- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Sum3D - premilled guide презентация

Содержание

- 1. Sum3D - premilled guide

- 2. EQUIPMENT MANAGEMENT (.EQP) PREMILLED MANAGEMENT (.BLK)

- 3. EQUIPMENT (.EQP)

- 4. The equipment defines: How many “premilled

- 7. IMPORTANT The CYLINDER_POSITION curve must

- 8. IMPORTANT After the cam file

- 9. IMPORTANT The CYLINDER_POSITION curve also

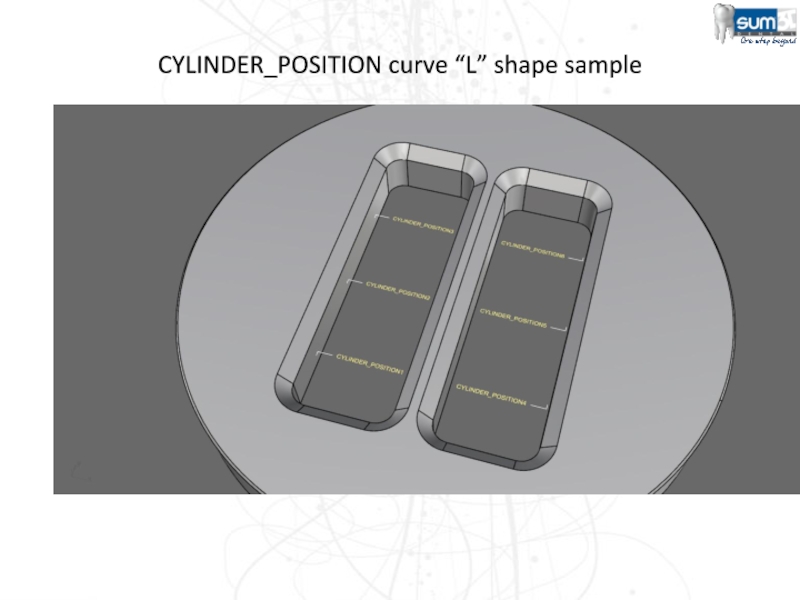

- 10. CYLINDER_POSITION curve “L” shape sample

- 11. PREMILLED CYLINDER (.BLK)

