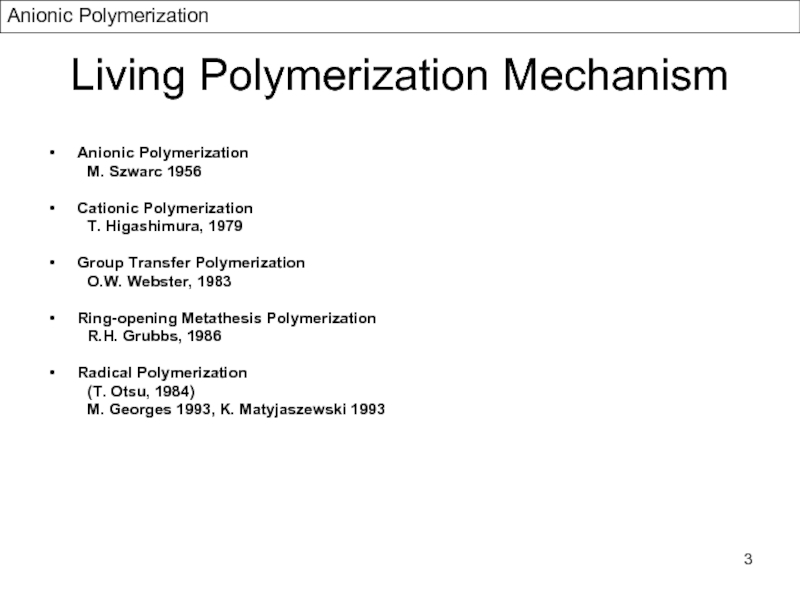

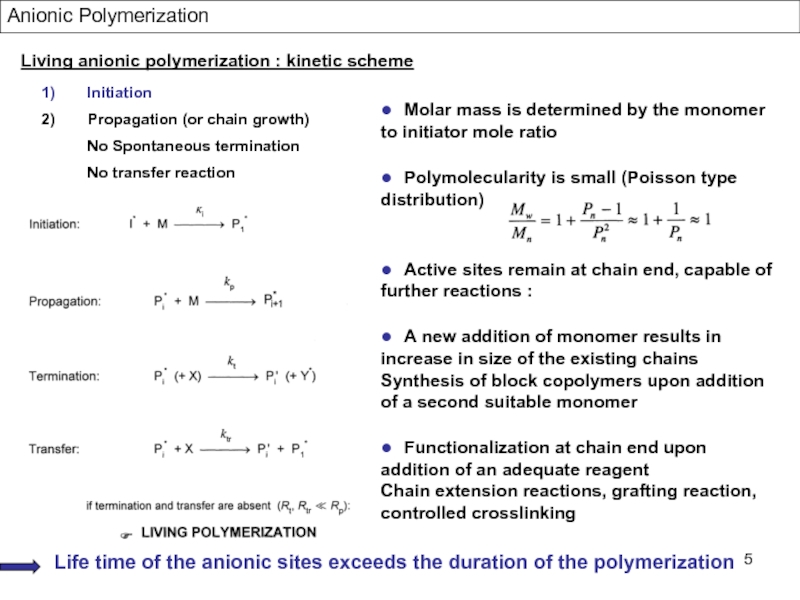

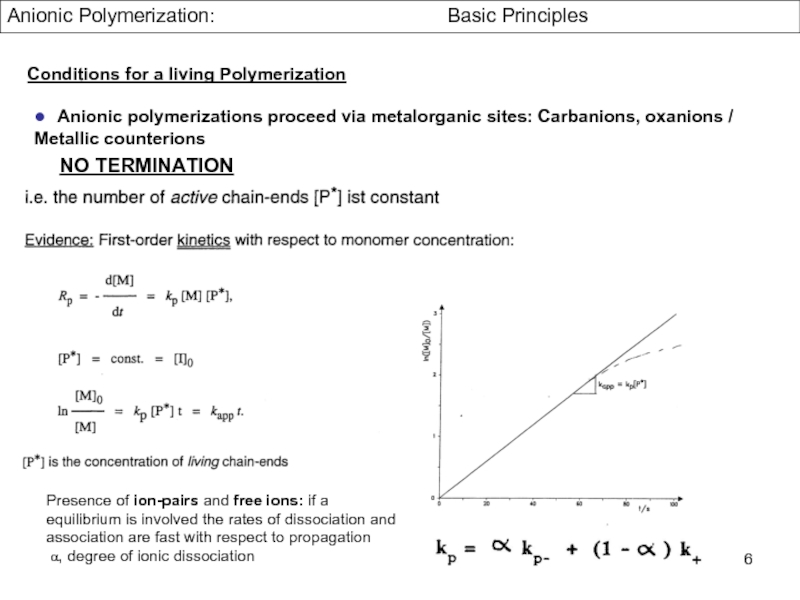

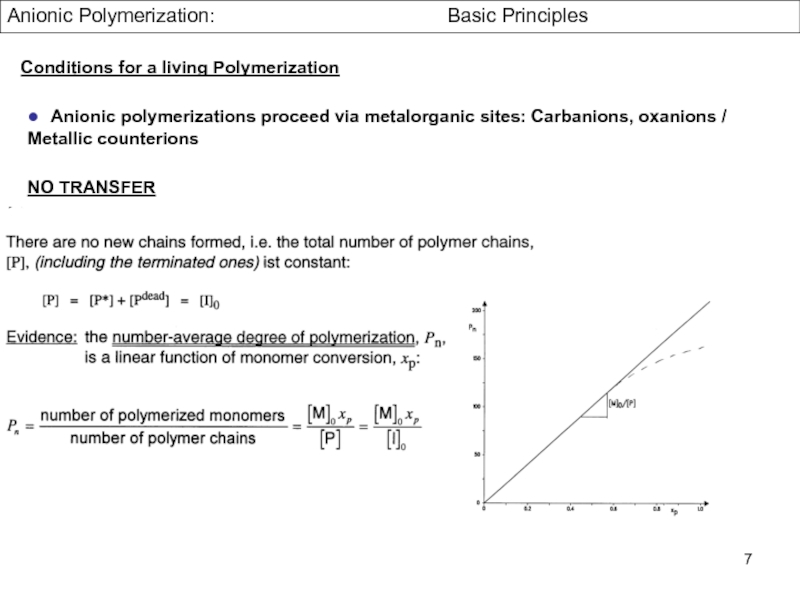

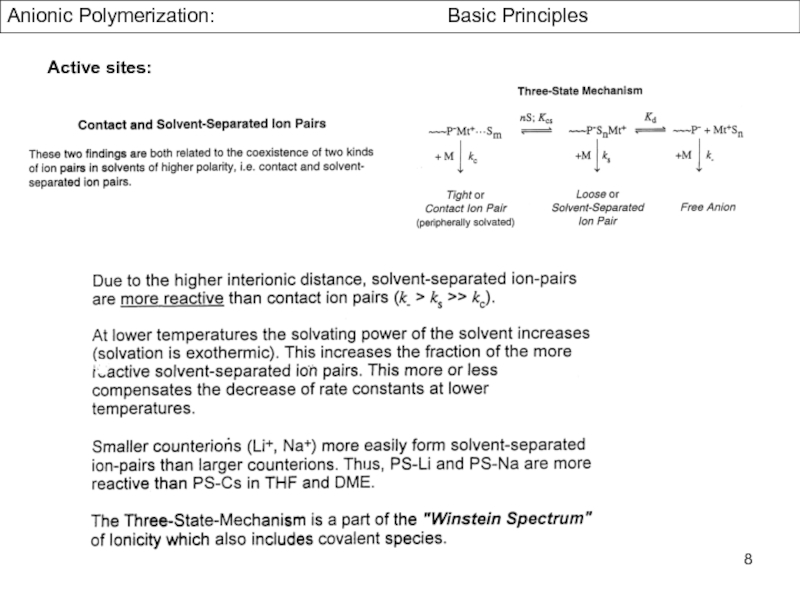

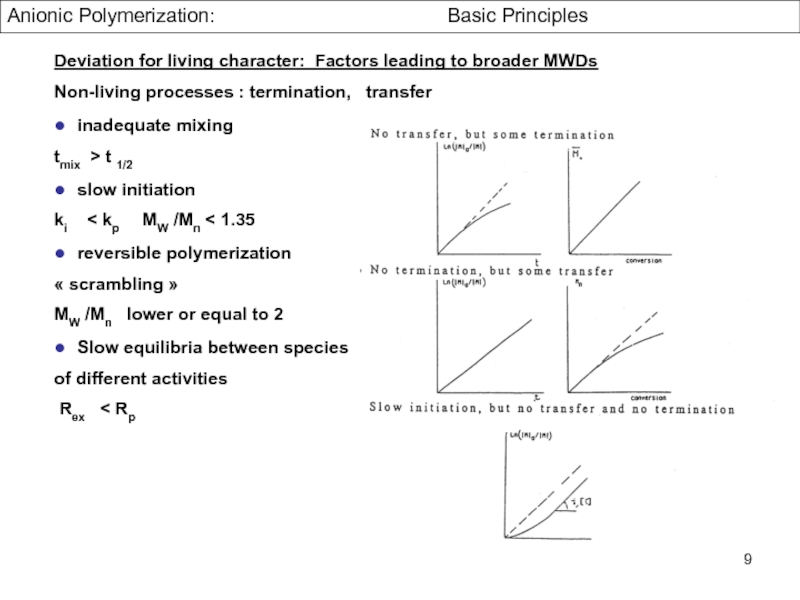

- Aspects of living Polymerization

- Factors Affecting the Molar Mass Distribution

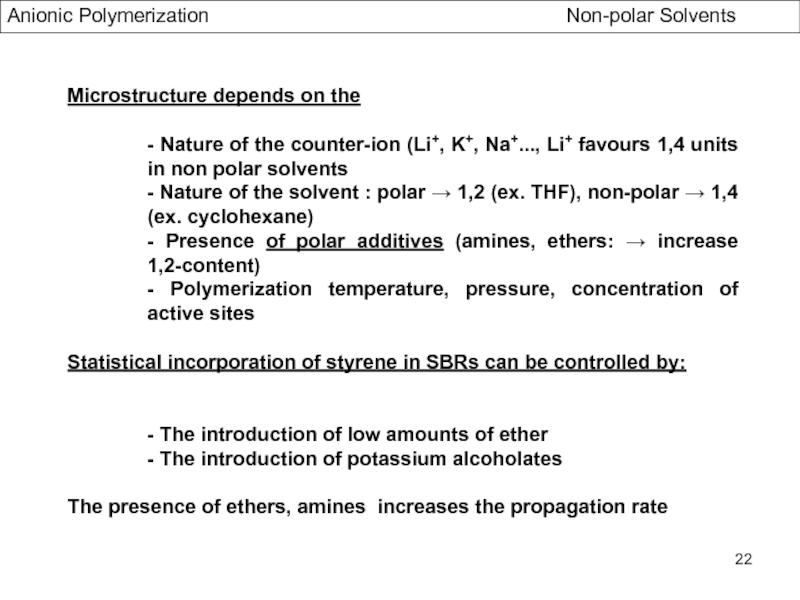

