- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

GM GMS overview problem solving презентация

Содержание

- 1. GM GMS overview problem solving

- 2. PROBLEM SOLVING IBC VEHICLES – STANDARD PROBLEM SOLVING PROCESS ‘7 Diamonds’

- 3. PROBLEM SOLVING What is 7 Diamonds?

- 4. Why do we need the 7 Diamonds

- 5. PROBLEM SOLVING Following the 7 Diamond process

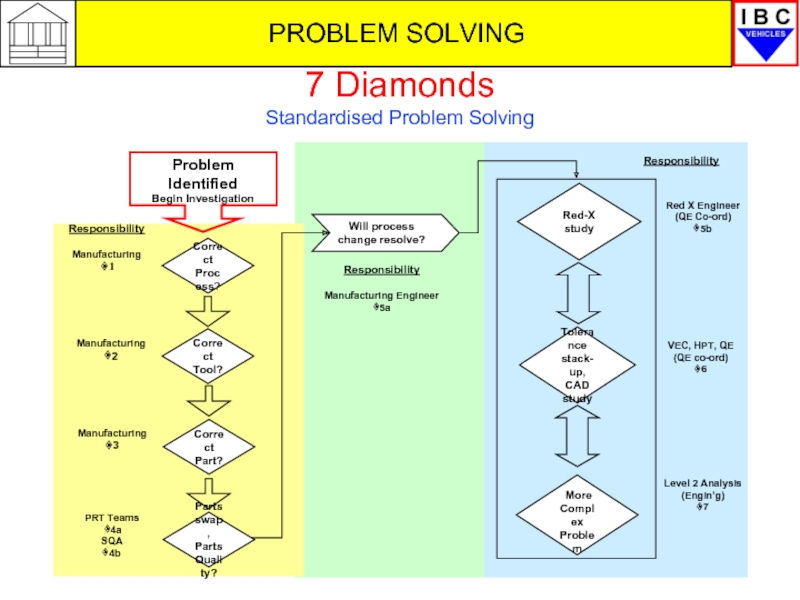

- 6. PROBLEM SOLVING 7 Diamonds Standardised Problem Solving

- 7. PROBLEM SOLVING Review

- 8. PROBLEM SOLVING Diamonds 1

- 9. PROBLEM SOLVING

- 10. PROBLEM SOLVING Diamonds 1-3 Review

- 11. PROBLEM SOLVING PCB – Problem Communication Brief

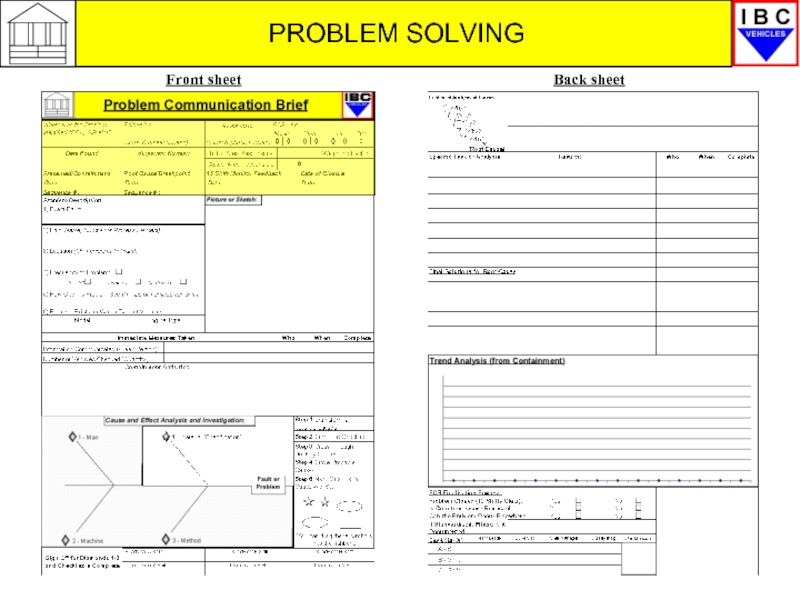

