- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Effect receiving modes, and heat treatment on the structure and properties of the magnetic powder of strontium hexaferrite презентация

Содержание

- 1. Effect receiving modes, and heat treatment on the structure and properties of the magnetic powder of strontium hexaferrite

- 2. Objective The aim of this study

- 3. To achieve this aim the following

- 4. Сomminution SAND planetary mill was used

- 5. The hysteresis loop of

- 6. Oxide glass crystallization method obtained submicrocrystalline

- 7. Thank you for attention!

Слайд 1Student: Vasilenko R.V.

Group: MF-13-1

Effect receiving modes, and heat treatment on the

Слайд 2Objective

The aim of this study was to investigate the magnetic properties

Слайд 3

To achieve this aim the following tasks:

Preparation of the alloy samples

Testing methods of heat treatment;

The study of the magnetic properties of the samples after grinding;

Tasks

Слайд 4

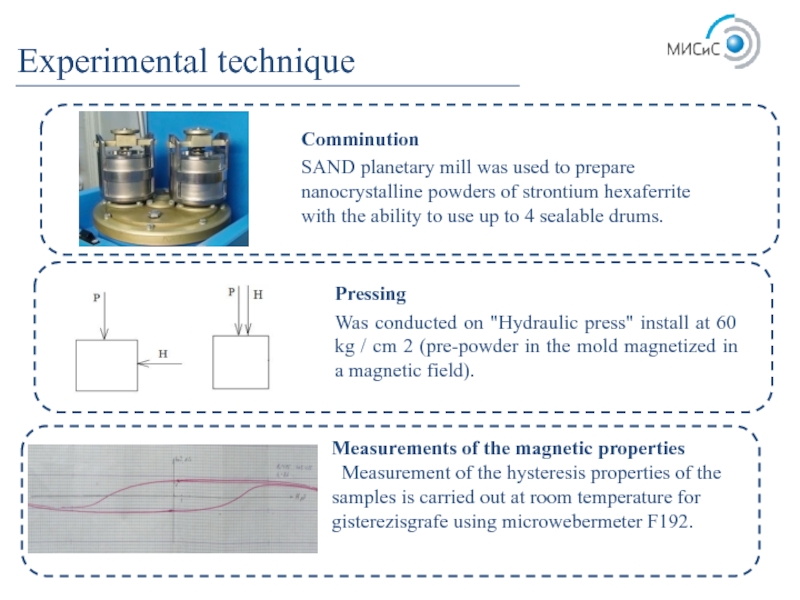

Сomminution

SAND planetary mill was used to prepare nanocrystalline powders of strontium

Measurements of the magnetic properties

Measurement of the hysteresis properties of the samples is carried out at room temperature for gisterezisgrafe using microwebermeter F192.

Pressing

Was conducted on "Hydraulic press" install at 60 kg / cm 2 (pre-powder in the mold magnetized in a magnetic field).

Experimental technique

Слайд 5

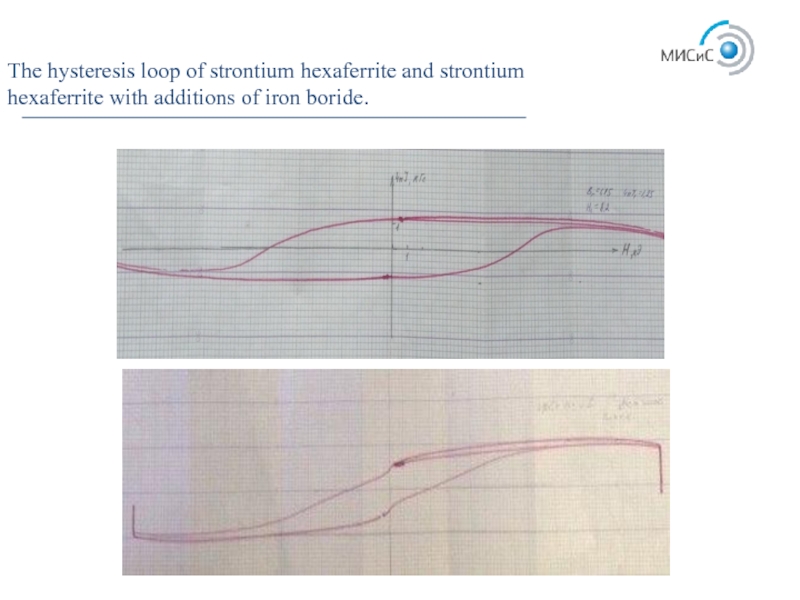

The hysteresis loop of strontium hexaferrite and strontium hexaferrite with additions

Слайд 6

Oxide glass crystallization method obtained submicrocrystalline rapidly quenched alloys and amorphous

It is shown that vitrified grinding in distilled water, compared to grinding in toluene resulted in a slight decrease in the coercive force (from 9 to kilooersted 8,2 kilooersted) and increase residual induction (from 0,75 kilogauss to 1,25 kilogauss, respectively.

After annealing at presszagotovki 1050 C at 30 min following magnetic properties obtained

Conclusions.