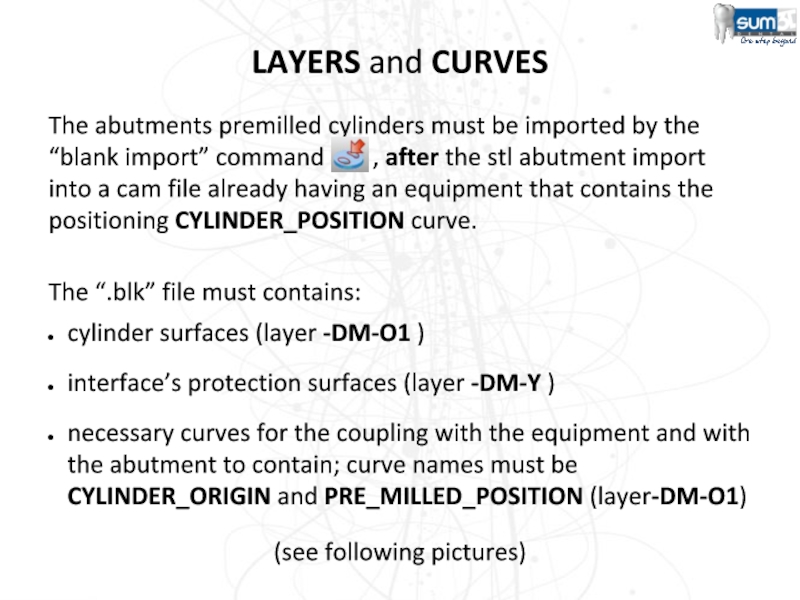

- 12. LAYERS and CURVES The abutments premilled

- 16. CYLINDER_ORIGIN e PRE_MILLED_POSITION For both

- 17. PRE_MILLED_PHASE Previous picture also show an

- 19. IMPORTANT The PRE_MILLED_PHASE curve must

- 20. Contact us CIMSYSTEM s.r.l. Via Monfalcone, 3

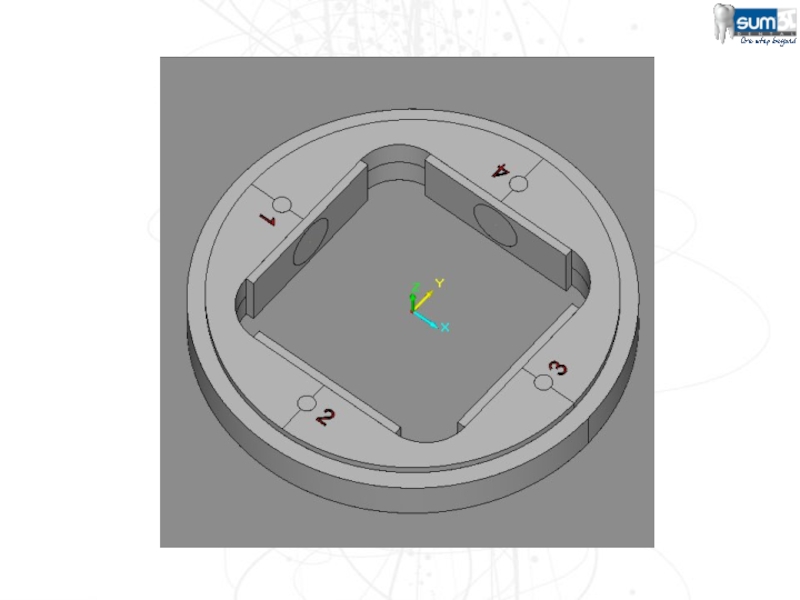

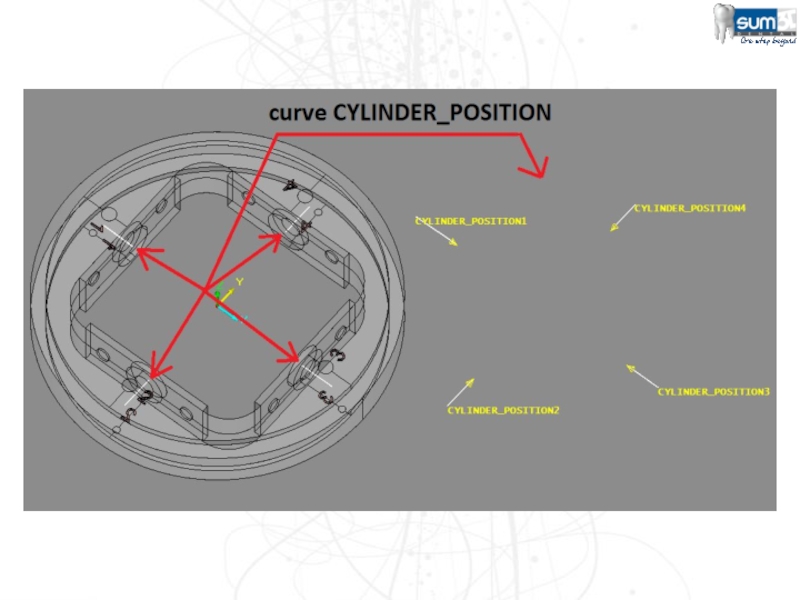

Слайд 4The equipment defines:

How many “premilled cylinders” is possible to insert in

the equipment

“premilled cylinders” positioning

In order to manage that, the equipment must contains the curve

(or more) named CYLINDER_POSITION

In case the equipment allows to use more “premilled cylinders”,

in each position will be necessary the related

CYLINDER_POSITION1 / CYLINDER_POSITION2 /

CYLINDER_POSITION3 curves…

(see following pictures)

“premilled cylinders” positioning

In order to manage that, the equipment must contains the curve

(or more) named CYLINDER_POSITION

In case the equipment allows to use more “premilled cylinders”,

in each position will be necessary the related

CYLINDER_POSITION1 / CYLINDER_POSITION2 /

CYLINDER_POSITION3 curves…

(see following pictures)

Слайд 7IMPORTANT

The CYLINDER_POSITION curve must be placed

in the center, at median

Z of the blank that will be

Imported.