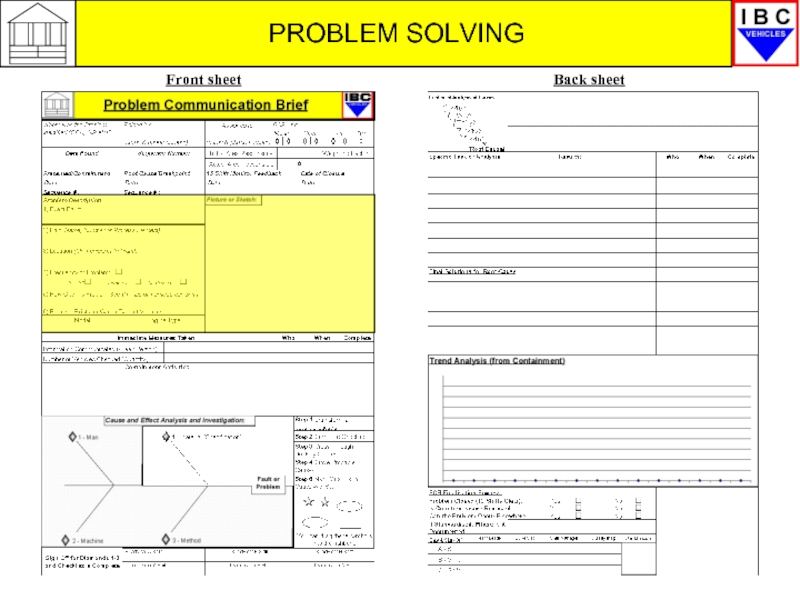

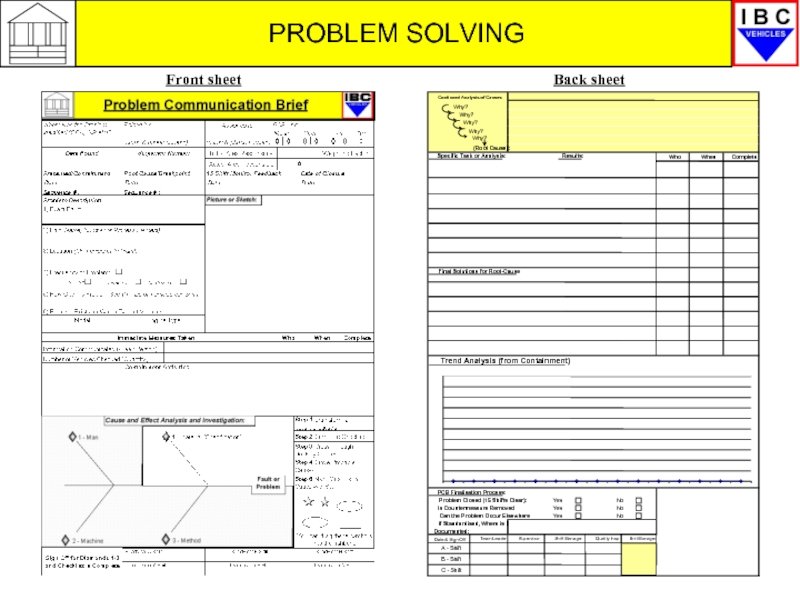

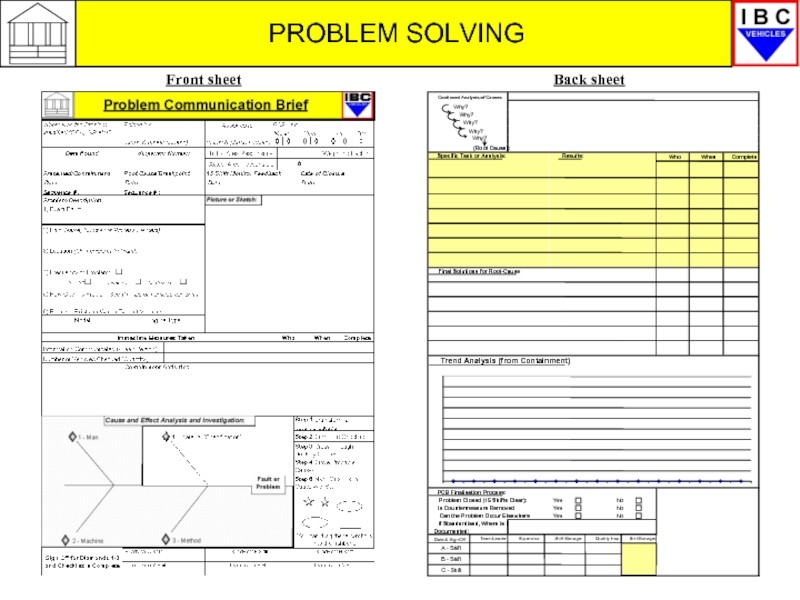

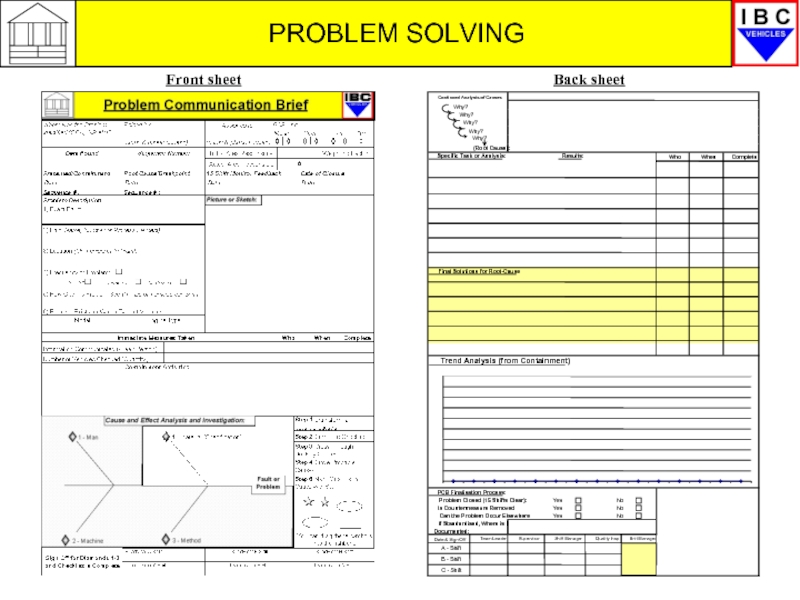

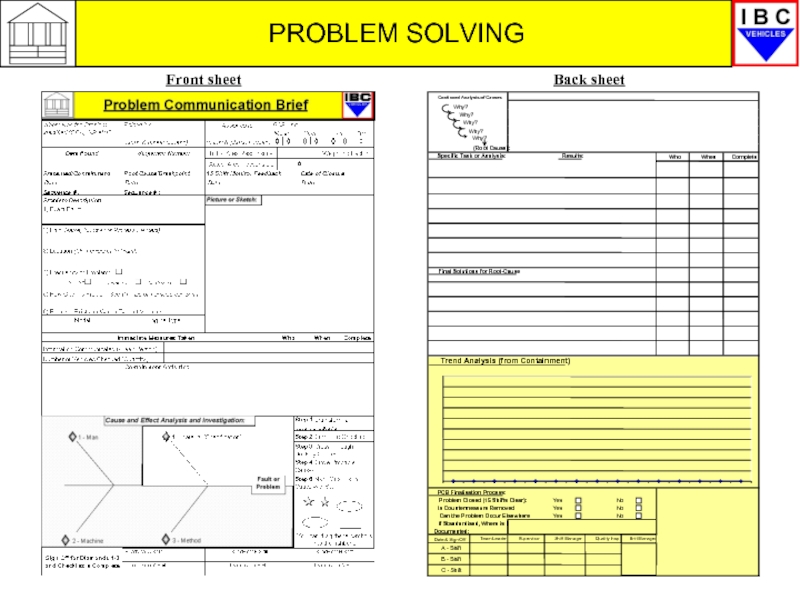

- 12. PROBLEM SOLVING Front sheet Back sheet

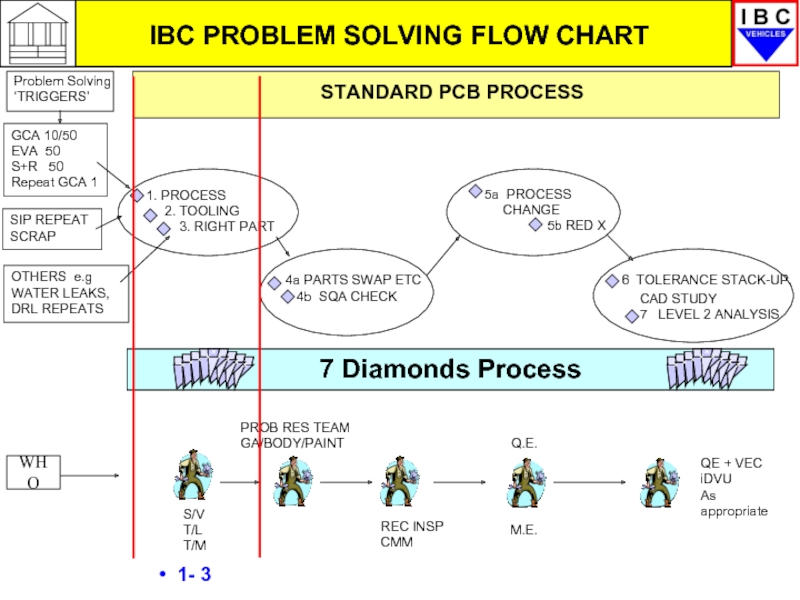

- 13. STANDARD PCB PROCESS IBC PROBLEM SOLVING FLOW CHART 1- 3

- 14. PROBLEM SOLVING Generating PCBs There are

- 15. PROBLEM SOLVING All PCBs are processed through

- 16. PROBLEM SOLVING All PCBs pertaining to any

- 17. PROBLEM SOLVING So how does the PCB

- 18. PROBLEM SOLVING Front sheet Back sheet

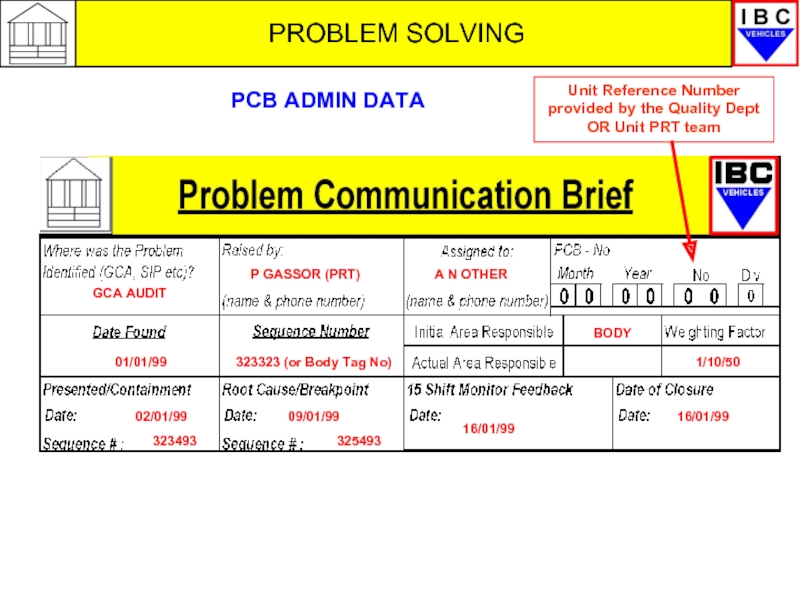

- 19. PROBLEM SOLVING GCA AUDIT P GASSOR (PRT)

