- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Introduction to ultrasonic testing презентация

Содержание

- 1. Introduction to ultrasonic testing

- 2. Krautkramer NDT Ultrasonic Systems

- 3. Krautkramer NDT Ultrasonic Systems

- 4. Krautkramer NDT Ultrasonic Systems

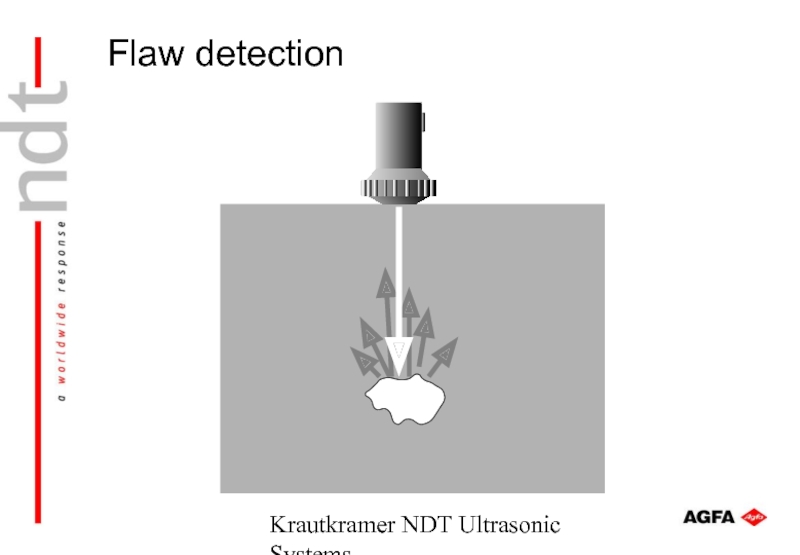

- 5. Krautkramer NDT Ultrasonic Systems Flaw detection

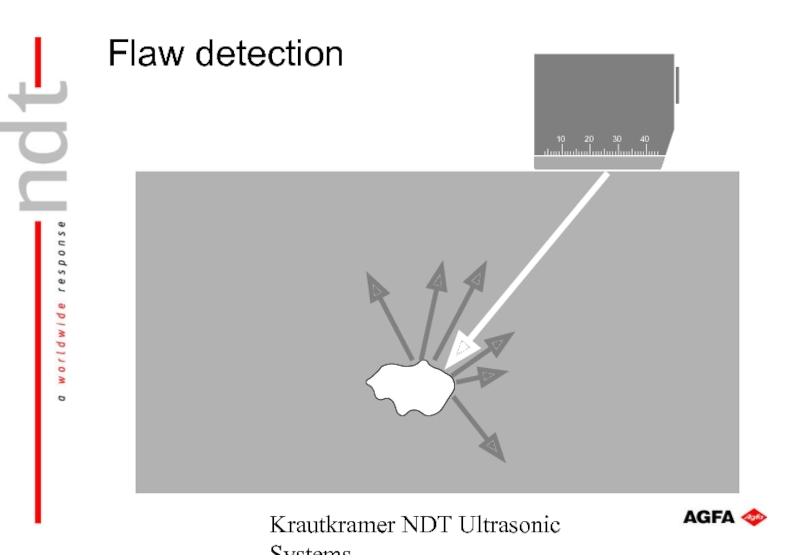

- 6. Krautkramer NDT Ultrasonic Systems Flaw detection

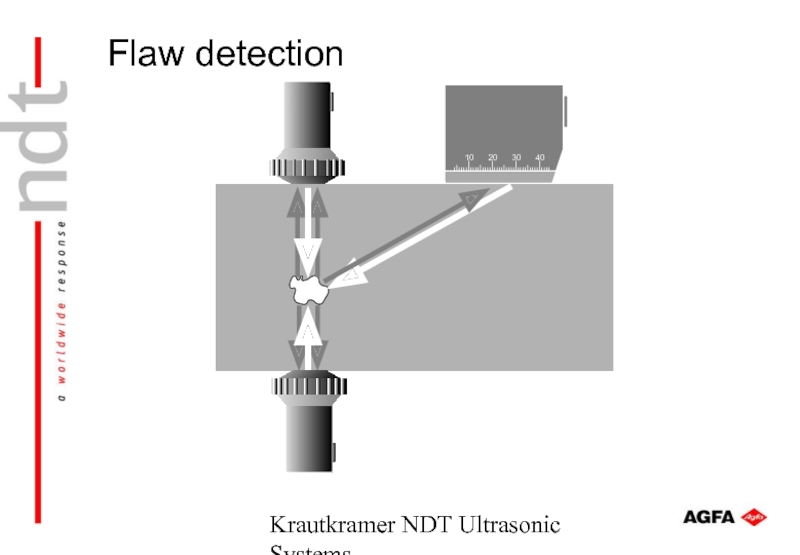

- 7. Krautkramer NDT Ultrasonic Systems Flaw detection

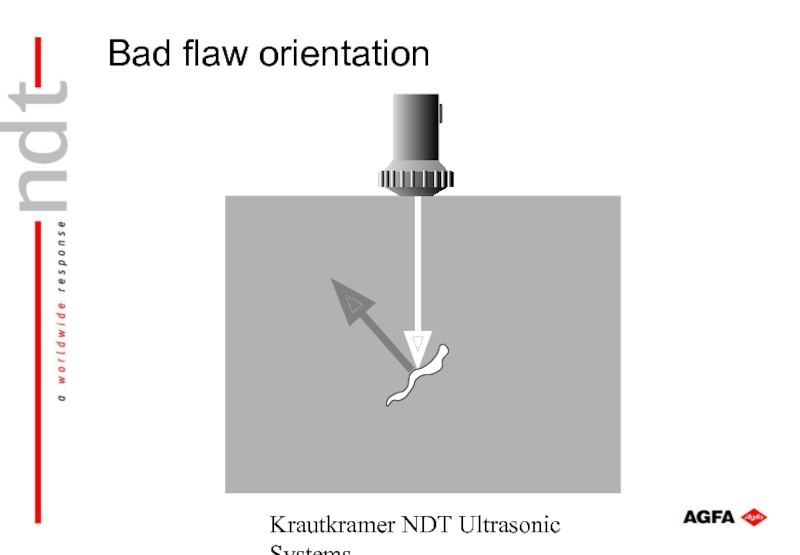

- 8. Krautkramer NDT Ultrasonic Systems Bad flaw orientation

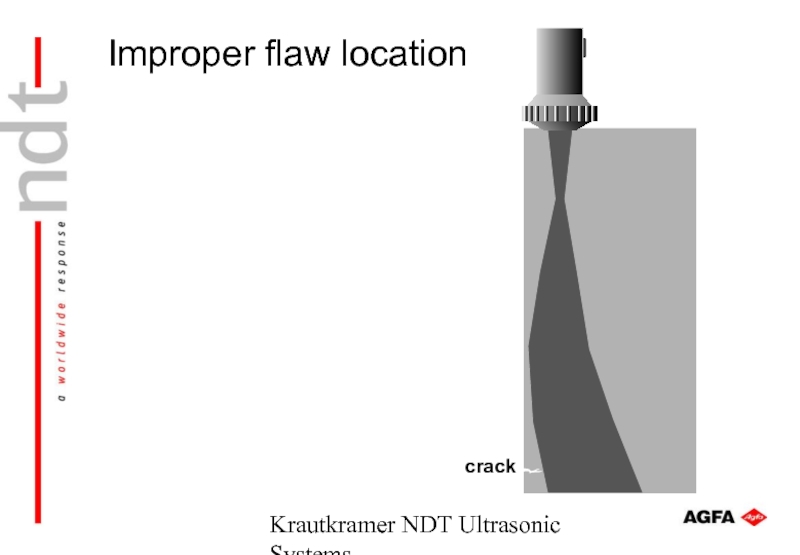

- 9. Krautkramer NDT Ultrasonic Systems crack Improper flaw location

- 10. Krautkramer NDT Ultrasonic Systems

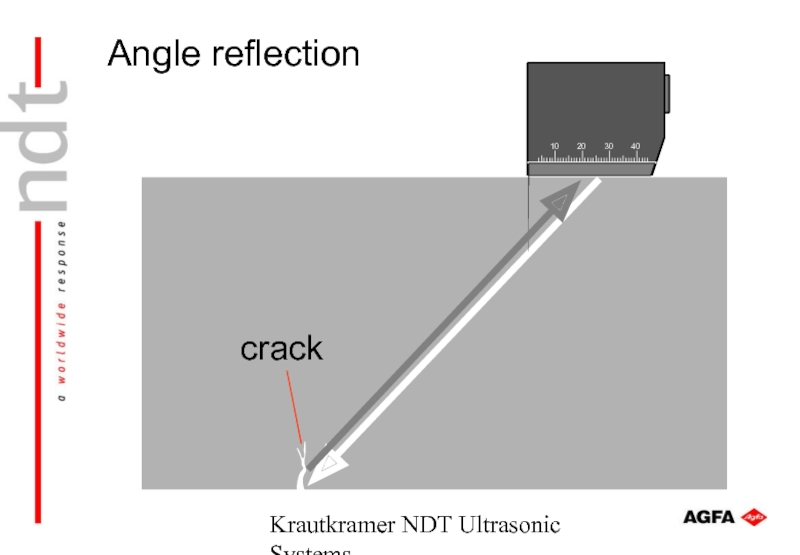

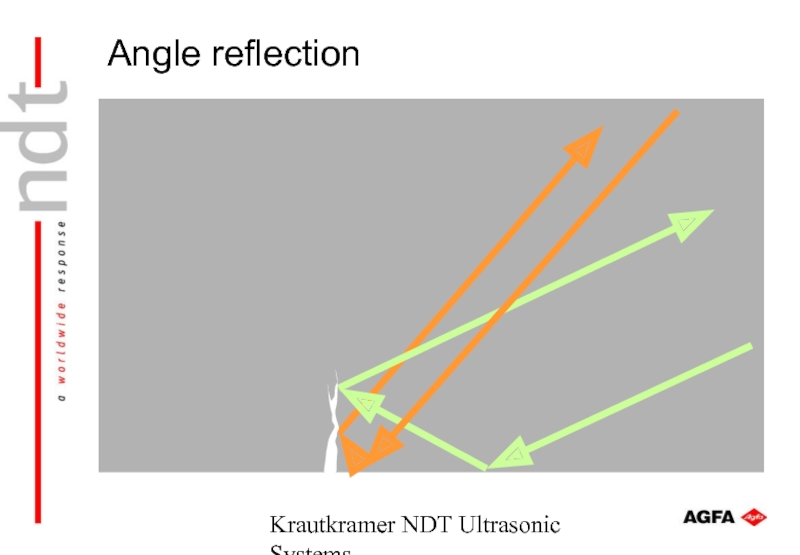

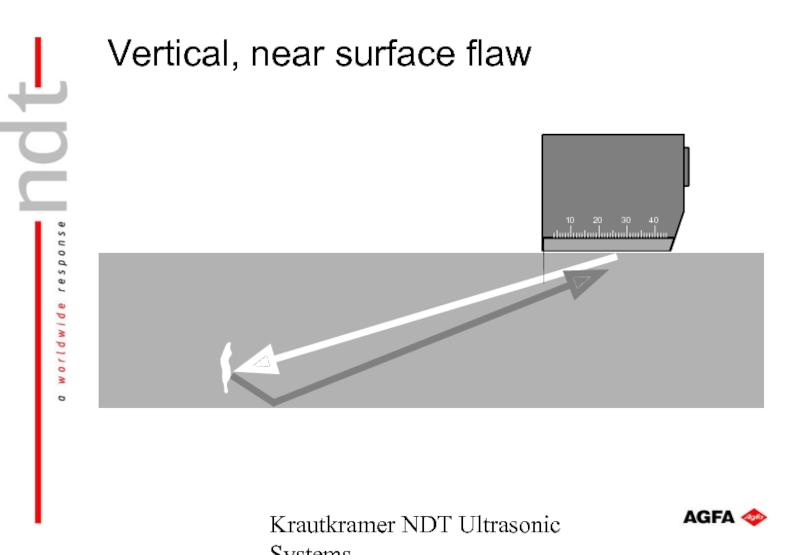

- 11. Krautkramer NDT Ultrasonic Systems Angle reflection

