- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Additives for Polymeric Materials презентация

Содержание

- 1. Additives for Polymeric Materials

- 2. The Top 3 Plastic Additives for UV

- 3. Ultraviolet Absorbers Absorbers are a type of

- 4. Quenchers Quenchers return excited states of the

- 5. Quenching Mechanism

- 6. Hindered Amine Light Stabilizers (HALS) HALS are

- 7. Nucleating Agents Nucleating agents improve mechanical properties,

- 8. How do Nucleating Agents work? Illustration

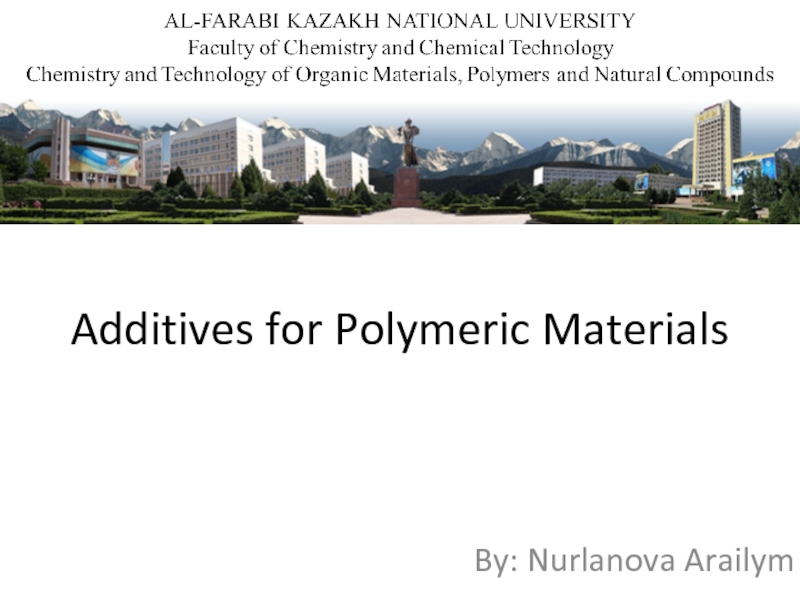

Слайд 2The Top 3 Plastic Additives for

UV Stabilization

Over time, exposure to the

UV radiation in sunlight will degrade plastics.

Polymer photodegradation occurs when UV light from the sun is absorbed by chemical groups in the polymer formation called chromophores.

UV stabilizers have been developed and are added to a polymer to inhibit the photoinitiation processes.

Polymer photodegradation occurs when UV light from the sun is absorbed by chemical groups in the polymer formation called chromophores.

UV stabilizers have been developed and are added to a polymer to inhibit the photoinitiation processes.

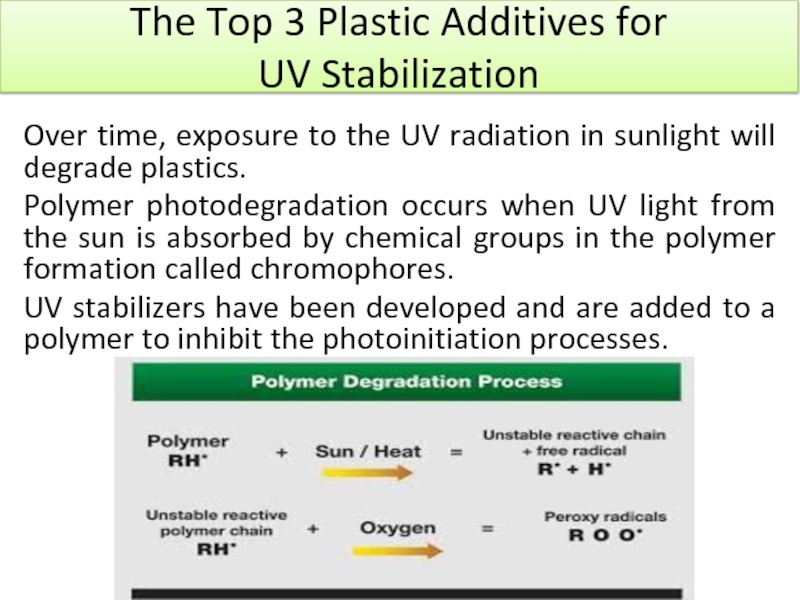

Слайд 3Ultraviolet Absorbers

Absorbers are a type of light stabilizer that functions by

competing with the chromophores to absorb UV radiation. Absorbers change harmful UV radiation into harmless infrared radiation.

The most effective and commonly used light absorber is – Carbon Black.

Another UV absorber is rutile titanium oxide which is effective in the 300-400 nm range.

Hydroxybenzophenone is also well known UV stabilizer that have the advantage of being suitable for neutral or transparent applications.

The most effective and commonly used light absorber is – Carbon Black.

Another UV absorber is rutile titanium oxide which is effective in the 300-400 nm range.

