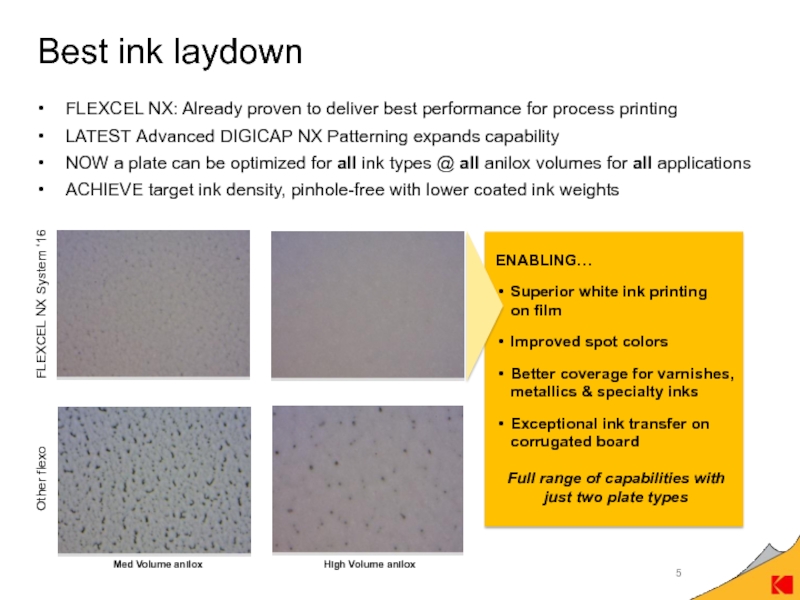

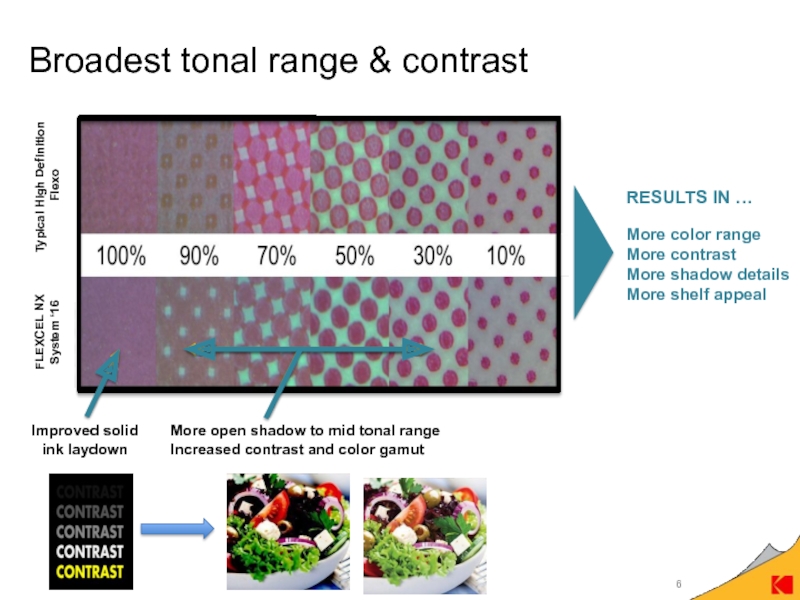

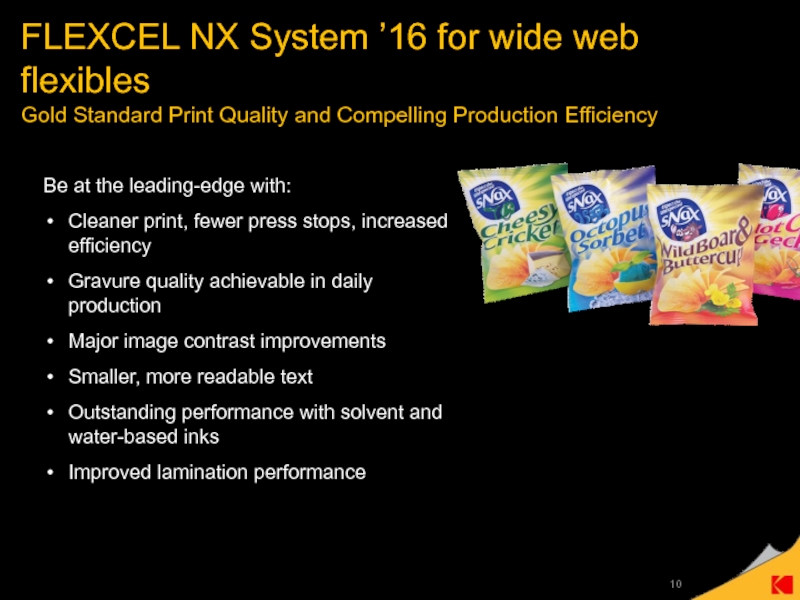

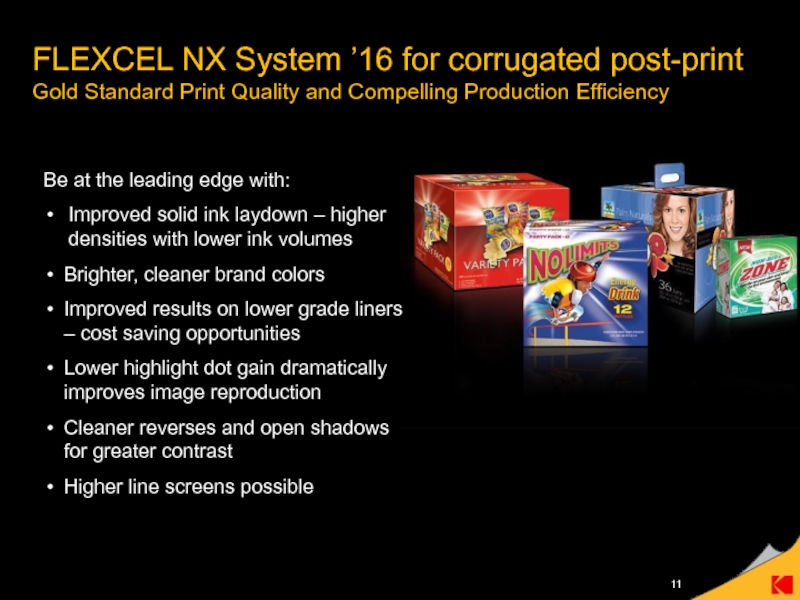