- 12. Krautkramer NDT Ultrasonic Systems

- 13. Krautkramer NDT Ultrasonic Systems

- 14. Krautkramer NDT Ultrasonic Systems

- 15. Krautkramer NDT Ultrasonic Systems

- 16. Krautkramer NDT Ultrasonic Systems

- 17. Krautkramer NDT Ultrasonic Systems

- 18. Krautkramer NDT Ultrasonic Systems sound

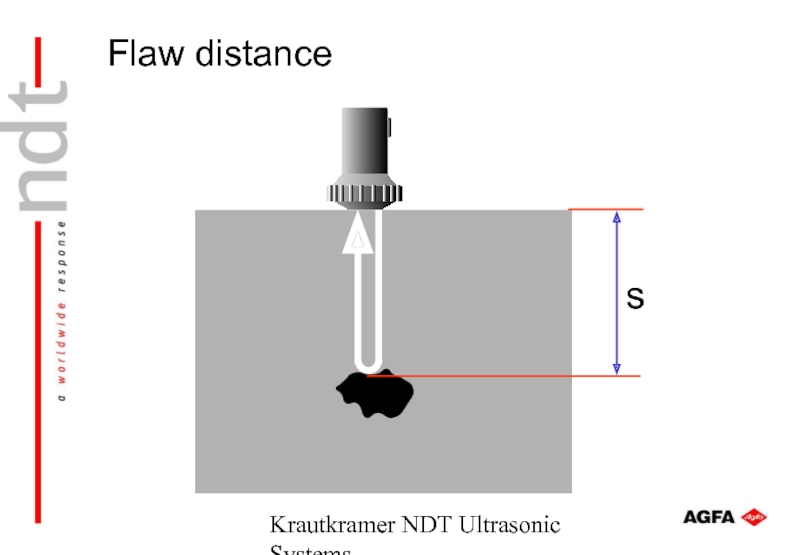

- 19. Krautkramer NDT Ultrasonic Systems s Flaw distance

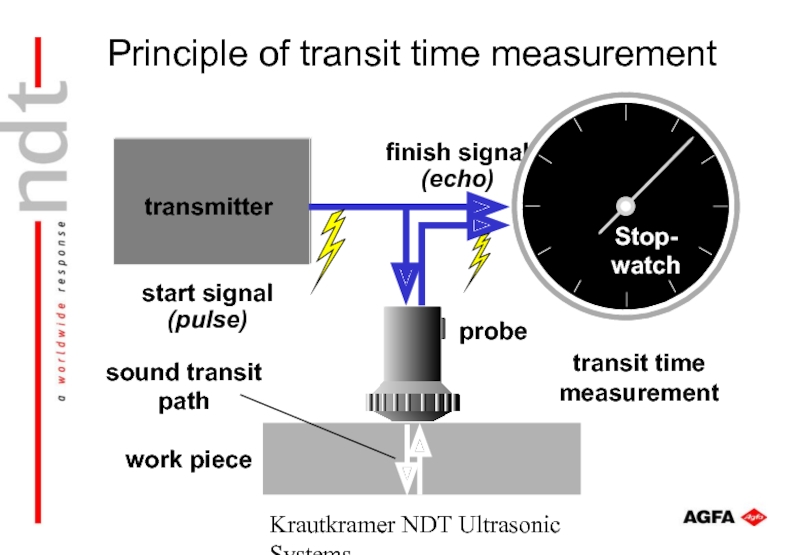

- 20. Krautkramer NDT Ultrasonic Systems start signal (pulse)

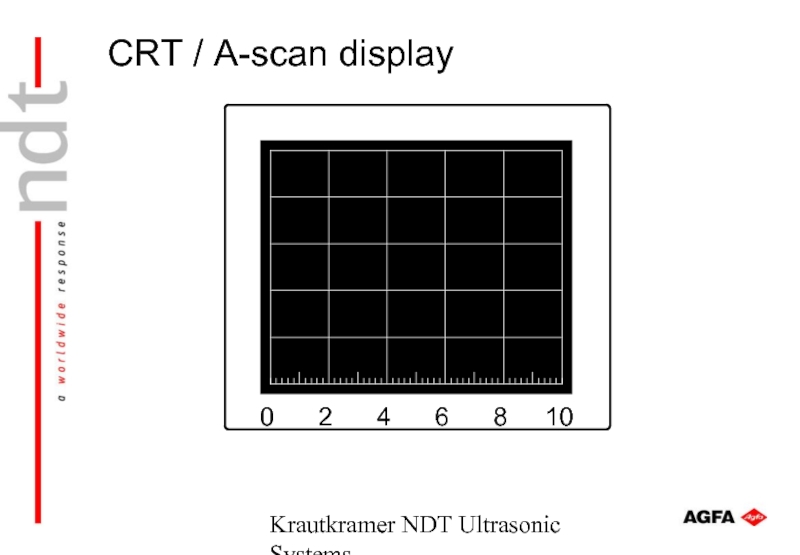

- 21. Krautkramer NDT Ultrasonic Systems CRT / A-scan display

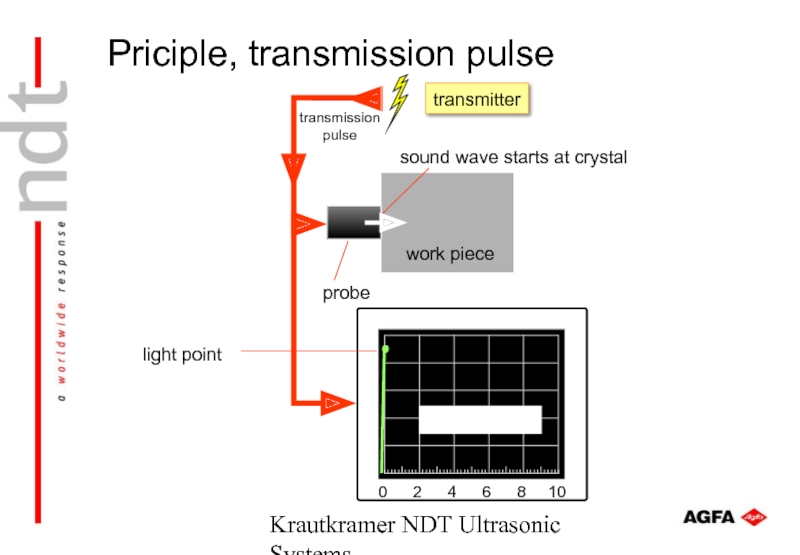

- 22. Krautkramer NDT Ultrasonic Systems

- 23. Krautkramer NDT Ultrasonic Systems

- 24. Krautkramer NDT Ultrasonic Systems

- 25. Krautkramer NDT Ultrasonic Systems transmitter Priciple, sound pulse at the coupling surface

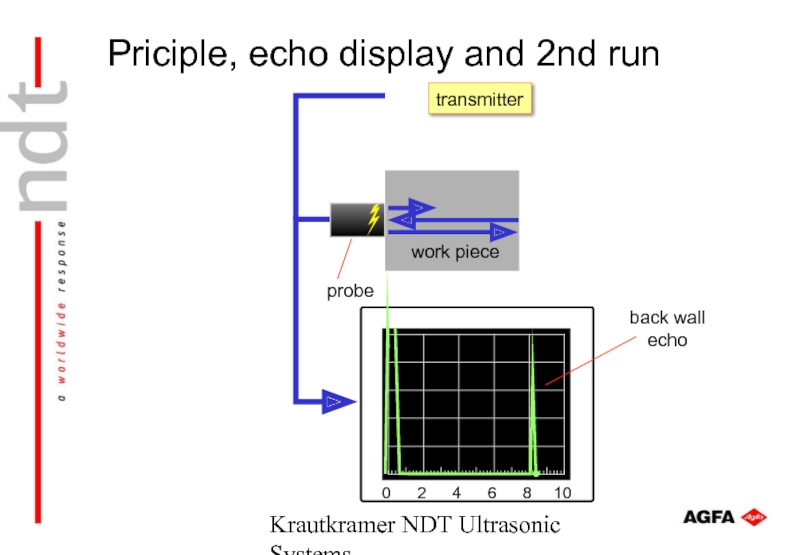

- 26. Krautkramer NDT Ultrasonic Systems transmitter Priciple, echo display and 2nd run