The CYLINDER_POSITION curve must be contained into

the –DM-clamps layer.

Imported.

The CYLINDER_POSITION curve must be contained into

the –DM-clamps layer.

Слайд 8IMPORTANT

After the cam file creation and the following automatic

equipment

loading (thanks to the postprocessor’s customization

code LOADEQP), the blank’s “hook” will be applied on the

CYLINDER_POSITION curve’s end.

Take care to the curve’s direction!

If that entity has an opposite direction than the requested one,

the imported blank will be placed on the opposite side of the

curve, that is on a wrong point!

No matter the curve’s length, important is its ending point.

code LOADEQP), the blank’s “hook” will be applied on the

CYLINDER_POSITION curve’s end.

Take care to the curve’s direction!

If that entity has an opposite direction than the requested one,

the imported blank will be placed on the opposite side of the

curve, that is on a wrong point!

No matter the curve’s length, important is its ending point.

Слайд 9IMPORTANT

The CYLINDER_POSITION curve also could have an “L” shape**.

In

that way, in addition to define the “premilled cylinder”

positioning, it will be even possible to properly orientate an

abutment having an interface with at least one planar surface

(antirotational) – for instance an hexagonal interface – in order

to align an interface’s planar surface to the “L”

CYLINDER_POSITION curve.

** Geometrically, the ends of the two segments of the "L" define three points ... and these three points go to define just one plane (having only one defined and unambiguous angle). For that reason the planar face of the interface will be well aligned according to the same angle of the curve "L".

positioning, it will be even possible to properly orientate an

abutment having an interface with at least one planar surface

(antirotational) – for instance an hexagonal interface – in order

to align an interface’s planar surface to the “L”

CYLINDER_POSITION curve.

** Geometrically, the ends of the two segments of the "L" define three points ... and these three points go to define just one plane (having only one defined and unambiguous angle). For that reason the planar face of the interface will be well aligned according to the same angle of the curve "L".