- 20. PROBLEM SOLVING Front sheet Back sheet

- 21. PROBLEM SOLVING WELD NUT MISSING FROM LH

- 22. PROBLEM SOLVING Front sheet Back sheet

- 23. PROBLEM SOLVING ALL SUPVN, T/Ls, T/MS ON

- 24. PROBLEM SOLVING Front sheet Back sheet

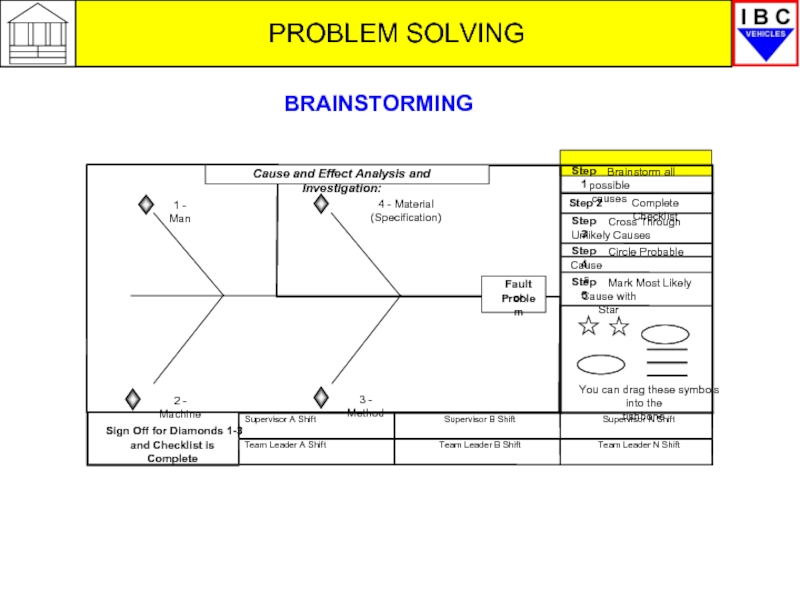

- 25. PROBLEM SOLVING BRAINSTORMING

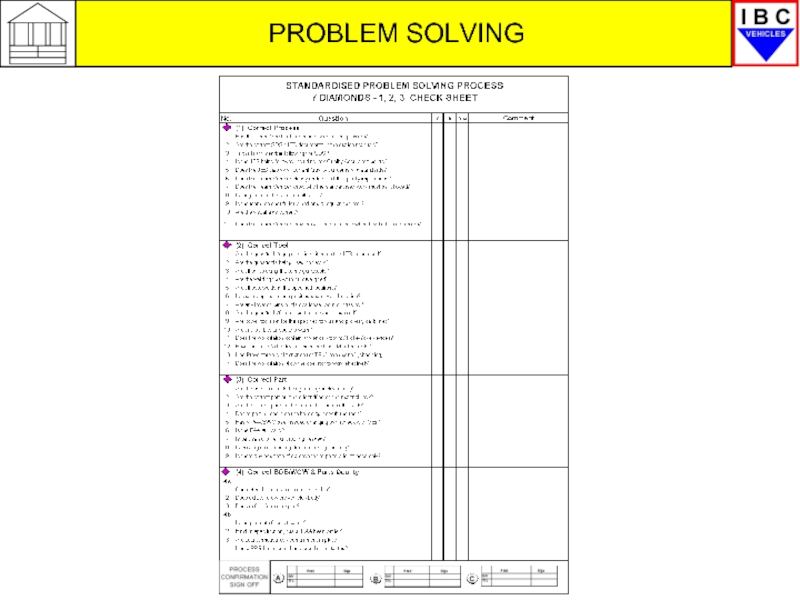

- 26. PROBLEM SOLVING DIAMONDS 1,2,3 - PROBLEM

- 27. DIAMONDS 1-3 PROBLEM SOLVING TOOLS PROBLEM

- 28. PROBLEM SOLVING DIAMONDS 1-3 PROBLEM SOLVING

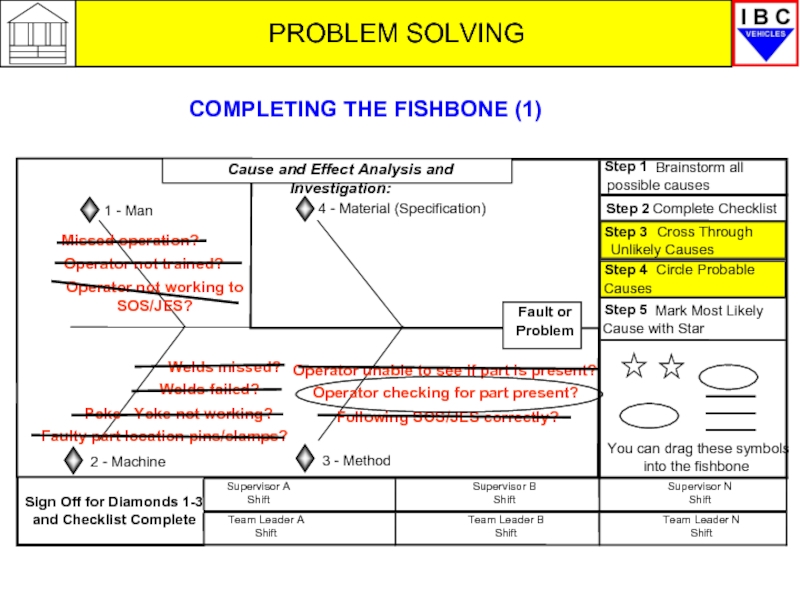

- 29. PROBLEM SOLVING Missed operation? Operator not

- 30. PROBLEM SOLVING

- 31. PROBLEM SOLVING

- 32. PROBLEM SOLVING (2) Correct Tool 1 Are

- 33. PROBLEM SOLVING

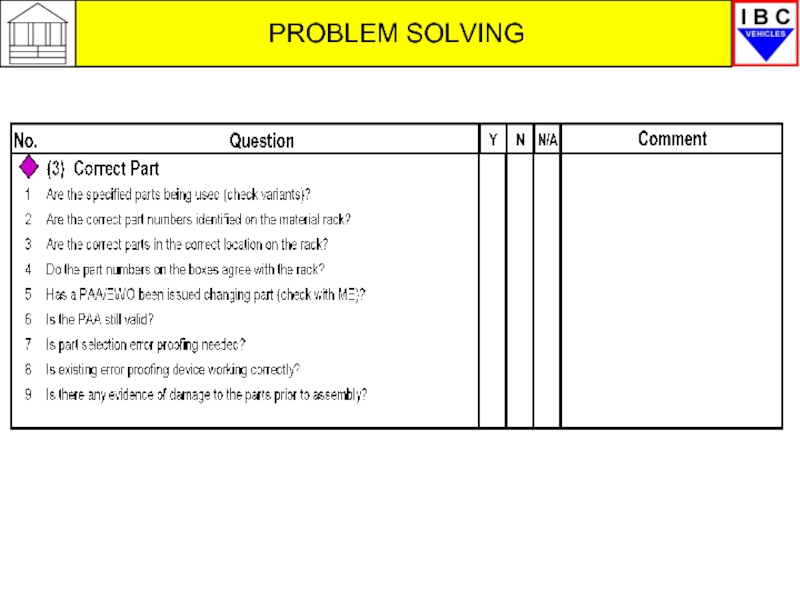

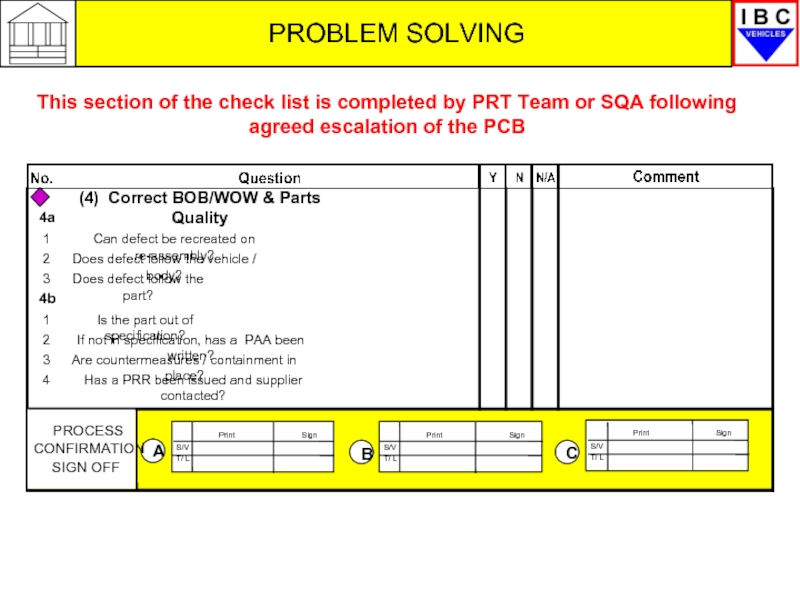

- 34. PROBLEM SOLVING This section of the check

- 35. PROBLEM SOLVING COMPLETING THE FISHBONE (1)