- 27. Krautkramer NDT Ultrasonic Systems 2 4

- 28. Krautkramer NDT Ultrasonic Systems

- 29. Krautkramer NDT Ultrasonic Systems Flaw location and echo display

- 30. Krautkramer NDT Ultrasonic Systems

- 31. Krautkramer NDT Ultrasonic Systems

- 32. Krautkramer NDT Ultrasonic Systems

- 33. Krautkramer NDT Ultrasonic Systems

- 34. Krautkramer NDT Ultrasonic Systems

- 35. Krautkramer NDT Ultrasonic Systems

- 36. Krautkramer NDT Ultrasonic Systems

- 37. Krautkramer NDT Ultrasonic Systems

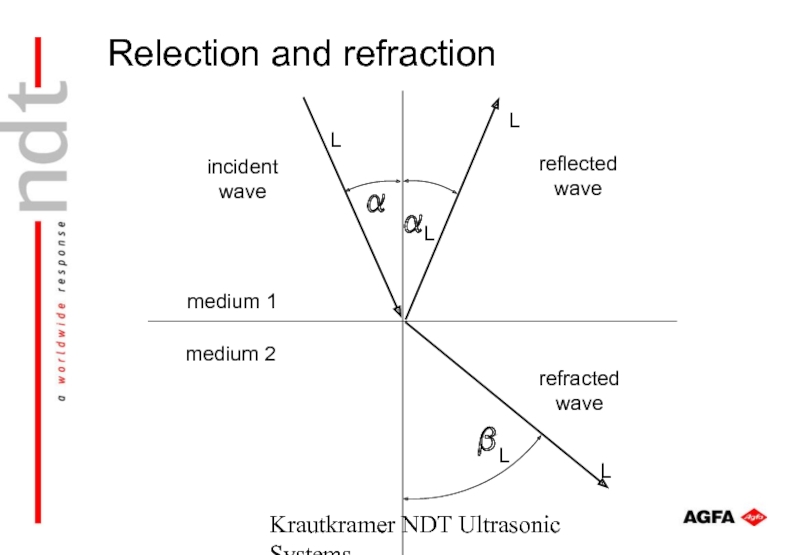

- 38. Krautkramer NDT Ultrasonic Systems Relection and refraction

- 39. Krautkramer NDT Ultrasonic Systems

- 40. Krautkramer NDT Ultrasonic Systems

- 41. Krautkramer NDT Ultrasonic Systems

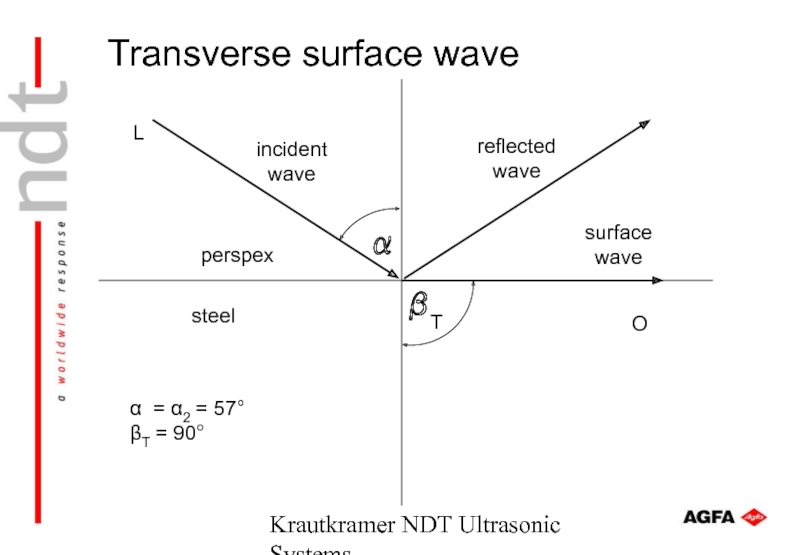

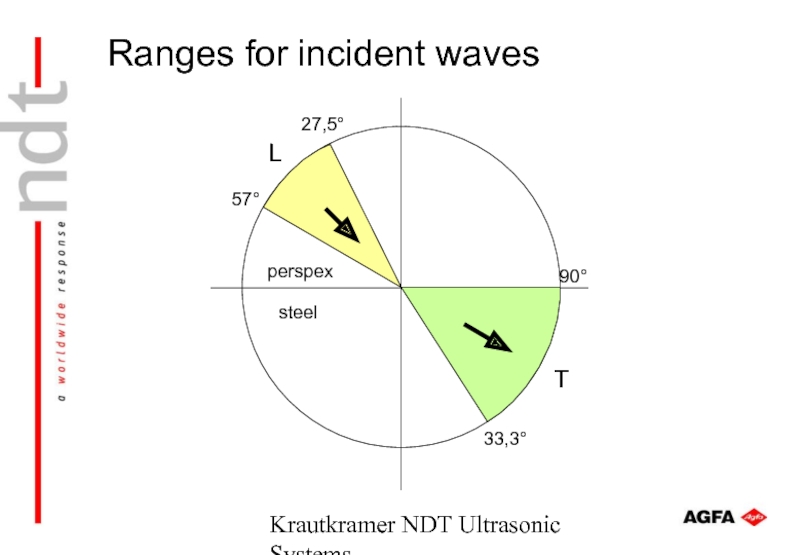

- 42. Krautkramer NDT Ultrasonic Systems Transverse surface wave

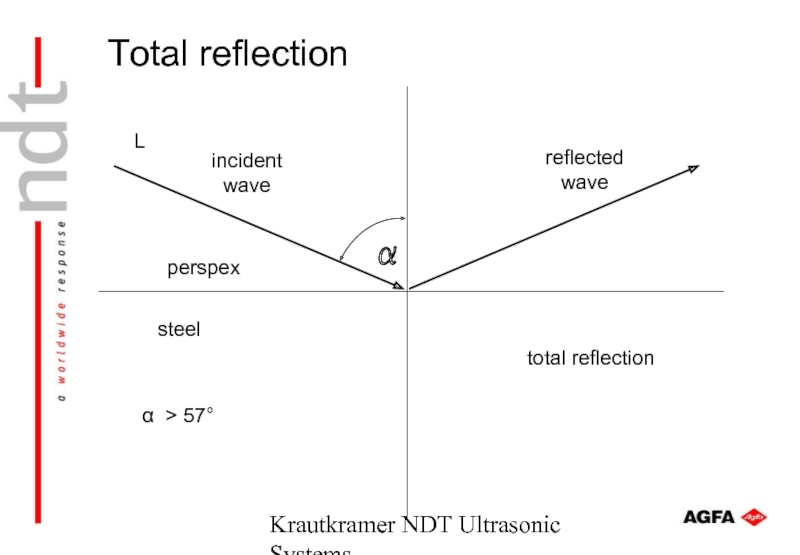

- 43. Krautkramer NDT Ultrasonic Systems Total reflection

- 44. Krautkramer NDT Ultrasonic Systems

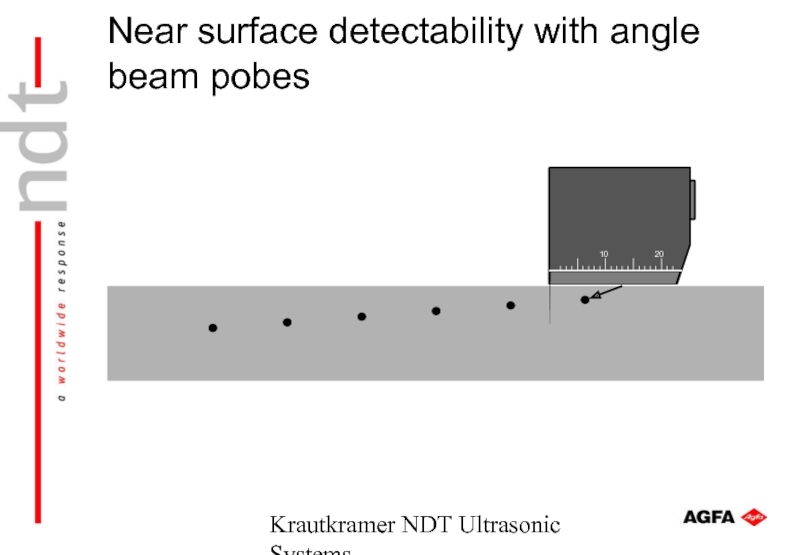

- 45. Krautkramer NDT Ultrasonic Systems

- 46. Krautkramer NDT Ultrasonic Systems

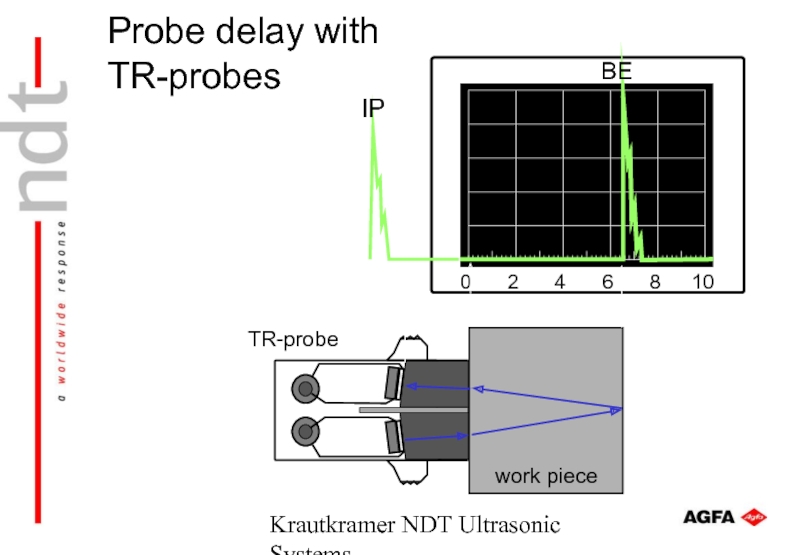

- 47. Krautkramer NDT Ultrasonic Systems Probe delay with TR-probes

- 48. Krautkramer NDT Ultrasonic Systems

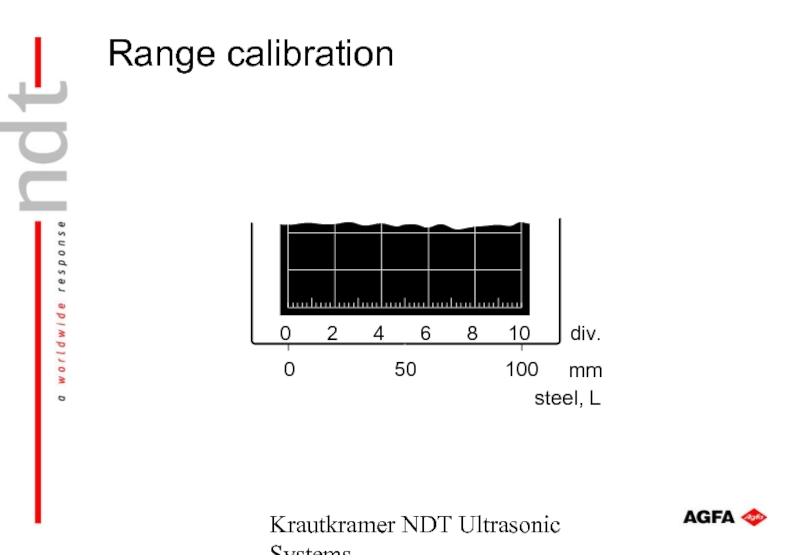

- 49. Krautkramer NDT Ultrasonic Systems 0

- 50. Krautkramer NDT Ultrasonic Systems

- 51. Krautkramer NDT Ultrasonic Systems

- 52. Krautkramer NDT Ultrasonic Systems

- 53. Krautkramer NDT Ultrasonic Systems

- 54. Krautkramer NDT Ultrasonic Systems 50 mm radius of calibration block 2