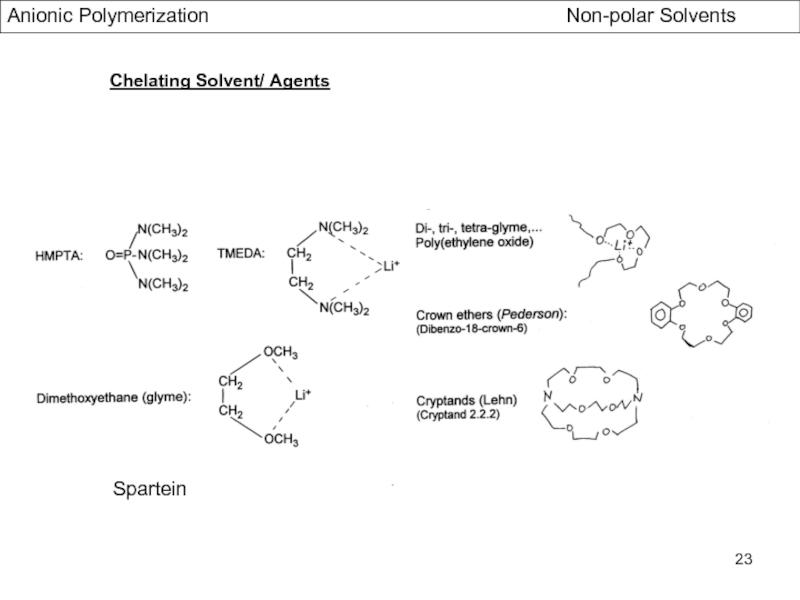

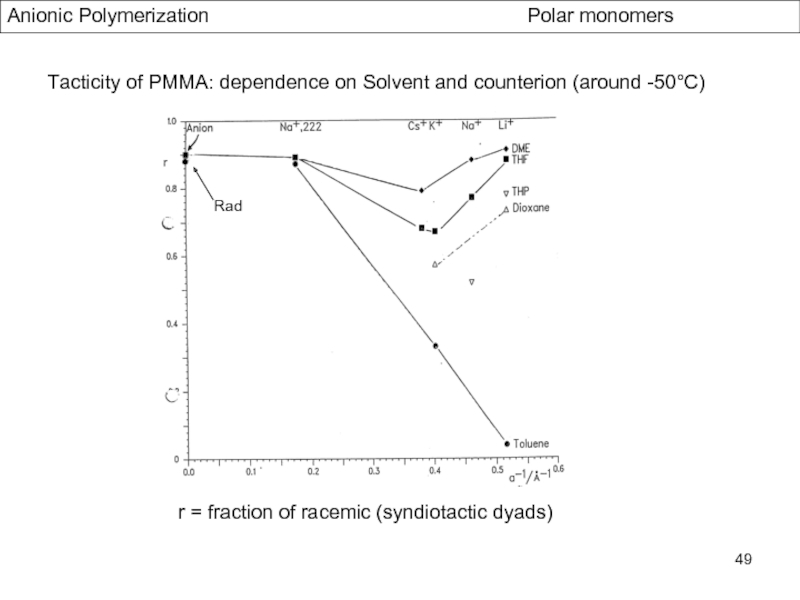

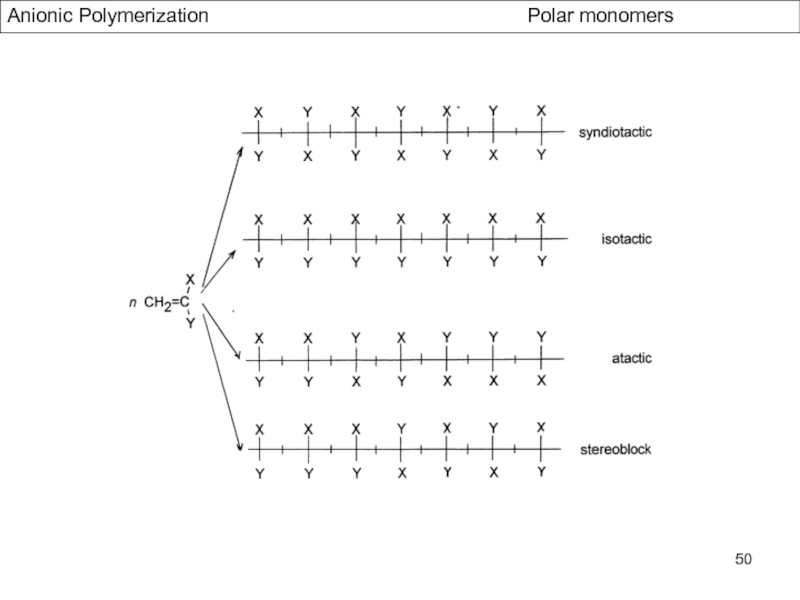

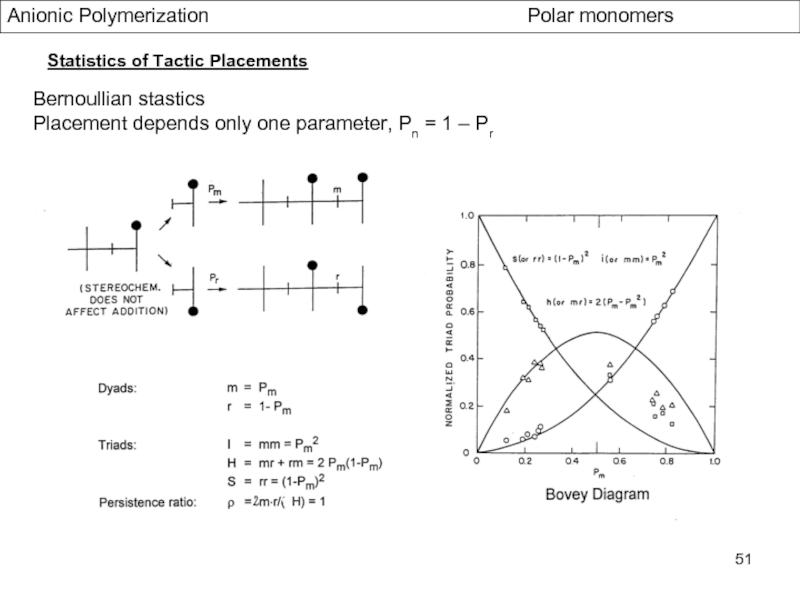

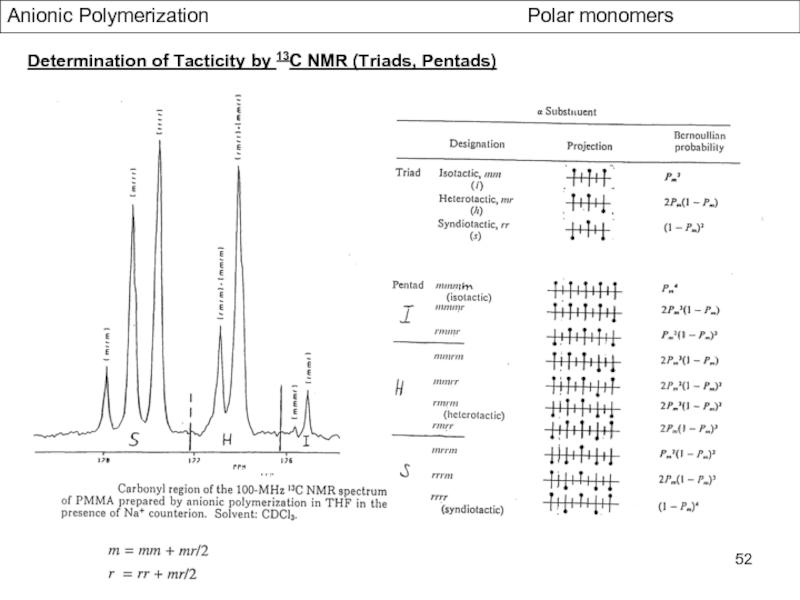

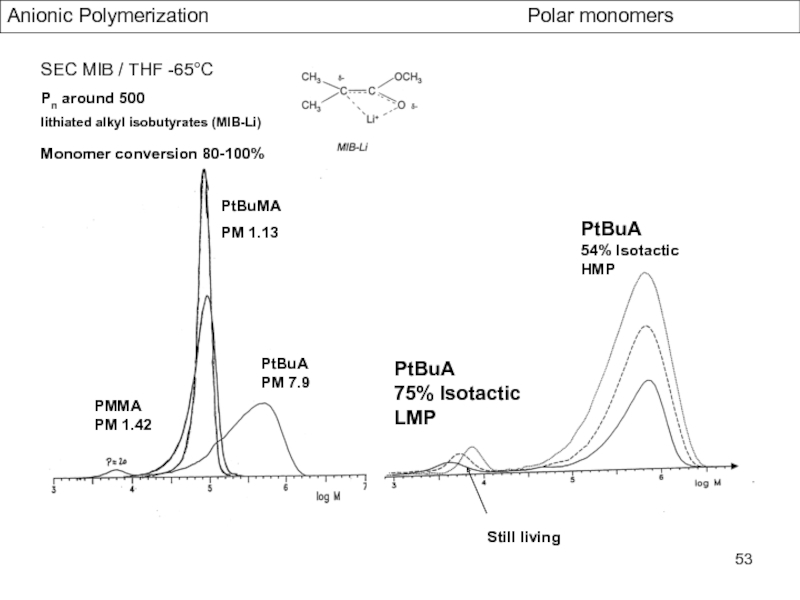

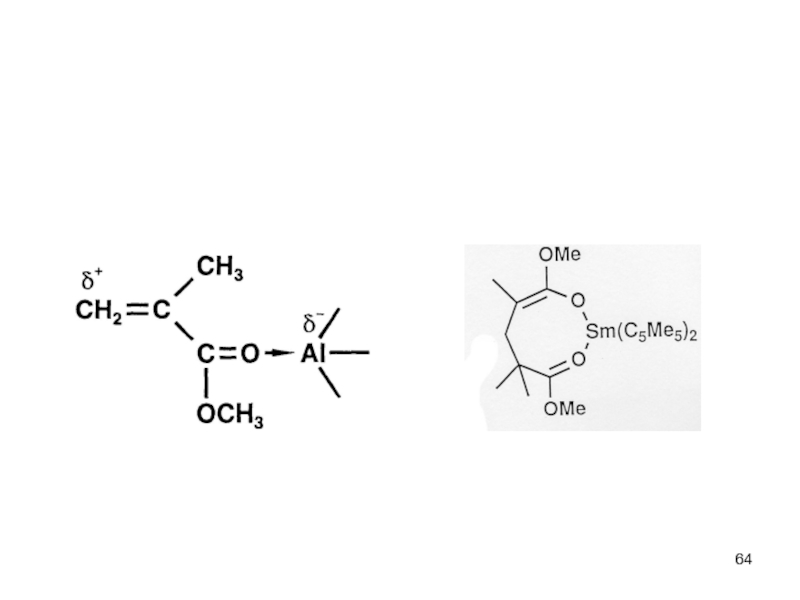

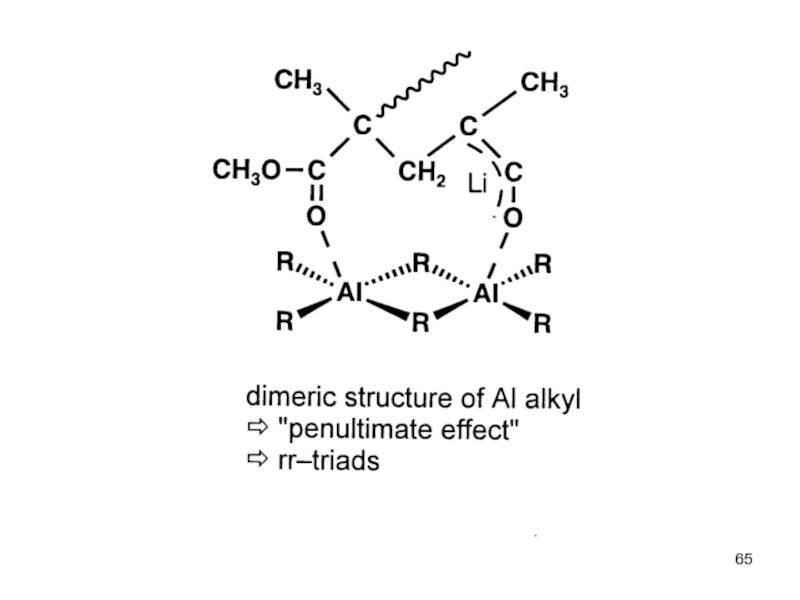