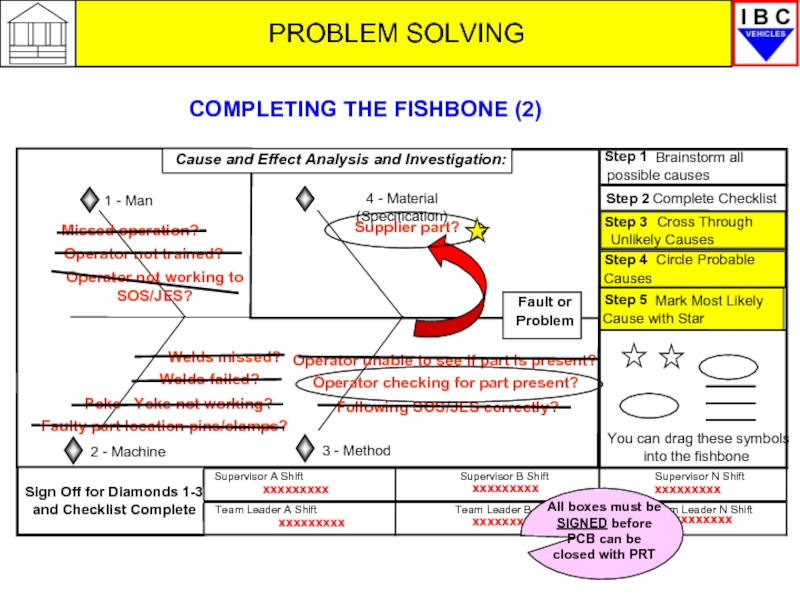

- 36. PROBLEM SOLVING Supervisor B

- 37. PROBLEM SOLVING Continued Analysis of

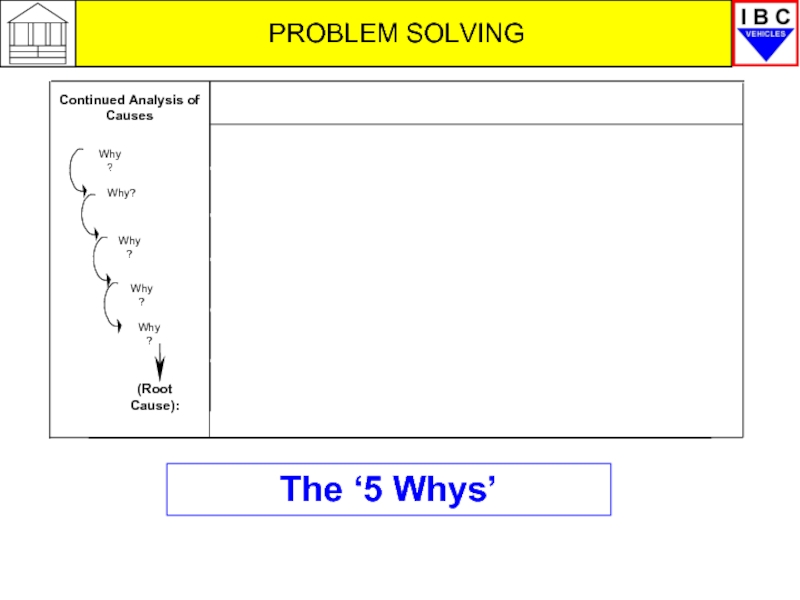

- 38. PROBLEM SOLVING (Root Cause): The ‘5 Whys’

- 39. PROBLEM SOLVING (Root Cause): Continued Analysis of

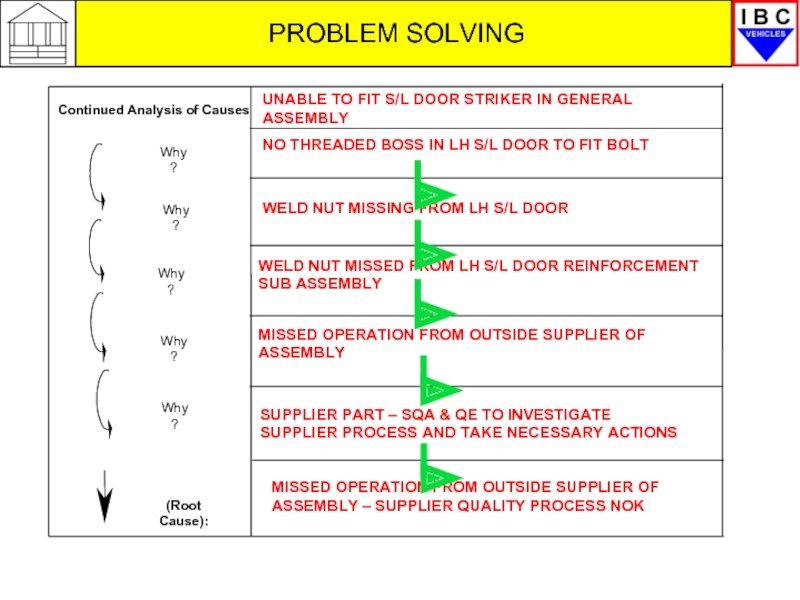

- 40. PROBLEM SOLVING Continued Analysis of

- 41. PROBLEM SOLVING Specific Task or Analysis: Results:

- 42. PROBLEM SOLVING Continued Analysis of

- 43. PROBLEM SOLVING Final Solutions for Root-Cause

- 44. PROBLEM SOLVING Continued Analysis of

- 45. PROBLEM SOLVING PCB Finalisation Process:

- 46. PROBLEM SOLVING PCB – Completion ONLY

- 47. GM GMS OVERVIEW SUSTAINABLE BUSINESS

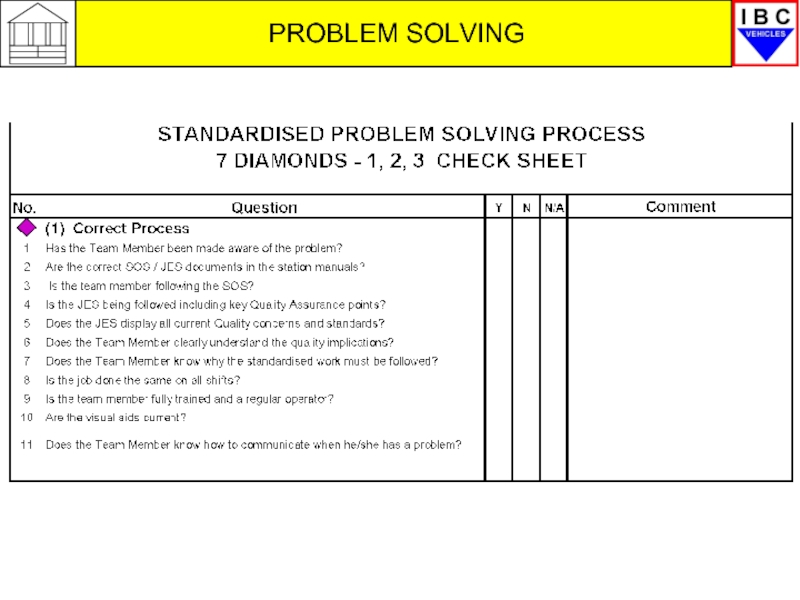

Слайд 3PROBLEM SOLVING

What is 7 Diamonds?

Seven Diamonds is a standard 7

Confirmation of these items MUST be made by Manufacturing before Engineering can be involved in any further, more detailed investigations.

70% of all Quality and Build problems are caused

by non-standard operating or tooling not working or

not being used correctly!

Слайд 4Why do we need the 7 Diamonds process?

We need to apply

We fully UNDERSTAND all of the issues

We determine the RIGHTFUL OWNER/S of the problem

We ensure that corrective actions are EFFECTIVE

We actually SOLVE the problem.

Currently

We don’t always follow the same steps or directions.

Too often we attempt to solve problems without really understanding

them and all of the contributary factors.

By not identifying the real owner we do not arrive at the real root

cause and are left with permanent containments (extra work).

We often think we have cured a problem only for it to resurface at

a later date.

PROBLEM SOLVING

Слайд 5PROBLEM SOLVING

Following the 7 Diamond process allows us to break a

Verify the basics first:

is the standardised work process being used?

is the tooling standardised and correctly applied?

are the right parts being used?

Confirm the process (if we can make one right, why not all?)

Understand the impact of variation in the process

Is the process running out of control?

Is the process capable?

Can the process be changed to prevent the problem/defect?

ONLY when we have ensured these items can we;

Involve Engineering to apply more technical investigative methods

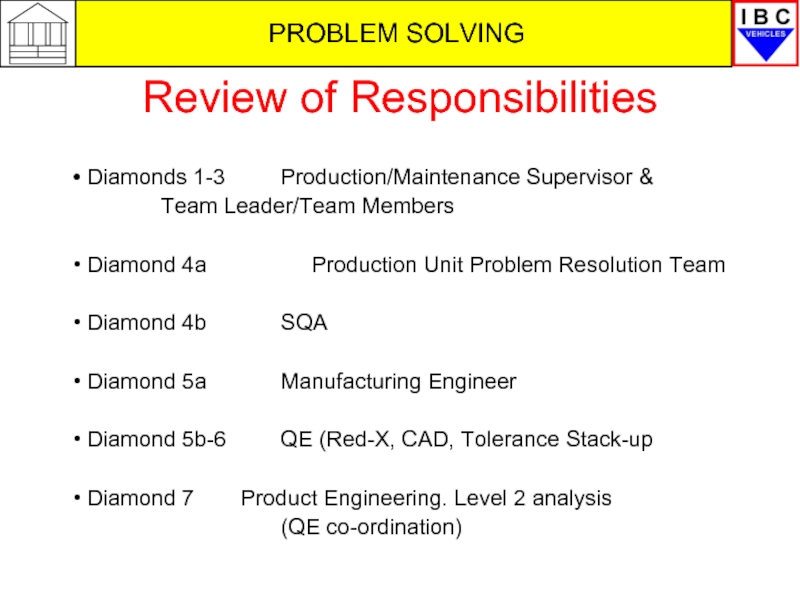

Слайд 7PROBLEM SOLVING

Review of Responsibilities

Diamonds 1-3 Production/Maintenance Supervisor & Team Leader/Team Members

Diamond 4b SQA

Diamond 5a Manufacturing Engineer

Diamond 5b-6 QE (Red-X, CAD, Tolerance Stack-up

Diamond 7 Product Engineering. Level 2 analysis

(QE co-ordination)

Слайд 8PROBLEM SOLVING

Diamonds 1 - 3

Diamonds 1 to 3 of the process

Production organisation is running the manufacturing process to design intent.