- 55. Krautkramer NDT Ultrasonic Systems

- 56. Krautkramer NDT Ultrasonic Systems

- 57. Krautkramer NDT Ultrasonic Systems flaw location

- 58. Krautkramer NDT Ultrasonic Systems

- 59. Krautkramer NDT Ultrasonic Systems

- 60. Krautkramer NDT Ultrasonic Systems

- 61. Krautkramer NDT Ultrasonic Systems

- 62. Krautkramer NDT Ultrasonic Systems

- 63. Krautkramer NDT Ultrasonic Systems "half

- 64. Krautkramer NDT Ultrasonic Systems

- 65. Krautkramer NDT Ultrasonic Systems

- 66. Krautkramer NDT Ultrasonic Systems

- 67. Krautkramer NDT Ultrasonic Systems

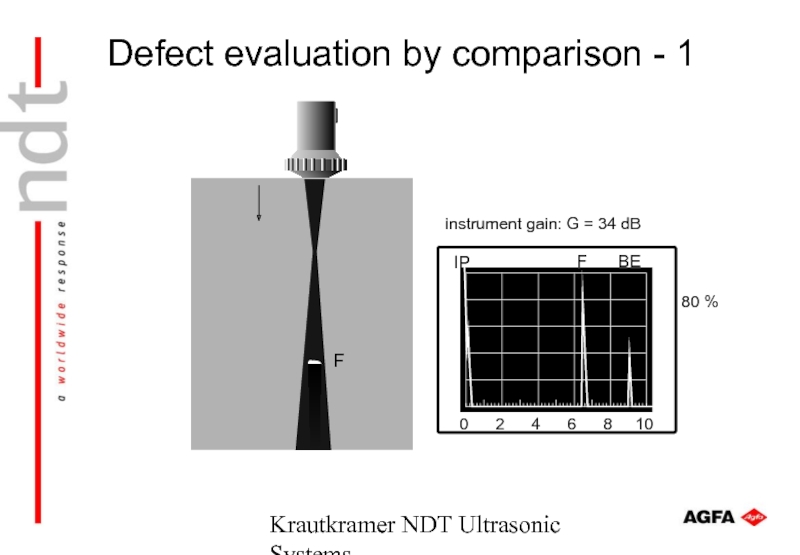

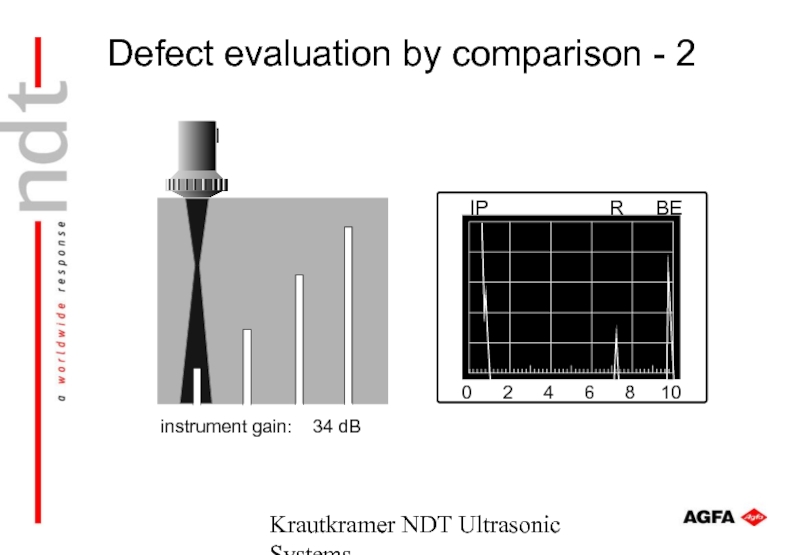

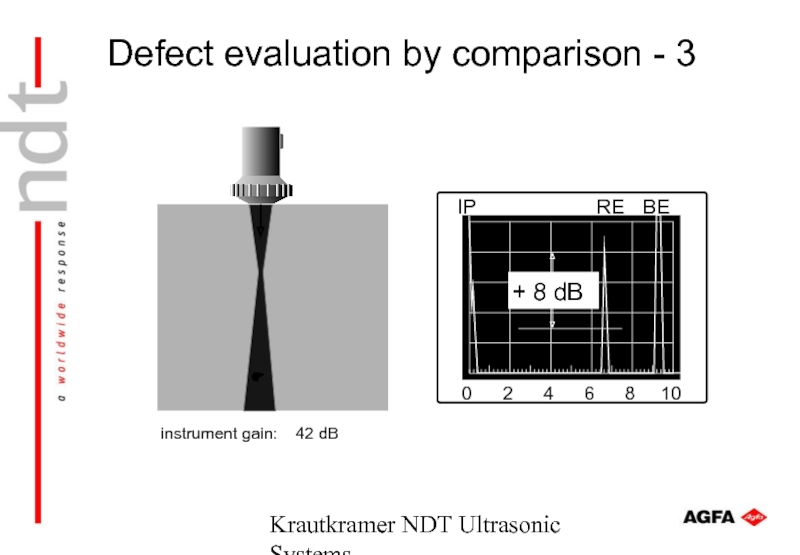

- 68. Krautkramer NDT Ultrasonic Systems instrument gain:

- 69. Krautkramer NDT Ultrasonic Systems

- 70. Krautkramer NDT Ultrasonic Systems

- 71. Krautkramer NDT Ultrasonic Systems

- 72. Krautkramer NDT Ultrasonic Systems

Слайд 1Krautkramer NDT Ultrasonic Systems

Introduction to

Ultrasonic Testing

SD 218

© Michael Berke

Agfa NDT GmbH,

1994 - 2002

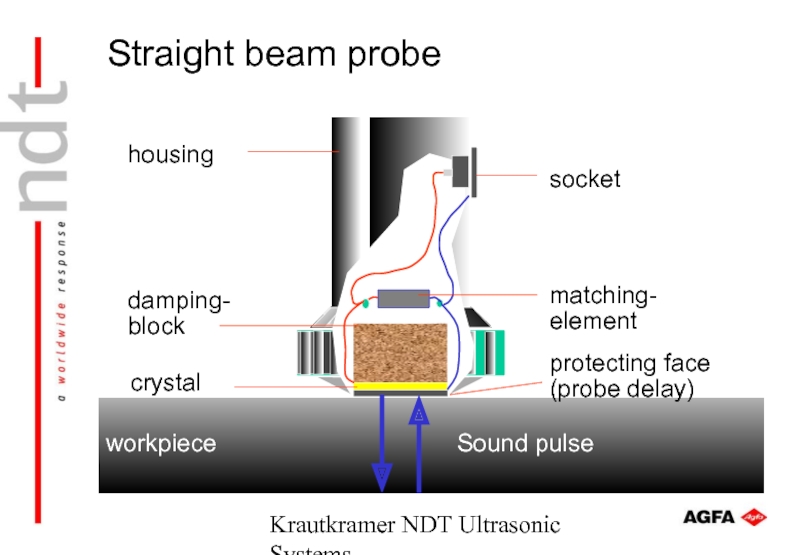

Слайд 2Krautkramer NDT Ultrasonic Systems

socket

matching-

element

damping-

block

crystal

protecting face

(probe delay)

housing

workpiece

Sound pulse

Straight beam probe

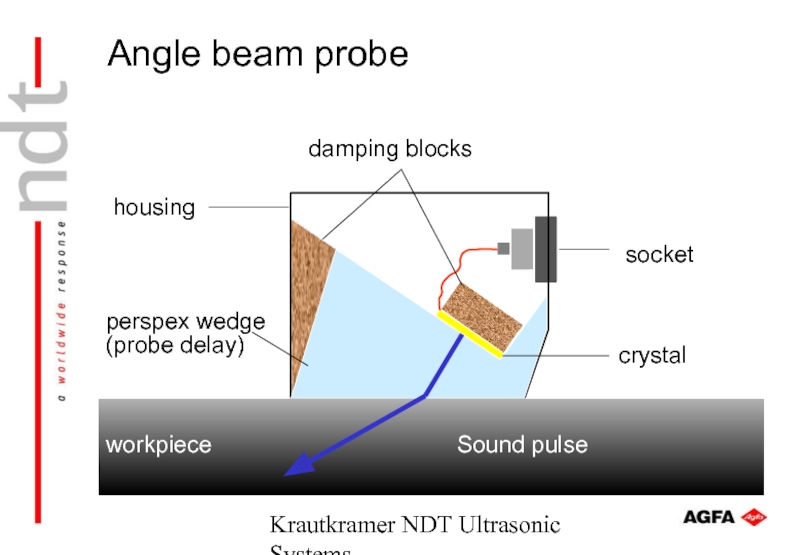

Слайд 3Krautkramer NDT Ultrasonic Systems

crystal

perspex wedge

(probe delay)

damping blocks

socket

housing

workpiece

Sound pulse

Angle beam probe

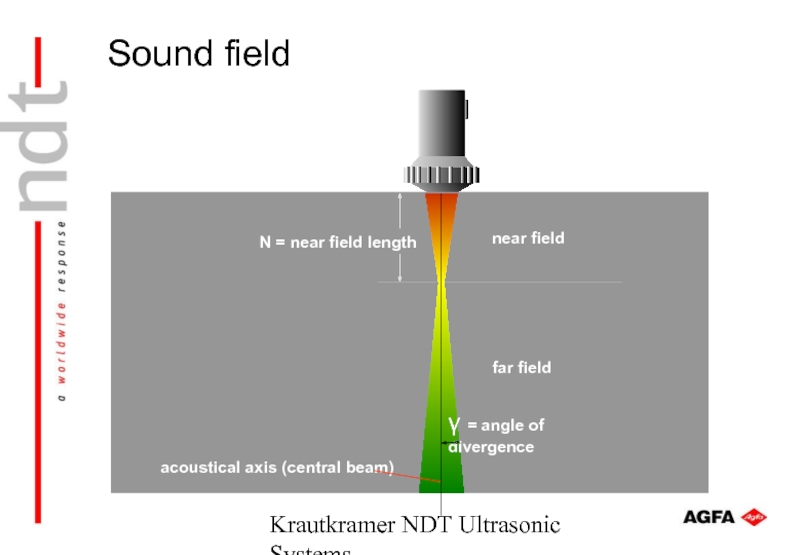

Слайд 4Krautkramer NDT Ultrasonic Systems

near field

far field

acoustical axis (central beam)

