- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Unit 2. Computer System’s Silicon miracles: How GPUs are made презентация

Содержание

- 1. Unit 2. Computer System’s Silicon miracles: How GPUs are made

- 2. Aims & Objectives: This lesson describes how

- 3. Sand to Silicon: Silicon is one of

- 4. Sand to Silicon: The carbon reacts with

- 5. From silicon to wafers… Silicon wafers are

- 6. The General / Graphical Processing Unit:

- 7. 1. The High Level Design One of

- 8. 2. Floorplan and Netlist The floorplan

- 9. 3. Circuit verification and emulation

- 10. 3. Circuit verification and emulation

- 11. 4. Making the masks With the

- 12. 5. Photolithography It involves applying a

- 13. 6. Patterned Oxide layer In the

- 14. 7. Creating the transistors A MOSFET (the

- 15. 7. Creating the Transistors In the following

- 16. 7. Creating the Transistors Two smaller islands

- 17. 8. Connecting Everything We now have a

- 18. 8. Connecting Everything This covers the entire

- 19. 9. Testing The initial manufacturing processes are

- 20. 10. Packaging Once testing is complete,

Слайд 2Aims & Objectives:

This lesson describes how using some of the most

advanced and intricate engineering modes and mechanisms

Silison can be transformed into some of the most Powerful General/Graphical Processing units we have ever seen

Silison can be transformed into some of the most Powerful General/Graphical Processing units we have ever seen

Слайд 3Sand to Silicon:

Silicon is one of the few chemical elements known

as aa Matalloid

This means it has the neccessary properties to form semiconductors

These semiconductors are the basis of all digital electronics

For silicon production ‘Silica’ sand is required, this sand is made of mainly silicon dioxide

Silica sand is heated to 2000 degrees centigrade in the presence of carbon

This means it has the neccessary properties to form semiconductors

These semiconductors are the basis of all digital electronics

For silicon production ‘Silica’ sand is required, this sand is made of mainly silicon dioxide

Silica sand is heated to 2000 degrees centigrade in the presence of carbon

Слайд 4Sand to Silicon:

The carbon reacts with the oxygen in the silica

to produce elemental silicon

The metallurgical grade silicon is 99% pure

For th GPU this silicon needs to further purified (1 in 1,000,000 pure)

Purification is achieved by reacting silicon with hydrogen chloride

The silicon compound is extracted by fractional distilation and re-intorduced to hydrogen

The metallurgical grade silicon is 99% pure

For th GPU this silicon needs to further purified (1 in 1,000,000 pure)

Purification is achieved by reacting silicon with hydrogen chloride

The silicon compound is extracted by fractional distilation and re-intorduced to hydrogen

Слайд 5From silicon to wafers…

Silicon wafers are usually 300mm in diameter and

0/775mm thick

Rather than being composed of lots of small crystals that would have a negative impact on the silicons electronic properties and to avoid defects silicon must be grown as a single crystal

Pure silicon is melted at just above its melting point of 1,414 degree’s centigrade

A tiny crystal of silicon is dipped into the molton silicon and slowly withdrawn (millimeters per hour)

A monocrystaline rod, called a boule is produced

It is sliced up using a wire saw

The wafers are then ground and polished so that they are flat within two thousandths of a millimeter

Rather than being composed of lots of small crystals that would have a negative impact on the silicons electronic properties and to avoid defects silicon must be grown as a single crystal

Pure silicon is melted at just above its melting point of 1,414 degree’s centigrade

A tiny crystal of silicon is dipped into the molton silicon and slowly withdrawn (millimeters per hour)

A monocrystaline rod, called a boule is produced

It is sliced up using a wire saw

The wafers are then ground and polished so that they are flat within two thousandths of a millimeter

Слайд 6The General / Graphical

Processing Unit:

Engineers have now managed to design

and build machines with components measuing as little as 40nm across…

A Nanometer measure one-thousandth the diameter of a human hair

A powerful Intel i7 sandbridge CPU boasts just short of one billion transistors

A leading edge general processing unit like AMDs Cayman, used in the Radeon HD 6970 graphics card clocks up a massive 2.64 billion transistors