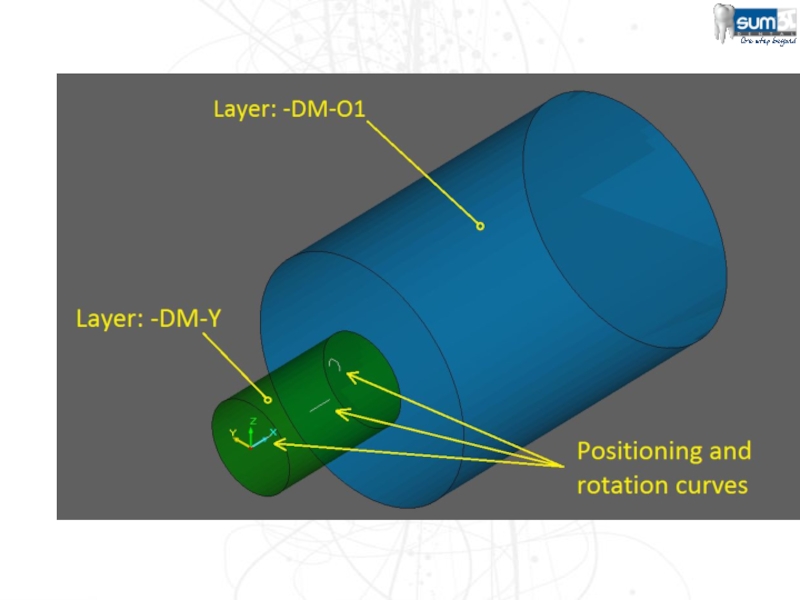

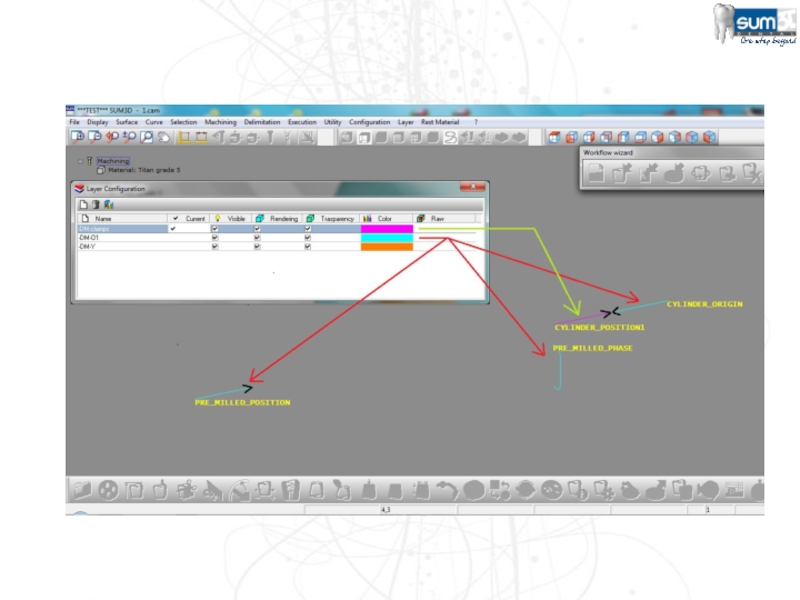

Слайд 12LAYERS and CURVES

The abutments premilled cylinders must be imported by the

“blank import” command , after the stl abutment import

into a cam file already having an equipment that contains the

positioning CYLINDER_POSITION curve.

The “.blk” file must contains:

cylinder surfaces (layer -DM-O1 )

interface’s protection surfaces (layer -DM-Y )

necessary curves for the coupling with the equipment and with the abutment to contain; curve names must be CYLINDER_ORIGIN and PRE_MILLED_POSITION (layer-DM-O1)

(see following pictures)