If the manufacturing process is NOT being managed to design intent, then it must be corrected and validated, before we can consider asking for Engineering assistance.

Engineering referral only occurs when the manufacturing process does meet design intent and the problem still exists.

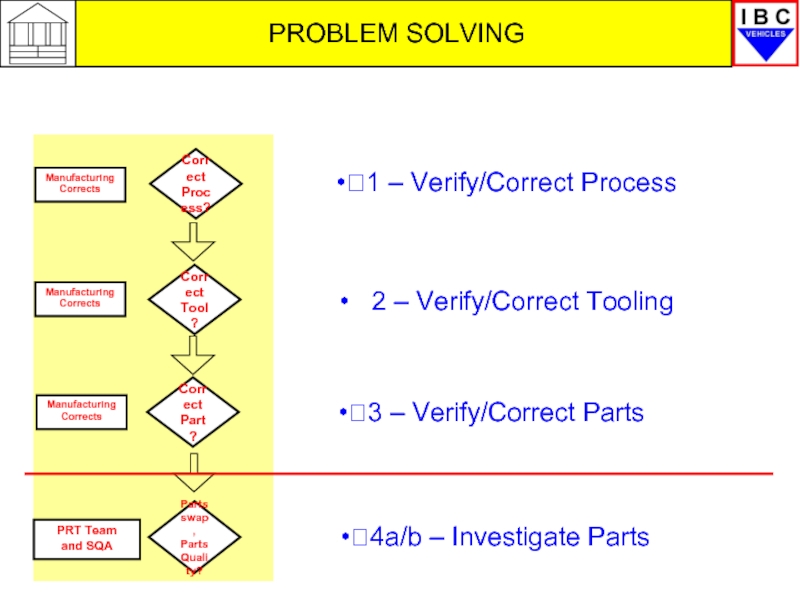

Слайд 9PROBLEM SOLVING

1 – Verify/Correct Process

Correct

Process?

Manufacturing

Corrects

Correct

Tool?

Manufacturing

Corrects

Correct

Part?

Manufacturing

Corrects

Parts swap,

Parts Quality?

PRT Team

and SQA

3 – Verify/Correct Parts

4a/b – Investigate Parts

Слайд 10PROBLEM SOLVING

Diamonds 1-3 Review

Once a problem has been identified, the

must be to immediately step through diamonds 1-3.

Diamonds 1-3 are for evaluating the stability of the process.

If the process is being applied correctly, diamonds 4a and 4b

are applied to determine if the parts are to specification

Following steps 1,2 & 3 must become inherent in our problem

solving thought process.

Слайд 11PROBLEM SOLVING

PCB – Problem Communication Brief

The PCB is a standard document

It ensures that everyone applies the same thought process towards understanding and resolving these problems.

As you will see the PCB is aligned to the 7 Diamonds process.

We will now look briefly at how the PCB works, remembering that the first 3 Diamonds are those you will be involved in.

Слайд 14PROBLEM SOLVING

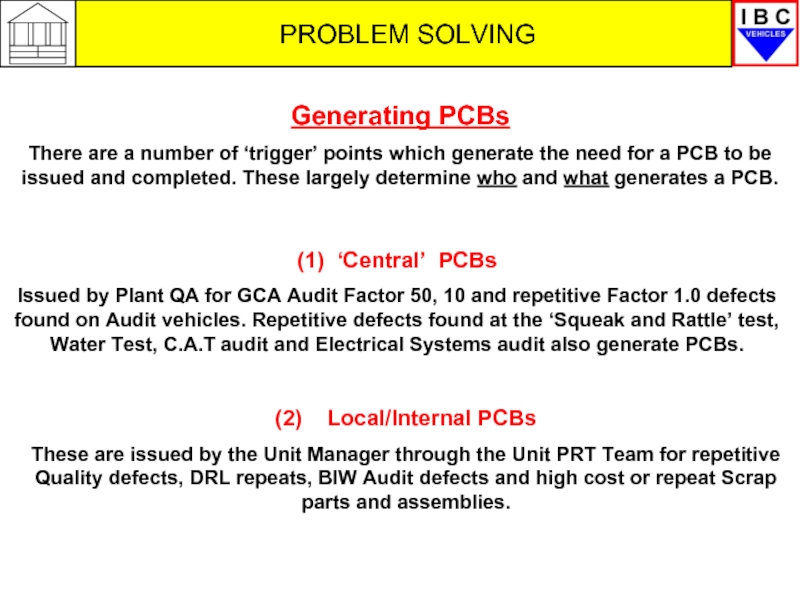

Generating PCBs

There are a number of ‘trigger’ points which

(1) ‘Central’ PCBs

Issued by Plant QA for GCA Audit Factor 50, 10 and repetitive Factor 1.0 defects found on Audit vehicles. Repetitive defects found at the ‘Squeak and Rattle’ test, Water Test, C.A.T audit and Electrical Systems audit also generate PCBs.

(2) Local/Internal PCBs

These are issued by the Unit Manager through the Unit PRT Team for repetitive Quality defects, DRL repeats, BIW Audit defects and high cost or repeat Scrap parts and assemblies.

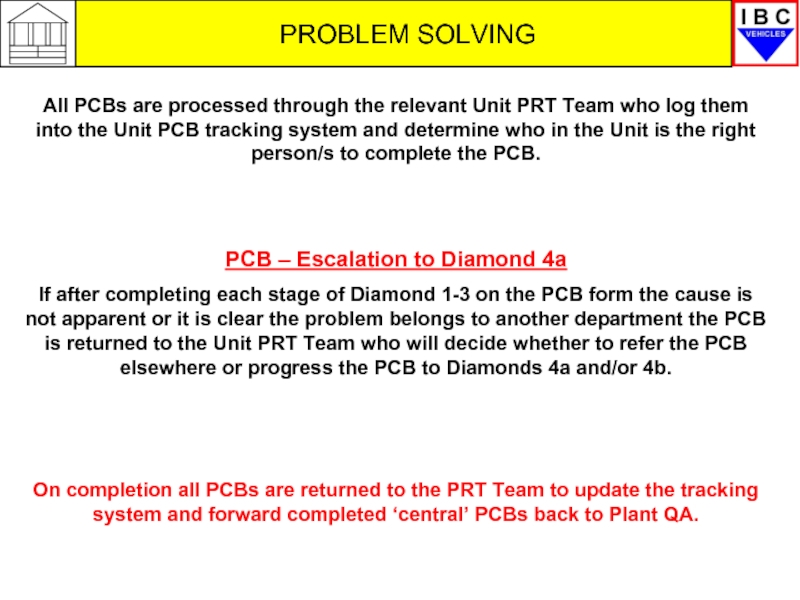

Слайд 15PROBLEM SOLVING

All PCBs are processed through the relevant Unit PRT Team

On completion all PCBs are returned to the PRT Team to update the tracking system and forward completed ‘central’ PCBs back to Plant QA.

PCB – Escalation to Diamond 4a

If after completing each stage of Diamond 1-3 on the PCB form the cause is not apparent or it is clear the problem belongs to another department the PCB is returned to the Unit PRT Team who will decide whether to refer the PCB elsewhere or progress the PCB to Diamonds 4a and/or 4b.

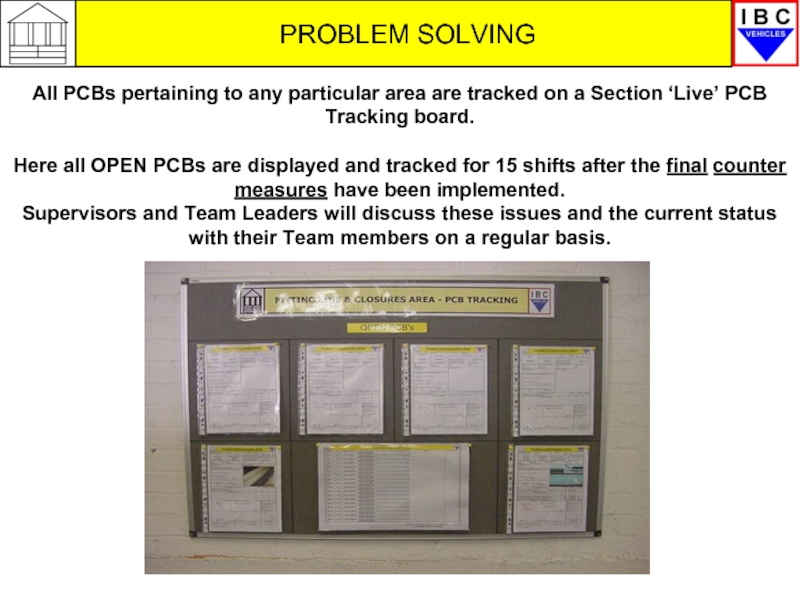

Слайд 16PROBLEM SOLVING

All PCBs pertaining to any particular area are tracked on

Here all OPEN PCBs are displayed and tracked for 15 shifts after the final counter measures have been implemented.

