- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

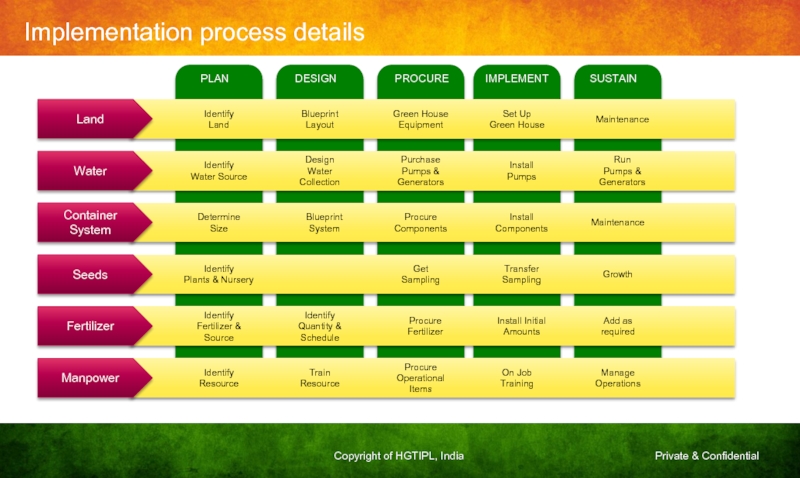

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Commercial Hydroponics Viability & Economic Preview презентация

