- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Rigsite for LWD. (Lesson 11) презентация

Содержание

- 1. Rigsite for LWD. (Lesson 11)

- 2. Depth Measurement All LWD data depend on

- 3. Depth Measurement Process Computer Depth sensors data are processed and added to the T/D dataset

- 4. Types of Failure or Error Mechanical failure

- 5. Accurate Depth Monitoring Vigilance catches depth errors

- 6. Time/Depth Datasets Entries in the time/depth dataset

- 7. Time/Depth Dataset

- 8. Activating the Depth Monitor If the icon

- 9. Depth Monitor

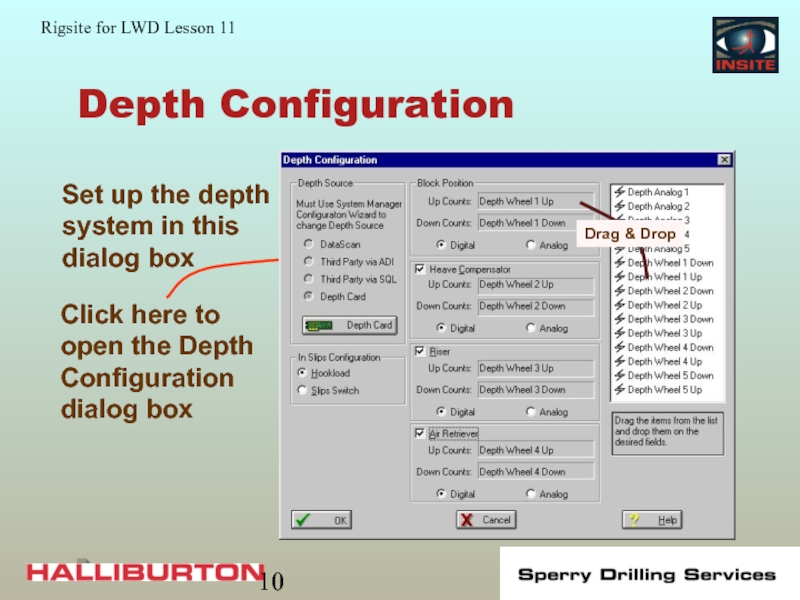

- 10. Depth Configuration

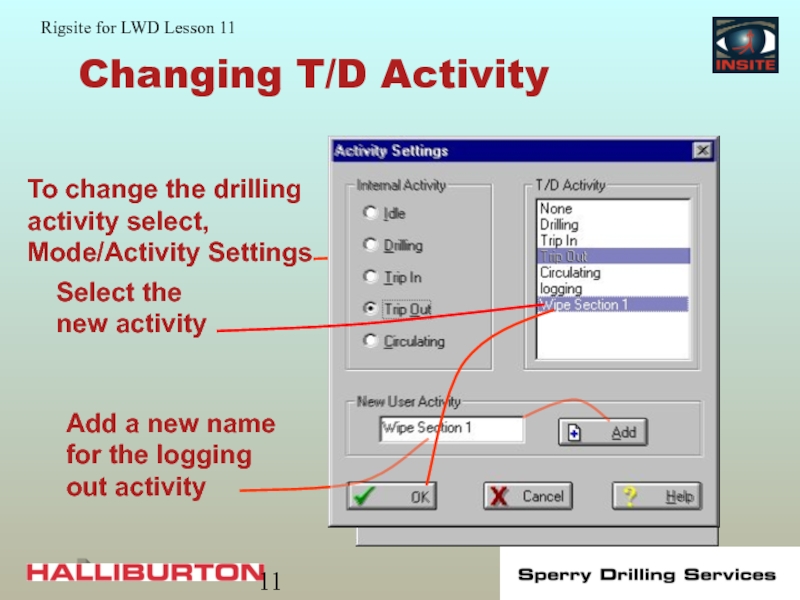

- 11. Changing T/D Activity

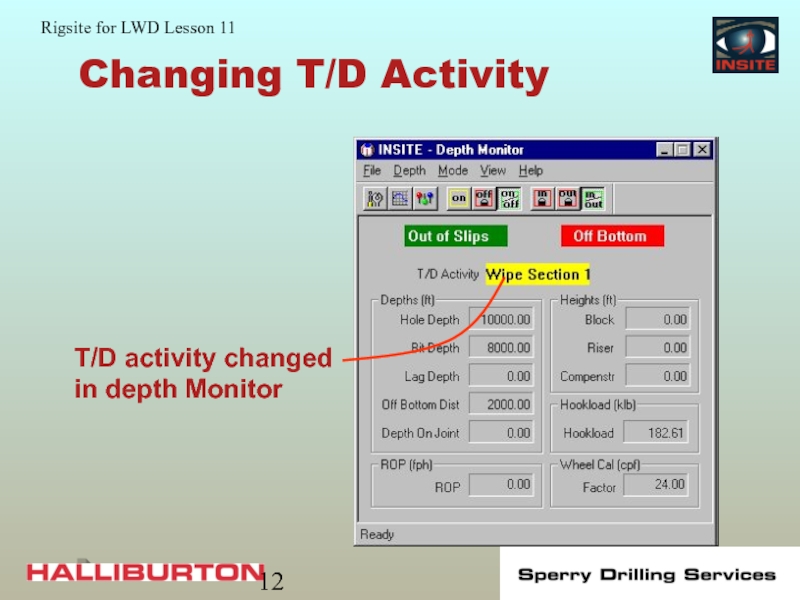

- 12. Changing T/D Activity

- 13. Logging Out of the Hole Set a

- 14. Surface Sensors Accurate calibration and reliable operation

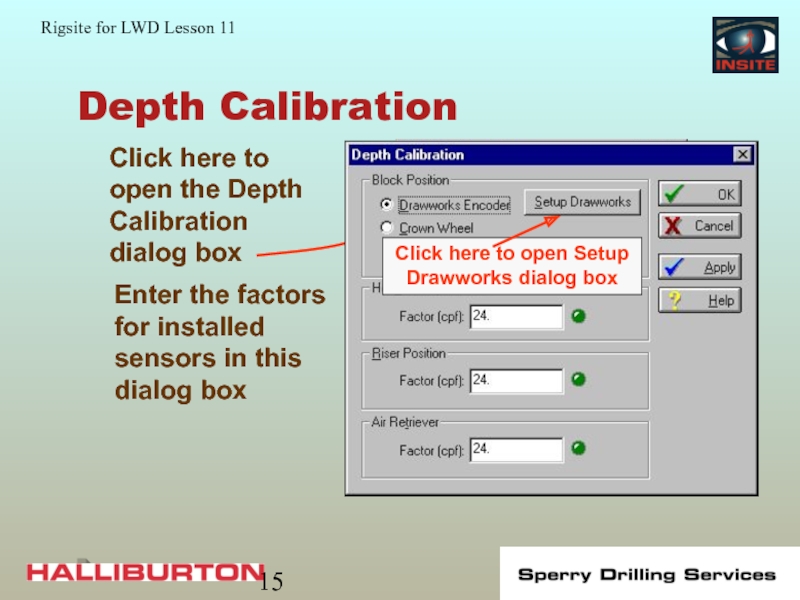

- 15. Depth Calibration Enter the factors for installed sensors in this dialog box