Hydroxybenzophenone is also well known UV stabilizer that have the advantage of being suitable for neutral or transparent applications.

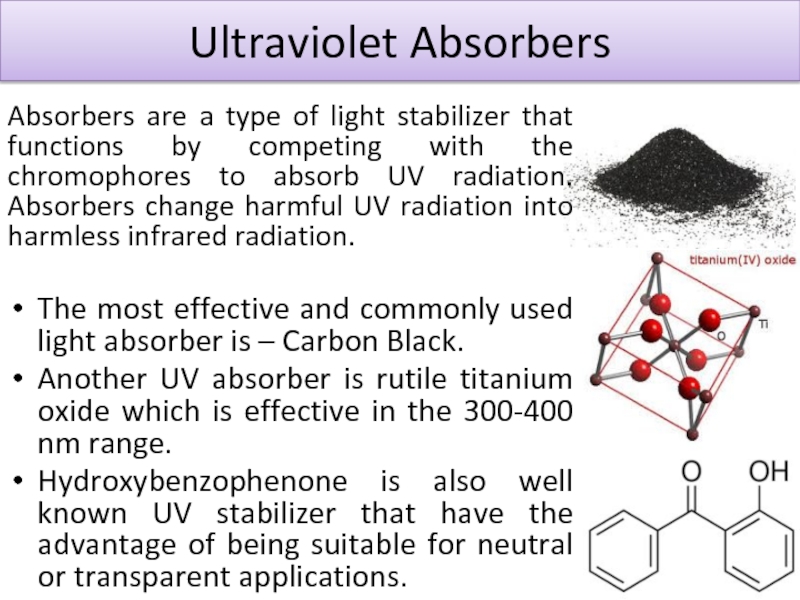

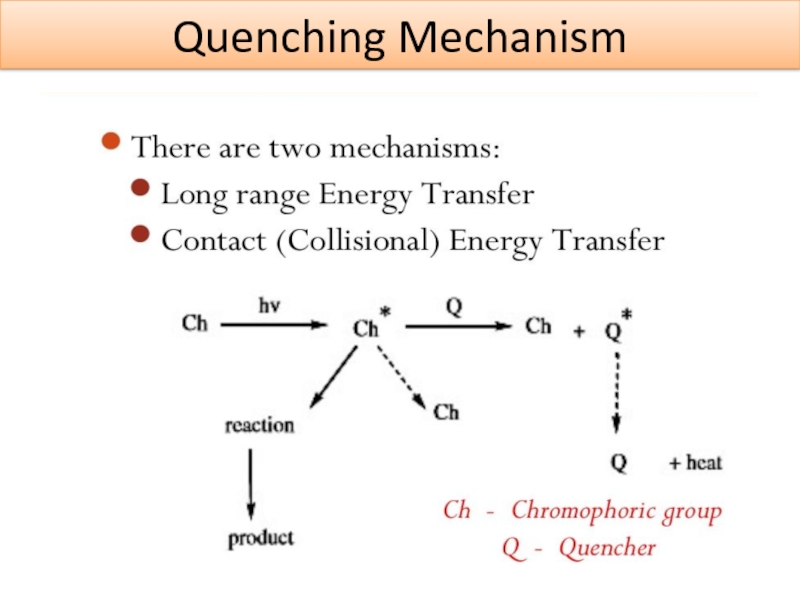

Слайд 4Quenchers

Quenchers return excited states of the chromophores to ground states by

an energy transfer process. The energy transfer agent functions by quenching the excited state of a carbonyl group formed during the photo-oxidation of a plastic material and through the decomposition of hydroperoxides.

They are used in agricultural film production.

They are used in agricultural film production.

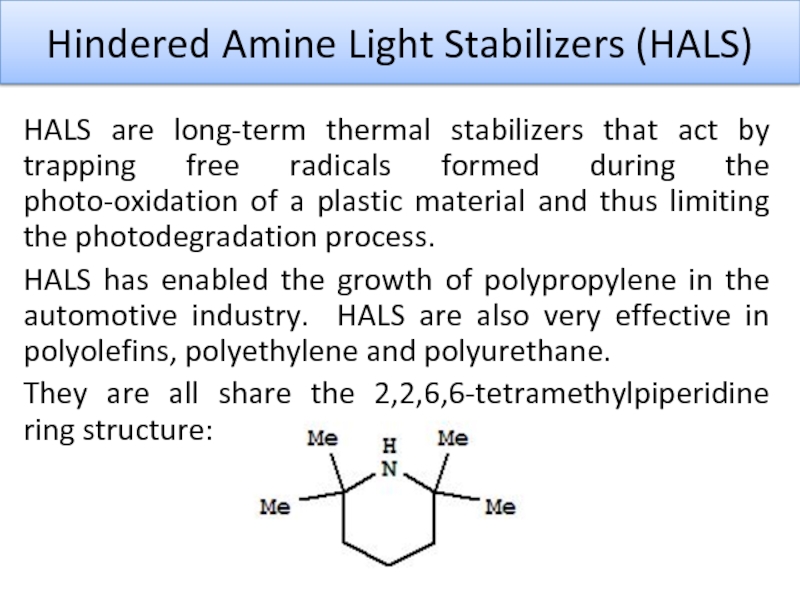

Слайд 6Hindered Amine Light Stabilizers (HALS)

HALS are long-term thermal stabilizers that act

by trapping free radicals formed during the photo-oxidation of a plastic material and thus limiting the photodegradation process.