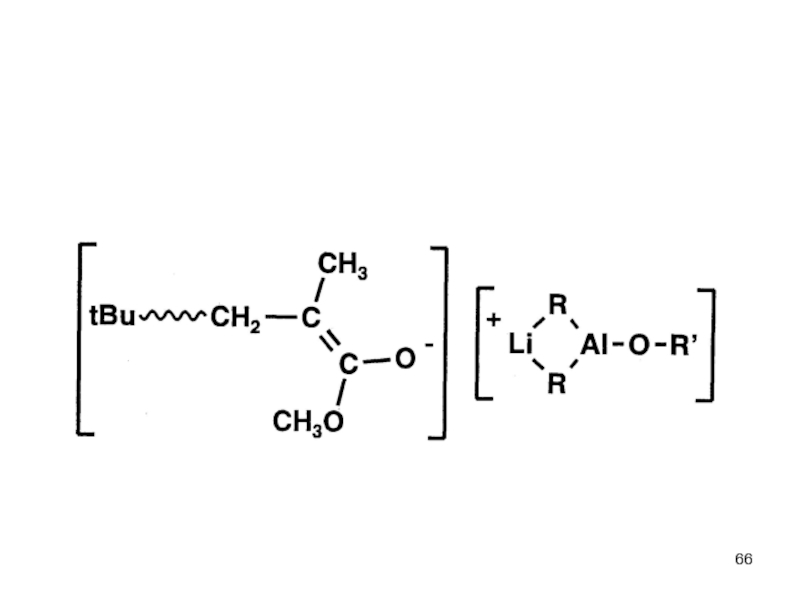

Control of Microstructure : Methods and distribution of tacticity

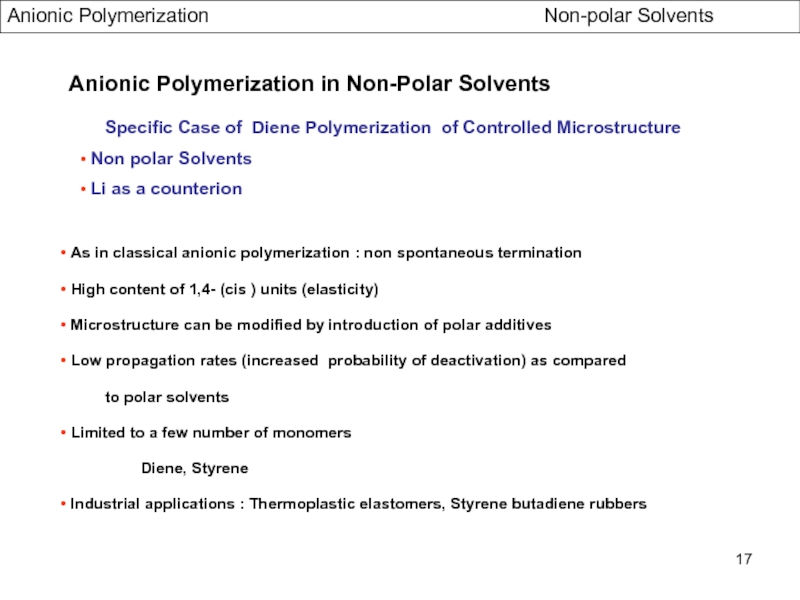

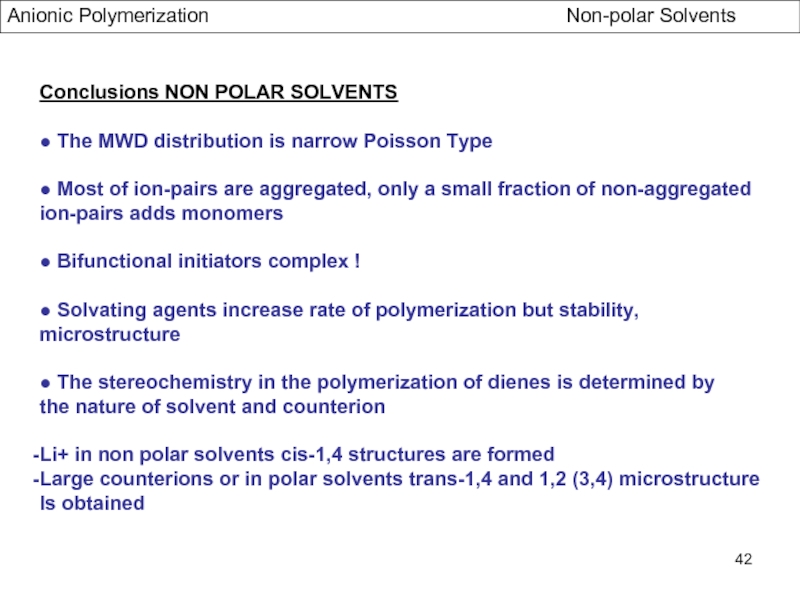

2 Anionic Polymerization of Non-polar Monomers

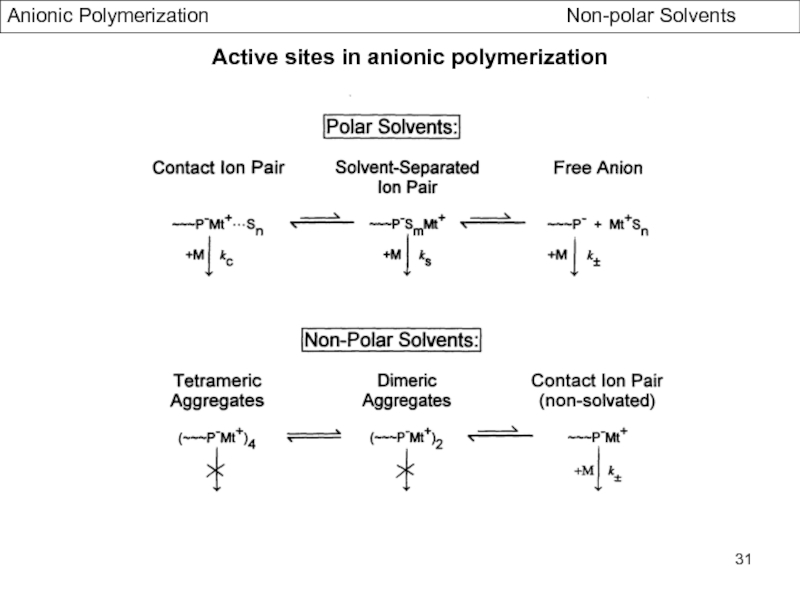

- Initiation and Propagation in Polar Solvents

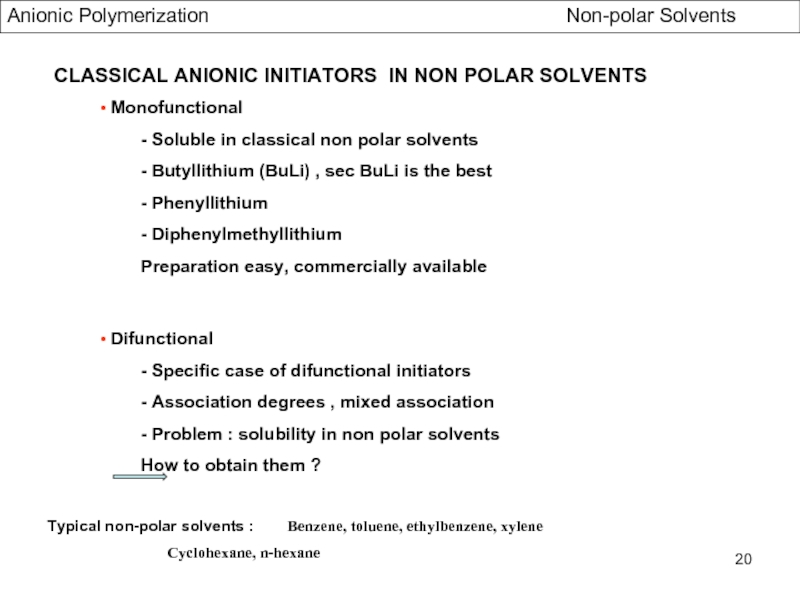

