Why is hydrogen needed?

A modern commercially available car with a range of 400 km burns about 24 kg of petrol in a combustion engine or 8 kg of hydrogen.

For the electric car where hydrogen reacts with oxygen in a fuel cell by means the reaction

Н2 → 2Н+ + 2e-

O2 + 4H+ + 4e- → 2H2O,

is needed only 4 kg of hydrogen

What is the problem?

At the temperature 20oC and pressure 1 bar

4 kg of hydrogen occupied a volume of 45 m3.

What`s the way to squeeze 4 kg of hydrogen in a car?

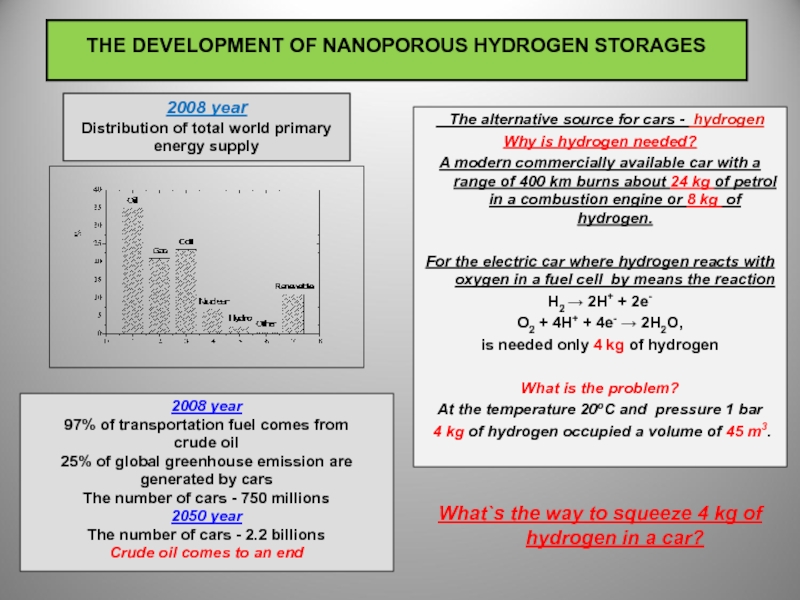

2008 year

97% of transportation fuel comes from

crude oil

25% of global greenhouse emission are generated by cars

The number of cars - 750 millions

2050 year

The number of cars - 2.2 billions

Crude oil comes to an end

2008 year

Distribution of total world primary energy supply