- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Meeting Topics Zekkert презентация

Содержание

- 1. Meeting Topics Zekkert

- 2. Glory New Introduction Zekkert Introduction Sales Review

- 3. Sales Review

- 4. Sales Review Zekkert Shipment Data at Glory

- 5. Test Report By Glory Chief Engineer

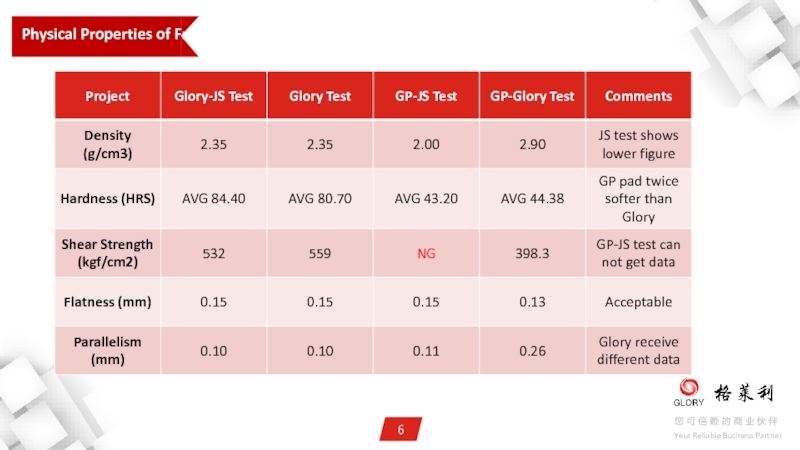

- 6. Physical Properties of Friction Materials

- 7. Lining Issue Hot Press Process is not

- 8. Bonding Strength Glory-JS Test: GP-JS Test: Bonding

- 9. Friction Coefficient Mean coefficient of friction 0.421

- 10. Appearance Dimension: Qualified Band Area: Over

- 11. Conclusion

- 12. Conclusion

- 13. New Range Items

- 14. New Range Items New Range Price situation

- 15. 2017 Purchase Plans

- 16. 2017 Purchase Plan Due to braking performance

Слайд 2Glory New Introduction

Zekkert Introduction

Sales Review

Test Report Explanation

Basic Friction & Noise

New Range

2017 Purchase Plan

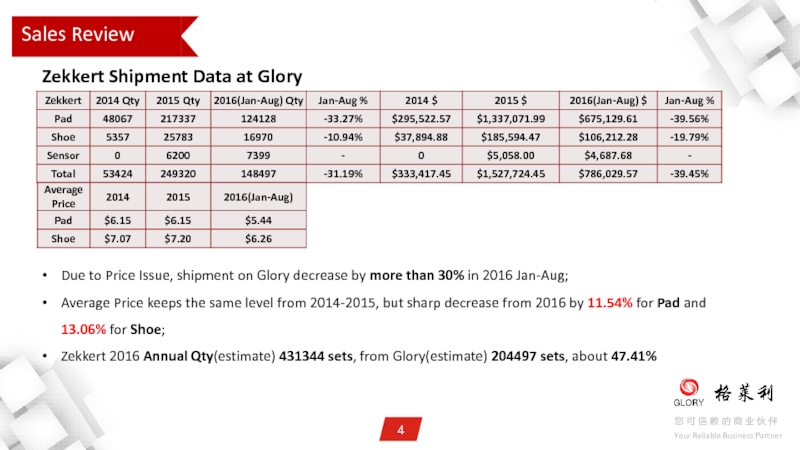

Слайд 4Sales Review

Zekkert Shipment Data at Glory

Due to Price Issue, shipment on

Average Price keeps the same level from 2014-2015, but sharp decrease from 2016 by 11.54% for Pad and 13.06% for Shoe;

Zekkert 2016 Annual Qty(estimate) 431344 sets, from Glory(estimate) 204497 sets, about 47.41%

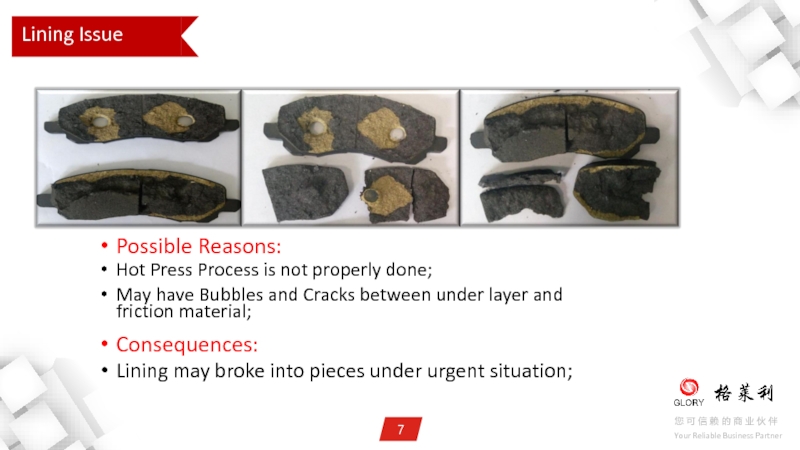

Слайд 7Lining Issue

Hot Press Process is not properly done;

May have Bubbles and

Possible Reasons:

Lining may broke into pieces under urgent situation;

Consequences:

Слайд 8Bonding Strength

Glory-JS Test:

GP-JS Test:

Bonding Area 100%

Normal Temperature Shear Strength 532kgf/cm²(Glory Standard

Good bonding strength between back plate, under layer and friction material

Bonding Area 100%

Unknown Shear Strength

Possible with good bonding strength between back plate and under layer, but not possible to tell the strength between under layer and friction material due to the unknown shear strength data.

