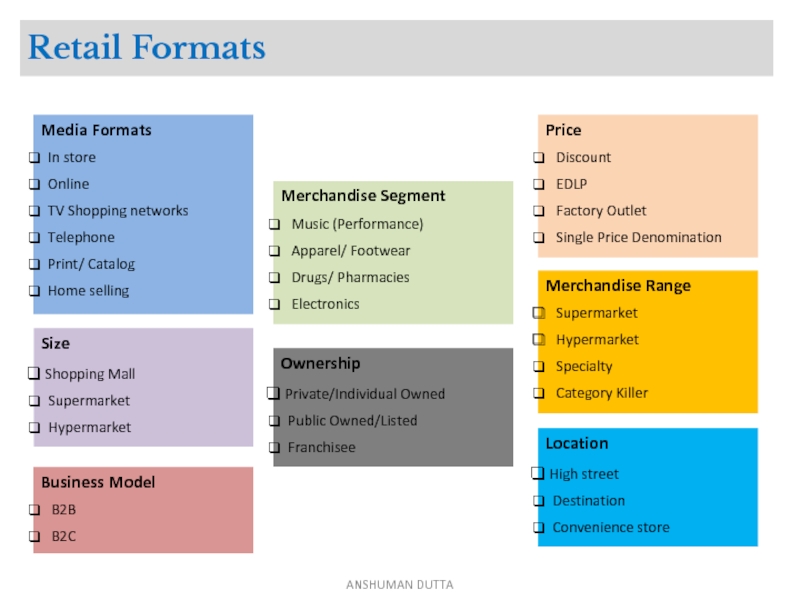

Слайд 4Media Formats

In store

Online

TV Shopping networks

Telephone

Home selling

Retail Formats

Location

High street

Destination

Convenience store

Size

Shopping Mall

Supermarket

Hypermarket

Ownership

Private/Individual Owned

Public Owned/Listed

Franchisee

Merchandise Range

Supermarket

Hypermarket

Specialty

Category Killer

Merchandise Segment

Music (Performance)