A Nanometer measure one-thousandth the diameter of a human hair

A powerful Intel i7 sandbridge CPU boasts just short of one billion transistors

A leading edge general processing unit like AMDs Cayman, used in the Radeon HD 6970 graphics card clocks up a massive 2.64 billion transistors

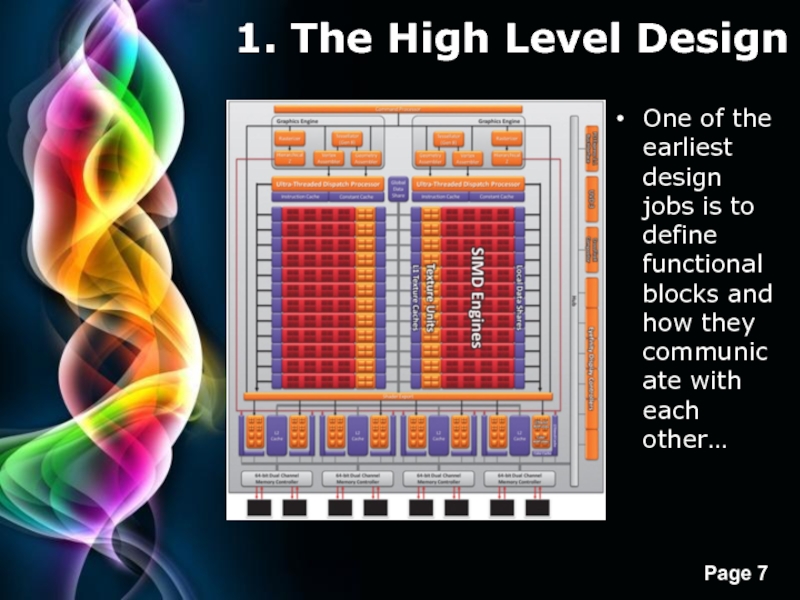

Слайд 71. The High Level Design

One of the earliest design jobs is

to define functional blocks and how they communicate with each other…

Слайд 82. Floorplan and Netlist

The floorplan must now be defined

This is

a physical representation that will take account of how large each block is expected to be and where it should be positioned relative to other blocks

Account is taken of how many signals pass between the blocks with the aim of reducing the lengths of the pathways

Other engineers work on the component level design of each of the blocks.

Account is taken of how many signals pass between the blocks with the aim of reducing the lengths of the pathways

Other engineers work on the component level design of each of the blocks.

Слайд 93. Circuit verification

and emulation

Designs as complicated as a GPU

are never 100 per cent correct on the first attempt

So the design is verified and emulated - a hugely processor-intensive operation that requires supercomputing resources

Verification involves testing individual blocks with perhaps thousands of tests per block

Each time anything fails, the design team backtracks to correct the errors and then performs a full set of simulation tests to make sure the remedial action hadn't broken something that previously worked correctly

So the design is verified and emulated - a hugely processor-intensive operation that requires supercomputing resources

Verification involves testing individual blocks with perhaps thousands of tests per block

Each time anything fails, the design team backtracks to correct the errors and then performs a full set of simulation tests to make sure the remedial action hadn't broken something that previously worked correctly

Слайд 103. Circuit verification

and emulation

Once all the individual blocks are

operational, the team moves to emulation

This means exercising the GPU as a whole, but given the amount of processing time needed to simulate a multi-billion transistor chip, these tests might initially be nothing more complicated than drawing a single pixel

In addition to functional testing, emulation also ensures that the chip meets its requirements in terms of processing speed.

This means exercising the GPU as a whole, but given the amount of processing time needed to simulate a multi-billion transistor chip, these tests might initially be nothing more complicated than drawing a single pixel

In addition to functional testing, emulation also ensures that the chip meets its requirements in terms of processing speed.