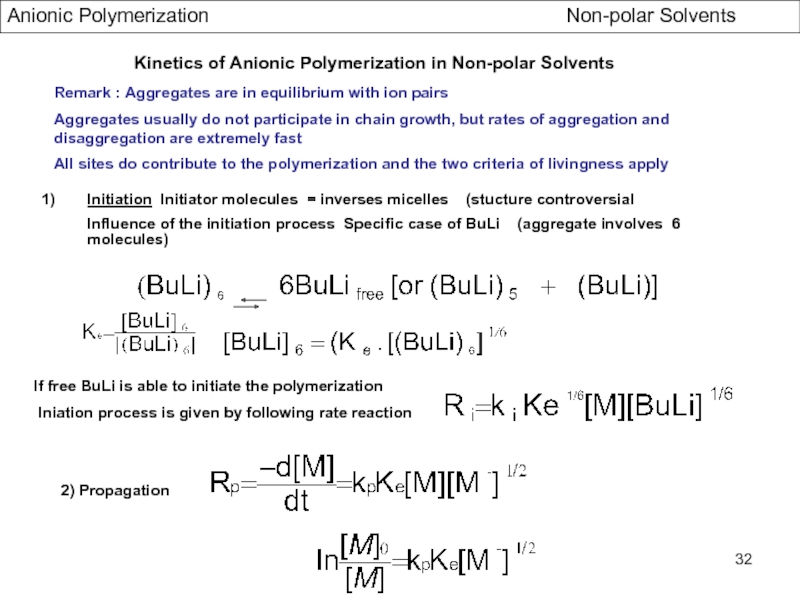

- Initiation and Propagation in Hydrocarbon Solvents

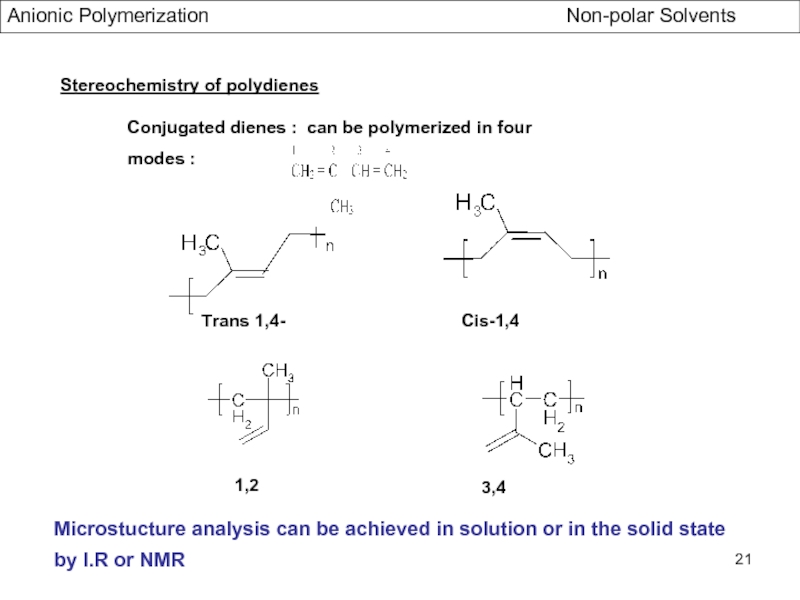

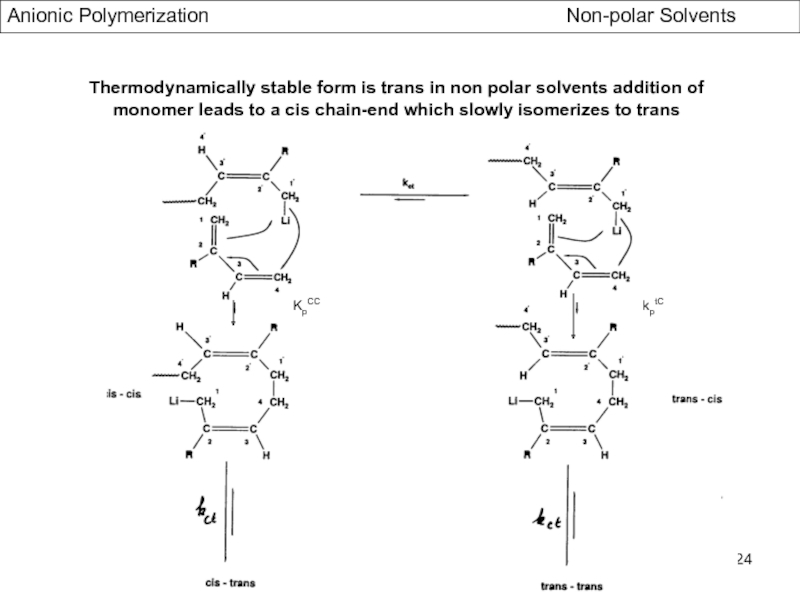

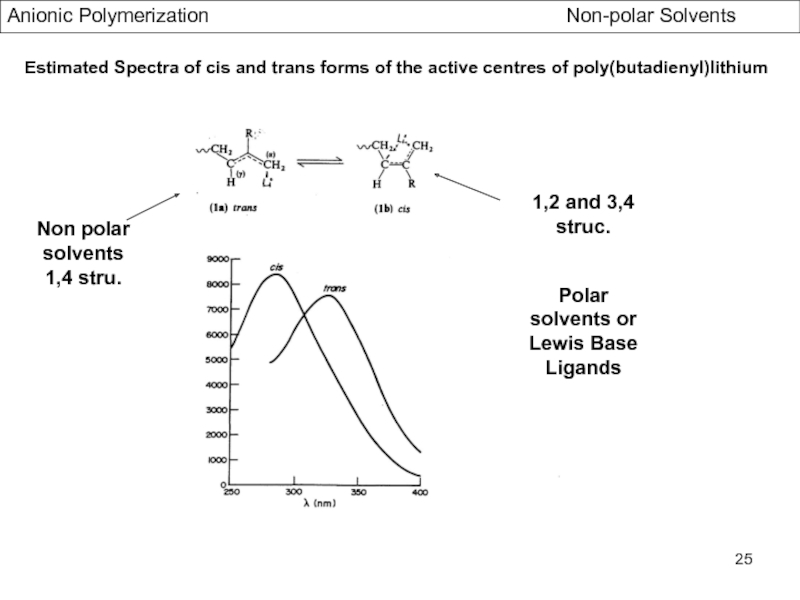

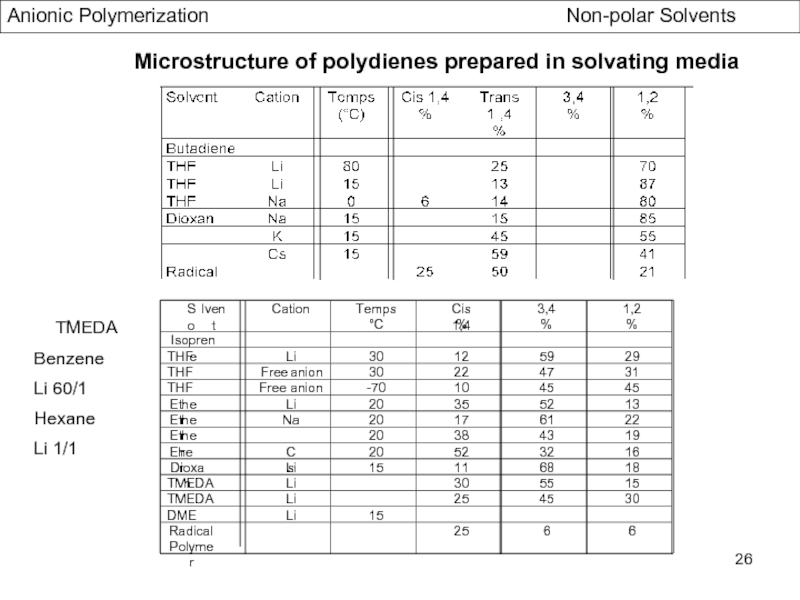

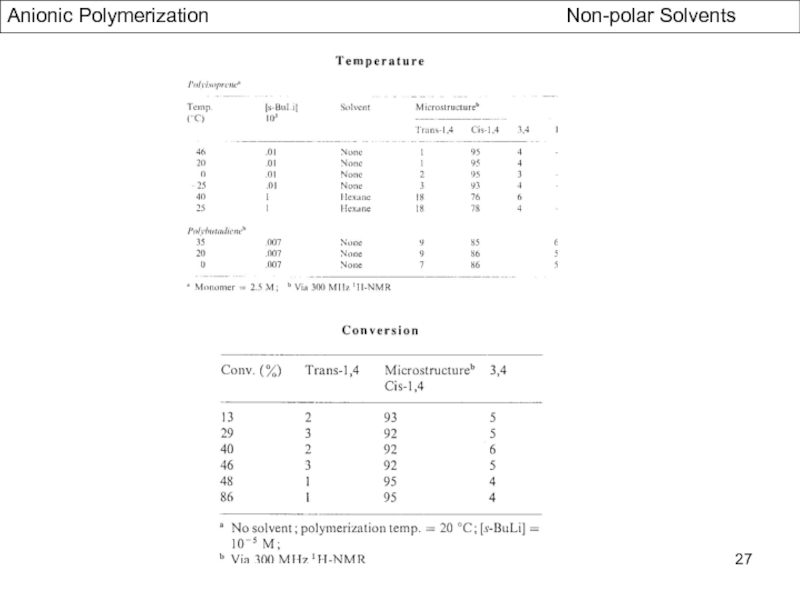

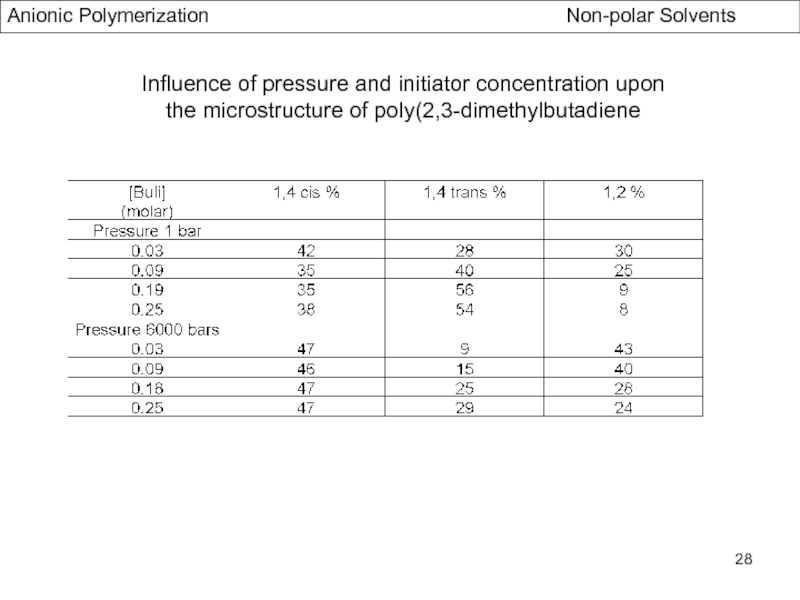

- Stereochemistry of Polydienes