Содержание

- 1. Commercial Hydroponics Viability & Economic Preview

- 2. “I am delighted that HGTIPL is being

- 3. Agenda Executive summary

- 4. Importance of water

- 5. What does a plant need to grow

- 6. Executive Summary

- 7. Executive Summary The Issue facing us Need

- 8. Presentation aims to Hydroponics Make you aware

- 9. What is Hydroponics

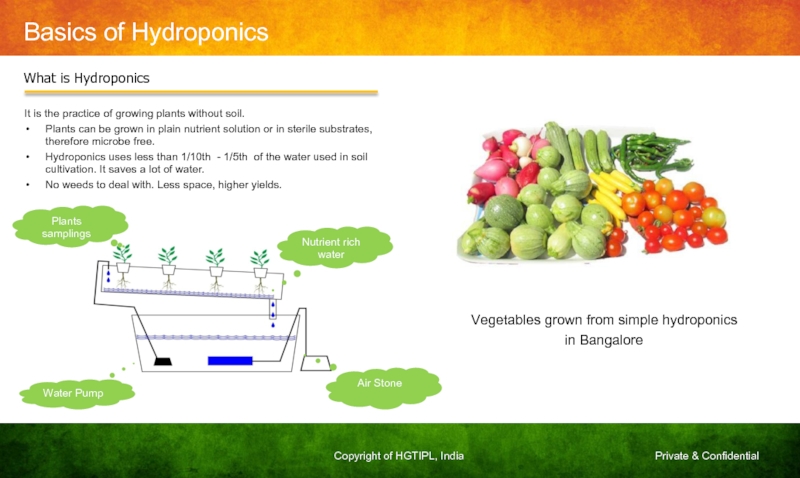

- 10. Basics of Hydroponics Vegetables grown from simple

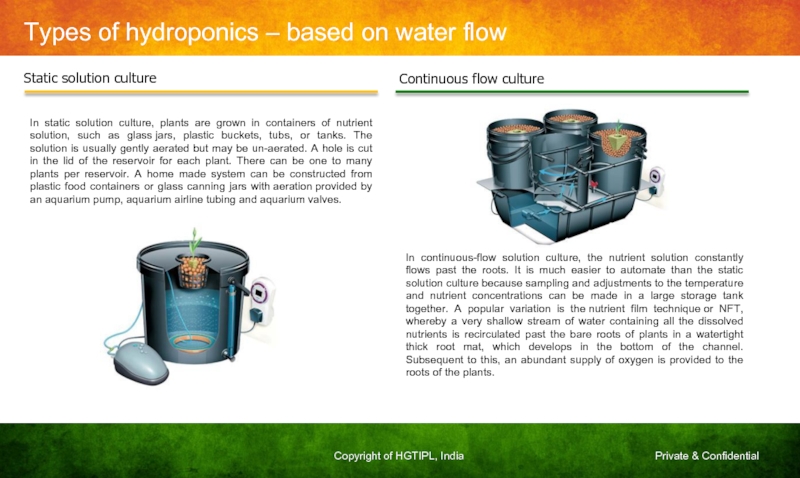

- 11. Types of hydroponics – based on water

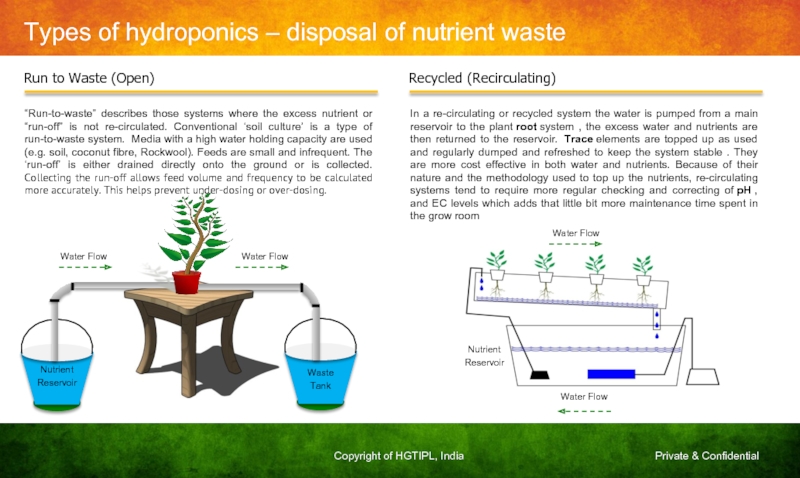

- 12. Types of hydroponics – disposal of nutrient

- 13. Types of hydroponics – based on medium

- 14. Types of hydroponic systems Nutrient Film Technique

- 15. Types of hydroponic systems Drip Method Deep

- 16. Primary benefits of Hydroponic cultivation Reduced labor

- 17. Secondary benefits Plants in hydroponics gain in

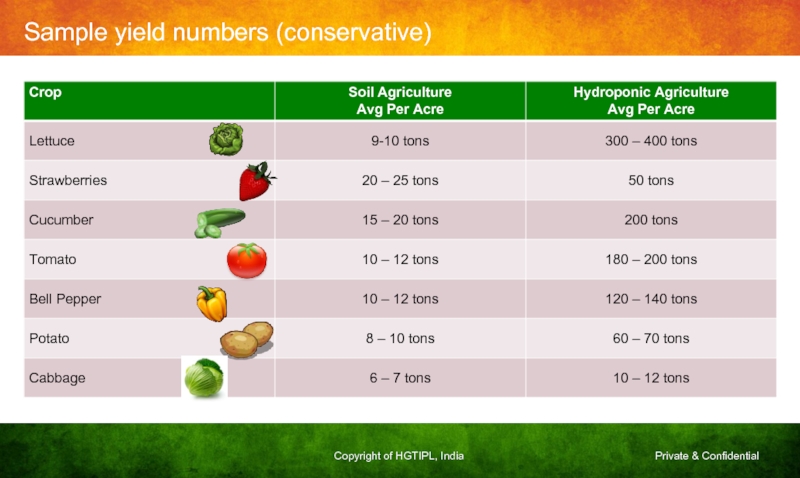

- 18. Sample yield numbers (conservative)