Слайд 114. Making the masks

With the simulation out of the way

the designers know that the circuit connections are correct

However, no thought has been given to where the components go on the chip

This is carried out using a special CAD package, driven by the floor-plan

This largely automated process places each component and routes the copper tracks that will ultimately connect them all together

The culmination of this process is a major milestone referred to as 'tape out', and marks the transition from design to fabrication

However, no thought has been given to where the components go on the chip

This is carried out using a special CAD package, driven by the floor-plan

This largely automated process places each component and routes the copper tracks that will ultimately connect them all together

The culmination of this process is a major milestone referred to as 'tape out', and marks the transition from design to fabrication

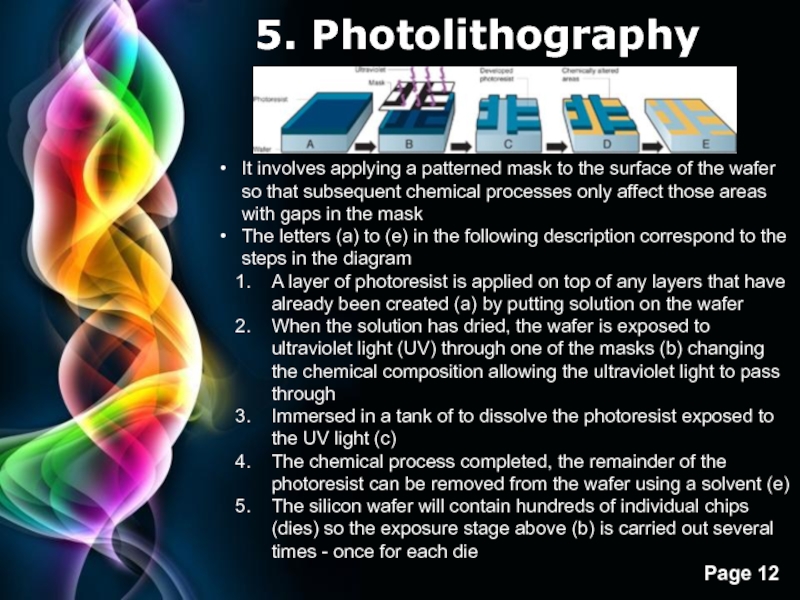

Слайд 125. Photolithography

It involves applying a patterned mask to the surface

of the wafer so that subsequent chemical processes only affect those areas with gaps in the mask

The letters (a) to (e) in the following description correspond to the steps in the diagram

A layer of photoresist is applied on top of any layers that have already been created (a) by putting solution on the wafer

When the solution has dried, the wafer is exposed to ultraviolet light (UV) through one of the masks (b) changing the chemical composition allowing the ultraviolet light to pass through

Immersed in a tank of to dissolve the photoresist exposed to the UV light (c)

The chemical process completed, the remainder of the photoresist can be removed from the wafer using a solvent (e)

The silicon wafer will contain hundreds of individual chips (dies) so the exposure stage above (b) is carried out several times - once for each die

The letters (a) to (e) in the following description correspond to the steps in the diagram

A layer of photoresist is applied on top of any layers that have already been created (a) by putting solution on the wafer

When the solution has dried, the wafer is exposed to ultraviolet light (UV) through one of the masks (b) changing the chemical composition allowing the ultraviolet light to pass through

Immersed in a tank of to dissolve the photoresist exposed to the UV light (c)

The chemical process completed, the remainder of the photoresist can be removed from the wafer using a solvent (e)

The silicon wafer will contain hundreds of individual chips (dies) so the exposure stage above (b) is carried out several times - once for each die