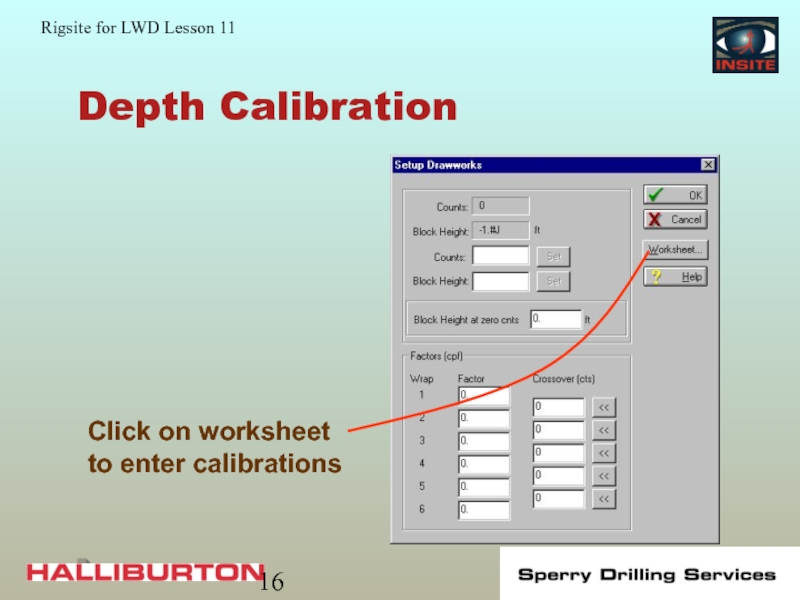

- 16. Depth Calibration

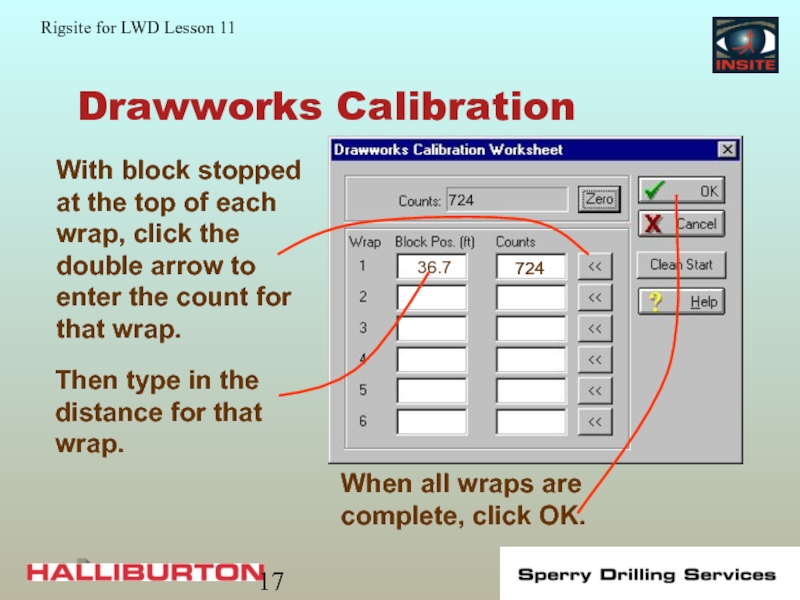

- 17. Drawworks Calibration

- 18. Drawworks Calibration

- 19. Pipe Tally Sheet Copy the pipe joint

- 20. Using the Pipe Tally Sheet

- 21. Depth Control Review Importance of depth monitoring

- 22. Sources of Depth Errors Incorrect entry in

- 23. Incorrect Entry in Tally Sheet First, check

- 24. Driller Used Pipe Out of Order The

- 25. Pipe Used Out of Order Depth drilled

- 26. Inconsistent Kelly Down Drilled depth does not

- 27. Inconsistent Kelly Down

- 28. Depth Calibration Error Same error showing up

- 29. Calibration Error Measurement Error - 0.58 ft

- 30. On Bottom Early Spike in the ROP

- 31. On Bottom Early 6.11 ft hole depth error

- 32. On Bottom Late Caused by Less compression