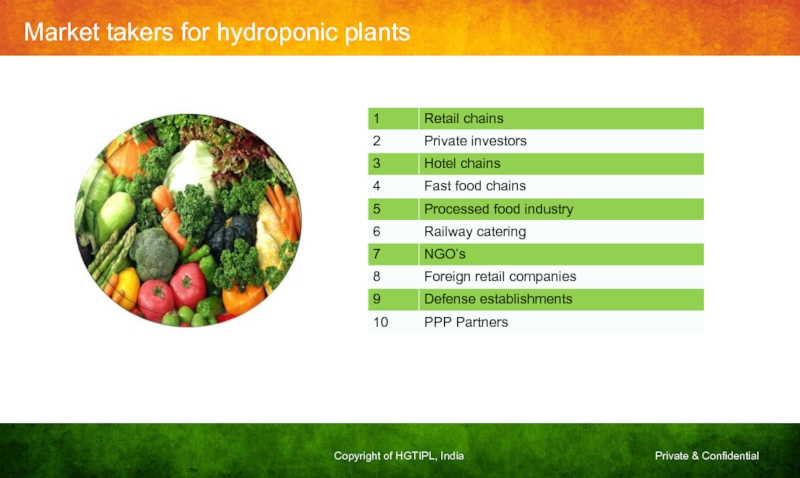

- 19. Market takers for hydroponic plants

- 20. Hydroponic agriculture – the global outlook Global

- 21. How is it implemented

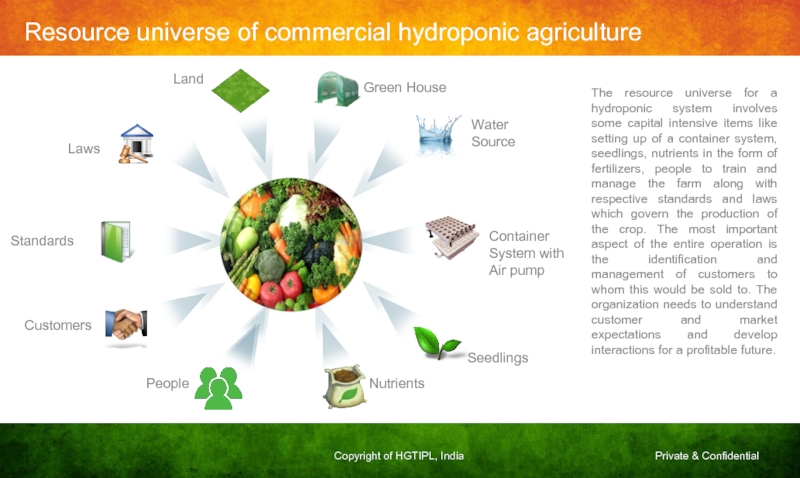

- 22. Standards Laws Water Source Container System

- 23. Plants grown in hydroponic systems Tomato's Lettuce Bell Pepper Cucumber Strawberries Water Lemon Potato Onion