Apparel/ Footwear

Drugs/ Pharmacies

Electronics

Price

Discount

EDLP

Factory Outlet

Single Price Denomination

Business Model

B2B

B2C

ANSHUMAN DUTTA

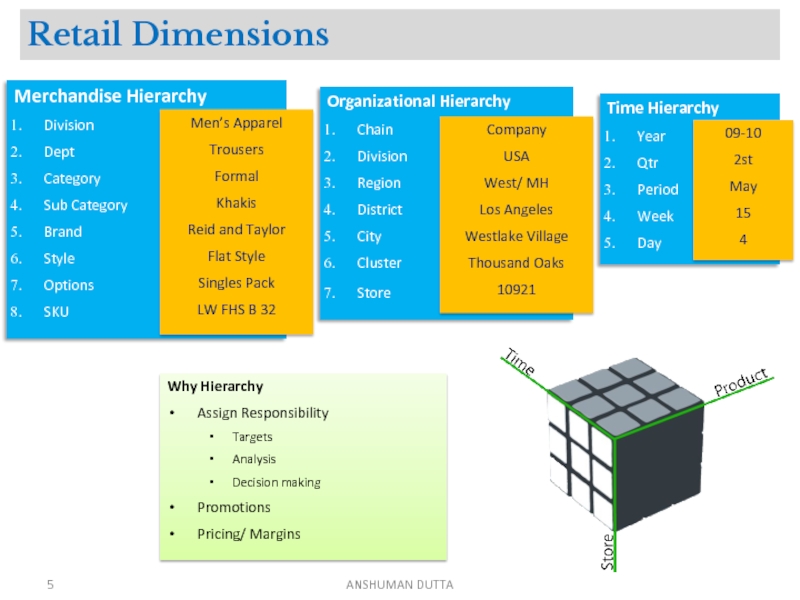

Слайд 5Retail Dimensions

Organizational Hierarchy

Chain

Division

Region

District

City

Cluster

Store

Company

USA

West/ MH

Los Angeles

Westlake Village

Thousand Oaks

10921

Why

Assign Responsibility

Targets

Analysis

Decision making

Promotions

Pricing/ Margins

Merchandise Hierarchy

Division

Dept

Category

Sub Category

Brand

Style

Options

SKU

Men’s Apparel

Trousers

Formal

Khakis

Reid and Taylor

Flat Style

Singles Pack

LW FHS B 32

Time Hierarchy

Year

Qtr

Period

Week

Day

09-10

2st

May

15

4

ANSHUMAN DUTTA

Слайд 7Value Chain of Retail

ANSHUMAN DUTTA

Merchandising

CORE

NON-CORE

Supply Chain

Store Operations

Finance

Legal

Marketing

Слайд 9Merchandise

Merchandise: Goods or services that may be sold or traded

Properties

SKU (Stock

Roles: Buyer – Merchandiser - Allocators

Colors, Sizes,

Dimensions

Pack Size – Unit Of Measurement

Price: Cost and Retail

Hierarchy (Dept – Sub Dept – Class – Sub Class)

Vendor

ANSHUMAN DUTTA

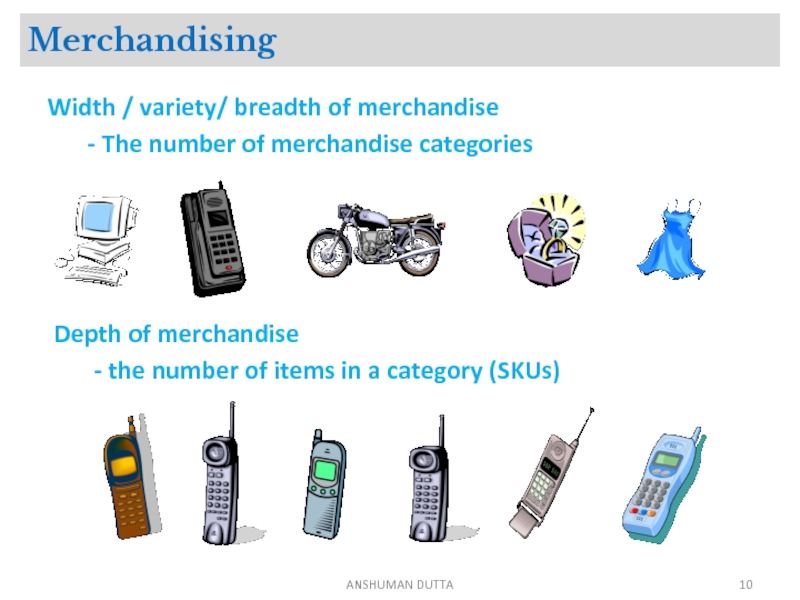

Слайд 10Width / variety/ breadth of merchandise

- The number of merchandise categories

Major

Depth of merchandise

- the number of items in a category (SKUs)