- 33. On Bottom Late

- 34. Crown Wheel Slipping Most likely to slip

- 35. Crown Wheel Slipping Measurement Error - 0.58

- 36. Time/Depth Editor Functions Find Expand and compress

- 37. Editing the Time/Depth Dataset Always back up

- 38. T/D Editor

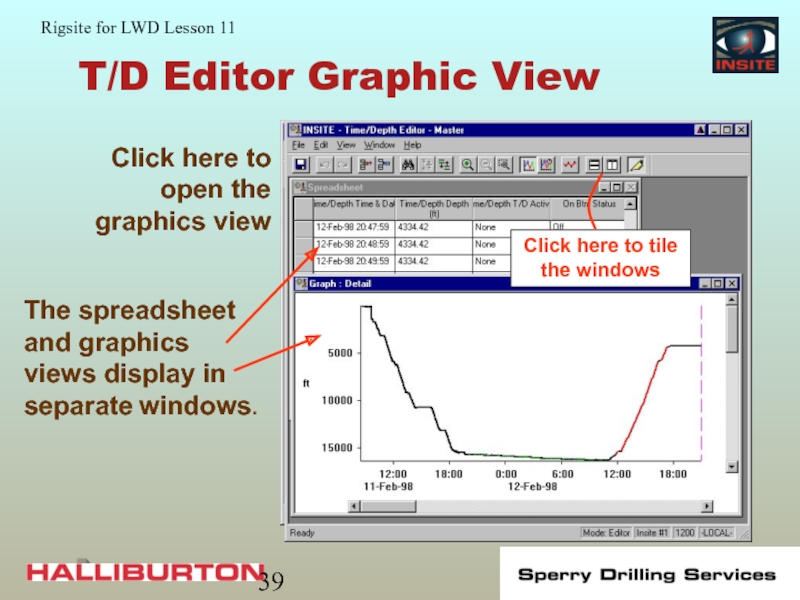

- 39. T/D Editor Graphic View

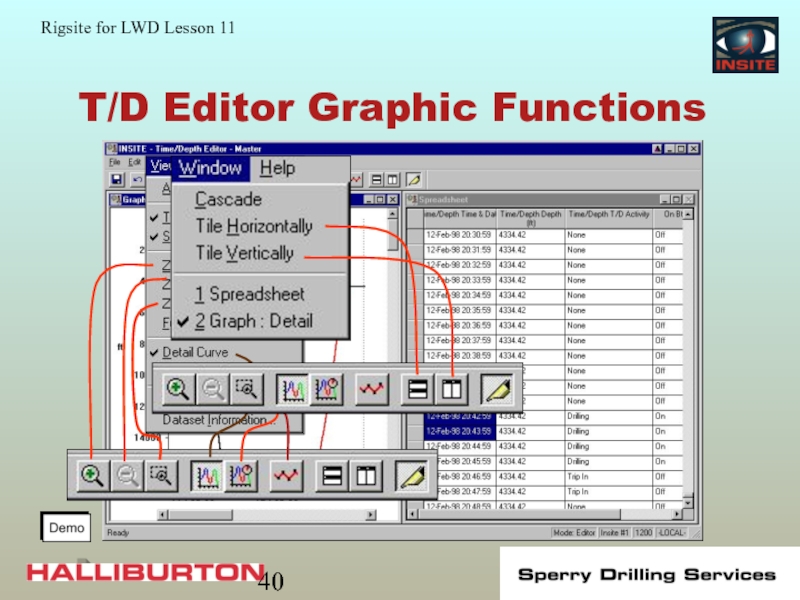

- 40. T/D Editor Graphic Functions

- 41. Time/Depth Review Sources of depth error Time/Depth

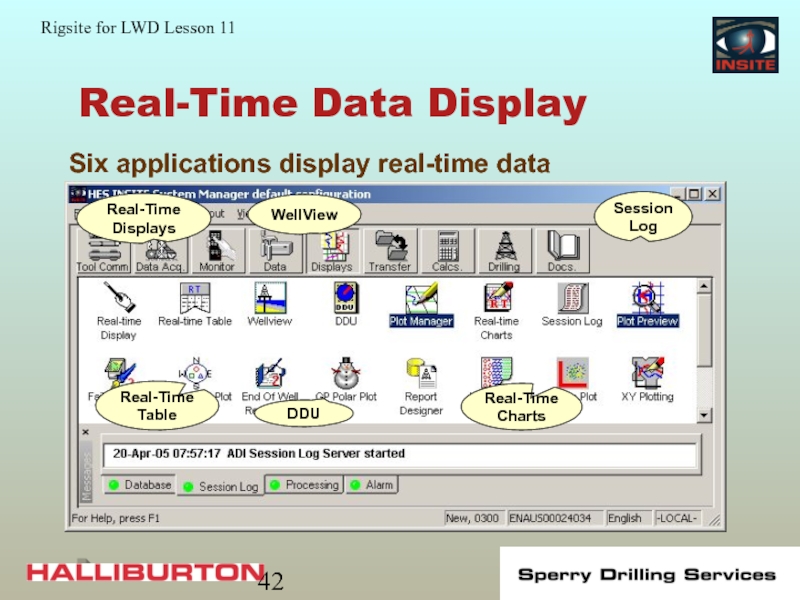

- 42. Real-Time Data Display Six applications display real-time

- 43. Real-Time Displays Real-time displays are customized for

- 44. Real-Time Setup Files Applications with real-time displays

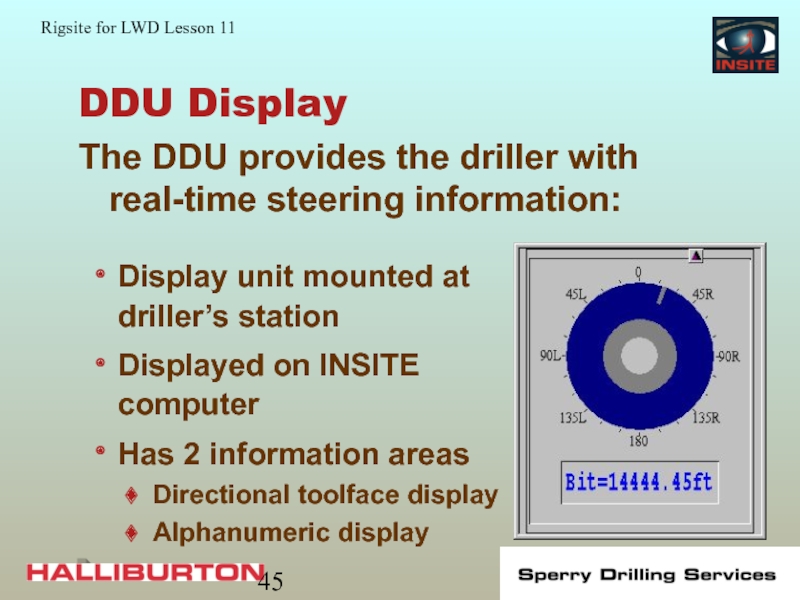

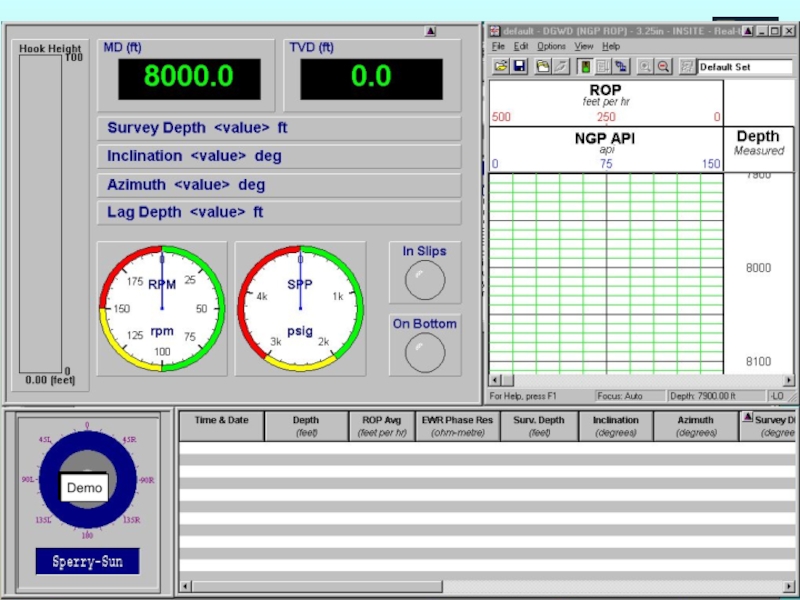

- 45. DDU Display The DDU provides the driller