HALS has enabled the growth of polypropylene in the automotive industry. HALS are also very effective in polyolefins, polyethylene and polyurethane.

They are all share the 2,2,6,6-tetramethylpiperidine ring structure:

HALS has enabled the growth of polypropylene in the automotive industry. HALS are also very effective in polyolefins, polyethylene and polyurethane.

They are all share the 2,2,6,6-tetramethylpiperidine ring structure:

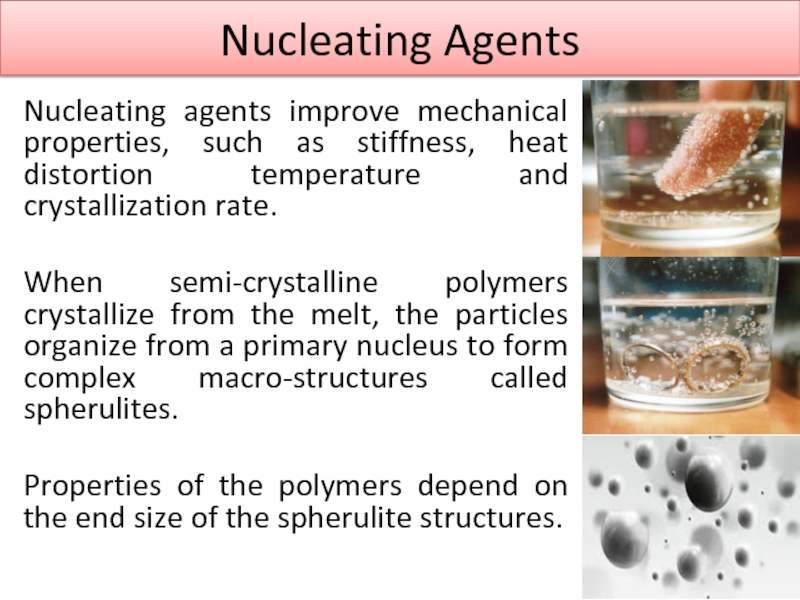

Слайд 7Nucleating Agents

Nucleating agents improve mechanical properties, such as stiffness, heat distortion

temperature and crystallization rate.

When semi-crystalline polymers crystallize from the melt, the particles organize from a primary nucleus to form complex macro-structures called spherulites.

Properties of the polymers depend on the end size of the spherulite structures.

When semi-crystalline polymers crystallize from the melt, the particles organize from a primary nucleus to form complex macro-structures called spherulites.

Properties of the polymers depend on the end size of the spherulite structures.

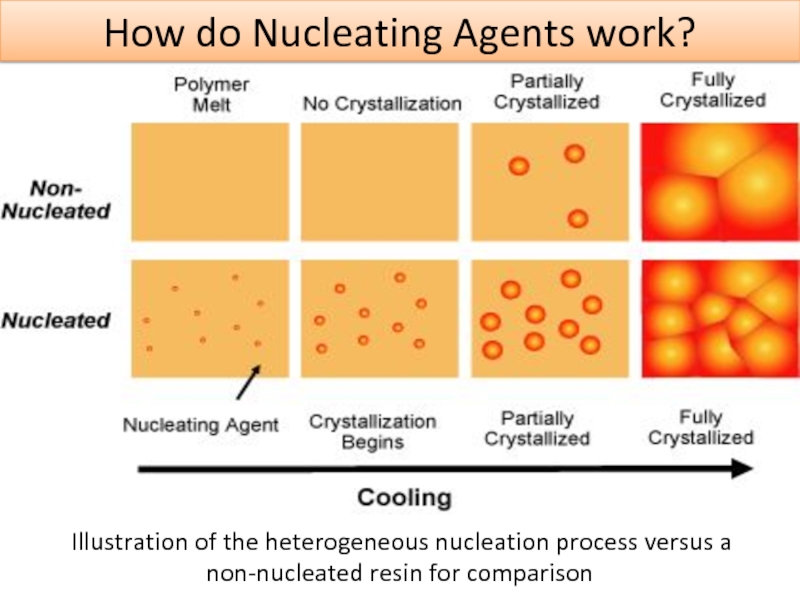

Слайд 8How do Nucleating Agents work?

Illustration of the heterogeneous nucleation process

versus a non-nucleated resin for comparison