Merchandising

ANSHUMAN DUTTA

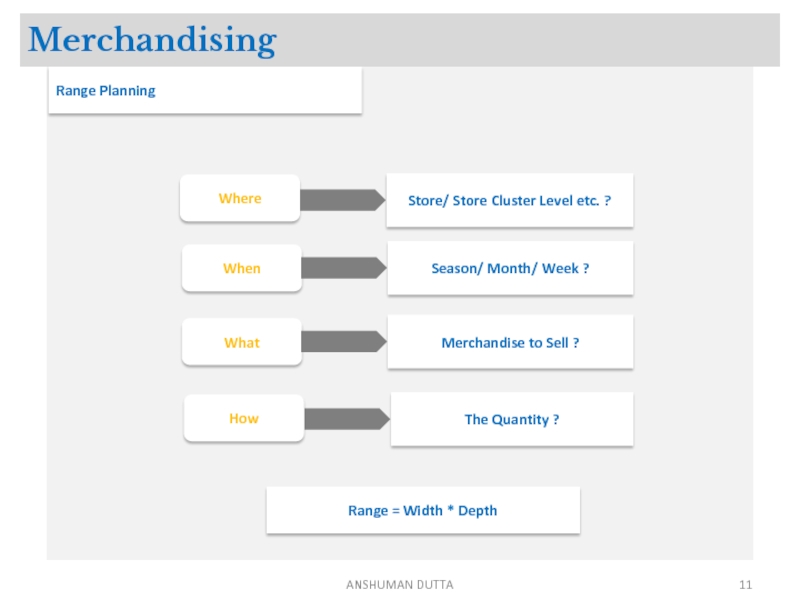

Слайд 13

Merchandising

ANSHUMAN DUTTA

Merchandise Order Planning

Open to Buy

Out of Season Planning

In Season

Open to buy is the dollar amount budgeted by a business for inventory purchases for a specific time period

Determines how much was spent and how much is left to spend

Слайд 15

Merchandising

Pricing is part of the marketing mix available to retailers

Markup

Markdown = Old MRP – New MRP

Pricing/Promotion Management

C

Pricing

Cost + Fixed Margin = Grocery

Cost + Margin Based on Demand = Apparel

Trade Promotions Management:

(1) Brand Based, (2) Location Based, (3) Account Based

ANSHUMAN DUTTA

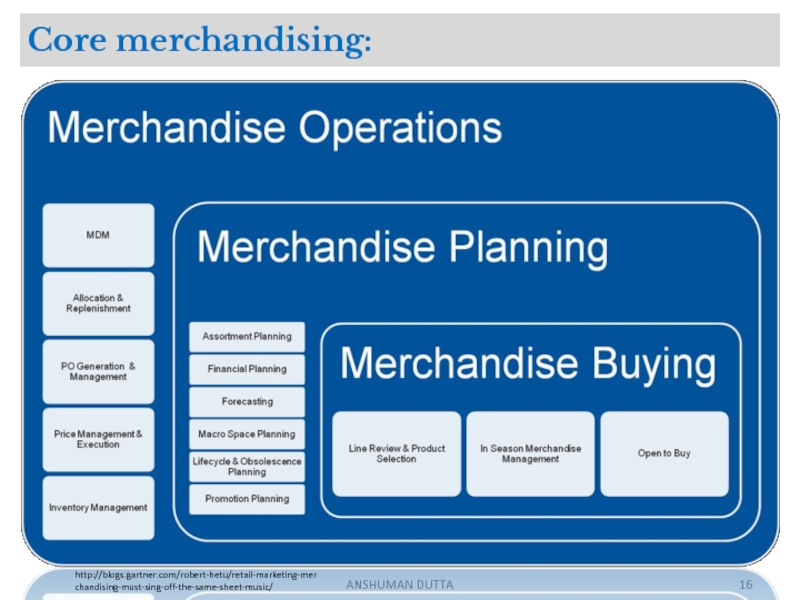

Слайд 16Core merchandising:

ANSHUMAN DUTTA

http://blogs.gartner.com/robert-hetu/retail-marketing-merchandising-must-sing-off-the-same-sheet-music/