- 46. Real-Time Table Real-time tables are customized for

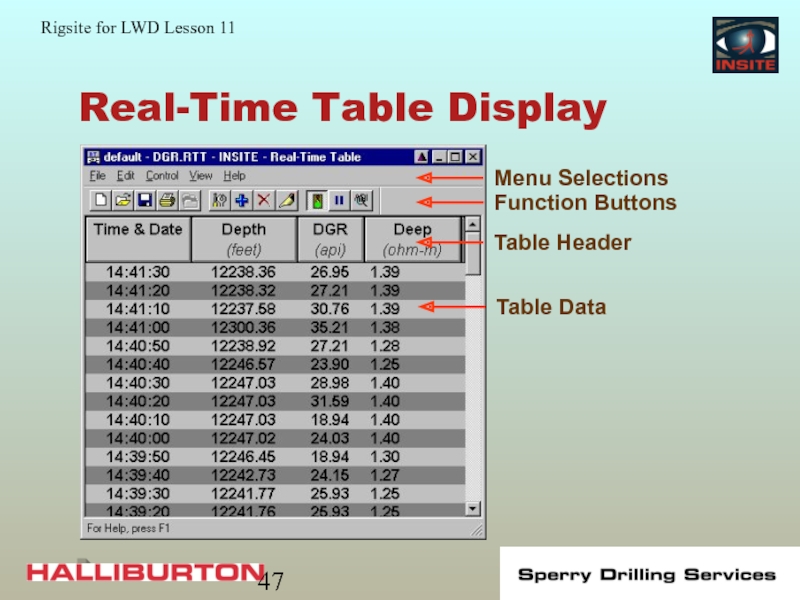

- 47. Real-Time Table Display

- 48. Real-Time Charts Real-time Charts: X,Y plot or

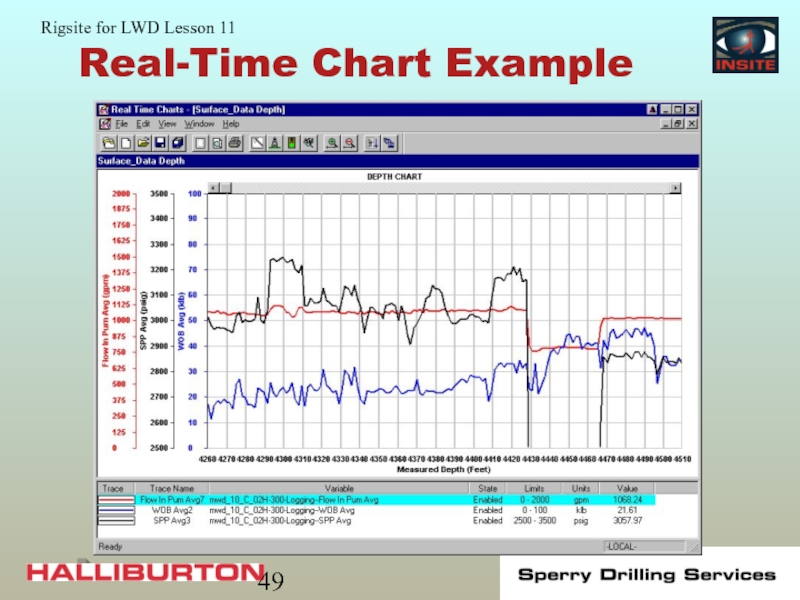

- 49. Real-Time Chart Example

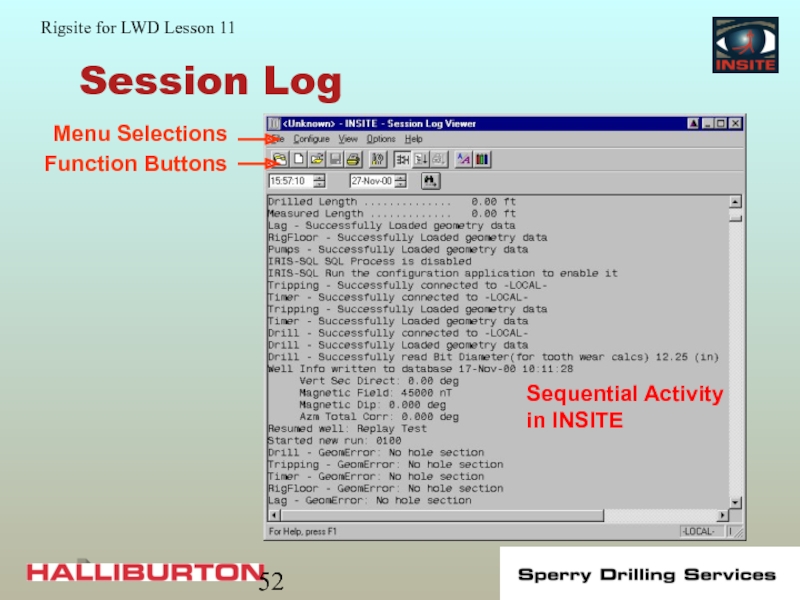

- 50. Session Log Record of all information received

- 51. Session Log continued Realtime or historical mode

- 52. Session Log Sequential Activity in INSITE

- 53. WellView WellView is a graphic presentation of

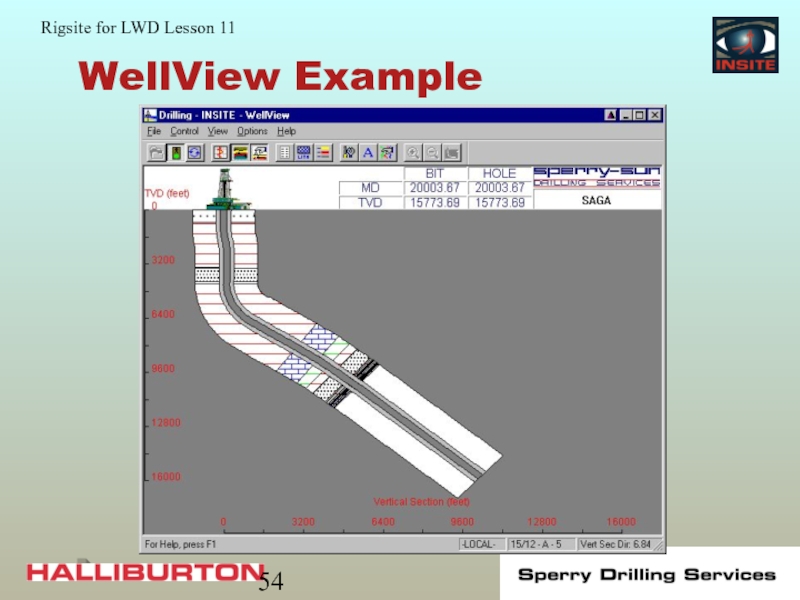

- 54. WellView Example

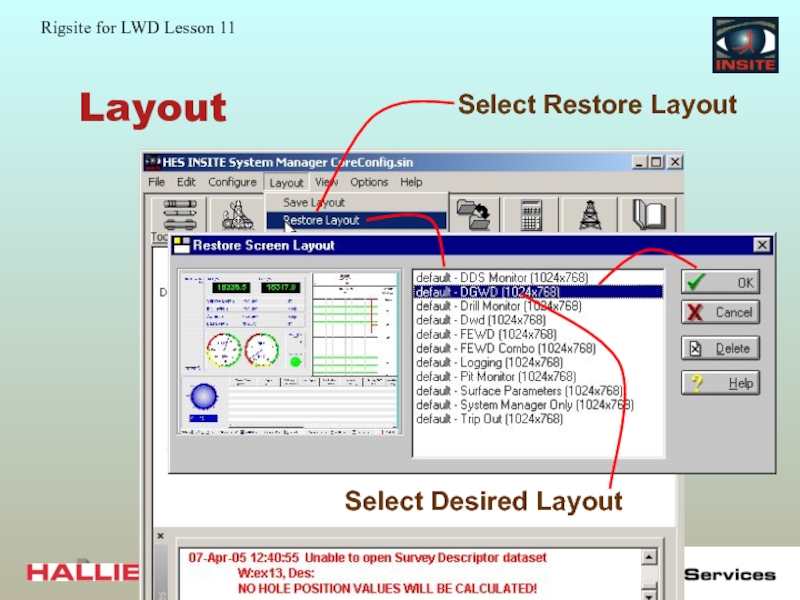

- 55. Layout Layout provides a set up of

- 56. Layout

- 57. Layout

- 58. Real-time Display Review DDU Tables Plots Session log Layout

- 59. End of Lesson 11

Слайд 2Depth Measurement