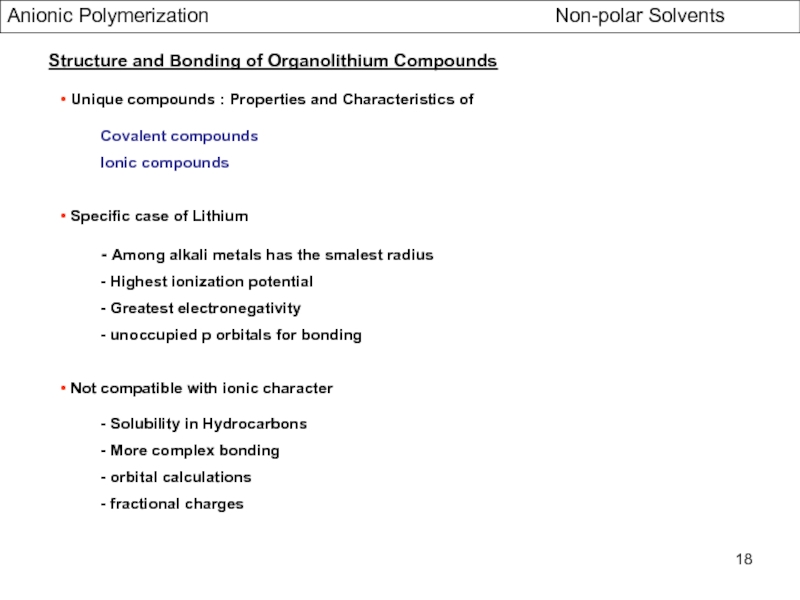

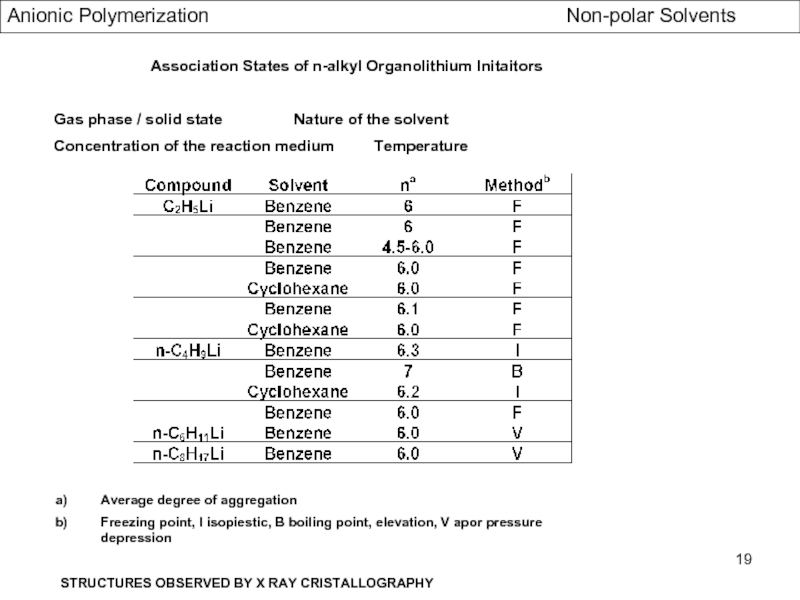

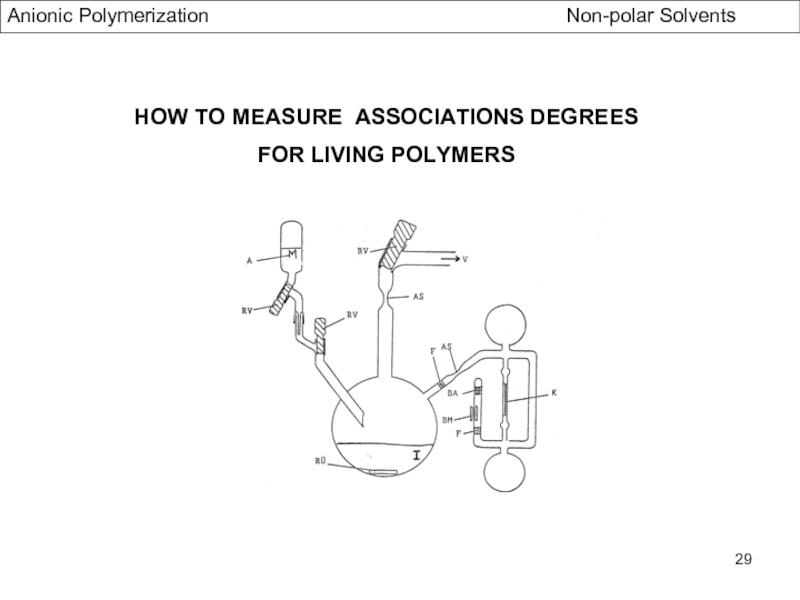

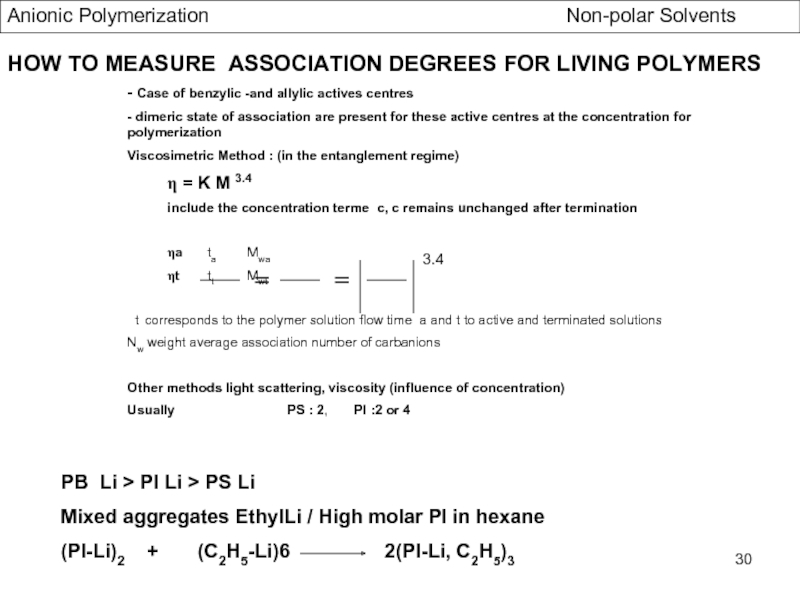

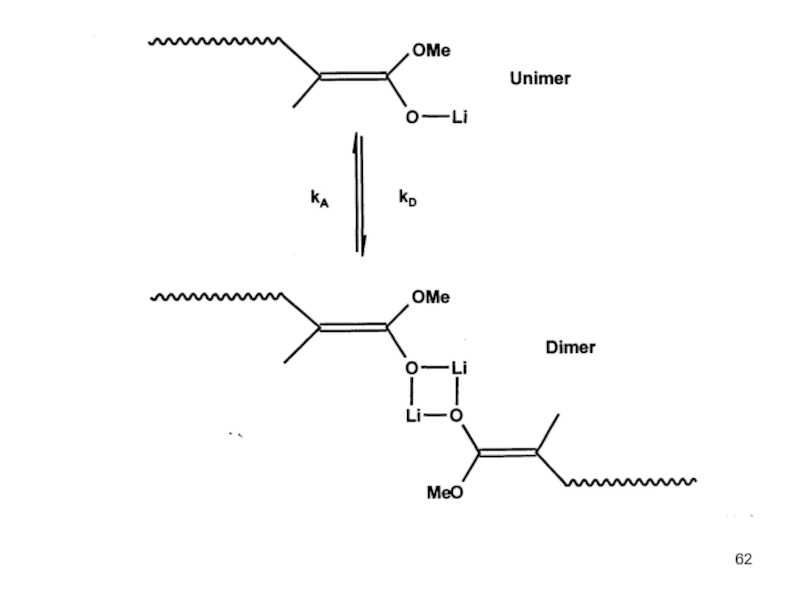

- Association Phenomena in non Polar Solvents

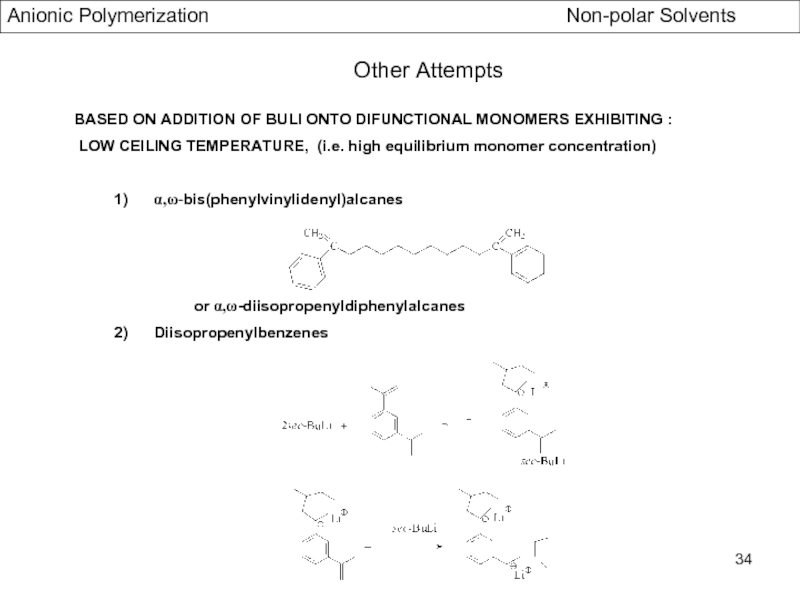

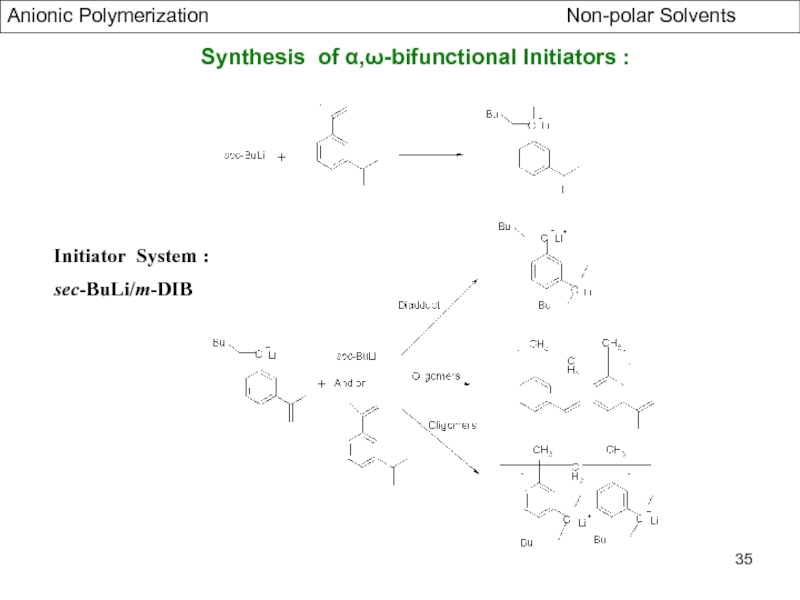