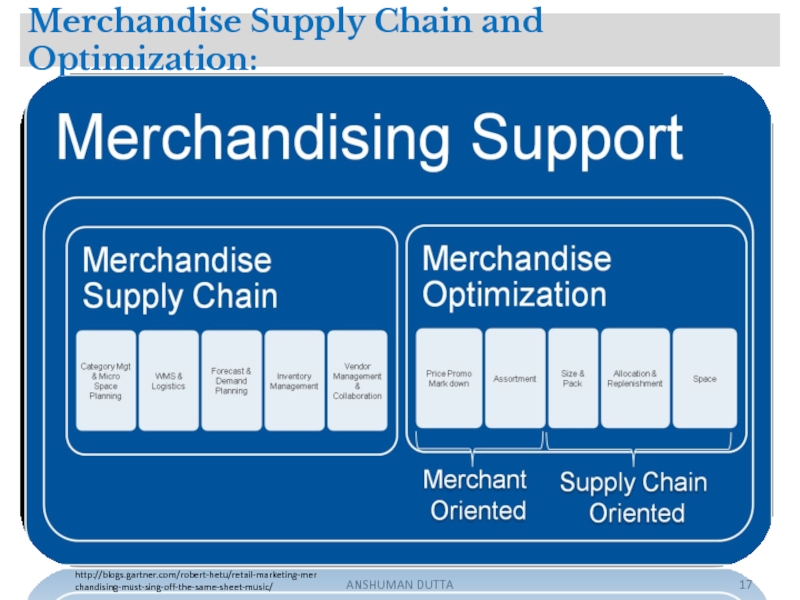

Слайд 17Merchandise Supply Chain and Optimization:

ANSHUMAN DUTTA

http://blogs.gartner.com/robert-hetu/retail-marketing-merchandising-must-sing-off-the-same-sheet-music/

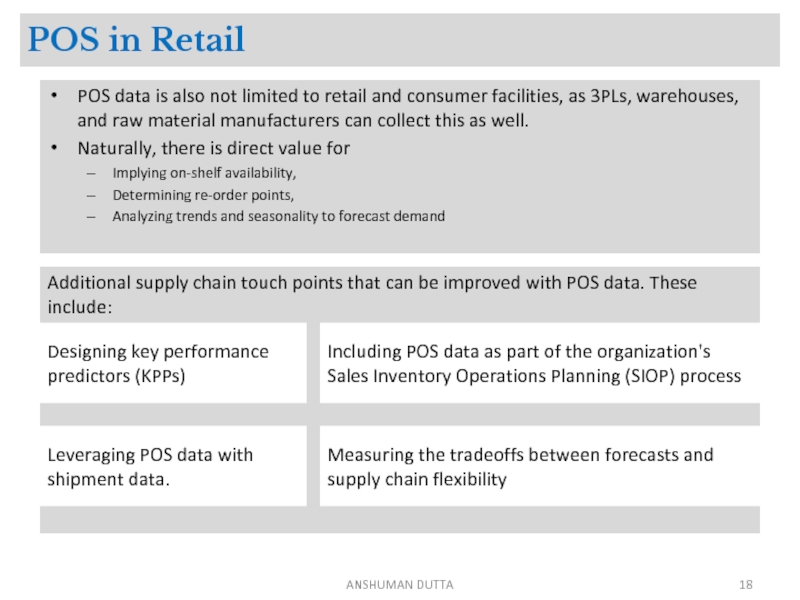

Слайд 18POS in Retail

POS data is also not limited to retail and

Naturally, there is direct value for

Implying on-shelf availability,

Determining re-order points,

Analyzing trends and seasonality to forecast demand

ANSHUMAN DUTTA

Additional supply chain touch points that can be improved with POS data. These include:

Designing key performance predictors (KPPs)

Including POS data as part of the organization's Sales Inventory Operations Planning (SIOP) process

Leveraging POS data with shipment data.