All LWD data depend on accurate depth measurements.

Accurate depth

Слайд 3Depth Measurement Process

Computer

Depth sensors data are processed and added to the

Слайд 4Types of Failure or Error

Mechanical failure

Software failure

Human Error

Three possible ways to

Слайд 5Accurate Depth Monitoring

Vigilance catches depth errors at each connection

Vigilance catches on/off

Maintaining an accurate time/depth dataset requires constant vigilance:

Vigilance produces an accurate time/depth dataset.

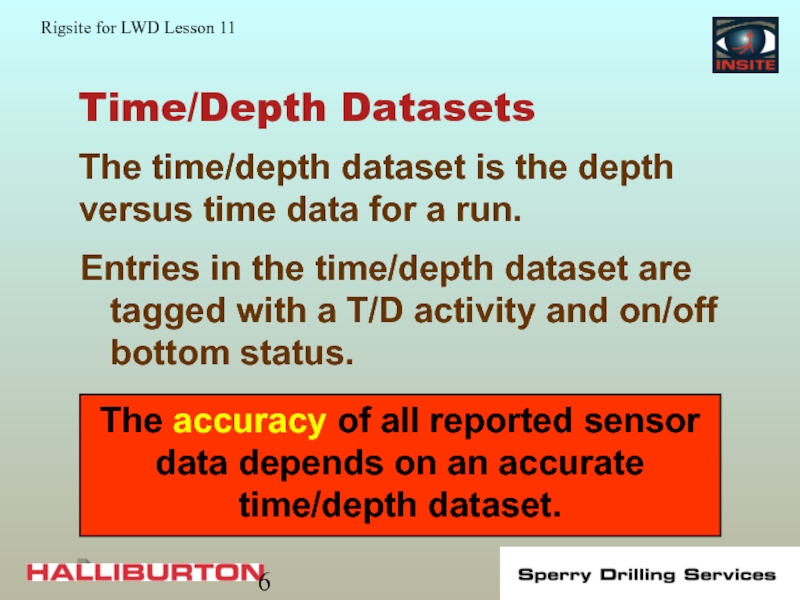

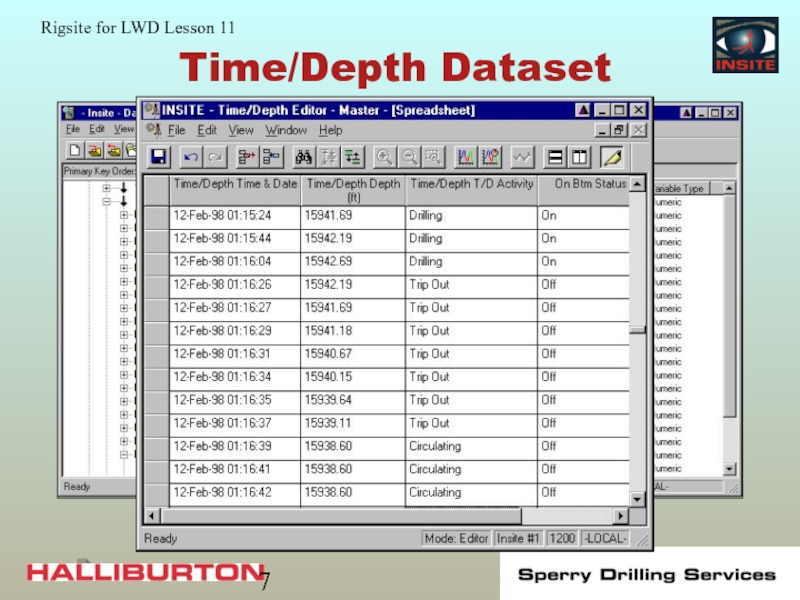

Слайд 6Time/Depth Datasets

Entries in the time/depth dataset are tagged with a T/D

The time/depth dataset is the depth versus time data for a run.

The accuracy of all reported sensor data depends on an accurate time/depth dataset.