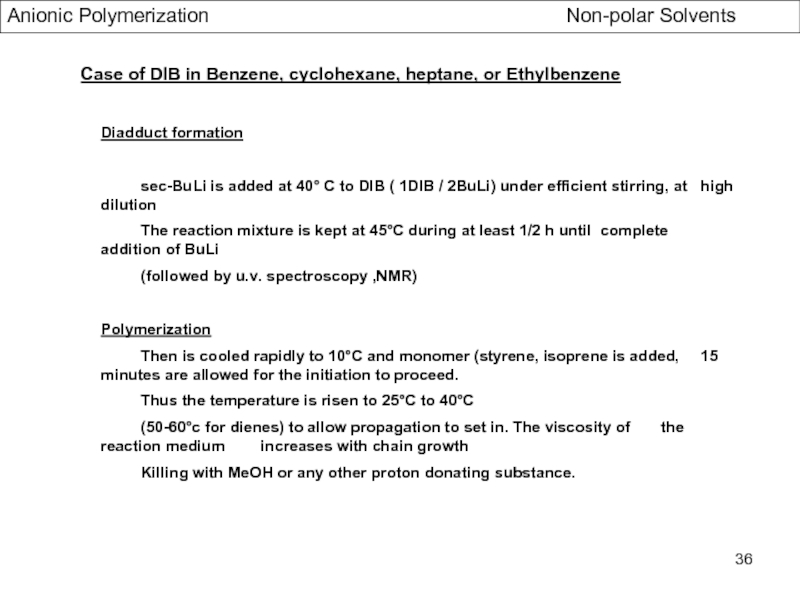

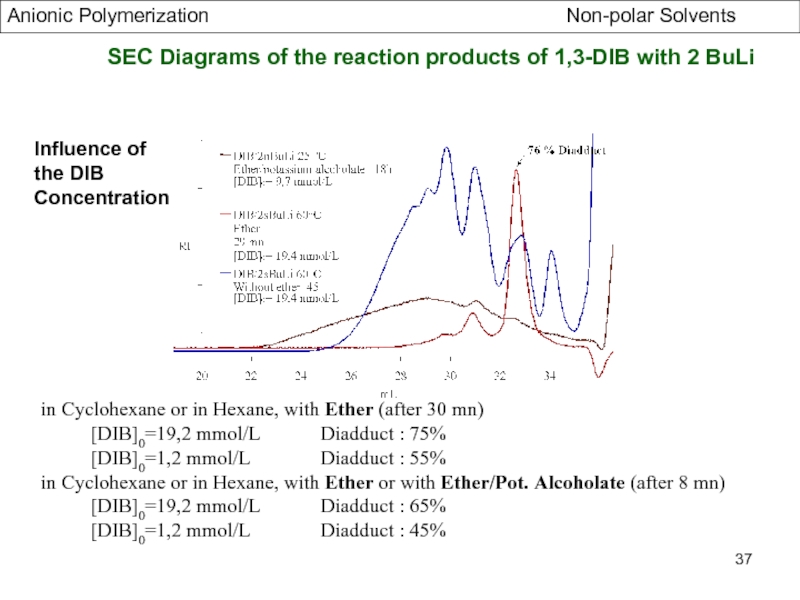

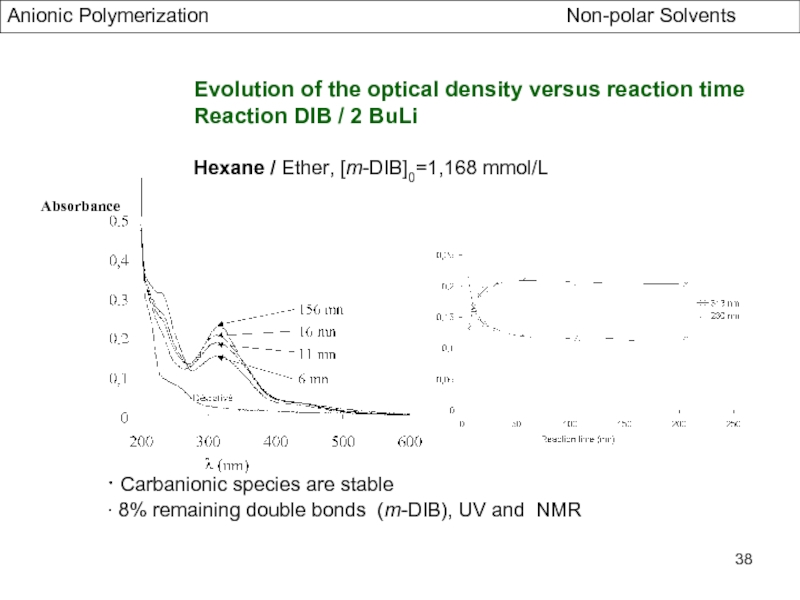

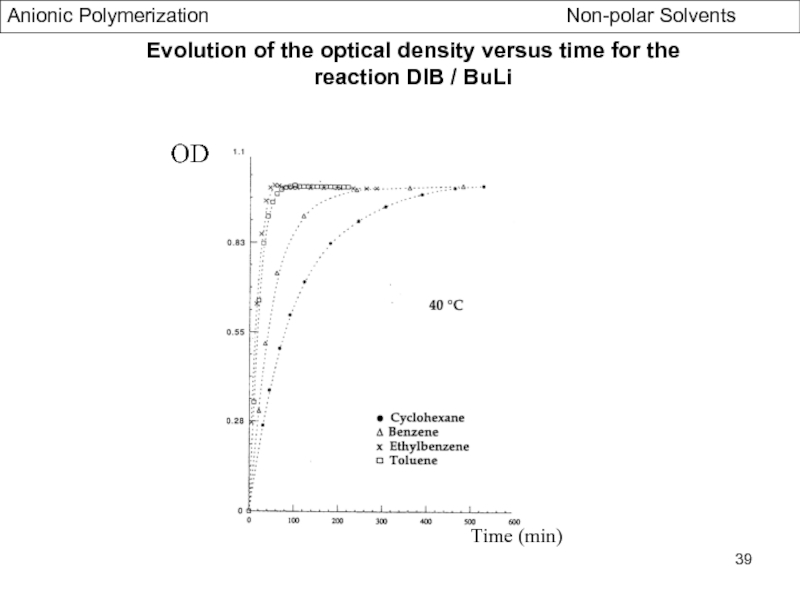

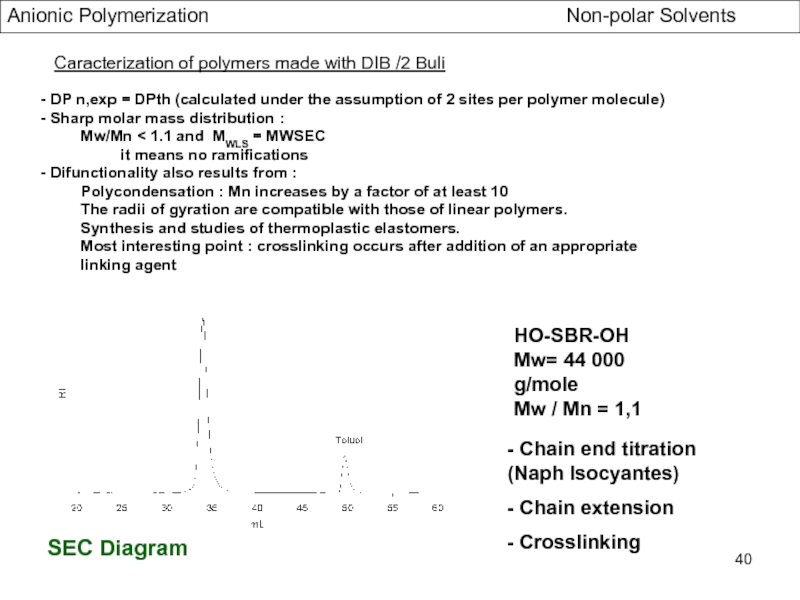

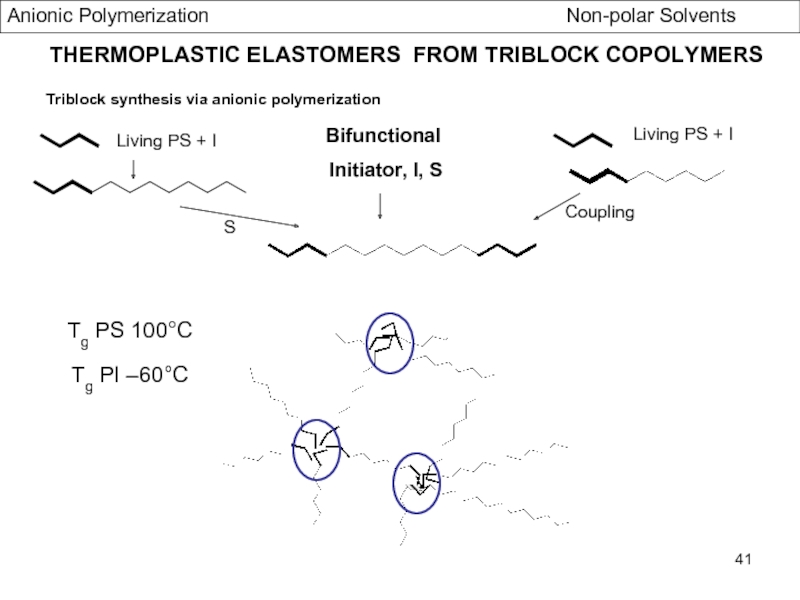

Specific Problems of bifunctional Initiators

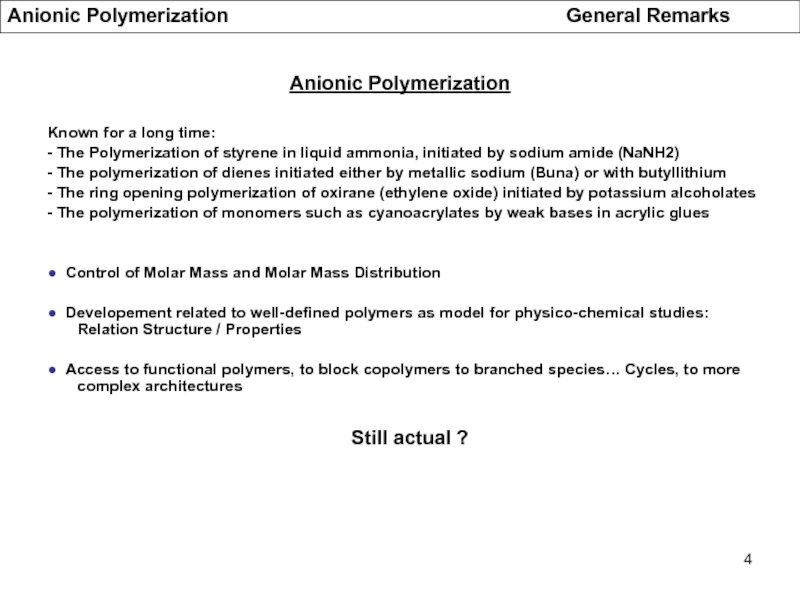

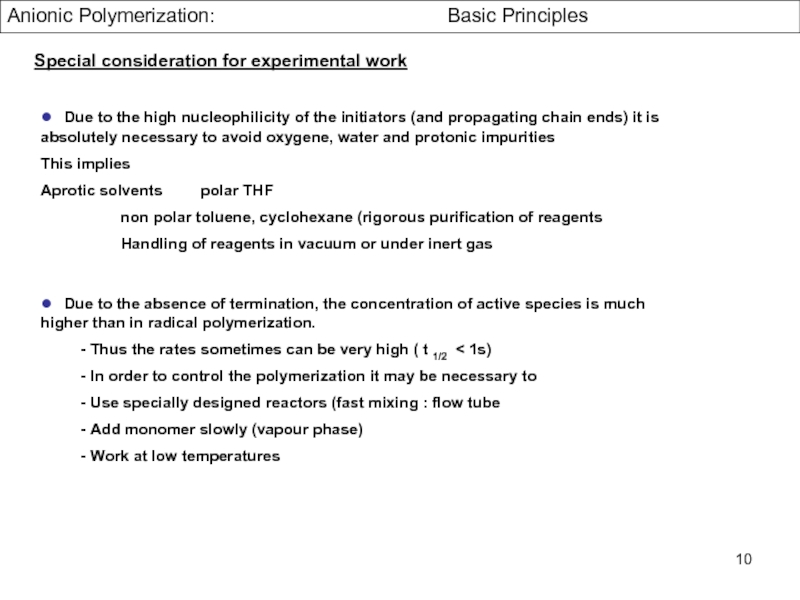