N = near

γ = angle of divergence

3

Sound field

Слайд 18Krautkramer NDT Ultrasonic Systems

sound beam

flat defect

15

10

5

reflected sound waves

Flaw detectability with improper

Слайд 20Krautkramer NDT Ultrasonic Systems

start signal

(pulse)

finish signal

(echo)

transmitter

transit time

measurement

probe

work piece

sound transit

path

Stop-

watch

Principle of transit

Слайд 22Krautkramer NDT Ultrasonic Systems

work piece

probe

sound wave starts at crystal

light point

transmitter

transmission

pulse

Priciple, transmission

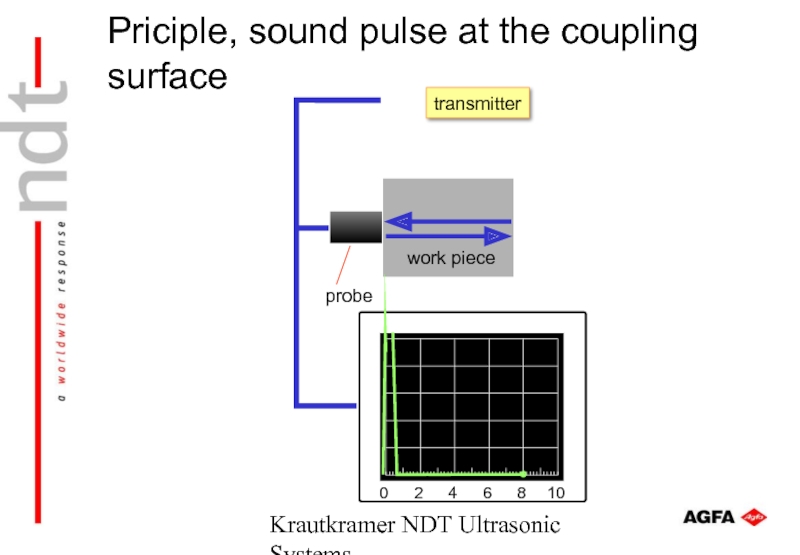

Слайд 23Krautkramer NDT Ultrasonic Systems

work piece

probe

sound wave

transmitter

Priciple, sound wave in the workpiece

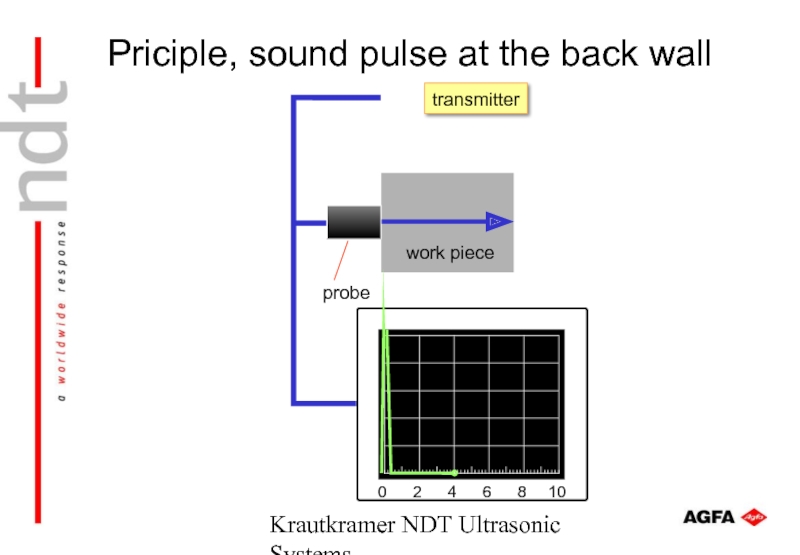

Слайд 24Krautkramer NDT Ultrasonic Systems

work piece

probe

transmitter

Priciple, sound pulse at the back wall

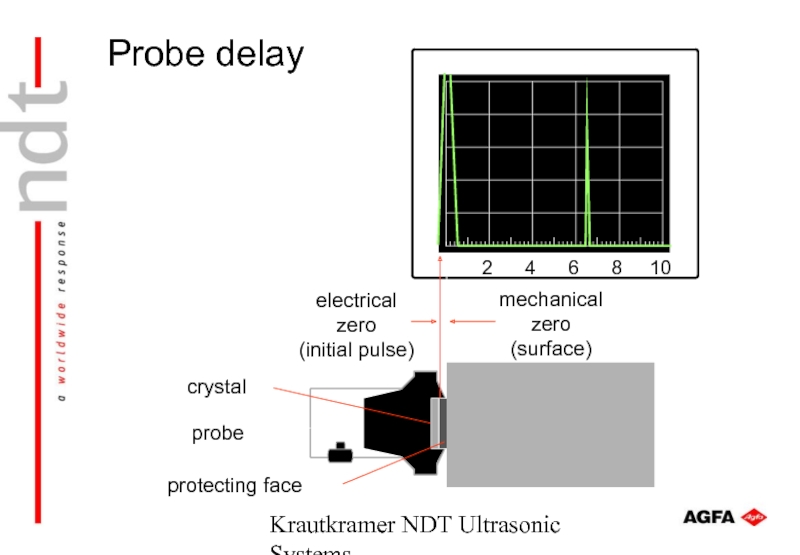

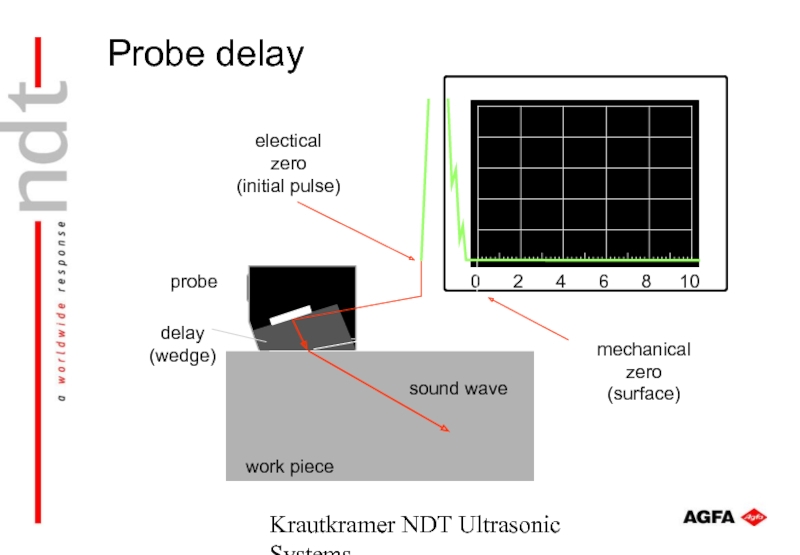

Слайд 27Krautkramer NDT Ultrasonic Systems

2

4

6

8

10

protecting face

crystal

probe

electrical

zero

(initial pulse)

mechanical

zero

(surface)

Probe delay

Слайд 28Krautkramer NDT Ultrasonic Systems

electical

zero

(initial pulse)

mechanical

zero

(surface)

sound wave

work piece

delay

(wedge)