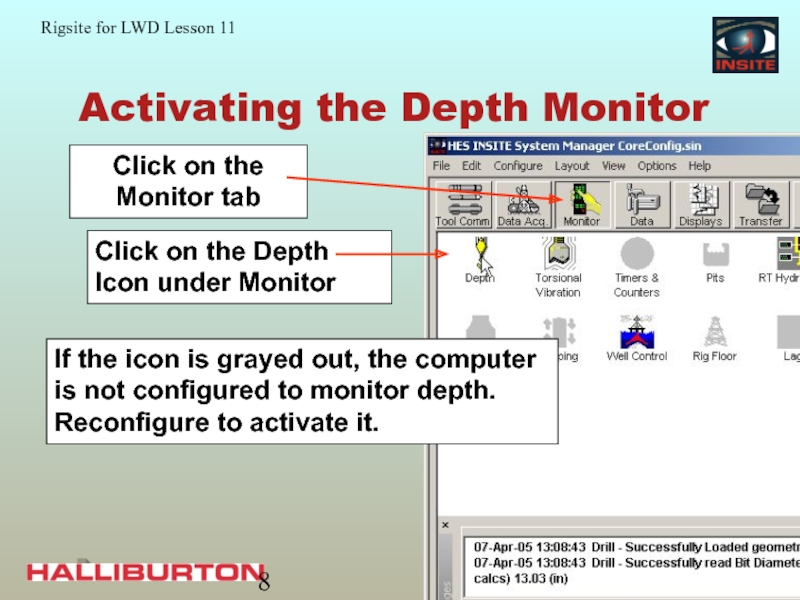

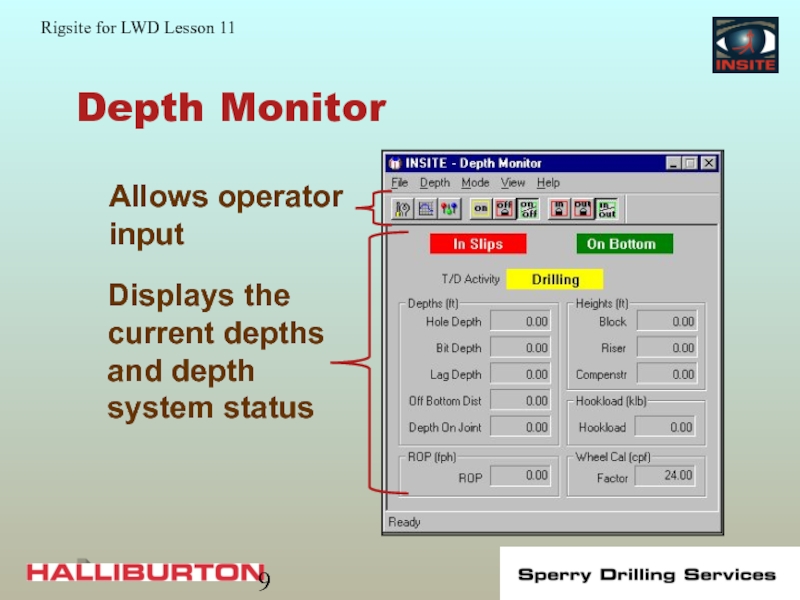

Слайд 8Activating the Depth Monitor

If the icon is grayed out, the computer

Слайд 13Logging Out of the Hole

Set a new T/D activity in the

Used until changed by the operator

Any named T/D activity must reflect professional standards

To identify wipe section data, it must be tagged with a unique T/D activity :

Слайд 14Surface Sensors

Accurate calibration and reliable operation of surface sensors are critical

Слайд 19Pipe Tally Sheet

Copy the pipe joint lengths from the driller's pipe

Use the tally sheet to keep a master record of hole depth

The Driller’s pipe tally is the final authority on well depth:

An accurate time/depth record is vital to the LWD job.

Слайд 21Depth Control Review

Importance of depth monitoring

T/D dataset

Depth monitor

Depth configuration

Depth calibration

Pipe tally

Слайд 22Sources of Depth Errors

Incorrect entry in tally sheet

Driller used pipe out

Not drilling to same spot on kelly

Depth sensor slipping

Depth calibration error

Inaccurate on/off bottom

The most common causes of depth error are:

Слайд 23Incorrect Entry in Tally Sheet

First, check for errors in the tally

Possible sources of error in the tally sheet

Incorrect addition

Transposed numbers

Entries out of order

When there is a difference between the IDMS depth and the tally sheet:

Слайд 24Driller Used Pipe Out of Order

The depth differences will even out

Size of the depth difference depends on difference in length between connections

Get the order used (if known) and make the changes in the tally sheet

When the driller picked up pipe in an order different from the tally book:

Слайд 25Pipe Used Out of Order

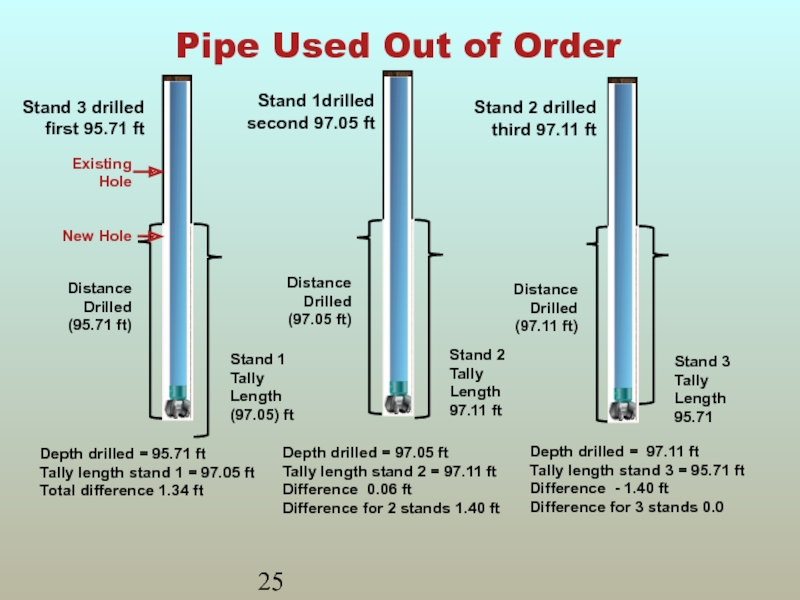

Depth drilled = 95.71 ft

Tally length stand

Total difference 1.34 ft

Depth drilled = 97.05 ft

Tally length stand 2 = 97.11 ft

Difference 0.06 ft

Difference for 2 stands 1.40 ft

Depth drilled = 97.11 ft

Tally length stand 3 = 95.71 ft

Difference - 1.40 ft

Difference for 3 stands 0.0

Слайд 26Inconsistent Kelly Down

Drilled depth does not equal the length of the

IDMS depth does not match the tally book

Depth differences vary from stand to stand

Depth differences even out as drilling continues

If the driller does not drill to the same spot on the kelly each time:

Слайд 28Depth Calibration Error

Same error showing up on each stand is a

A small error may require several stands to become apparent

Correction for this error is to recalibrate the sensor

Calibration errors show up as a consistent gain or loss of depth:

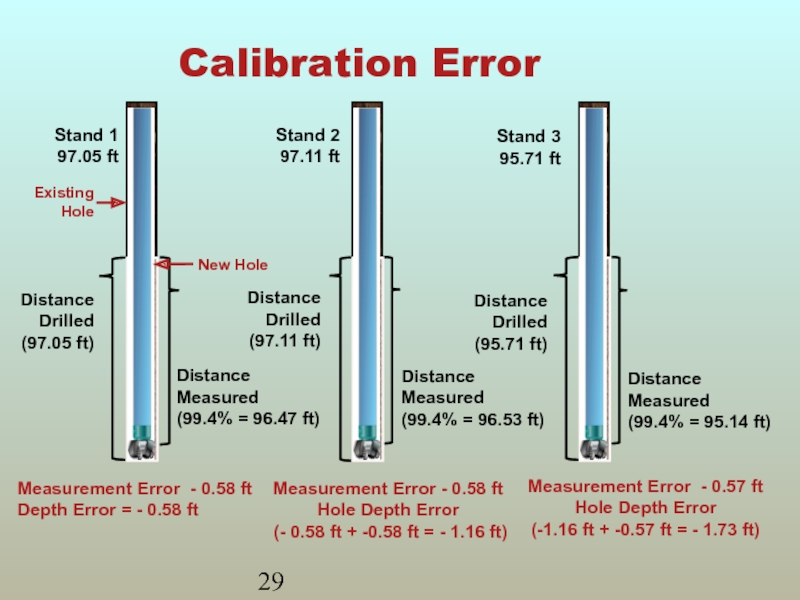

Слайд 29Calibration Error

Measurement Error - 0.58 ft

Depth Error = - 0.58 ft

Measurement

(- 0.58 ft + -0.58 ft = - 1.16 ft)

Measurement Error - 0.57 ft

Hole Depth Error

(-1.16 ft + -0.57 ft = - 1.73 ft)

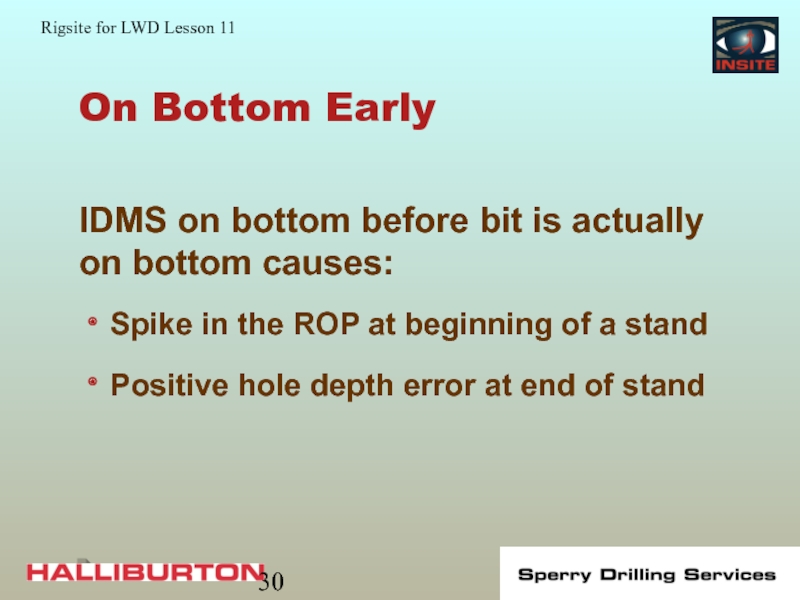

Слайд 30On Bottom Early

Spike in the ROP at beginning of a stand

Positive

IDMS on bottom before bit is actually on bottom causes:

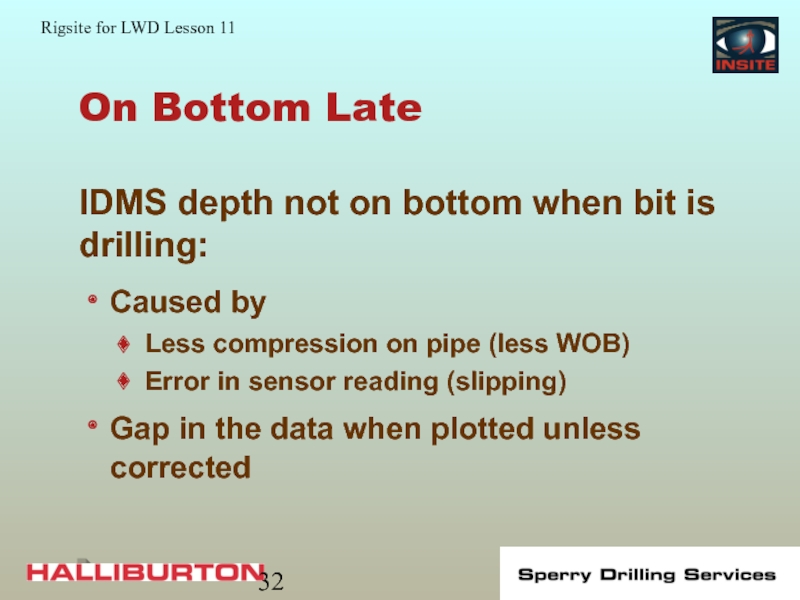

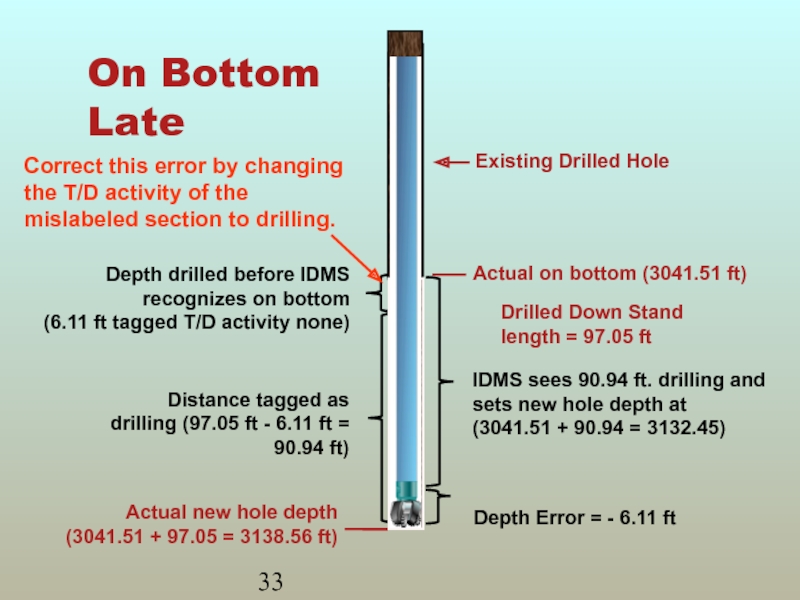

Слайд 32On Bottom Late

Caused by

Less compression on pipe (less WOB)