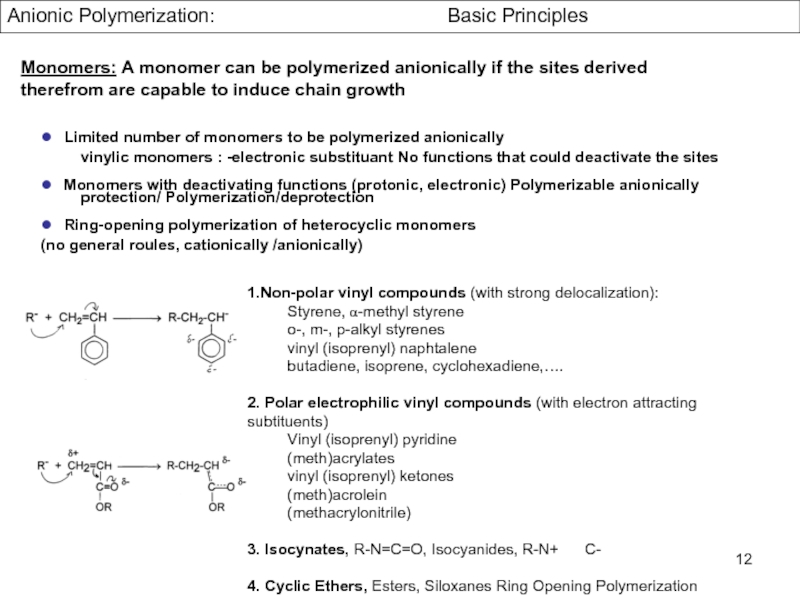

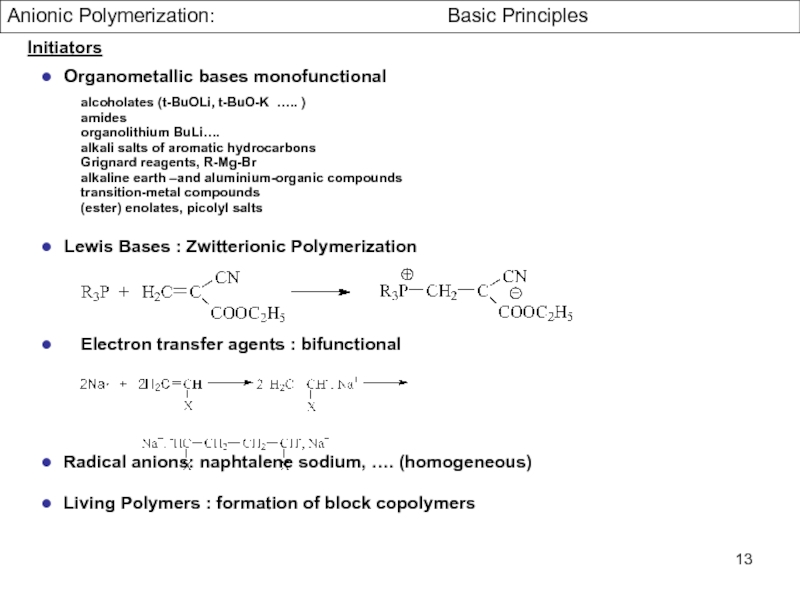

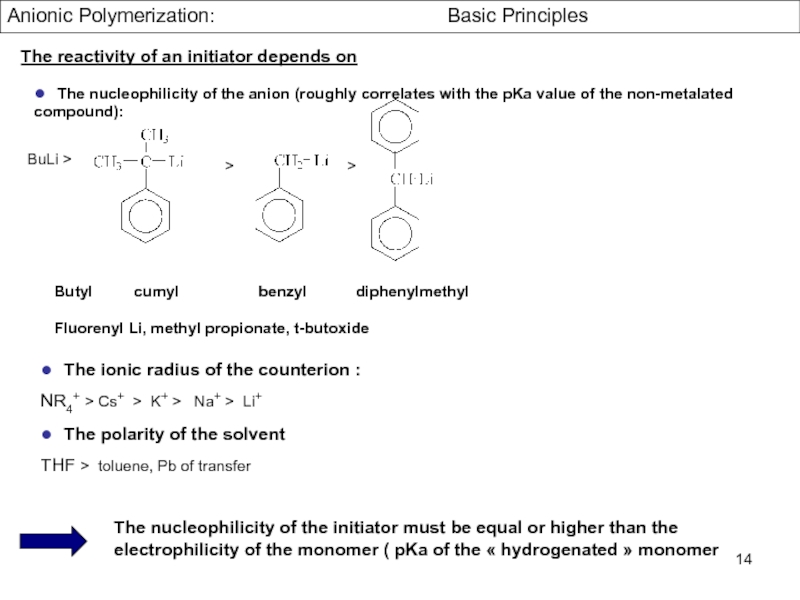

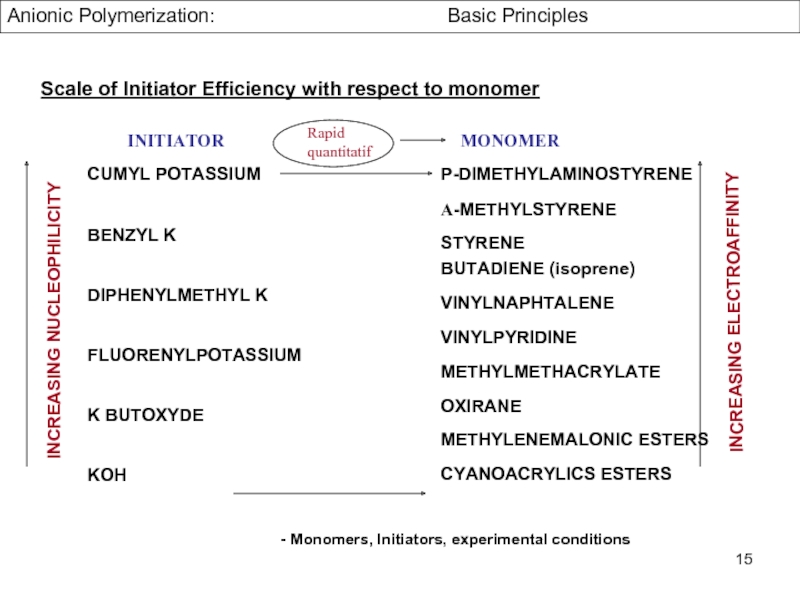

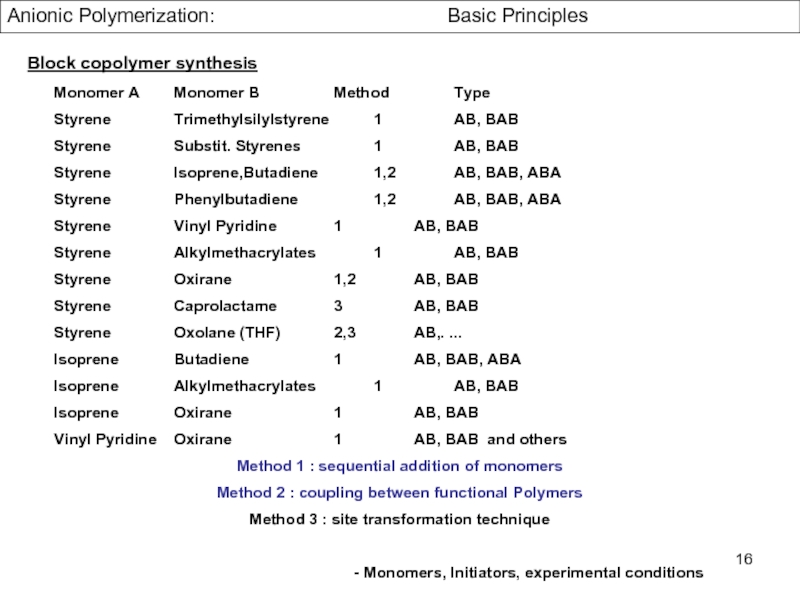

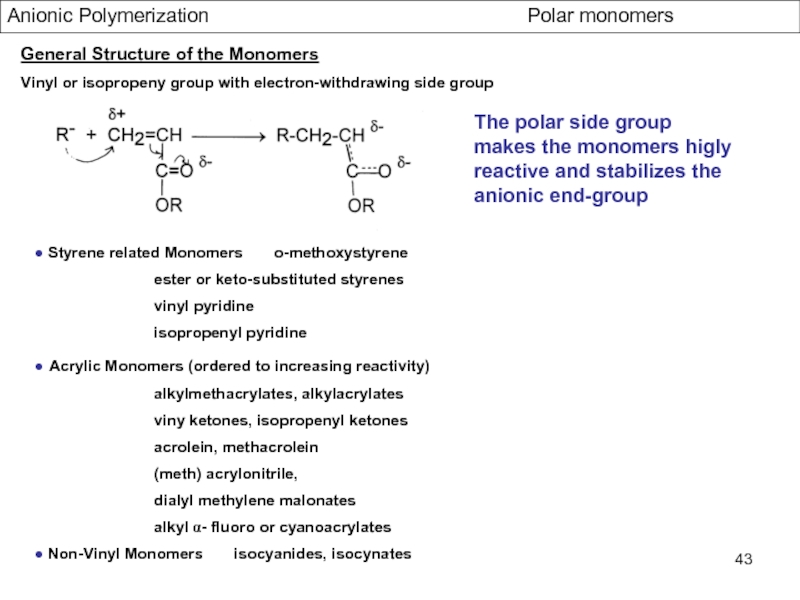

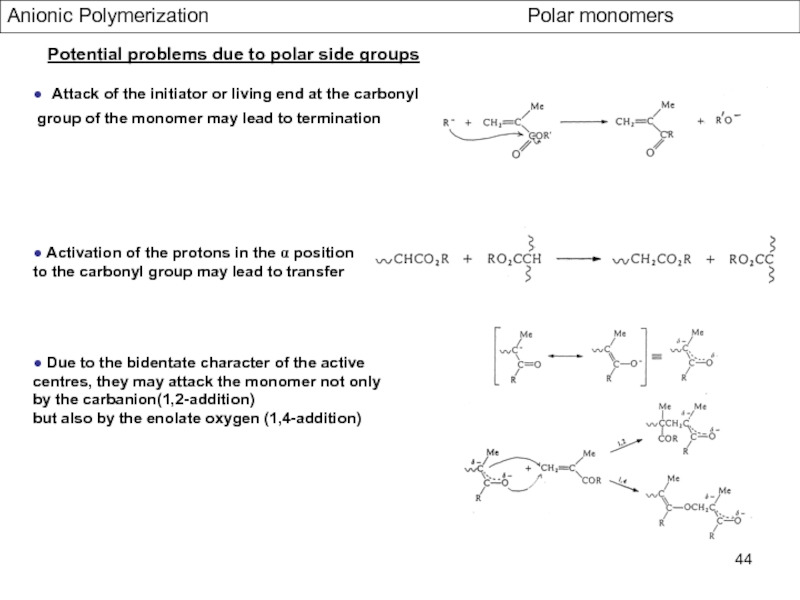

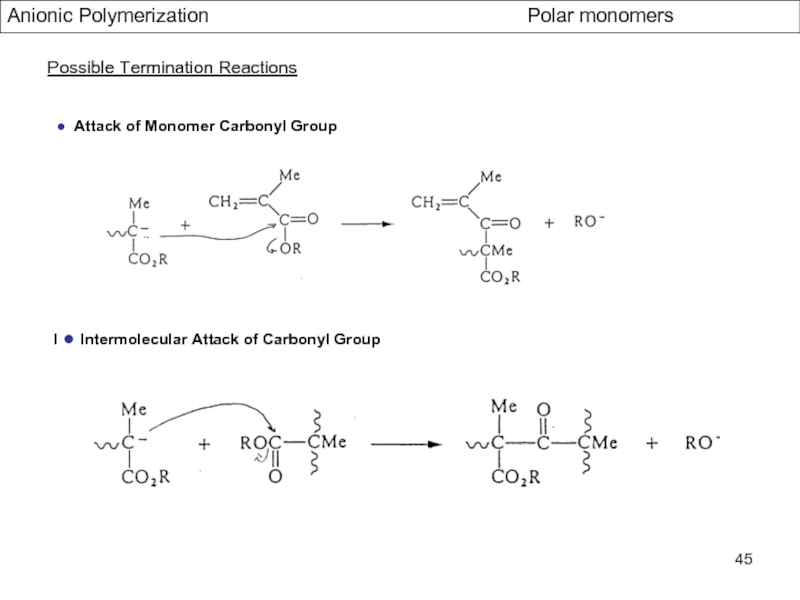

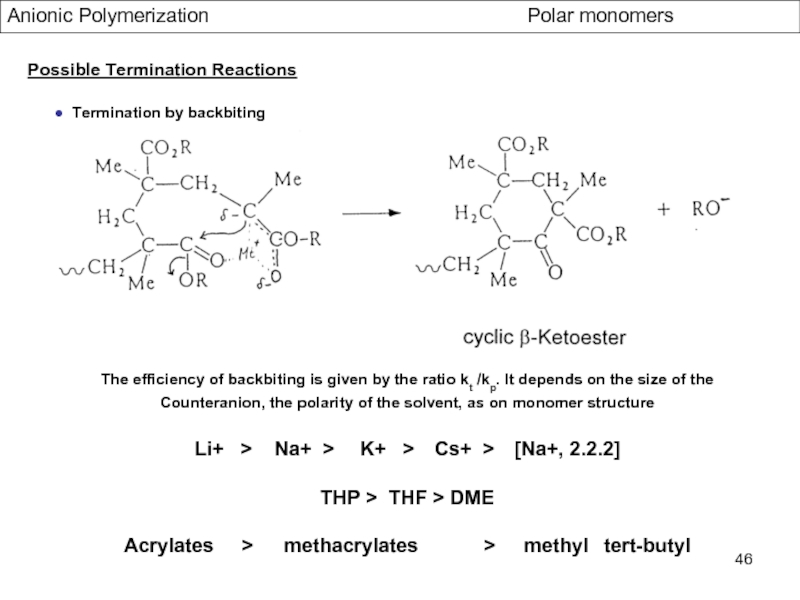