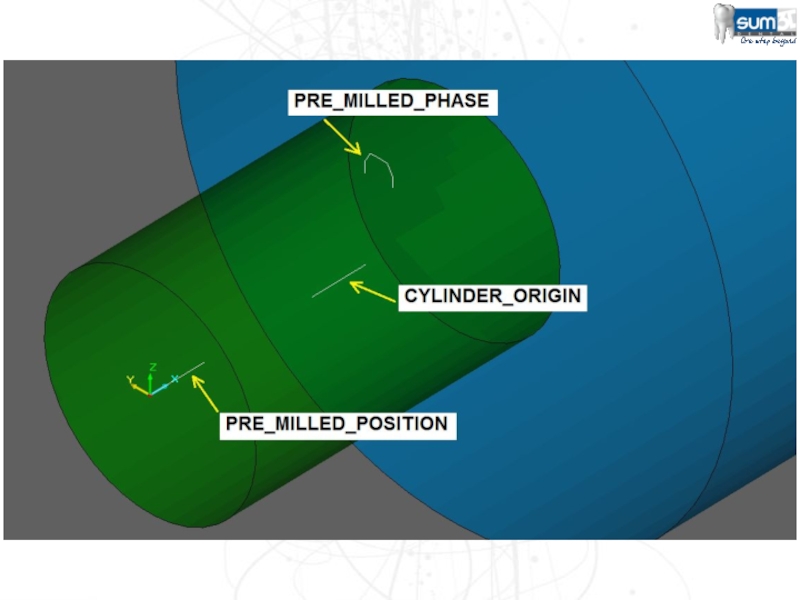

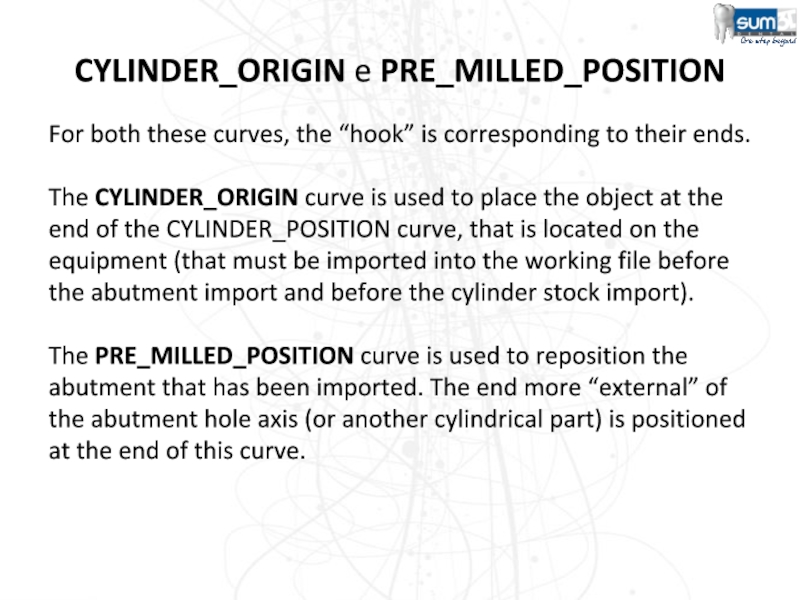

Слайд 16CYLINDER_ORIGIN e PRE_MILLED_POSITION

For both these curves, the “hook” is corresponding

to their ends.

The CYLINDER_ORIGIN curve is used to place the object at the end of the CYLINDER_POSITION curve, that is located on the equipment (that must be imported into the working file before the abutment import and before the cylinder stock import).

The PRE_MILLED_POSITION curve is used to reposition the abutment that has been imported. The end more “external” of the abutment hole axis (or another cylindrical part) is positioned at the end of this curve.

The CYLINDER_ORIGIN curve is used to place the object at the end of the CYLINDER_POSITION curve, that is located on the equipment (that must be imported into the working file before the abutment import and before the cylinder stock import).

The PRE_MILLED_POSITION curve is used to reposition the abutment that has been imported. The end more “external” of the abutment hole axis (or another cylindrical part) is positioned at the end of this curve.