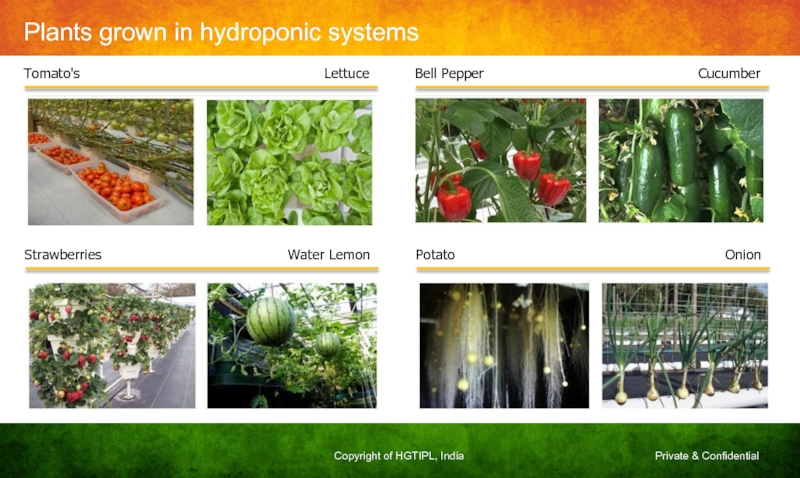

- 24. Nutrient Solutions / Fertilizer Introduction Plant nutrients

- 25. Implementation process The HGTIPL assisted implementation process

- 26. Implementation process details

- 27. Hydroponics in India

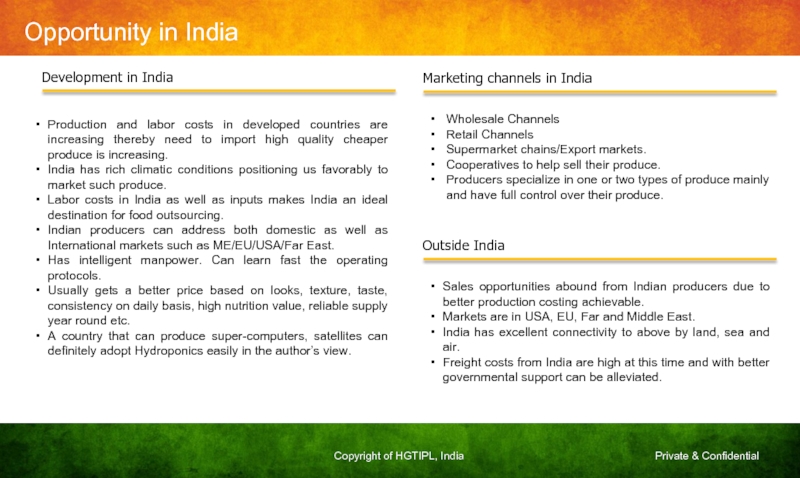

- 28. Opportunity in India Production and labor

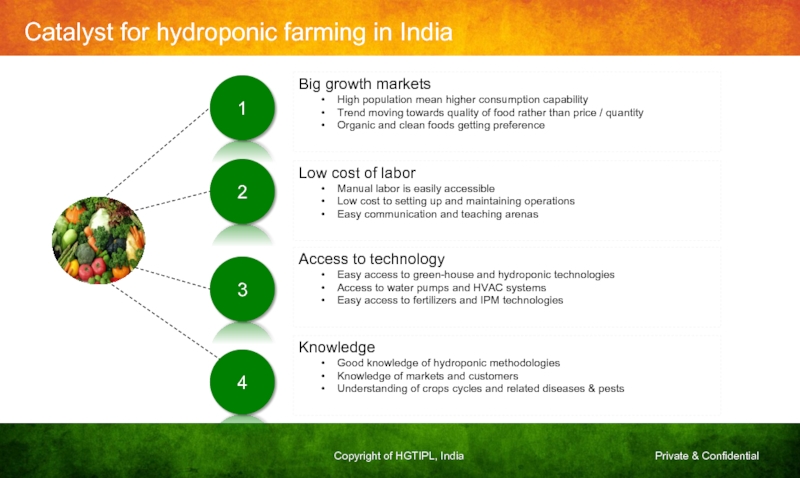

- 29. Catalyst for hydroponic farming in India

- 30. SWOT analysis for hydroponic farming Makes any

- 31. Challenges in India to overcome Capital costs

- 32. Commercial Viability

- 33. Cost buckets Capital costs Operational costs Drip

- 34. Revenue flow (when land is owned) Revenue

- 35. Revenue flow (when land is bought) Revenue

- 36. Revenue flow (when land is leased) Revenue

- 37. Reasons for failure Venture not established in

- 38. Who we are

- 39. Who we are CV Prakash The Farmer

- 40. How can we help

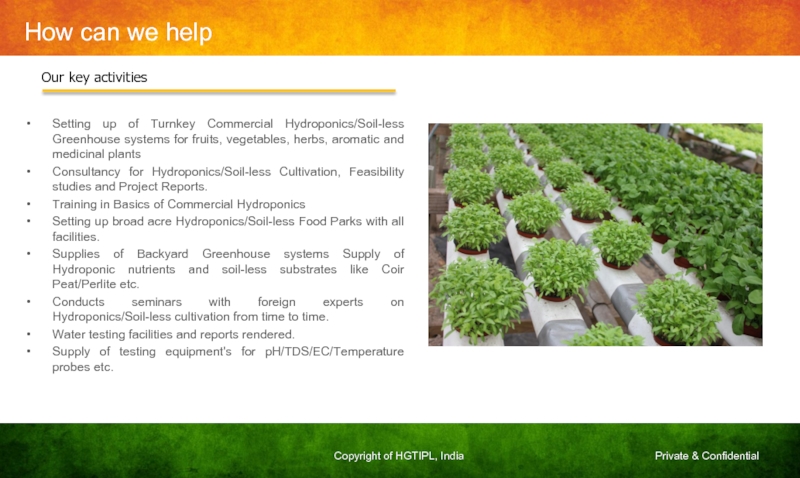

- 41. How can we help Setting up of

- 42. Success Stories

- 43. Some successful commercial installations Hydroponic Strawberry System

- 44. Thank You

Слайд 2“I am delighted that HGTIPL is being given this opportunity to

I am a former Officer of the Indian Navy. Upon my retirement, I migrated to Australia in 2001. I learnt Hydroponics from the best of growers and consultants in the Hydroponics Industry in Australia and I am a passionate proponent and pioneer in the field of Hydroponics in India.