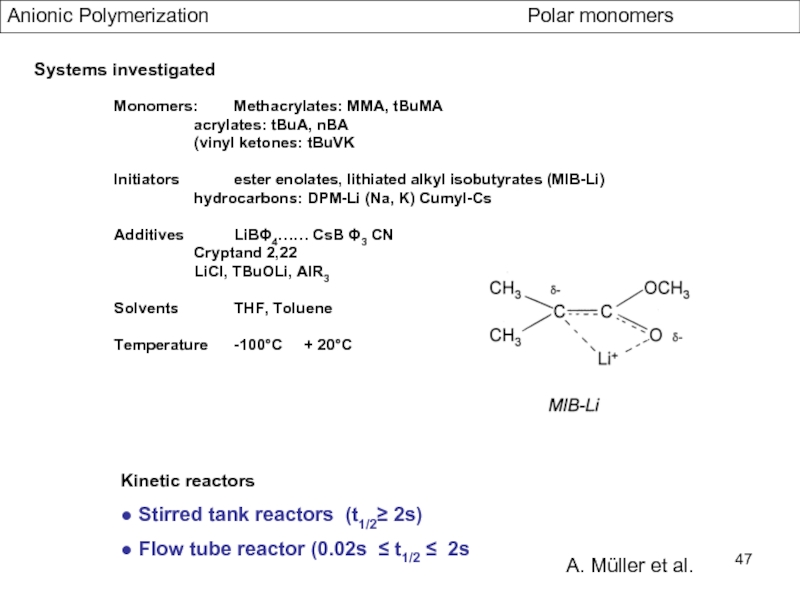

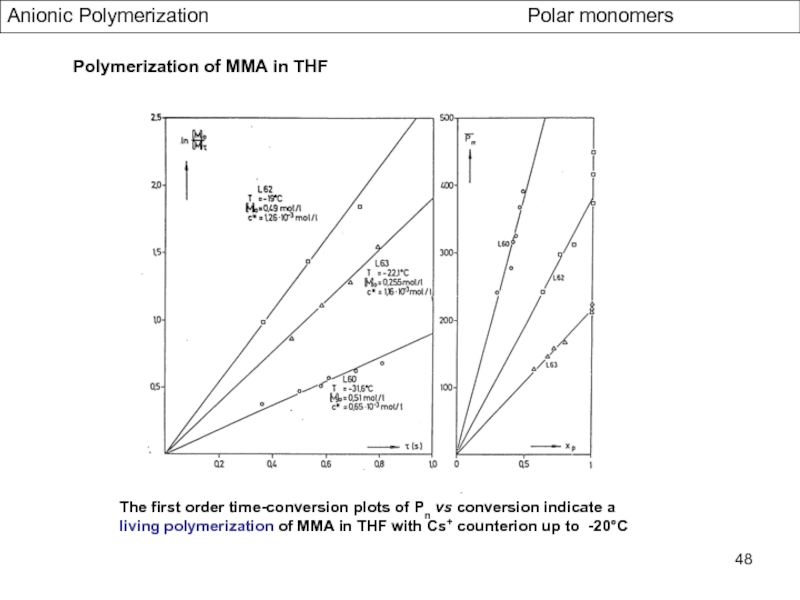

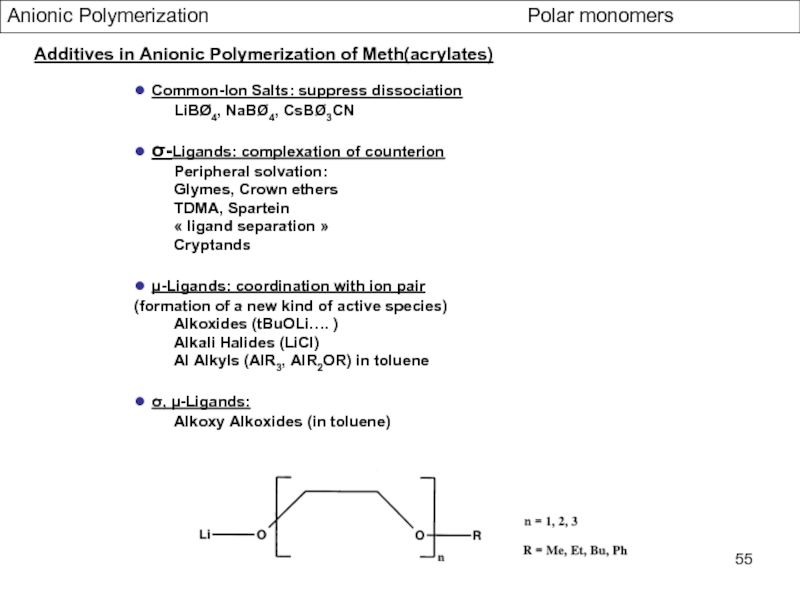

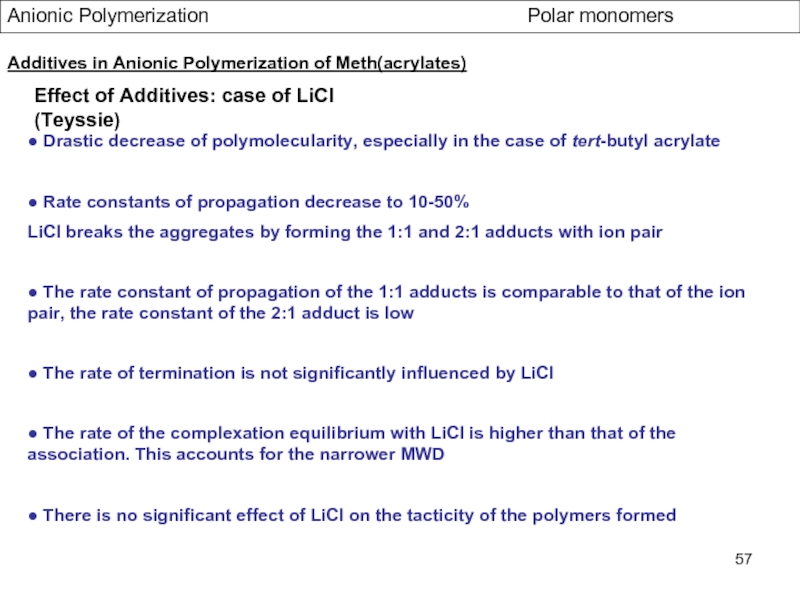

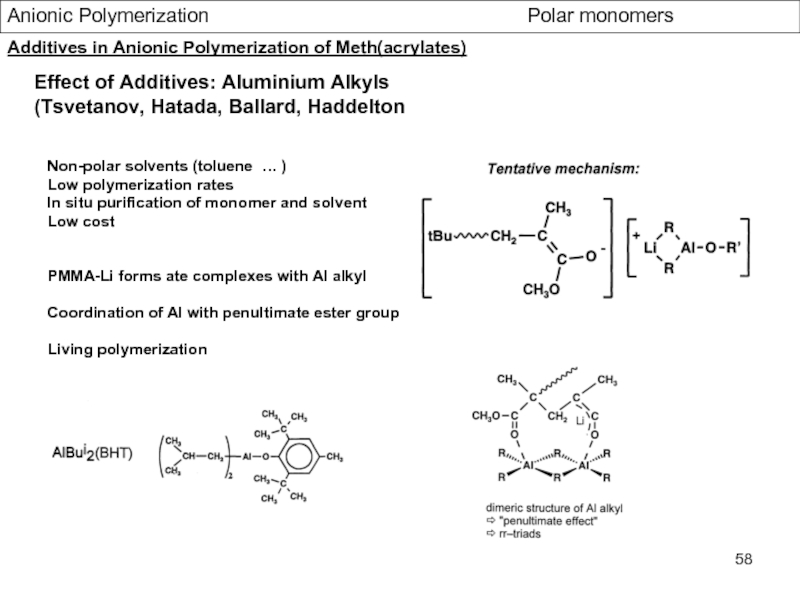

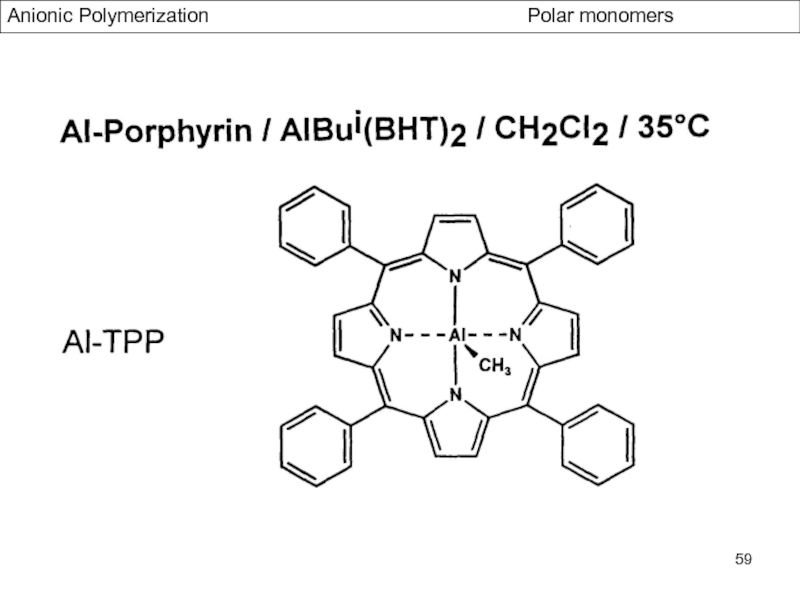

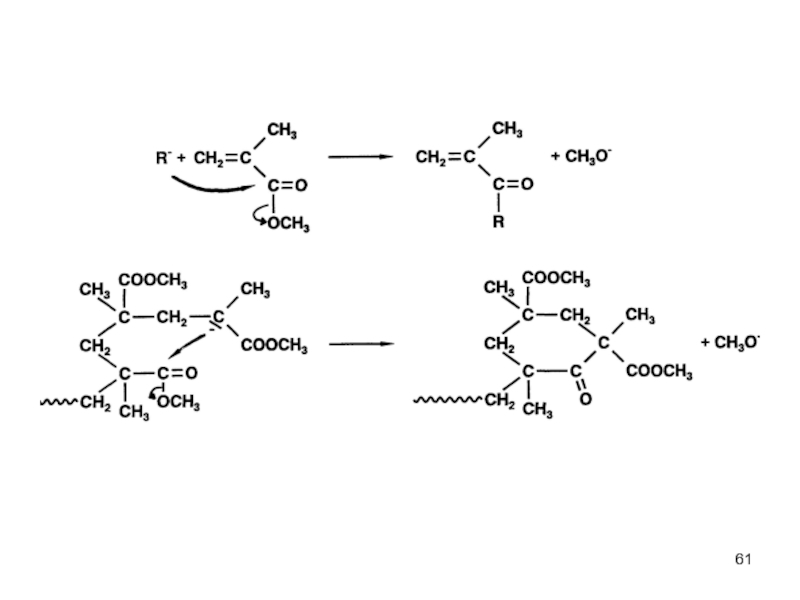

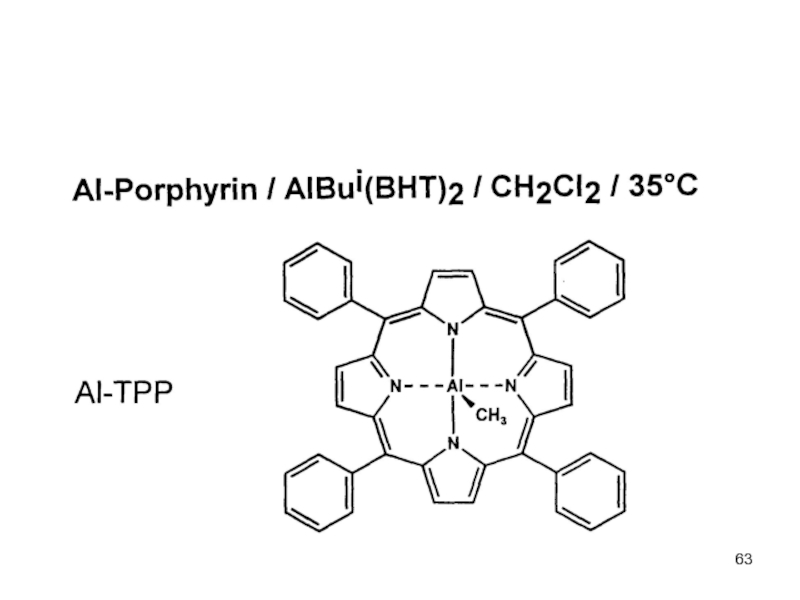

Anionic Polymerization