Measuring the tradeoffs between forecasts and supply chain flexibility

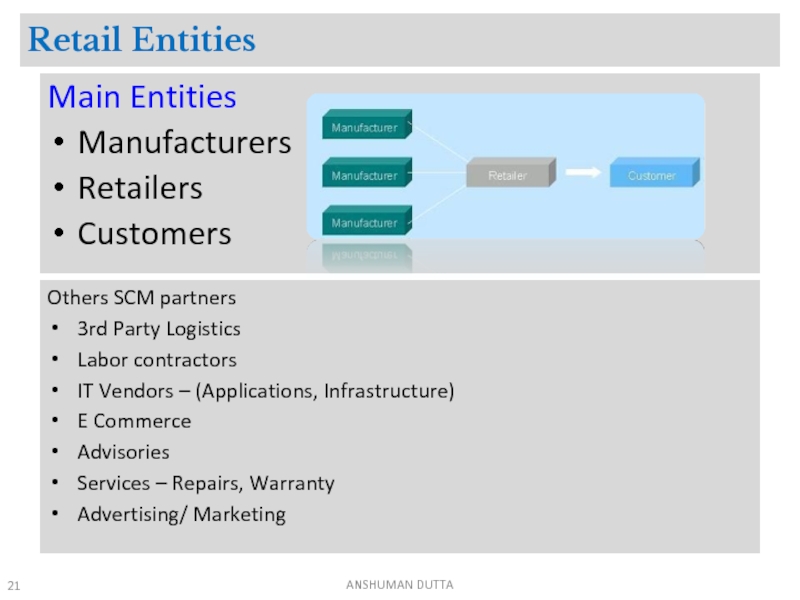

Слайд 21Retail Entities

Main Entities

Manufacturers

Retailers

Customers

Others SCM partners

3rd Party Logistics

Labor contractors

IT Vendors – (Applications,

E Commerce

Advisories

Services – Repairs, Warranty

Advertising/ Marketing

ANSHUMAN DUTTA

Слайд 23Supply Chain Management

“Supply Chain Management is a set of approaches utilized

The 3 key processes in the supply chain are:

Inventory Management

Warehouse Management

Transportation Management

ANSHUMAN DUTTA

Слайд 25SCM key processes

The Supply Chain Management Program integrates topics from manufacturing

Customer Relationship Management

Customer Service Management

Demand Management

Order Fulfillment

Manufacturing Flow Management

Procurement

Product Development and Commercialization

Returns

ANSHUMAN DUTTA

Слайд 26Warehouse Management

Warehouse management aims to enhance inventory management by

Decreasing inventory levels

Improving

Reducing order cycle time

ANSHUMAN DUTTA

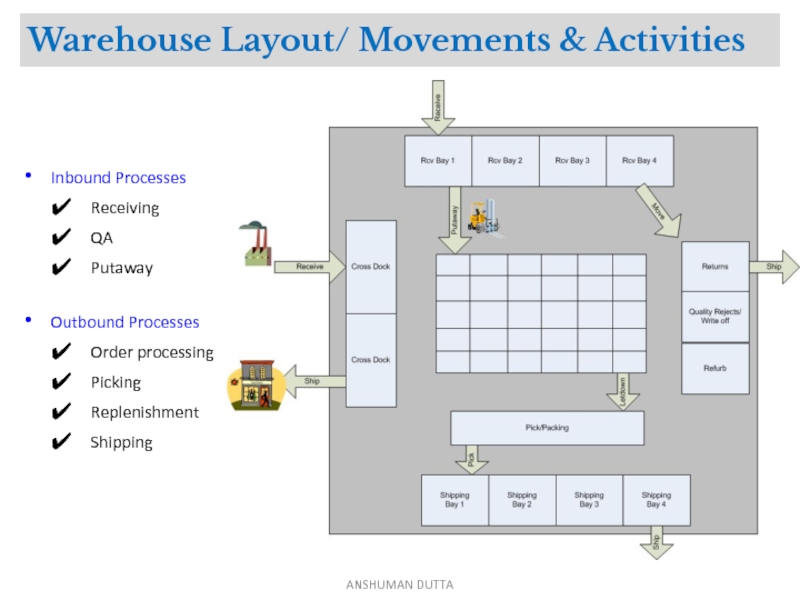

Слайд 27Warehouse Layout/ Movements & Activities

Inbound Processes

Receiving

QA

Putaway

Outbound Processes

Order processing

Picking

Replenishment

Shipping

ANSHUMAN DUTTA

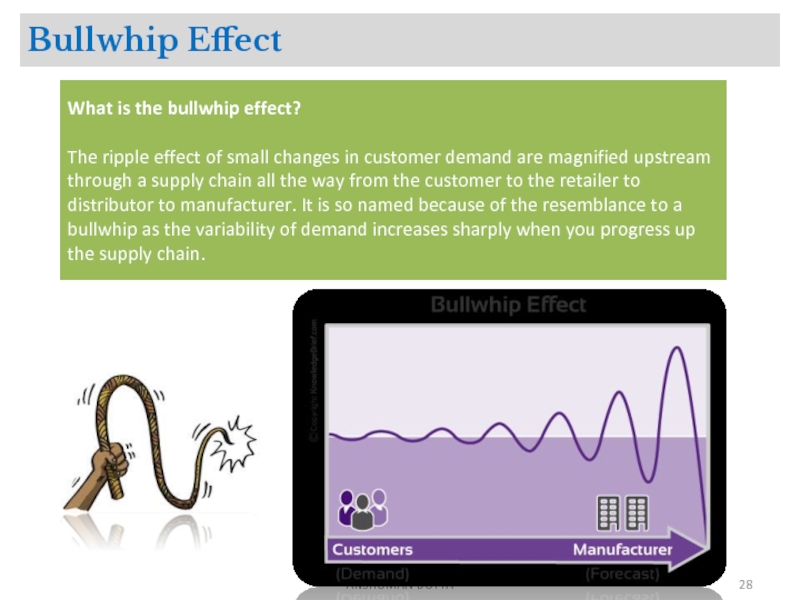

Слайд 28Bullwhip Effect

ANSHUMAN DUTTA

What is the bullwhip effect?

The ripple effect of small

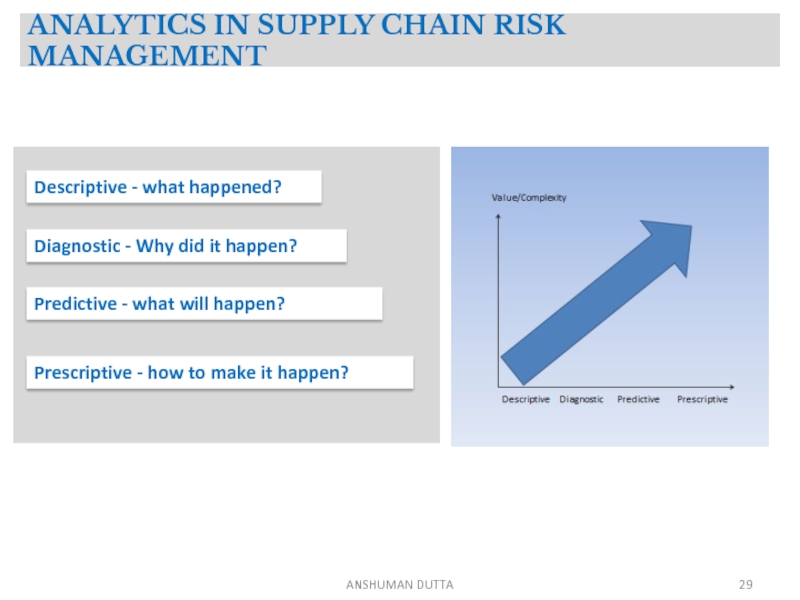

Слайд 29

ANALYTICS IN SUPPLY CHAIN RISK MANAGEMENT

ANSHUMAN DUTTA

Descriptive - what happened?

Diagnostic -

Predictive - what will happen?

Prescriptive - how to make it happen?

Слайд 3015 Key Innovations in supply chain strategy

Ford Assembly Line – Henry Ford

ANSHUMAN DUTTA

Ocean Shipping Container: - Malcom McLean invented the standard steel shipping container first implemented in 1956 at the port of New Jersey

Electronic Data Interchange (EDI) –Started when computer systems first had the capability to transfer data to other computer systems. Enables the exchange of electronic business documents.

Material Resource Planning (MRP) – Josef Orlicky makes the first MRP system in Racine, Wisconsin. A year later, Gene Thomas from IBM invents the Bill of Materials Processor. For the first time, manufacturers could break down the BOM on a computer

Universal Product Code (UPC) – a company called Logicon wrote a standard for something close to what became known as the Universal Product Code (UPC) to identify via a barcode a specific SKU. The first implementation of the UPC was in 1974 at a Marsh's supermarket in Troy, OH.