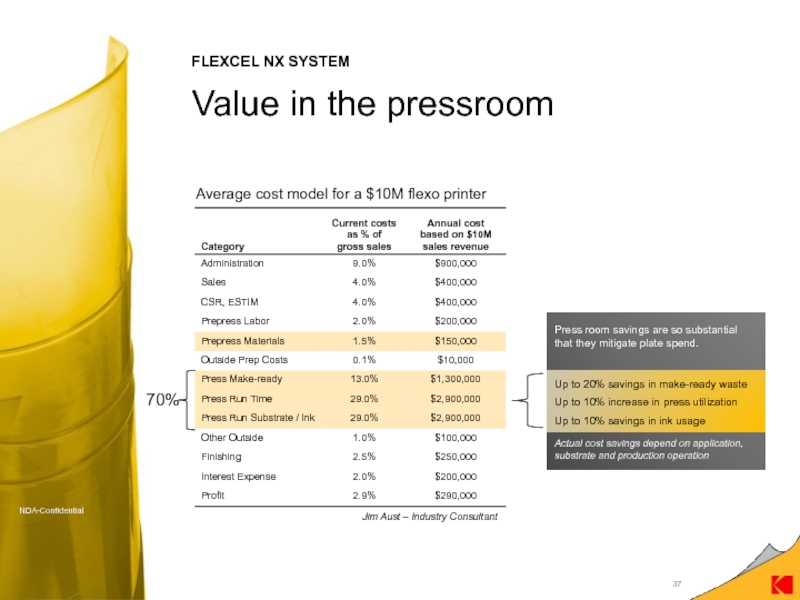

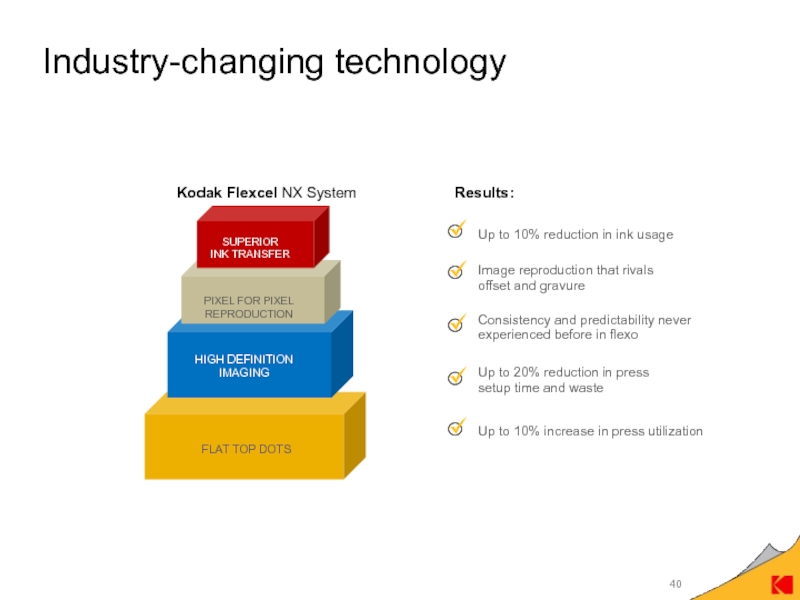

and COMPELLING PRODUCTION EFFICIENCY

Across the broadest range of applications and print conditions:

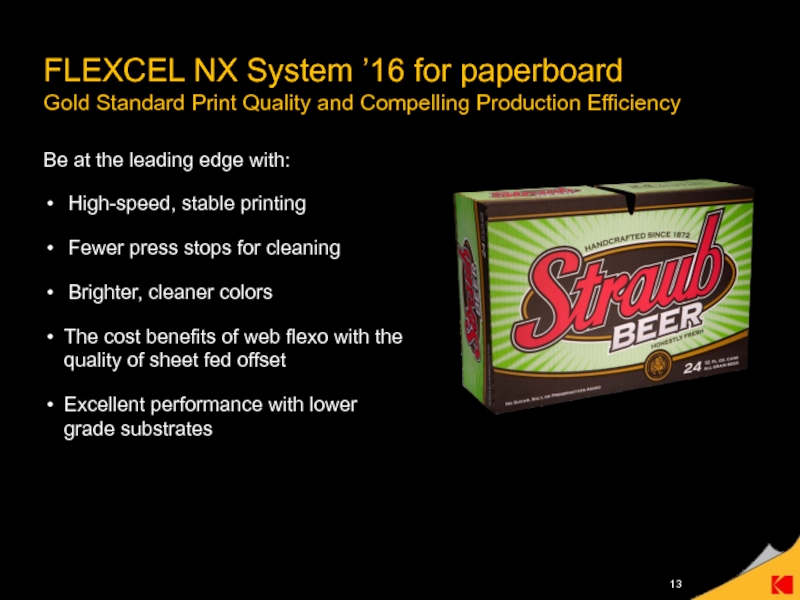

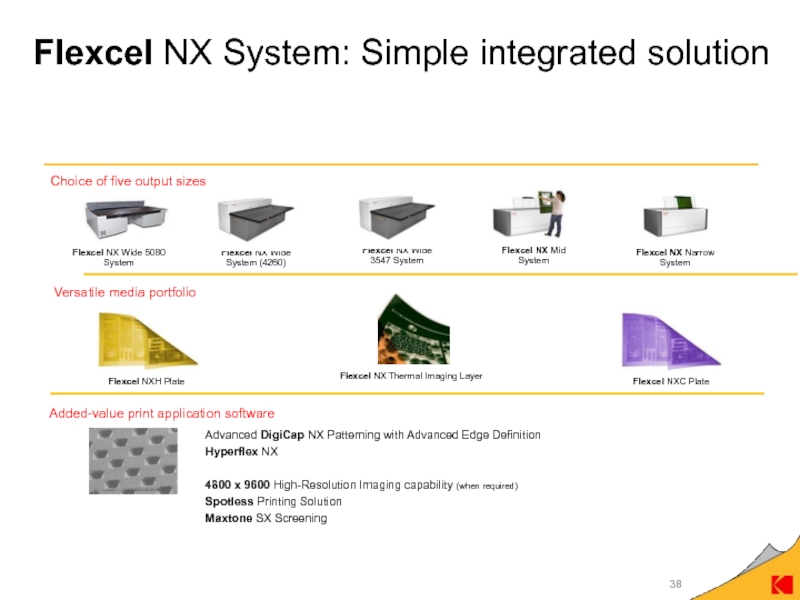

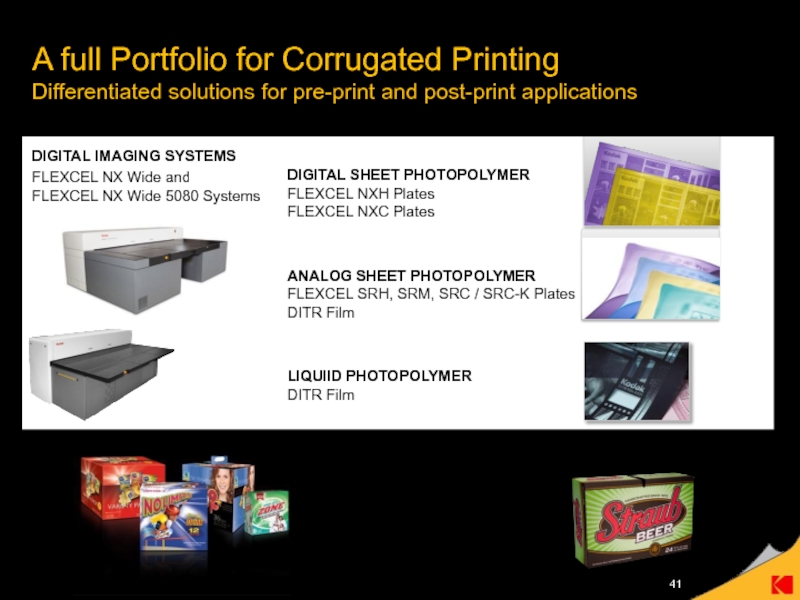

Tag and Label | Flexible Packaging | Folding Carton | Corrugated Boxes | Security