probe

Probe delay

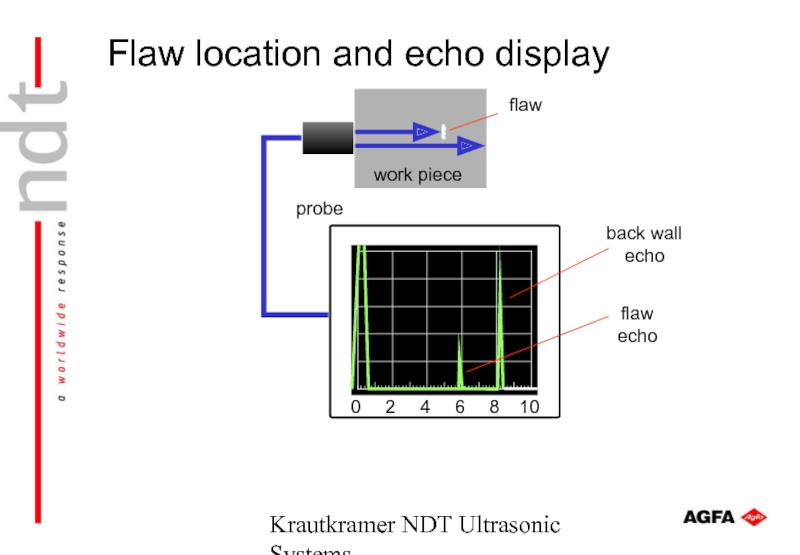

Слайд 30Krautkramer NDT Ultrasonic Systems

work piece

probe

back wall

echo

flaw

flaw

echo

Flaw location and echo display

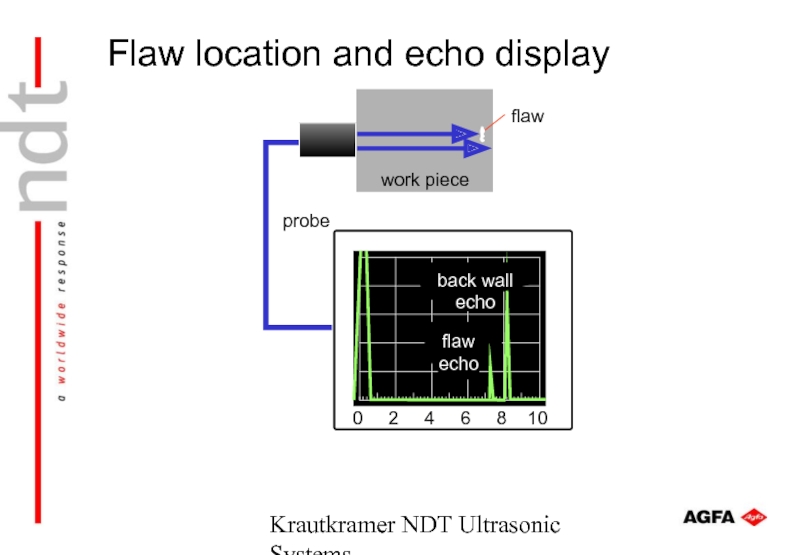

Слайд 31Krautkramer NDT Ultrasonic Systems

work piece

probe

back wall

echo

flaw

flaw

echo

Flaw location and echo display

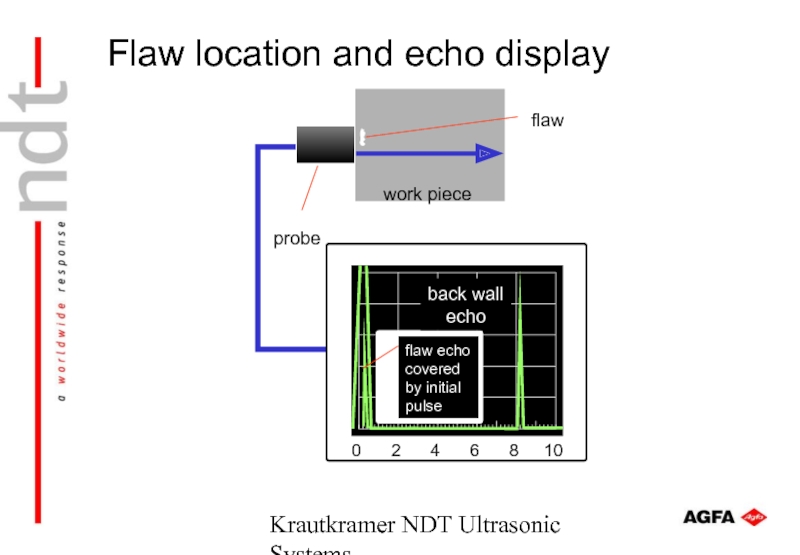

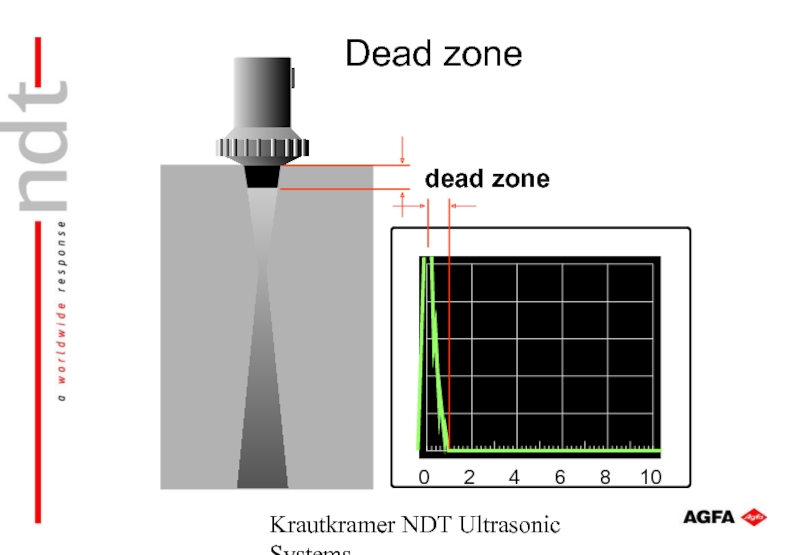

Слайд 32Krautkramer NDT Ultrasonic Systems

flaw echo

covered

by initial

pulse

work piece

probe

back wall

echo

flaw

Flaw location and echo

Слайд 33Krautkramer NDT Ultrasonic Systems

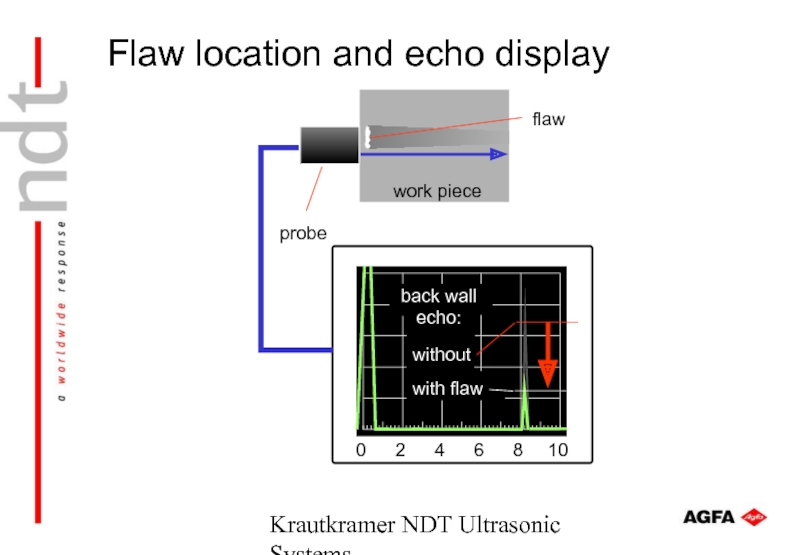

back wall

echo:

without

with flaw

work piece

probe

flaw

Flaw location and echo display

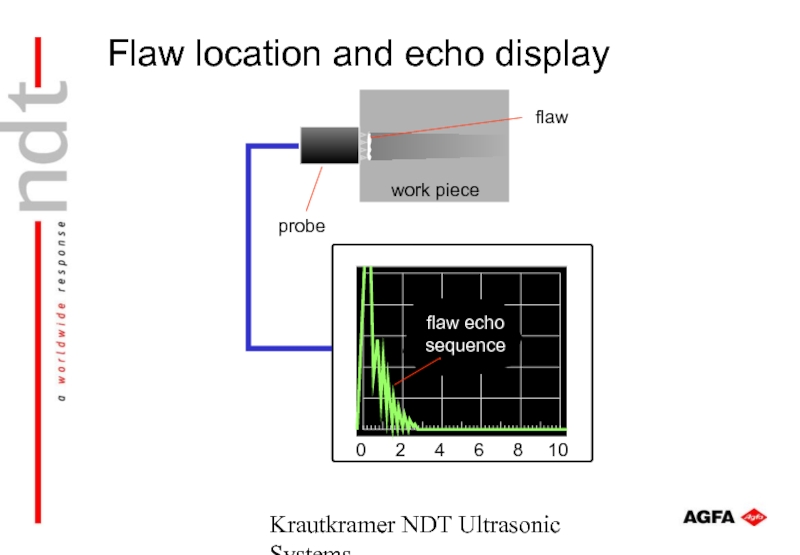

Слайд 34Krautkramer NDT Ultrasonic Systems

flaw echo

sequence

work piece

probe

flaw

Flaw location and echo display

Слайд 36Krautkramer NDT Ultrasonic Systems

direction of

osscillation

direction of propagation

wave length

Longitudinal wave

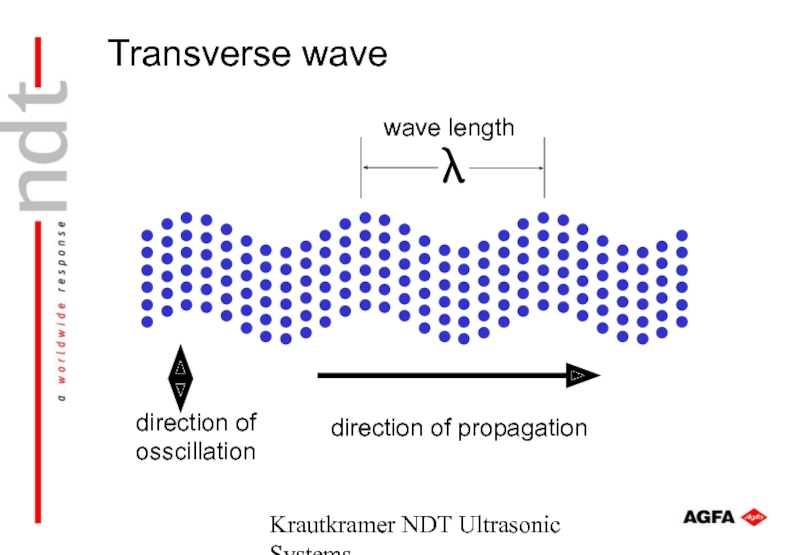

Слайд 37Krautkramer NDT Ultrasonic Systems

direction of

osscillation

direction of propagation

wave length

Transverse wave

Слайд 39Krautkramer NDT Ultrasonic Systems

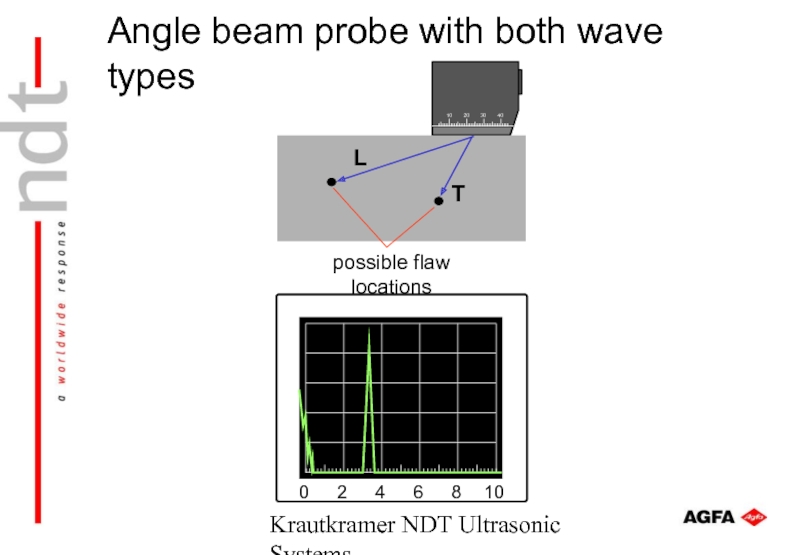

10

20

30

40

L

T

possible flaw

locations

Angle beam probe with both wave types

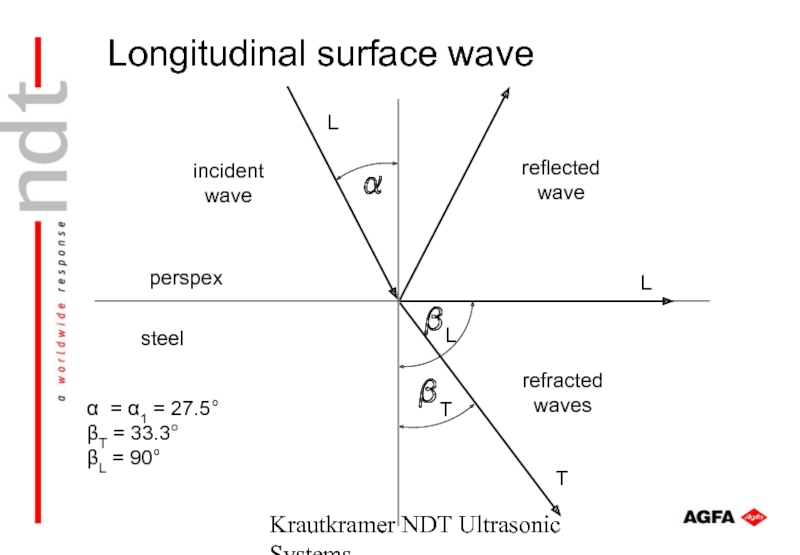

Слайд 40Krautkramer NDT Ultrasonic Systems

T

L

L

T

L

perspex

steel

reflected

wave

refracted

waves

incident

wave

α = α1 = 27.5°

βT = 33.3°

βL =

Longitudinal surface wave

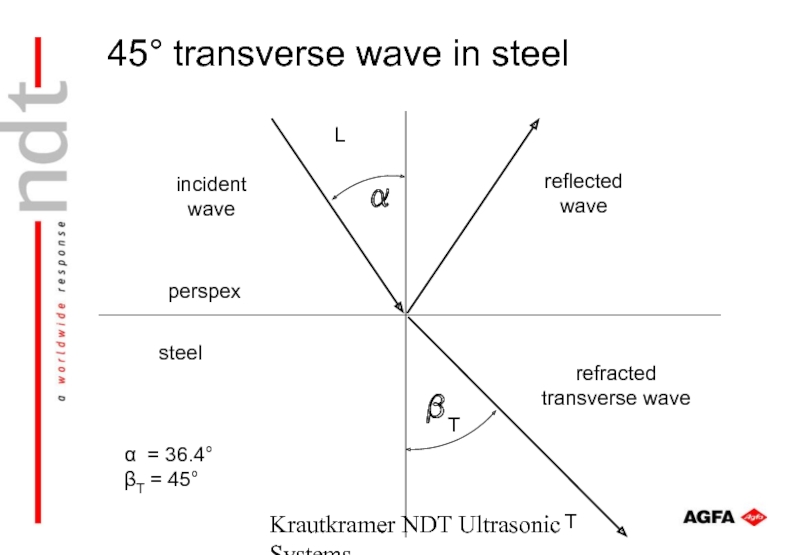

Слайд 41Krautkramer NDT Ultrasonic Systems

T

L

T

perspex

steel

reflected

wave

refracted

transverse wave

incident

wave

α = 36.4°

βT = 45°

45° transverse wave

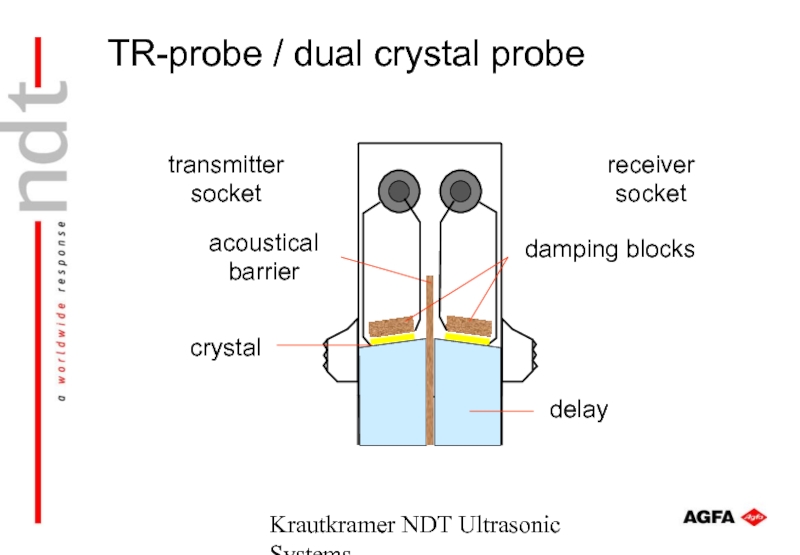

Слайд 46Krautkramer NDT Ultrasonic Systems

receiver

socket

transmitter

socket

damping blocks

crystal

delay

acoustical

barrier

TR-probe / dual crystal probe

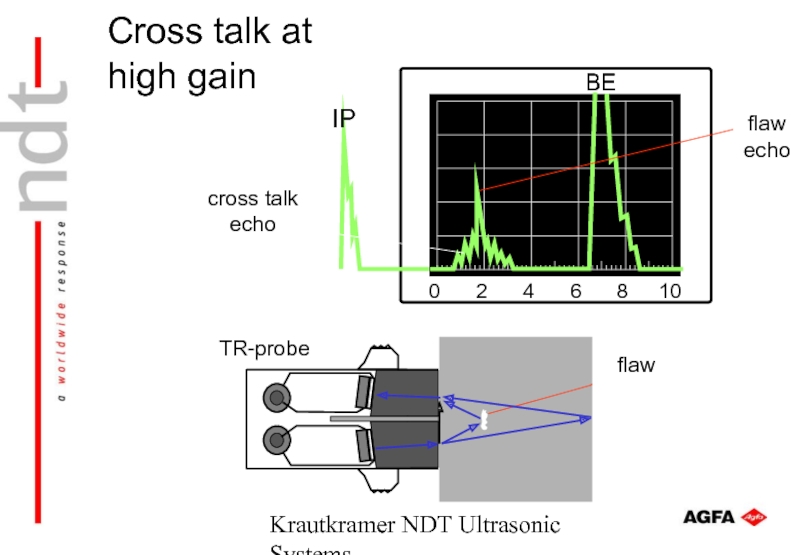

Слайд 48Krautkramer NDT Ultrasonic Systems

IP

BE

flaw

cross talk

echo

flaw

echo

TR-probe

Cross talk at

high gain

Слайд 50Krautkramer NDT Ultrasonic Systems

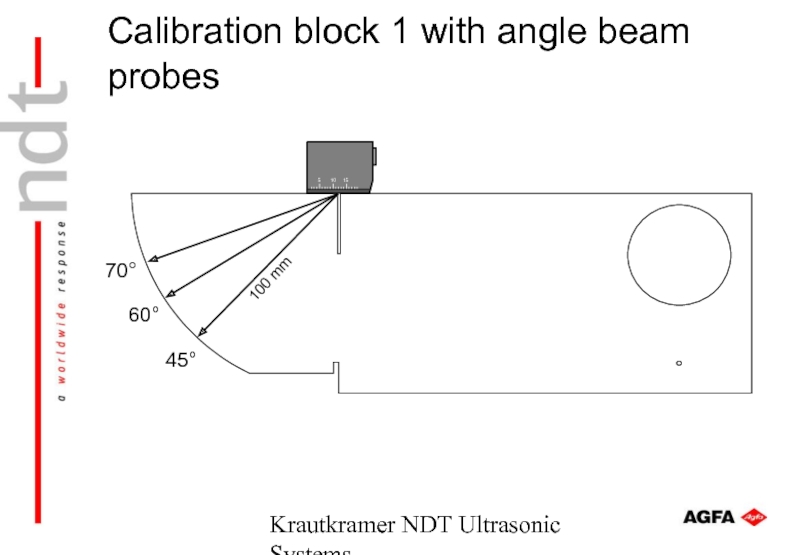

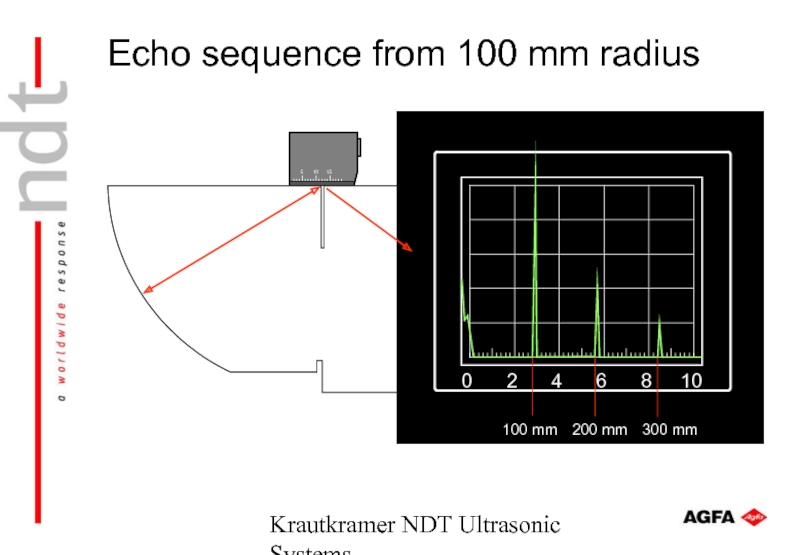

5

10

15

70°

45°

100 mm

60°

Calibration block 1 with angle beam probes

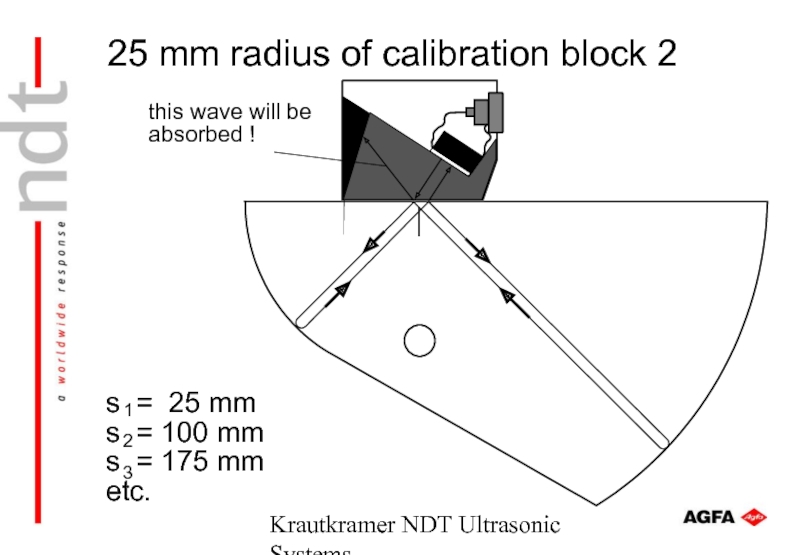

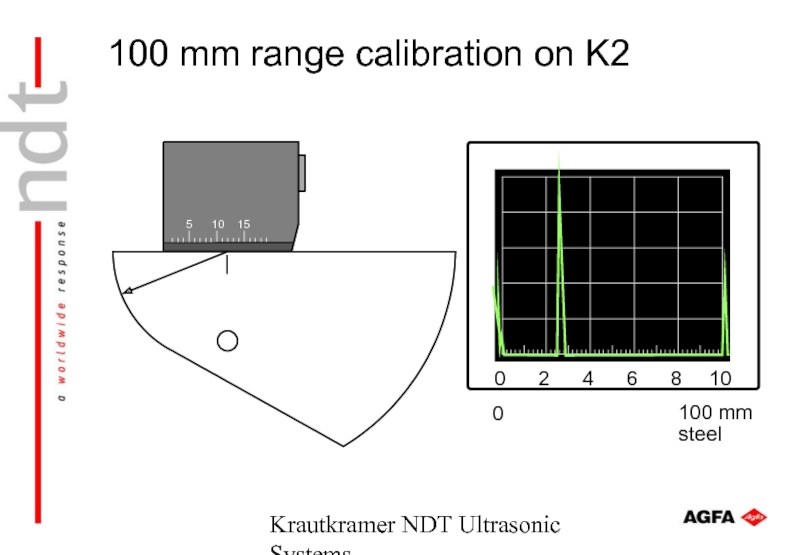

Слайд 53Krautkramer NDT Ultrasonic Systems

this wave will be

absorbed !