Enterprise Resource Planning – In 1990, Gartner Group first employed the acronym ERP which came to represent a larger whole, reflecting the evolution of application integration beyond manufacturing.

Dell Direct Orders – Michael Dell started his company in his dorm room shipping computers to customers. This developed into a unique model of make to order that provided custom configurations to customers and shipped to them

FedEx Tracking System – After re-inventing the category of express parcel shipments, FedEx went a step further by developing a new computerized tracking system that provided near real-time information about package delivery. Outfitting drivers with small

handheld computers for scanning pick-ups and deliveries, a shipment's status was available end to end.

P&G's Continuous Replenishment: Order patterns were totally dependent on sales and retail buyer input until P&G bought a mainframe application from IBM for "continuous replenishment" re-wrote it for retail, and changed that entire value chain by driving orders based on DC withdrawals and sales data.

Walmart Cross Docking – With rapid expansion in the number of Walmart stores, the company needed an effective communication system. They introduced the first cross docking system, which enabled them to track goods across all their DCs and stores.

The Toyota Production System: Pioneered by Toyota's Taiichi Ohno and a few colleagues, TPS not only is the foundation for today's lean manufacturing and supply chain practices, but the concepts have penetrated virtually every area business

Rise of the PC and Internet – this allowed the development of decision support systems for the supply chain on PCs as well as collaboration platforms for companies with their trading partners.

HP Postponement – The ability to delay differentiation in product design can convey many advantages. HP was the first to use this approach delaying some of the localized decision for its DeskJet printers by customizing the printers at its local distribution centers rather than at its factories.

Слайд 3115 Key Innovations in Supply Chain Strategy

1998 – Amazon Order & Delivery

ANSHUMAN DUTTA

2000s – RFID , Track and Trace – RFID was developed at the MIT Auto-ID Center. It is a code-carrying technology, and can be used in place of a barcode to enable non-line of sight-reading. Synonymous with track-and-trace solutions, and has a critical role to play in supply chains.

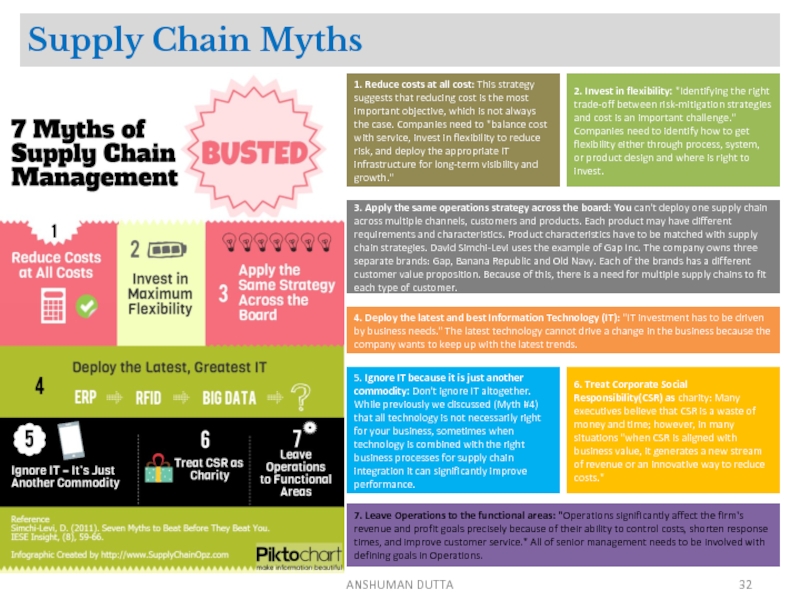

Слайд 32Supply Chain Myths

ANSHUMAN DUTTA

1. Reduce costs at all cost: This strategy

2. Invest in flexibility: "Identifying the right trade-off between risk-mitigation strategies and cost is an important challenge." Companies need to identify how to get flexibility either through process, system, or product design and where is right to invest.