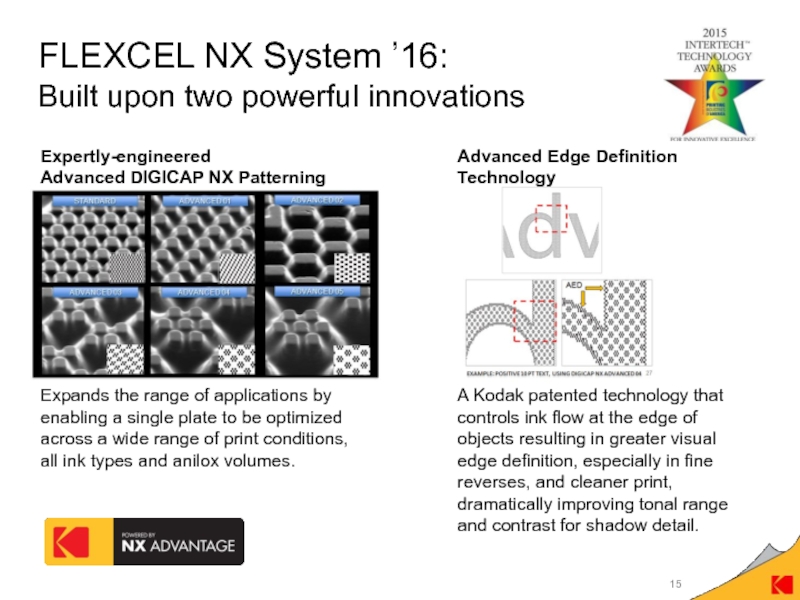

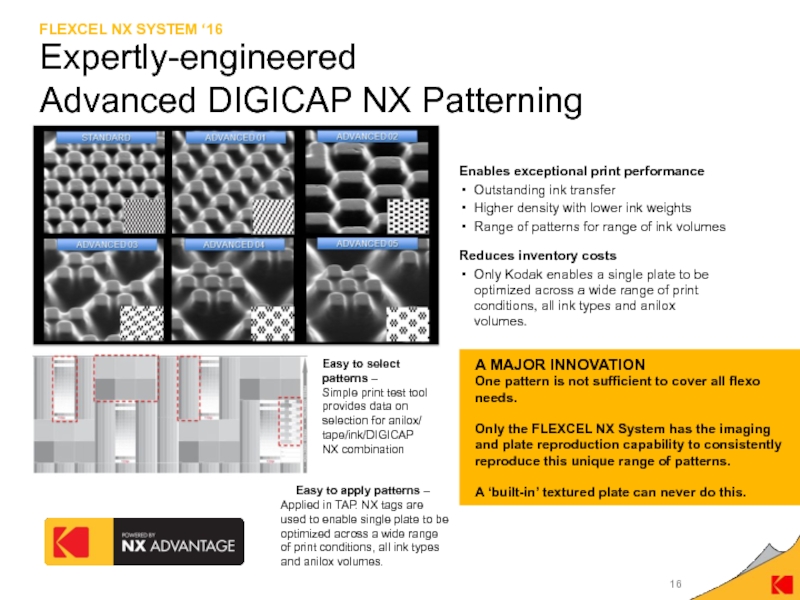

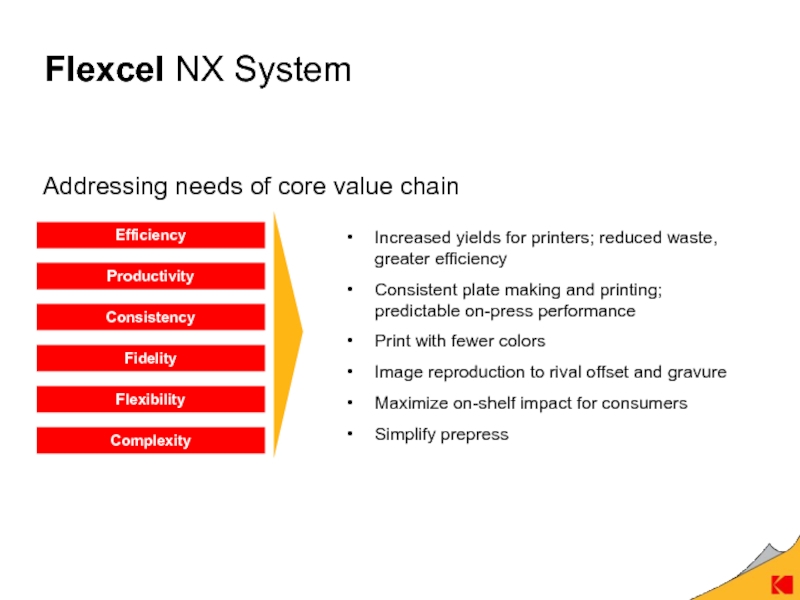