Supervisors and Team Leaders will discuss these issues and the current status with their Team members on a regular basis.

Слайд 17PROBLEM SOLVING

So how does the PCB work?

We will now look briefly

Слайд 19PROBLEM SOLVING

GCA AUDIT

P GASSOR (PRT)

A N OTHER

01/01/99

323323 (or Body Tag No)

1/10/50

09/01/99

16/01/99

16/01/99

325493

BODY

PCB

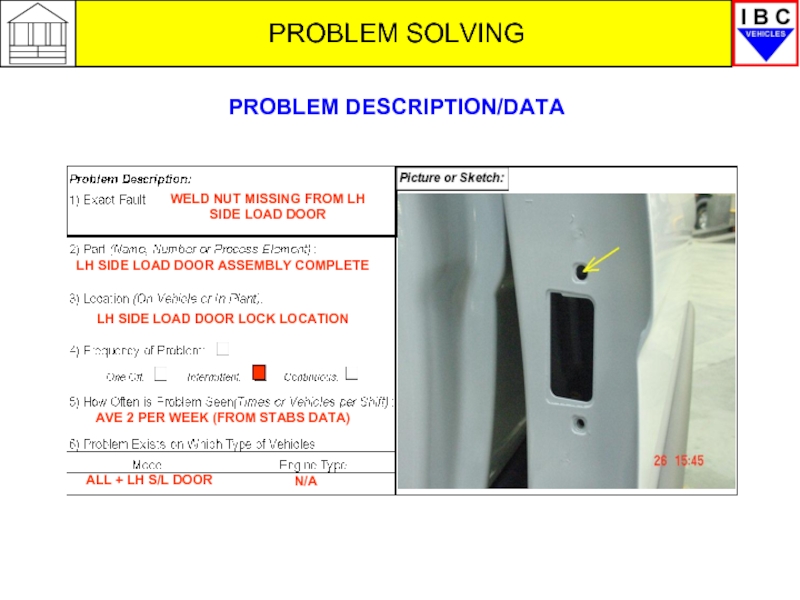

Слайд 21PROBLEM SOLVING

WELD NUT MISSING FROM LH SIDE LOAD DOOR

LH SIDE LOAD

LH SIDE LOAD DOOR LOCK LOCATION

AVE 2 PER WEEK (FROM STABS DATA)

ALL + LH S/L DOOR

N/A

PROBLEM DESCRIPTION/DATA

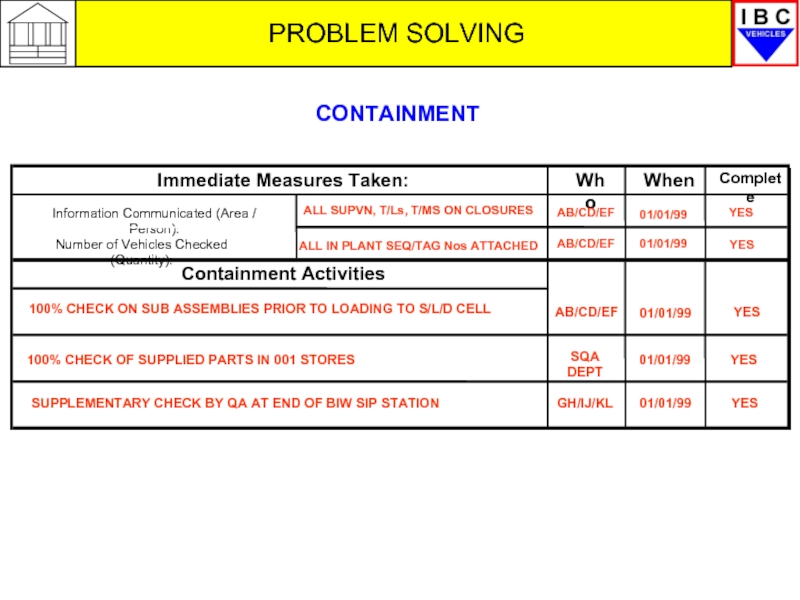

Слайд 23PROBLEM SOLVING

ALL SUPVN, T/Ls, T/MS ON CLOSURES

AB/CD/EF

01/01/99

YES

ALL IN PLANT SEQ/TAG Nos

AB/CD/EF

01/01/99

YES

100% CHECK ON SUB ASSEMBLIES PRIOR TO LOADING TO S/L/D CELL

100% CHECK OF SUPPLIED PARTS IN 001 STORES

SUPPLEMENTARY CHECK BY QA AT END OF BIW SIP STATION

AB/CD/EF

SQA DEPT

GH/IJ/KL

01/01/99

01/01/99

01/01/99

YES

YES

YES

CONTAINMENT

Слайд 26PROBLEM SOLVING

DIAMONDS 1,2,3 - PROBLEM SOLVING

When completing the

To generate the possible causes we use a simple but effective technique known as ‘brainstorming’ which is used to help create as many ideas in as short a time as possible.

BRAINSTORMING

Слайд 27 DIAMONDS 1-3 PROBLEM SOLVING TOOLS

PROBLEM SOLVING

HOW TO BRAINSTORM?

It is best

Ensure all group members are aware of the nature of the problem/defect e.g. missing part, damage, wrong part etc.

Next, ask each person to think of as many possible causes for the defect (however likely or unlikely they may seem).

Get each person to briefly explain their ideas and note down EVERY idea clearly on a flipchart/paper.

As a group discuss each idea and agree on the most likely causes.

Where possible ask group members to verify/investigate the most likely causes and suggest suitable countermeasures

Слайд 28PROBLEM SOLVING

DIAMONDS 1-3 PROBLEM SOLVING TOOLS

BRAINSTORMING – DO’s and

DO – record and discuss every idea – however extreme they may appear (quite often even the strangest ideas prove to contain some benefits)

DON’T – never dismiss or ridicule any ideas. This is likely to switch that person off and refrain from any further positive input.

DO – try to ensure that all ideas are fully understood – ask individuals to explain them and ask questions to ensure there are no misunderstandings.

DON’T – be influenced by any previous history of a particular problem or defect – always start with a blank sheet of paper!

DO – ensure whenever an idea is discarded, that the individual who came up with it fully understands why it will not be pursued.

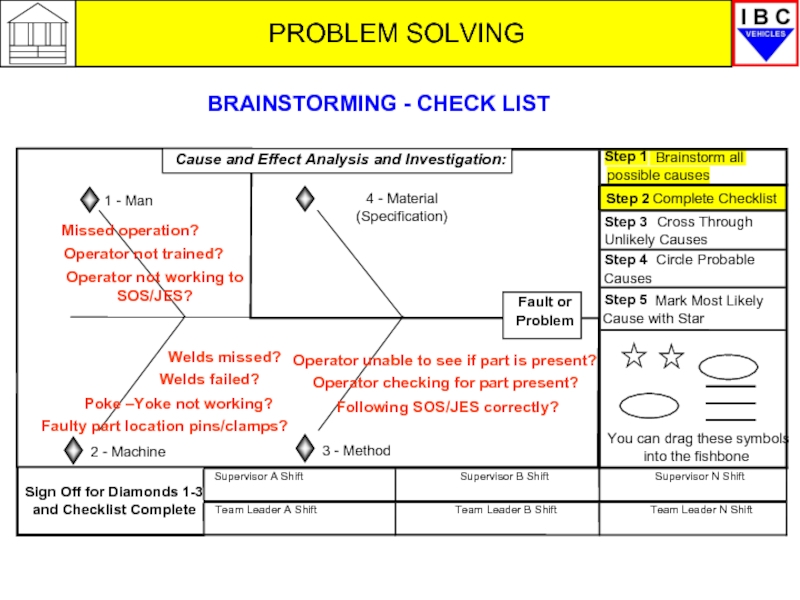

Слайд 29

PROBLEM SOLVING

Missed operation?

Operator not trained?

Operator not working to SOS/JES?

Welds missed?

Welds failed?

Poke

Following SOS/JES correctly?

Operator checking for part present?

Operator unable to see if part is present?

Faulty part location pins/clamps?