Our firm is distinguished by the extent of its global knowledge base, in the way we think, the way we work together and the way we are structured to provide the best practices Hydroponics.

I am confident that our well qualified team will consistently exceed your expectations and we honestly believe that we can bring you true value and prosperity on the table.

Farmer-In-Chief

Lt Cdr (retd) CV Prakash

Слайд 3

Agenda

Executive summary

What is Hydroponics

How is it implemented

Hydroponics in India

Commercial Viability

Who we

How can we help

Success stories

Слайд 4Importance of water

Water is Food is

No Water-No Food! Simple

Hydroponics Needs Clean Water

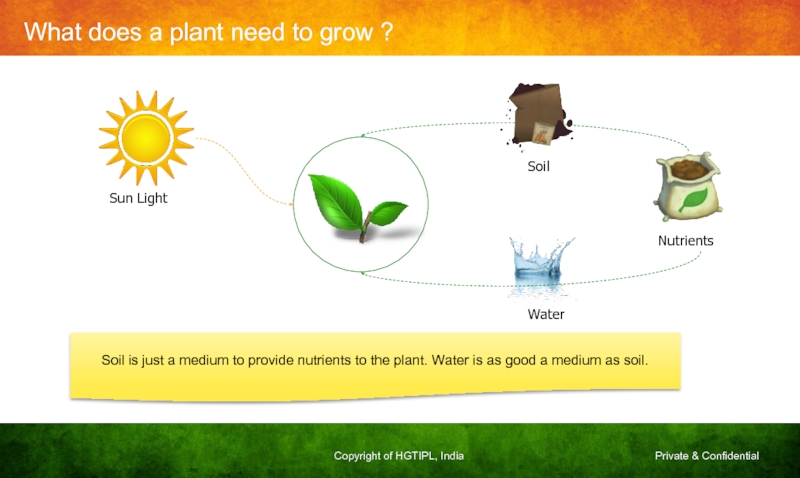

Слайд 5What does a plant need to grow ?

Soil is just a

Sun Light

Nutrients

Soil

Water

Слайд 7Executive Summary

The Issue facing us

Need for a solution

Introduction to Hydroponics

Advantages of

Today Indian farmers face the following challenges

Drought conditions and unpredictable weather

Rising temperatures

Polluted water systems

Lack of irrigation

Poor water management

Under-nourished or over nourished crops

India today needs food security which entails that all people at all times have physical and economic access to safe and nutritious food to meet dietary needs.

Lack of water for agriculture leads to production of lesser food which means more hunger and malnutrition

We are going to highlight the need for technology in agriculture that can contribute towards water savings and have a positive impact on food production and availability.

Hydroponics is one methodology of soil-less cultivation.

It is a method of growing plants using mineral nutrient solutions, in water, without soil.

The earliest published work on growing terrestrial plants without soil was the 1627 book Sylva Sylvarum by Francis Bacon.

Some of the reasons why hydroponics is being adopted around the world for food production are the following:

No soil is needed for hydroponics

The water stays in the system and can be reused

It is possible to control the nutrition levels accurately

It is stable and provides high yields hence economically viable

Pests and diseases are easier to get rid of

Ease of harvesting

It is better for consumption

Слайд 8Presentation aims to

Hydroponics

Make you aware of

Describe advantages of

Implementation strategy

Commercial viability of

Слайд 10Basics of Hydroponics

Vegetables grown from simple hydroponics

in Bangalore

What is Hydroponics

It

Plants can be grown in plain nutrient solution or in sterile substrates, therefore microbe free.

Hydroponics uses less than 1/10th - 1/5th of the water used in soil cultivation. It saves a lot of water.

No weeds to deal with. Less space, higher yields.

Nutrient rich water

Air Stone

Water Pump

Plants samplings

Слайд 11Types of hydroponics – based on water flow

Static solution culture

Continuous

In static solution culture, plants are grown in containers of nutrient solution, such as glass jars, plastic buckets, tubs, or tanks. The solution is usually gently aerated but may be un-aerated. A hole is cut in the lid of the reservoir for each plant. There can be one to many plants per reservoir. A home made system can be constructed from plastic food containers or glass canning jars with aeration provided by an aquarium pump, aquarium airline tubing and aquarium valves.