Delivered with the simplest plate portfolio in the industry

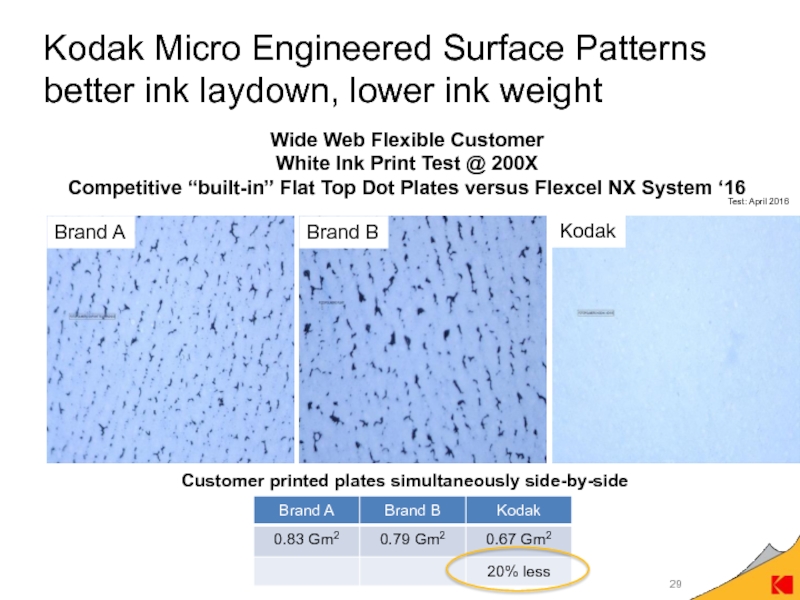

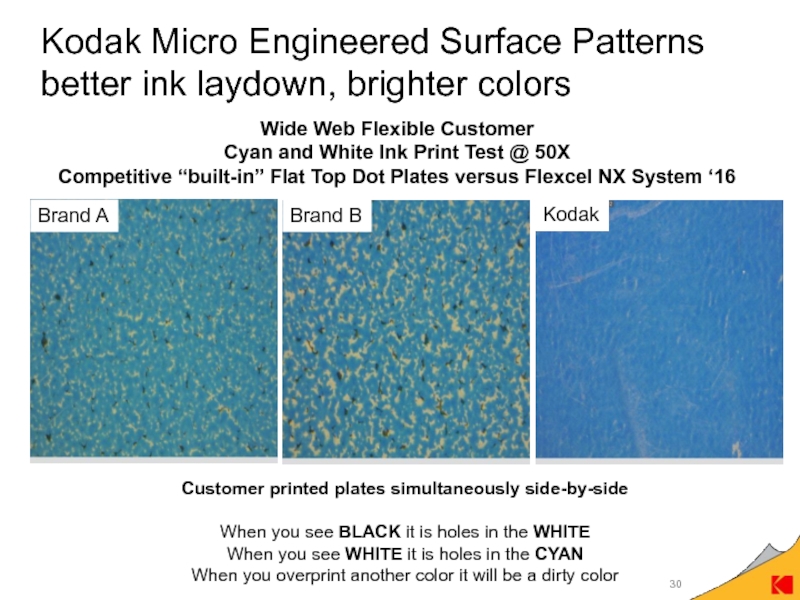

Fully integrated and