BRAINSTORMING - CHECK LIST

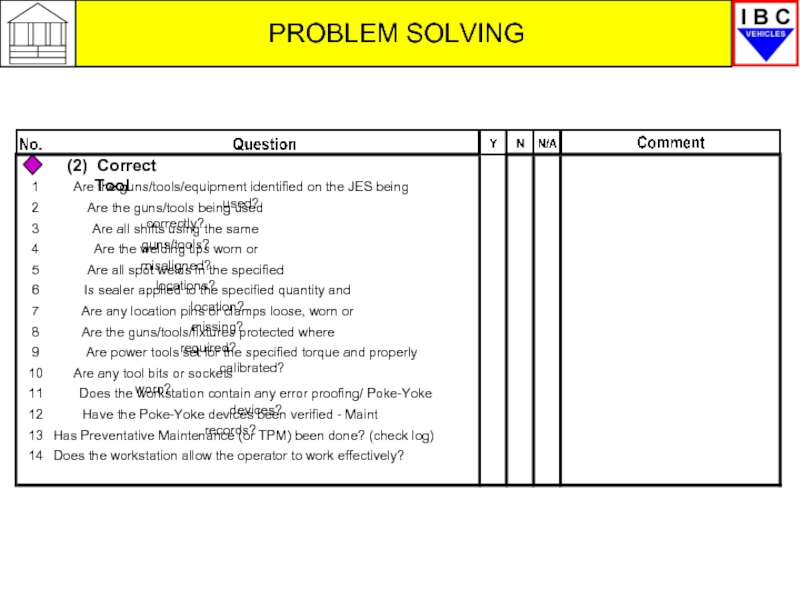

Слайд 32PROBLEM SOLVING

(2) Correct Tool

1

Are the guns/tools/equipment identified on the JES being

2

Are the guns/tools being used correctly?

3

Are all shifts using the same guns/tools?

4

Are the welding tips worn or misaligned?

5

Are all spot welds in the specified locations?

6

Is sealer applied to the specified quantity and location?

7

Are any location pins or clamps loose, worn or missing?

8

Are the guns/tools/fixtures protected where required?

9

Are power tools set for the specified torque and properly calibrated?

10

Are any tool bits or sockets worn?

11

Does the workstation contain any error proofing/ Poke-Yoke devices?

12

Have the Poke-Yoke devices been verified - Maint records?

13

Has Preventative Maintenance (or TPM) been done? (check log)

14

Does the workstation allow the operator to work effectively?

Слайд 34PROBLEM SOLVING

This section of the check list is completed by PRT

Слайд 36

PROBLEM SOLVING

Supervisor B Shift

Team Leader B Shift

Supervisor N Shift

Team Leader N

You can drag these symbols

into the fishbone

Step 3

Cross Through

Unlikely Causes

Step 4

Circle Probable

Causes

Step 5

Mark Most Likely

Cause with Star

Team Leader A Shift

Supervisor A Shift

Step 1

Brainstorm all

possible causes

Step 2

Complete Checklist

Sign Off for Diamonds 1-3

and Checklist Complete

Fault or

Problem

1 - Man

4 - Material (Specification)

2 - Machine

3 - Method

Cause and Effect Analysis and Investigation:

Missed operation?

Operator not trained?

Operator not working to SOS/JES?

Welds missed?

Welds failed?

Poke –Yoke not working?

Following SOS/JES correctly?

Operator checking for part present?

Operator unable to see if part is present?

Faulty part location pins/clamps?

Supplier part?

COMPLETING THE FISHBONE (2)

Слайд 37

PROBLEM SOLVING

Continued Analysis of Causes

Specific Task or Analysis:

Results:

PCB Finalisation Process:

Yes

No

Is Countermeasure

Yes

No

Can the Problem Occur Elsewhere

Yes

No

Trend Analysis (from Containment)

Problem Closed (15 Shifts Clear):

Final Solutions for Root-Cause

Complete

Who

When

(Root Cause):

If Standardised, Where is it

Documented:

Why?

Why?

Why?

Why?

Why?

Date & Sign-Off

Team Leader

Supervisor

Shift Manager

Quality Insp

Unit Manager

A - Shift

B - Shift

C - Shift

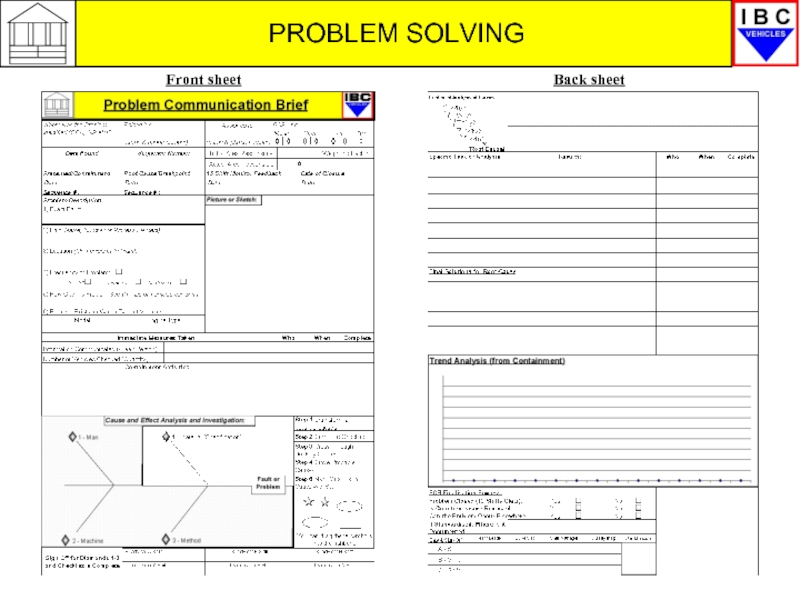

Front sheet

Back sheet

Слайд 39PROBLEM SOLVING

(Root Cause):

Continued Analysis of Causes

Why?

Why?

Why?

Why?

Why?

UNABLE TO FIT S/L DOOR STRIKER

NO THREADED BOSS IN LH S/L DOOR TO FIT BOLT

WELD NUT MISSING FROM LH S/L DOOR

WELD NUT MISSED FROM LH S/L DOOR REINFORCEMENT SUB ASSEMBLY

SUPPLIER PART – SQA & QE TO INVESTIGATE SUPPLIER PROCESS AND TAKE NECESSARY ACTIONS

MISSED OPERATION FROM OUTSIDE SUPPLIER OF ASSEMBLY

MISSED OPERATION FROM OUTSIDE SUPPLIER OF ASSEMBLY – SUPPLIER QUALITY PROCESS NOK

Слайд 40

PROBLEM SOLVING

Continued Analysis of Causes

Specific Task or Analysis:

Results:

PCB Finalisation Process:

Yes

No

Is Countermeasure

Yes

No

Can the Problem Occur Elsewhere

Yes

No

Trend Analysis (from Containment)

Problem Closed (15 Shifts Clear):

Final Solutions for Root-Cause

Complete

Who

When

(Root Cause):

If Standardised, Where is it

Documented:

Why?

Why?

Why?

Why?

Why?

Date & Sign-Off

Team Leader

Supervisor

Shift Manager

Quality Insp

Unit Manager

A - Shift

B - Shift

C - Shift

Front sheet

Back sheet

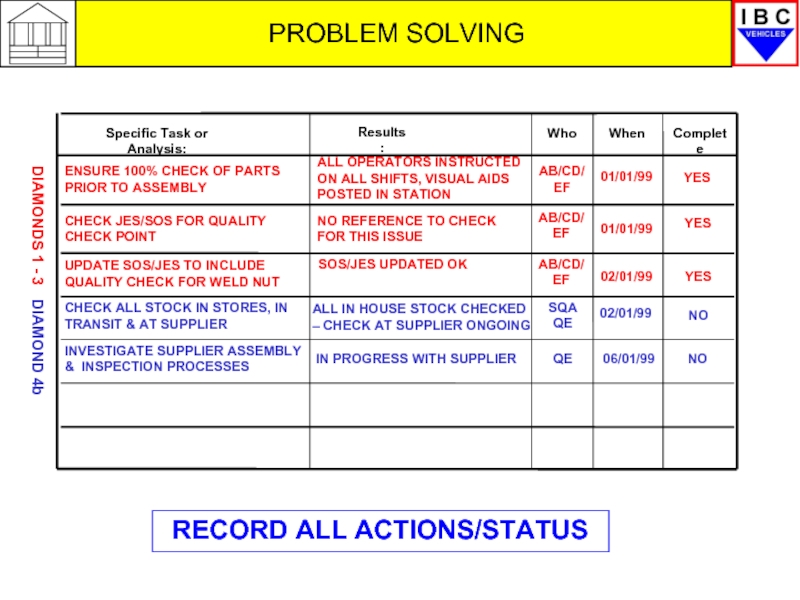

Слайд 41PROBLEM SOLVING

Specific Task or Analysis:

Results:

Complete

Who

When

ENSURE 100% CHECK OF PARTS PRIOR TO

CHECK JES/SOS FOR QUALITY CHECK POINT

UPDATE SOS/JES TO INCLUDE QUALITY CHECK FOR WELD NUT

CHECK ALL STOCK IN STORES, IN TRANSIT & AT SUPPLIER

INVESTIGATE SUPPLIER ASSEMBLY & INSPECTION PROCESSES

ALL OPERATORS INSTRUCTED ON ALL SHIFTS, VISUAL AIDS POSTED IN STATION

AB/CD/EF

01/01/99

YES

NO REFERENCE TO CHECK FOR THIS ISSUE

AB/CD/EF

01/01/99

YES

SOS/JES UPDATED OK

AB/CD/EF

02/01/99

YES

ALL IN HOUSE STOCK CHECKED – CHECK AT SUPPLIER ONGOING

SQA QE

02/01/99

NO

IN PROGRESS WITH SUPPLIER

QE

06/01/99

NO

DIAMONDS 1 - 3

DIAMOND 4b

RECORD ALL ACTIONS/STATUS

Слайд 42

PROBLEM SOLVING

Continued Analysis of Causes

Specific Task or Analysis:

Results:

PCB Finalisation Process:

Yes

No

Is Countermeasure

Yes

No

Can the Problem Occur Elsewhere

Yes

No

Trend Analysis (from Containment)

Problem Closed (15 Shifts Clear):

Final Solutions for Root-Cause

Complete

Who

When

(Root Cause):

If Standardised, Where is it

Documented:

Why?