3. Apply the same operations strategy across the board: You can't deploy one supply chain across multiple channels, customers and products. Each product may have different requirements and characteristics. Product characteristics have to be matched with supply chain strategies. David Simchi-Levi uses the example of Gap Inc. The company owns three separate brands: Gap, Banana Republic and Old Navy. Each of the brands has a different customer value proposition. Because of this, there is a need for multiple supply chains to fit each type of customer.

4. Deploy the latest and best Information Technology (IT): "IT investment has to be driven by business needs." The latest technology cannot drive a change in the business because the company wants to keep up with the latest trends.

5. Ignore IT because it is just another commodity: Don't ignore IT altogether. While previously we discussed (Myth #4) that all technology is not necessarily right for your business, sometimes when technology is combined with the right business processes for supply chain integration it can significantly improve performance.

6. Treat Corporate Social Responsibility(CSR) as charity: Many executives believe that CSR is a waste of money and time; however, in many situations "when CSR is aligned with business value, it generates a new stream of revenue or an innovative way to reduce costs."

7. Leave Operations to the functional areas: "Operations significantly affect the firm's revenue and profit goals precisely because of their ability to control costs, shorten response times, and improve customer service." All of senior management needs to be involved with defining goals in Operations.

Слайд 35Store Operations

What all are needed for the store to run smooth

Understanding

Practices to prevent and cut short losses due to various sources

Practices to best utilize all available resources in the store

ANSHUMAN DUTTA

Слайд 36Store Operations - LP

Merchandise

cash taken in from the sales of merchandise,

store fixtures

equipments required to sell merchandise,

building itself

people in the store: Associates, Managers, and Customers.

Shrinkage = Actual Physical Inventory – Book Value

Research says the % of reasons for shrinkage

Employee theft, 46.8%

Shoplifting/ Customer Theft 31.6%

Administrative error, 14.4%

Vendor error 3.75%

Unknown error 2.86%

Loss prevention is all about protecting the assets of the company and the store.

ANSHUMAN DUTTA

Слайд 37Why are Retailers use Multiple Channels

Customer wants to interact in different

Each channel offers a unique set of benefits for Customers

ANSHUMAN DUTTA

Слайд 38Why Multichannel Retailing

Increasing Online sales

Increasing Internet usage

Consumers interest to enjoy channel

Consumers expect more from retailers in terms of product information, convenience and customer service.

ANSHUMAN DUTTA

Слайд 39Merchandizing :

Out of Stock leading to loss of sales

Pilferage & shop-lifting

Managing

Workforce Management:

Time & Attendance management

Labor budgeting/scheduling

Recruitment & training

Staff productivity

Point of Sales :

Poor connectivity between store and host systems

No up-to-date information and customized promotions and services

Absence of synchronized view of the customer and inventory information

Supply Chain Analytics:

Visibility in SKU availability, Perfect order fulfillment, optimizing inventory holdings

Supplier performance measurement

Merchandise Analytics:

Optimize merchandise mix

Track promotion effectiveness

POS Analytics:

Understanding Demand Patterns

Measuring store ,category, SKU performance

Customer Analytics:

Understand most profitable customers and cost to serve them

Assortment planning and optimization

Low Inventory Turns :

Lack of accurate inventory information

Sporadic Demand of many items

Poor Supply Chain visibility

Demand Response

Lack of demand planning & forecasting processes

Very Price Sensitive Customers, volatile demand pattern

Total Landing Costs :

Some suppliers, multiple tiers of distribution

Lack of Transportation Management Systems

Lack of Distribution planning & scheduling mechanisms

Customer Experience & Loyalty:

Providing seamless Omni-channel experience

Personalized shopping assistance

Personalized promotions

Social Media engagement:

Brand crises management

Search Engine Optimization & Social Media Optimization

Multi-channel Fulfillment :

Supply Chain & logistics pressures

Smaller, customized package sizes lead to high transportation and labor costs

In-store Challenges

Analytics Challenges

Supply Chain Challenges

Omni Channel and Digital Media Challenges

Challenges in Retail Industry