GP-Glory Test:

Bonding Area 98%

Normal Temperature Shear Strength 398.3kgf/cm²(Glory Standard 392kgf/cm²)

Good bonding strength between back plate and under layer, less bonding strength between under layer and friction material

Glory Test:

Bonding Area 100%

Normal Temperature Shear Strength 532kgf/cm²(Glory Standard 392kgf/cm²)

Good bonding strength between back plate, under layer and friction material

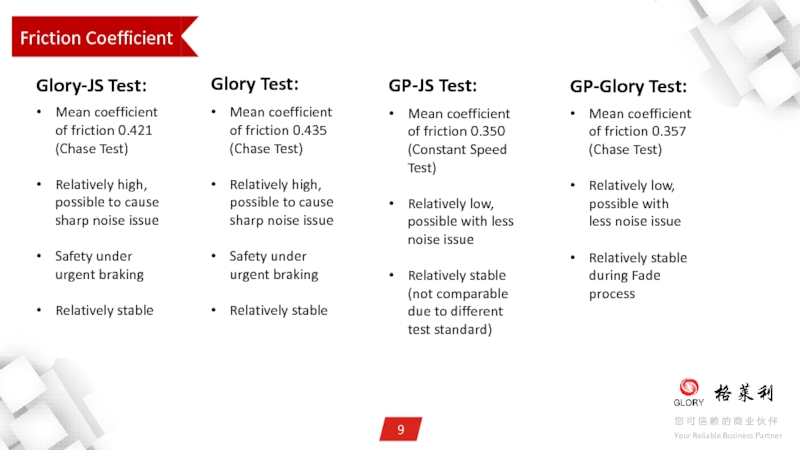

Слайд 9Friction Coefficient

Mean coefficient of friction 0.421 (Chase Test)

Relatively high, possible to

Safety under urgent braking

Relatively stable

Glory-JS Test:

GP-JS Test:

Mean coefficient of friction 0.350 (Constant Speed Test)

Relatively low, possible with less noise issue

Relatively stable (not comparable due to different test standard)

GP-Glory Test:

Mean coefficient of friction 0.357 (Chase Test)

Relatively low, possible with less noise issue

Relatively stable during Fade process

Glory Test:

Mean coefficient of friction 0.435 (Chase Test)

Relatively high, possible to cause sharp noise issue

Safety under urgent braking

Relatively stable

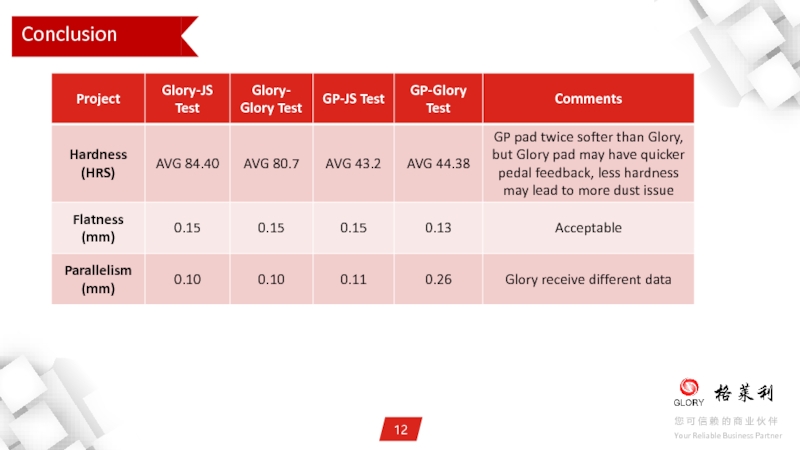

Слайд 10Appearance

Dimension: Qualified

Band Area: Over 80%

Flatness: 0.15

Parallelism: 0.10

Clean: not mentioned

Glory-JS Test:

GP-JS Test:

Dimension:

Band Area: Over 80%

Flatness: 0.15

Parallelism: 0.11

Clean: not mentioned

GP-Glory Test:

Dimension: Qualified

Band Area: Over 80%

Flatness: 0.15

Parallelism: 0.26

Clean: Dust Issue

Dimension: Qualified

Band Area: Over 80%

Flatness: 0.15

Parallelism: 0.10

Clean: Acceptable

Glory Test:

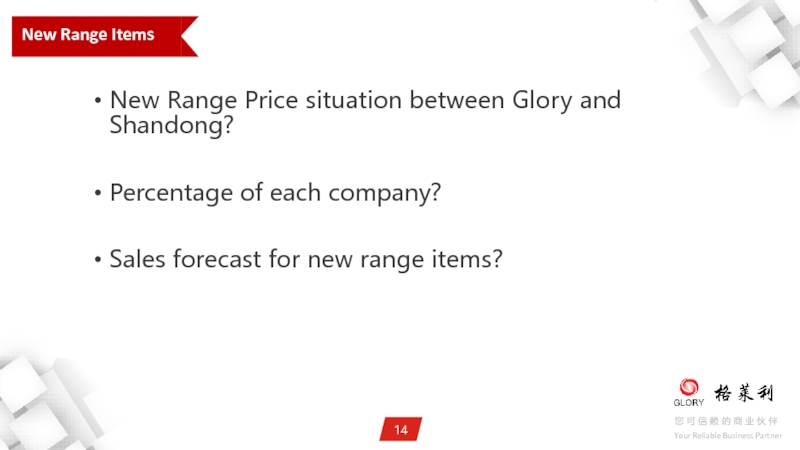

Слайд 14New Range Items

New Range Price situation between Glory and Shandong?

Percentage of

Sales forecast for new range items?

Слайд 162017 Purchase Plan

Due to braking performance difference between Shandong pad and

2017 purchase plan (estimate quantity)

Percentage of each company