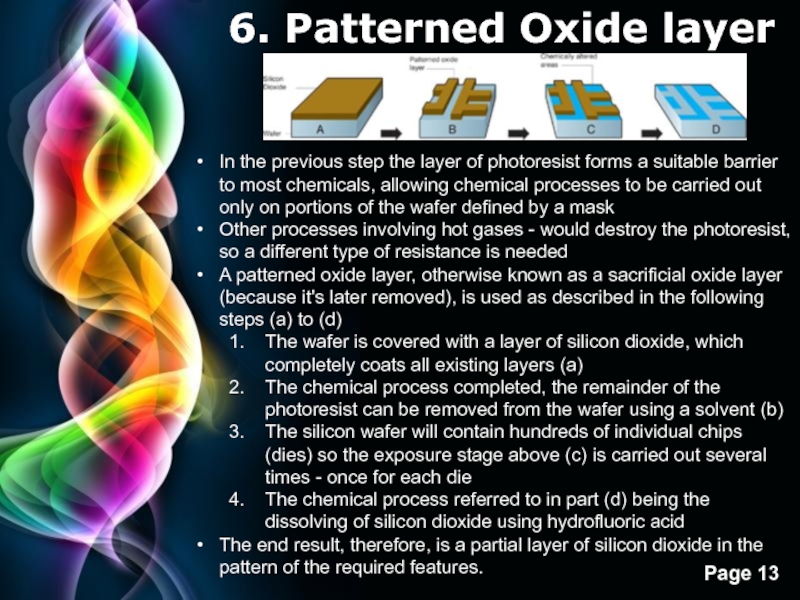

Слайд 136. Patterned Oxide layer

In the previous step the layer of

photoresist forms a suitable barrier to most chemicals, allowing chemical processes to be carried out only on portions of the wafer defined by a mask

Other processes involving hot gases - would destroy the photoresist, so a different type of resistance is needed

A patterned oxide layer, otherwise known as a sacrificial oxide layer (because it's later removed), is used as described in the following steps (a) to (d)

The wafer is covered with a layer of silicon dioxide, which completely coats all existing layers (a)

The chemical process completed, the remainder of the photoresist can be removed from the wafer using a solvent (b)

The silicon wafer will contain hundreds of individual chips (dies) so the exposure stage above (c) is carried out several times - once for each die

The chemical process referred to in part (d) being the dissolving of silicon dioxide using hydrofluoric acid

The end result, therefore, is a partial layer of silicon dioxide in the pattern of the required features.

Other processes involving hot gases - would destroy the photoresist, so a different type of resistance is needed

A patterned oxide layer, otherwise known as a sacrificial oxide layer (because it's later removed), is used as described in the following steps (a) to (d)

The wafer is covered with a layer of silicon dioxide, which completely coats all existing layers (a)

The chemical process completed, the remainder of the photoresist can be removed from the wafer using a solvent (b)

The silicon wafer will contain hundreds of individual chips (dies) so the exposure stage above (c) is carried out several times - once for each die

The chemical process referred to in part (d) being the dissolving of silicon dioxide using hydrofluoric acid

The end result, therefore, is a partial layer of silicon dioxide in the pattern of the required features.

Слайд 147. Creating the transistors

A MOSFET (the type of transistor used in

GPUs) is an electronic switch

It is an electronic component that uses a signal on one circuit to control the flow of current in another

This is the most fundamental requirement in digital electronics

Here we see how an n-channel MOSFET is created, but p-channel MOSFETs are also required.

They differ only in that one has n-type material where the other has p-type, and vice versa

It is an electronic component that uses a signal on one circuit to control the flow of current in another

This is the most fundamental requirement in digital electronics

Here we see how an n-channel MOSFET is created, but p-channel MOSFETs are also required.

They differ only in that one has n-type material where the other has p-type, and vice versa

Слайд 157. Creating the Transistors

In the following description, changes are made selectively

to parts of the wafer by use of either a layer of photoresist or a patterned oxide layer

The wafer is bombarded with phosphorous ions that implant themselves into the silicon through the gaps in the photoresist to create so-called wells of n-type material

This is a modified form of silicon that has additional electrodes to carry an electrical current

The wafer is bombarded with phosphorous ions that implant themselves into the silicon through the gaps in the photoresist to create so-called wells of n-type material

This is a modified form of silicon that has additional electrodes to carry an electrical current

Слайд 167. Creating the Transistors

Two smaller islands of p-type material are created

within the n-type wells

These form the two electrodes known as the source and the drain of the MOSFETs

Then, a very thin insulating layer of silicon dioxide, just a few molecules thick, is deposited on the surface of the silicon between the source and the drain