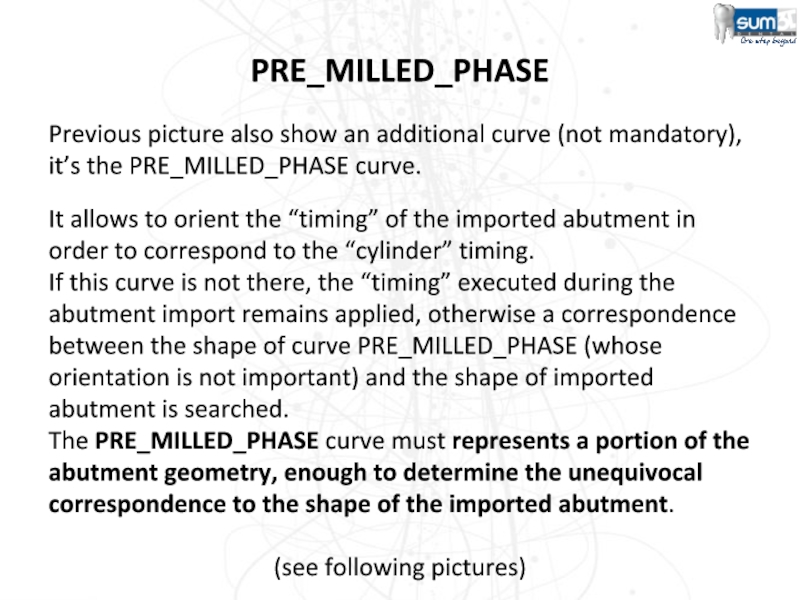

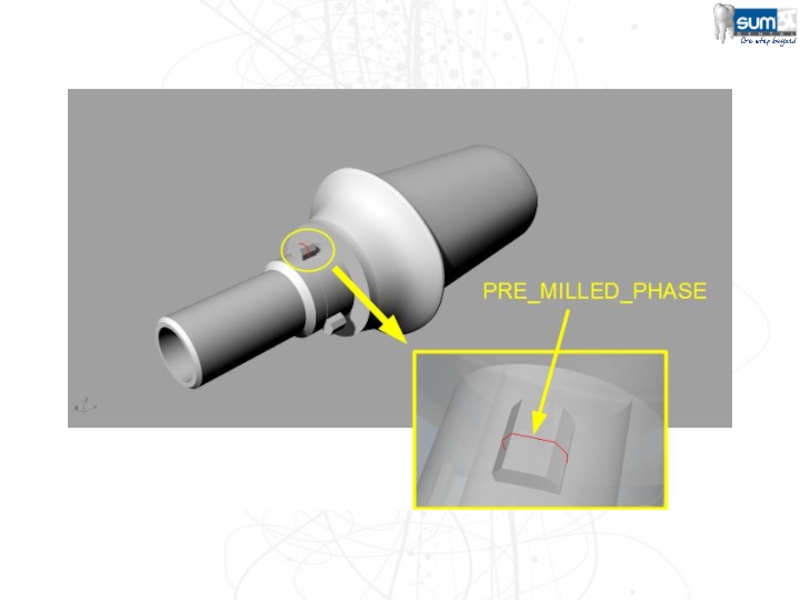

Слайд 17PRE_MILLED_PHASE

Previous picture also show an additional curve (not mandatory), it’s the

PRE_MILLED_PHASE curve.

It allows to orient the “timing” of the imported abutment in order to correspond to the “cylinder” timing.

If this curve is not there, the “timing” executed during the abutment import remains applied, otherwise a correspondence between the shape of curve PRE_MILLED_PHASE (whose orientation is not important) and the shape of imported abutment is searched.

The PRE_MILLED_PHASE curve must represents a portion of the abutment geometry, enough to determine the unequivocal correspondence to the shape of the imported abutment.

(see following pictures)

It allows to orient the “timing” of the imported abutment in order to correspond to the “cylinder” timing.

If this curve is not there, the “timing” executed during the abutment import remains applied, otherwise a correspondence between the shape of curve PRE_MILLED_PHASE (whose orientation is not important) and the shape of imported abutment is searched.

The PRE_MILLED_PHASE curve must represents a portion of the abutment geometry, enough to determine the unequivocal correspondence to the shape of the imported abutment.

(see following pictures)

Слайд 19IMPORTANT

The PRE_MILLED_PHASE curve must be positioned in same area

in which

the corresponding part to be coupled (it’s into stl file to

import) will be placed, in order to be able to determine the

unambiguous correspondence with the shape of the imported

abutment.

If that curve were to be placed in a not correct point, a

"matching error" message will appears during the blank import

(cylinder premilled. "blk").

import) will be placed, in order to be able to determine the

unambiguous correspondence with the shape of the imported

abutment.

If that curve were to be placed in a not correct point, a

"matching error" message will appears during the blank import

(cylinder premilled. "blk").

Слайд 20Contact us

CIMSYSTEM s.r.l.

Via Monfalcone, 3

20092 Cinisello Balsamo (MI) Italy

Phone +39 02

87213185

Fax +39 02 6129306

Web Site: www.sum3ddental.com

www.cimsystem.com

www.rhinoplugins.com

Technical Support : support@cimsystem.com

Fax +39 02 6129306

Web Site: www.sum3ddental.com

www.cimsystem.com

www.rhinoplugins.com

Technical Support : support@cimsystem.com