25 mm radius

Слайд 56Krautkramer NDT Ultrasonic Systems

5

10

15

work piece

reflector

s

s = k•R

s = sound path

k =

R = screen reading

Flaw loaction

Слайд 57Krautkramer NDT Ultrasonic Systems

flaw location

a

s

d

Sound entry point

projection

point

a = s•sin ß

d =

ß

ß

ß = probe angle

s = sound path

a = surface distance

d = depth

"flaw triangle"

Flaw location with angle beam probes

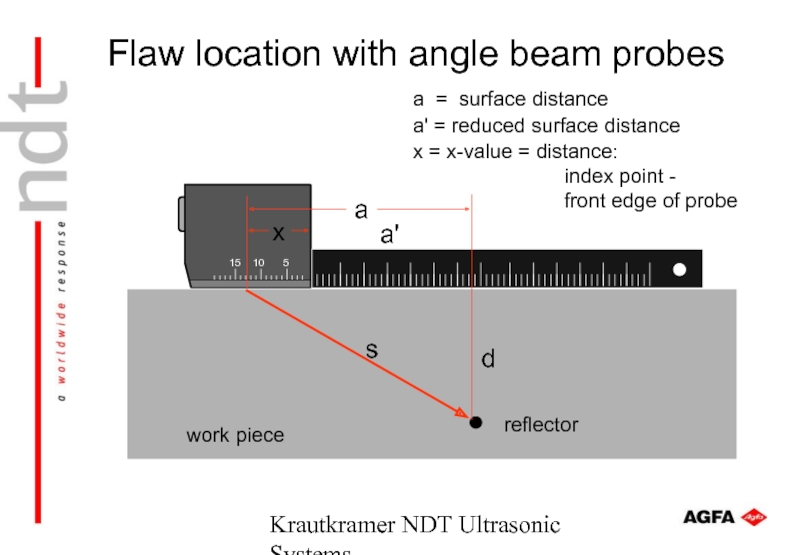

Слайд 58Krautkramer NDT Ultrasonic Systems

5

10

15

work piece

reflector

a

a'

s

d

x

index point -

front edge of probe

a =

a' = reduced surface distance

x = x-value = distance:

Flaw location with angle beam probes

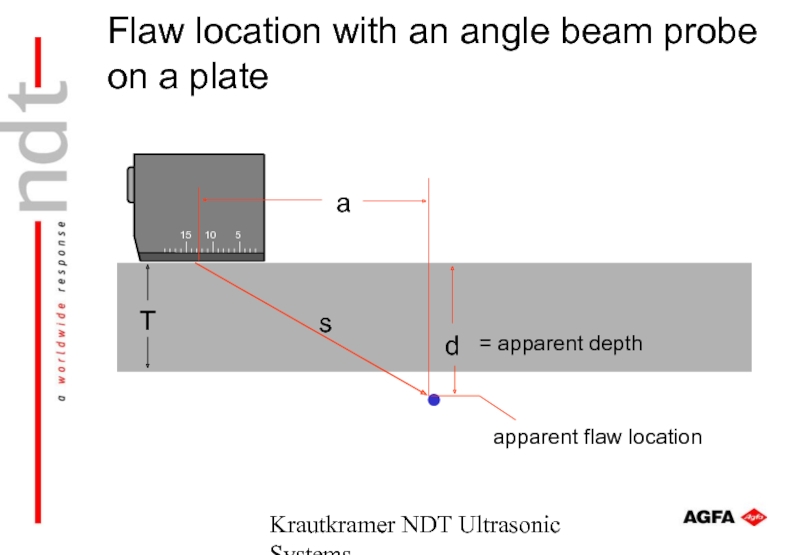

Слайд 59Krautkramer NDT Ultrasonic Systems

5

10

15

apparent flaw location

a

s

d

= apparent depth

T

Flaw location with

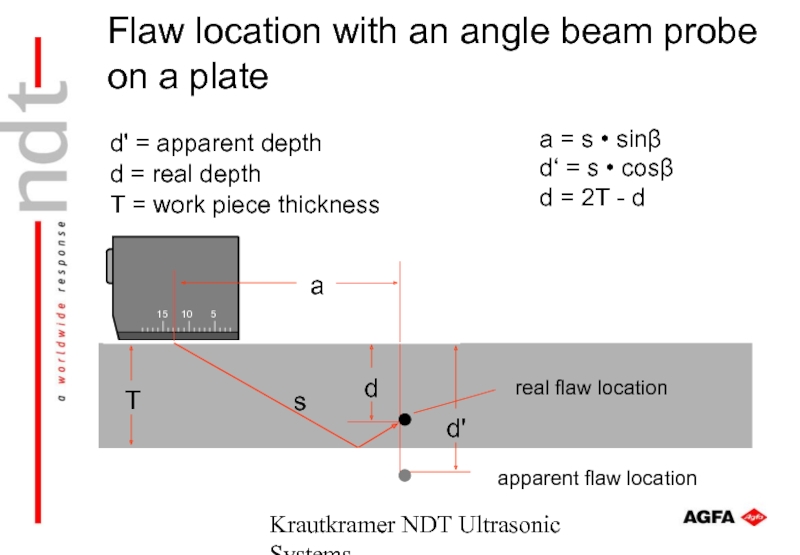

Слайд 60Krautkramer NDT Ultrasonic Systems

5

10

15

apparent flaw location

real flaw location

a

s

d

d'

d' = apparent depth

d

T = work piece thickness

T

a = s • sinβ

d‘ = s • cosβ

d = 2T - d

Flaw location with an angle beam probe on a plate

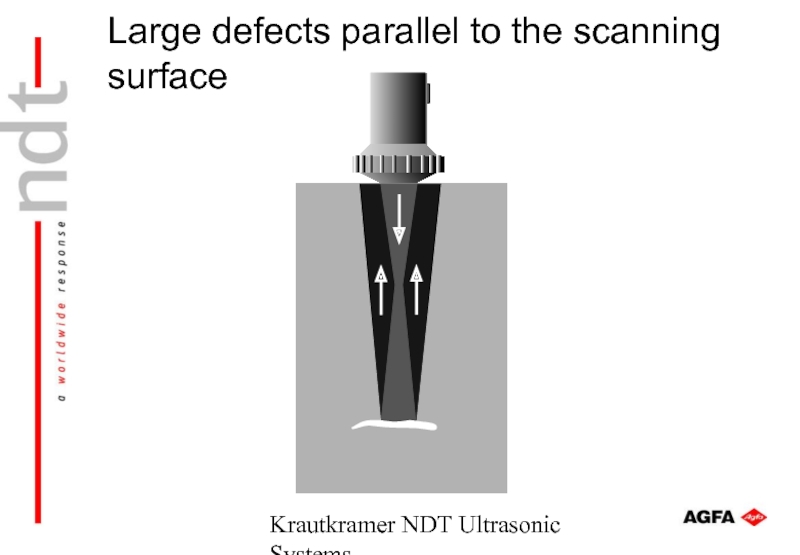

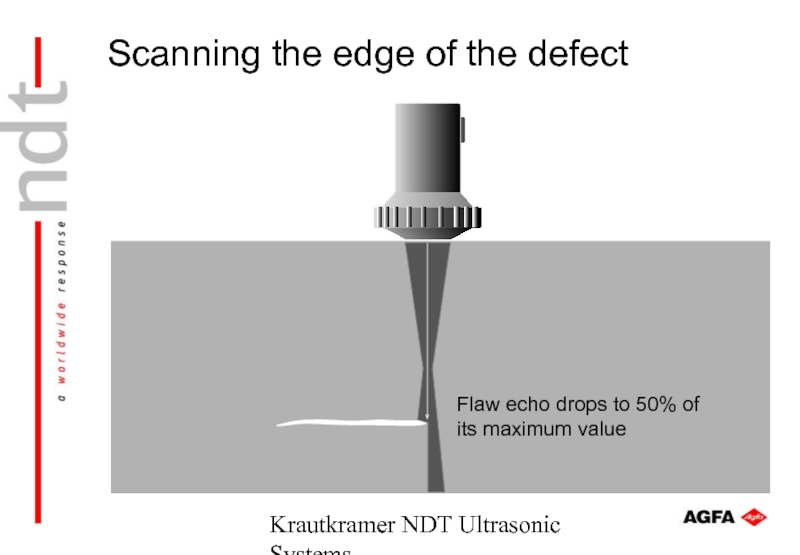

Слайд 62Krautkramer NDT Ultrasonic Systems

Scanning the edge of the defect

Flaw echo drops

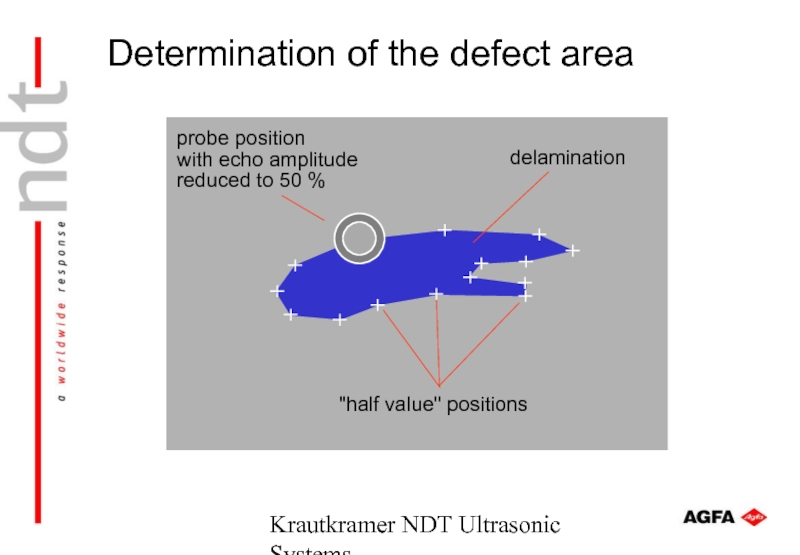

Слайд 63Krautkramer NDT Ultrasonic Systems

"half value" positions

delamination

probe position

with echo amplitude

reduced to 50

Determination of the defect area