This is done in a furnace filled with gases to chemically modify the silicon

Finally, a layer of silicon is applied over the oxide layer to create the MOSFETs' third and final electrode, which is called the gate

These form the two electrodes known as the source and the drain of the MOSFETs

Then, a very thin insulating layer of silicon dioxide, just a few molecules thick, is deposited on the surface of the silicon between the source and the drain

This is done in a furnace filled with gases to chemically modify the silicon

Finally, a layer of silicon is applied over the oxide layer to create the MOSFETs' third and final electrode, which is called the gate

Слайд 178. Connecting Everything

We now have a wafer comprising several dies, each

of which contains billions of transistors, but to convert these from isolated components into a working circuit they have to be connected using copper tracks

First, an insulating layer of silicon dioxide is applied to the wafer so that the interconnecting tracks don't short all the MOSFETs together

Next, holes are etched in the silicon dioxide so that connections can be made to the MOSFETs' electrodes

Then, trenches in the shape of the tracks are etched into the silicon dioxide before a layer of copper is applied by electro-plating

First, an insulating layer of silicon dioxide is applied to the wafer so that the interconnecting tracks don't short all the MOSFETs together

Next, holes are etched in the silicon dioxide so that connections can be made to the MOSFETs' electrodes

Then, trenches in the shape of the tracks are etched into the silicon dioxide before a layer of copper is applied by electro-plating

Слайд 188. Connecting Everything

This covers the entire surface of the silicon dioxide,

and fills the trenches and the holes to make contact with the MOSFETs.

Finally, the excess copper is removed using a process called chemical-mechanical polishing so that copper only remains in the trenches and holes

A single layer of copper interconnections isn't enough to create a viable circuit

it isn't possible to connect everything in a single layer without making shorts, additional layers are used, each created in the same way as the first copper layer

Increasing the number of layers can reduce the size of the chip, and some layers have to be dedicated to providing power, so ten or more layers isn't unusual in top-end chips.

Finally, the excess copper is removed using a process called chemical-mechanical polishing so that copper only remains in the trenches and holes

A single layer of copper interconnections isn't enough to create a viable circuit

it isn't possible to connect everything in a single layer without making shorts, additional layers are used, each created in the same way as the first copper layer

Increasing the number of layers can reduce the size of the chip, and some layers have to be dedicated to providing power, so ten or more layers isn't unusual in top-end chips.

Слайд 199. Testing

The initial manufacturing processes are now complete to the extent

that the wafer will contain several hundred dies

next is to test the dies one at a time, this is carried out using a sophisticated piece of equipment called a wafer prober, which makes electrical contact with microscopic pads on the dies

In this fully automated process, the machine remembers which of the dies passed the test

Typically, for a state-of-the-art chip, the yield is in the 50-60% area

next is to test the dies one at a time, this is carried out using a sophisticated piece of equipment called a wafer prober, which makes electrical contact with microscopic pads on the dies

In this fully automated process, the machine remembers which of the dies passed the test

Typically, for a state-of-the-art chip, the yield is in the 50-60% area

Слайд 2010. Packaging

Once testing is complete, the wafer is sawn up

into individual dies and the non-functional ones are discarded

The final step is to take the working dies - tiny rectangles of silicon that are far too flimsy to be used as regular electronic components - and package them into what most people think of as a chip, ready to be soldered onto a circuit board

This involves bonding the die onto a substrate, and making connections between the minuscule pads on the die and the somewhat larger solder bumps that will eventually be used to make the electrical connections on a graphics card

A final functional test is carried out to ensure that the packing has been successful, and this miracle of digital technology is then ready to be shipped to the graphics card manufacturing facility

The final step is to take the working dies - tiny rectangles of silicon that are far too flimsy to be used as regular electronic components - and package them into what most people think of as a chip, ready to be soldered onto a circuit board

This involves bonding the die onto a substrate, and making connections between the minuscule pads on the die and the somewhat larger solder bumps that will eventually be used to make the electrical connections on a graphics card

A final functional test is carried out to ensure that the packing has been successful, and this miracle of digital technology is then ready to be shipped to the graphics card manufacturing facility