Why?

Why?

Why?

Why?

Date & Sign-Off

Team Leader

Supervisor

Shift Manager

Quality Insp

Unit Manager

A - Shift

B - Shift

C - Shift

Front sheet

Back sheet

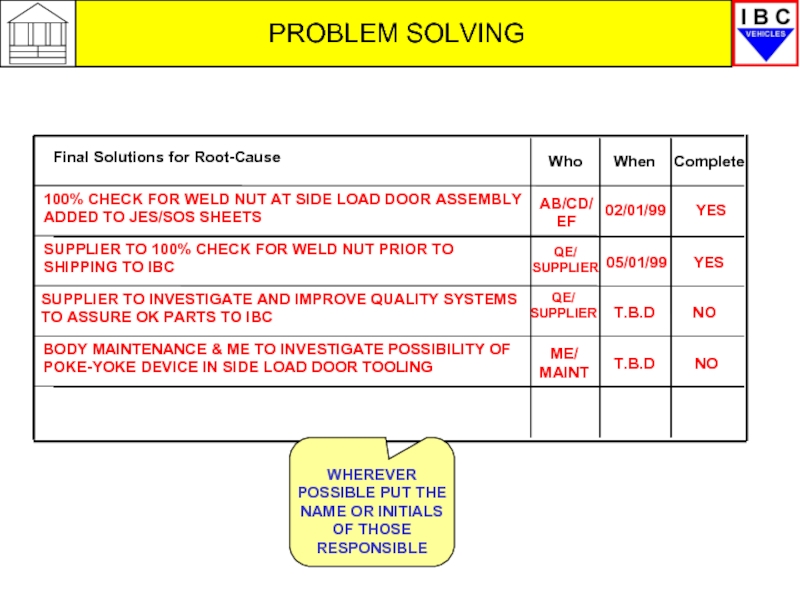

Слайд 43PROBLEM SOLVING

Final Solutions for Root-Cause

100% CHECK FOR WELD NUT AT SIDE

SUPPLIER TO 100% CHECK FOR WELD NUT PRIOR TO SHIPPING TO IBC

BODY MAINTENANCE & ME TO INVESTIGATE POSSIBILITY OF POKE-YOKE DEVICE IN SIDE LOAD DOOR TOOLING

Who

When

Complete

AB/CD/ EF

QE/ SUPPLIER

ME/ MAINT

02/01/99

05/01/99

T.B.D

YES

YES

NO

SUPPLIER TO INVESTIGATE AND IMPROVE QUALITY SYSTEMS TO ASSURE OK PARTS TO IBC

QE/ SUPPLIER

T.B.D

NO

Слайд 44

PROBLEM SOLVING

Continued Analysis of Causes

Specific Task or Analysis:

Results:

PCB Finalisation Process:

Yes

No

Is Countermeasure

Yes

No

Can the Problem Occur Elsewhere

Yes

No

Trend Analysis (from Containment)

Problem Closed (15 Shifts Clear):

Final Solutions for Root-Cause

Complete

Who

When

(Root Cause):

If Standardised, Where is it

Documented:

Why?

Why?

Why?

Why?

Why?

Date & Sign-Off

Team Leader

Supervisor

Shift Manager

Quality Insp

Unit Manager

A - Shift

B - Shift

C - Shift

Front sheet

Back sheet

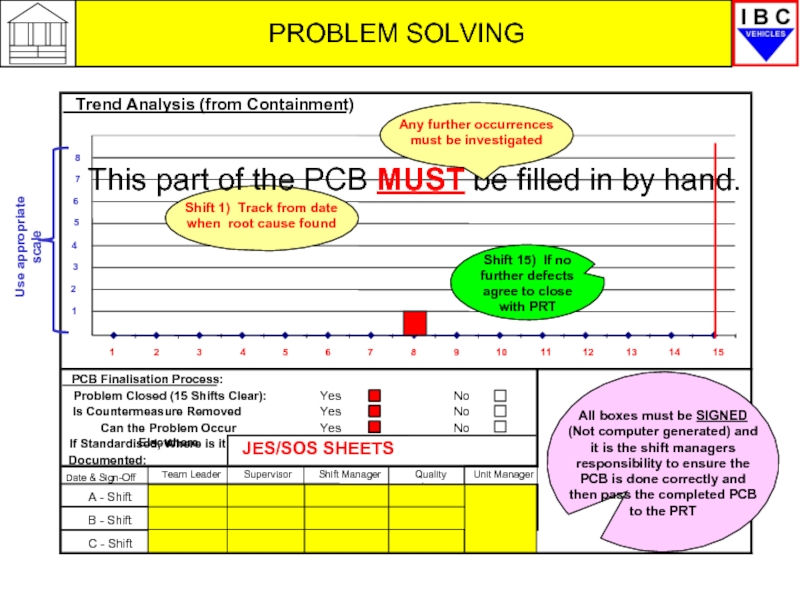

Слайд 45

PROBLEM SOLVING

PCB Finalisation Process:

Yes

No

Is Countermeasure Removed

Yes

No

Can the Problem Occur Elsewhere

Yes

No

Trend Analysis

Problem Closed (15 Shifts Clear):

If Standardised, Where is it

Documented:

Date & Sign-Off

Team Leader

Supervisor

Shift Manager

Quality Insp

Unit Manager

A - Shift

B - Shift

C - Shift

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

Use appropriate scale

JES/SOS SHEETS

This part of the PCB MUST be filled in by hand.

Слайд 46PROBLEM SOLVING

PCB – Completion

ONLY after the PCB has been signed off

If the issuing body (e.g. Plant QA, Unit PRT Team etc.) agree that a problem has been clear for 15 shifts following the introduction of suitable counter-measures, then the PCB can be closed.

On completion and closure all PCBs will be archived by the PRT Team and the tracking system updated. External PCBs will be forwarded to the relevant locations by the PRT Team.

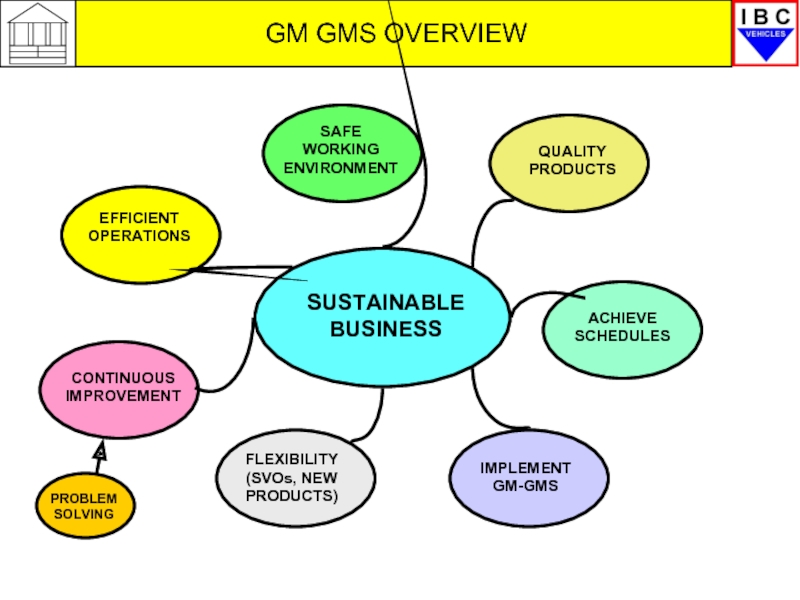

Слайд 47GM GMS OVERVIEW

SUSTAINABLE BUSINESS

QUALITY PRODUCTS

SAFE WORKING ENVIRONMENT

EFFICIENT OPERATIONS

ACHIEVE SCHEDULES

IMPLEMENT GM-GMS

CONTINUOUS IMPROVEMENT

FLEXIBILITY

PROBLEM SOLVING