Error in

Gap in the data when plotted unless corrected

IDMS depth not on bottom when bit is drilling:

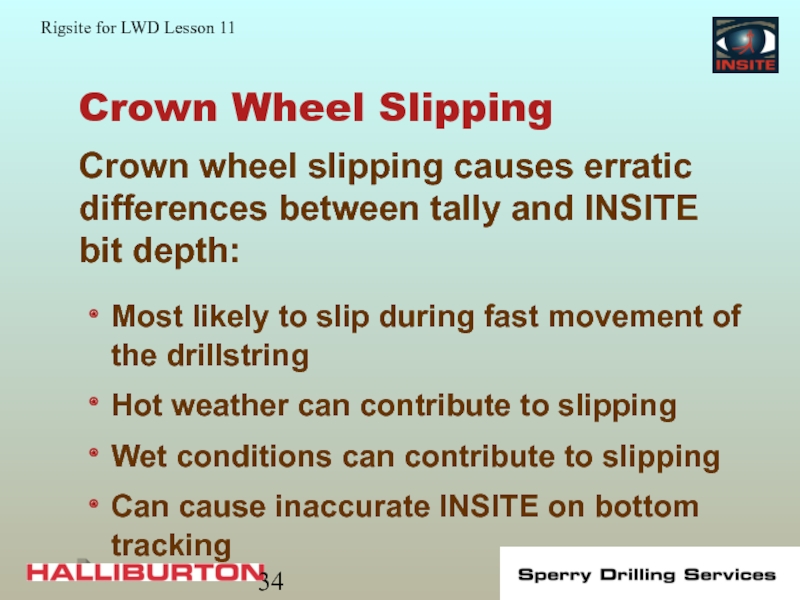

Слайд 34Crown Wheel Slipping

Most likely to slip during fast movement of the

Hot weather can contribute to slipping

Wet conditions can contribute to slipping

Can cause inaccurate INSITE on bottom tracking

Crown wheel slipping causes erratic differences between tally and INSITE bit depth:

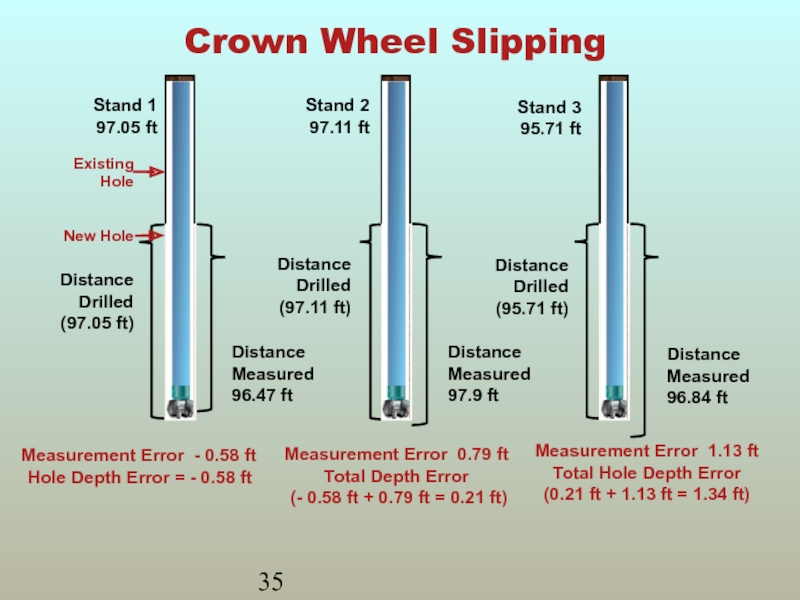

Слайд 35Crown Wheel Slipping

Measurement Error - 0.58 ft

Hole Depth Error = -

Measurement Error 0.79 ft Total Depth Error

(- 0.58 ft + 0.79 ft = 0.21 ft)

Measurement Error 1.13 ft

Total Hole Depth Error

(0.21 ft + 1.13 ft = 1.34 ft)

Слайд 36Time/Depth Editor Functions

Find

Expand and compress

Shift

Insert and append

Delete

Edit single records

Functions of the

Слайд 37Editing the Time/Depth Dataset

Always back up the Time/Depth dataset before editing.

After

Caution

Do not change the Time/Depth dataset until all other possible remedies have been tried.

Слайд 41Time/Depth Review

Sources of depth error

Time/Depth editor layout

Editing functions and when to

Graphic display

Слайд 42Real-Time Data Display

Six applications display real-time data

Real-Time Displays

WellView

Session Log

Real-Time Table

DDU

Real-Time Charts

Слайд 43Real-Time Displays

Real-time displays are customized for specific tools or situations:

Built up

Give a familiar form to the data

Display any type of data

Changes display at set limits

Saved as .rtf files in the INSITE/Data/ RTDisplay folder

Слайд 44Real-Time Setup Files

Applications with real-time displays (except DDU and WellView) can

Saved in the INSITE/Data /application folder

Opened from System Manager/Displays application set

Default and saved templates for each application can be copied to other computers

Слайд 45DDU Display

The DDU provides the driller with real-time steering information:

Display

Displayed on INSITE computer

Has 2 information areas

Directional toolface display

Alphanumeric display

Слайд 46Real-Time Table

Real-time tables are customized for specific tools or situations:

Easier to

Highlight data outside limits

Display any variable in the datasets

Saved as .rtt files in the INSITE/Data/ RTTable folder

No historical data

Слайд 48Real-Time Charts

Real-time Charts:

X,Y plot or bar chart of selected data

Used

Used more by mud loggers than LWD

Слайд 50Session Log

Record of all information received and operations performed by INSITE:

Scrolling

Each entry is time/date indexed

Provides help in troubleshooting

Viewed through System Manager/ Displays/Session Log

Слайд 51Session Log continued

Realtime or historical mode

Can view previous Session Logs

Previous Session

Session Logs can be backed up during ADI export

Слайд 53WellView

WellView is a graphic presentation of the drilling track:

Provides a visual

Memory intensive

Generally not run by LWD engineer

Run on customer workstations

Слайд 55Layout

Layout provides a set up of real-time displays:

Contains templates for different

Templates can be modified for specific job situations

Saves custom layouts

Changes layout when drilling activity changes with sequencer