differentiated plate making solution

Unparalleled consistency

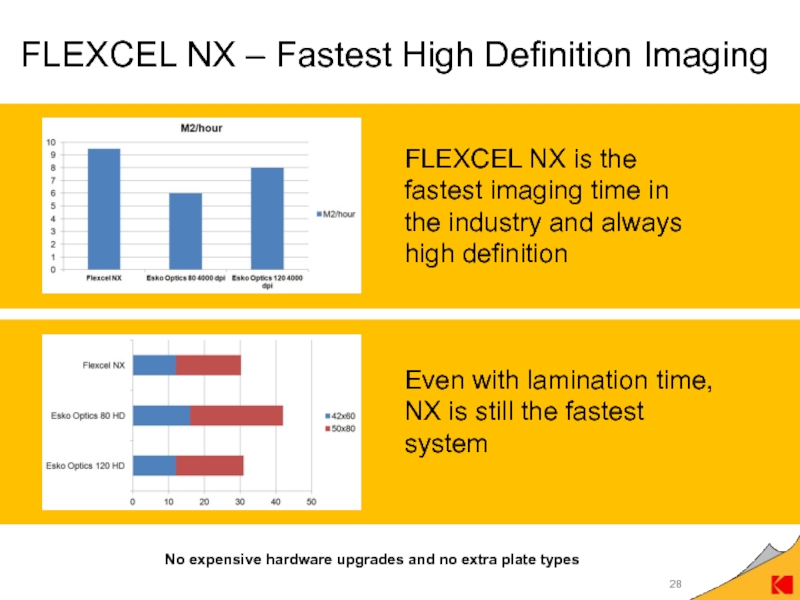

Fastest imaging

Fully upgradeable platform