In continuous-flow solution culture, the nutrient solution constantly flows past the roots. It is much easier to automate than the static solution culture because sampling and adjustments to the temperature and nutrient concentrations can be made in a large storage tank together. A popular variation is the nutrient film technique or NFT, whereby a very shallow stream of water containing all the dissolved nutrients is recirculated past the bare roots of plants in a watertight thick root mat, which develops in the bottom of the channel. Subsequent to this, an abundant supply of oxygen is provided to the roots of the plants.

Слайд 12Types of hydroponics – disposal of nutrient waste

Run to Waste

Recycled (Recirculating)

Nutrient

Reservoir

Waste

Tank

“Run-to-waste” describes those systems where the excess nutrient or “run-off” is not re-circulated. Conventional ‘soil culture’ is a type of run-to-waste system. Media with a high water holding capacity are used (e.g. soil, coconut fibre, Rockwool). Feeds are small and infrequent. The ‘run-off’ is either drained directly onto the ground or is collected. Collecting the run-off allows feed volume and frequency to be calculated more accurately. This helps prevent under-dosing or over-dosing.

Water Flow

In a re-circulating or recycled system the water is pumped from a main reservoir to the plant root system , the excess water and nutrients are then returned to the reservoir. Trace elements are topped up as used and regularly dumped and refreshed to keep the system stable . They are more cost effective in both water and nutrients. Because of their nature and the methodology used to top up the nutrients, re-circulating systems tend to require more regular checking and correcting of pH , and EC levels which adds that little bit more maintenance time spent in the grow room

Nutrient

Reservoir

Water Flow

Water Flow

Water Flow

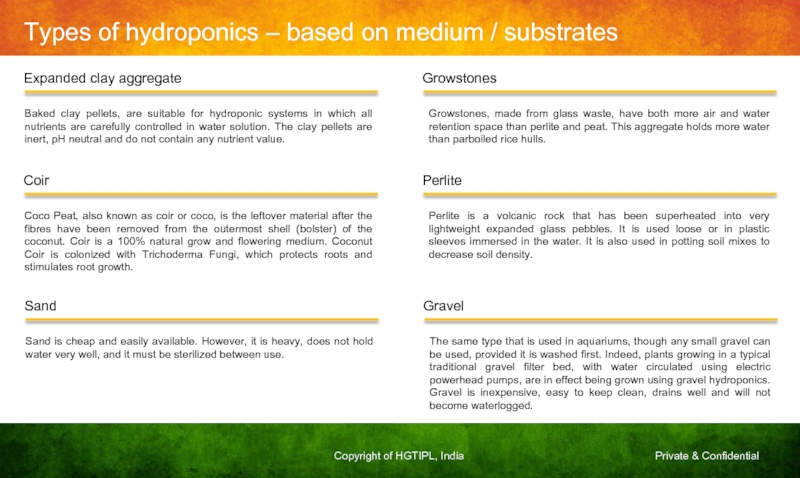

Слайд 13Types of hydroponics – based on medium / substrates

Expanded clay aggregate

Growstones

Baked

Growstones, made from glass waste, have both more air and water retention space than perlite and peat. This aggregate holds more water than parboiled rice hulls.

Coir

Perlite

Coco Peat, also known as coir or coco, is the leftover material after the fibres have been removed from the outermost shell (bolster) of the coconut. Coir is a 100% natural grow and flowering medium. Coconut Coir is colonized with Trichoderma Fungi, which protects roots and stimulates root growth.

Perlite is a volcanic rock that has been superheated into very lightweight expanded glass pebbles. It is used loose or in plastic sleeves immersed in the water. It is also used in potting soil mixes to decrease soil density.

Sand

Gravel

Sand is cheap and easily available. However, it is heavy, does not hold water very well, and it must be sterilized between use.

The same type that is used in aquariums, though any small gravel can be used, provided it is washed first. Indeed, plants growing in a typical traditional gravel filter bed, with water circulated using electric powerhead pumps, are in effect being grown using gravel hydroponics. Gravel is inexpensive, easy to keep clean, drains well and will not become waterlogged.

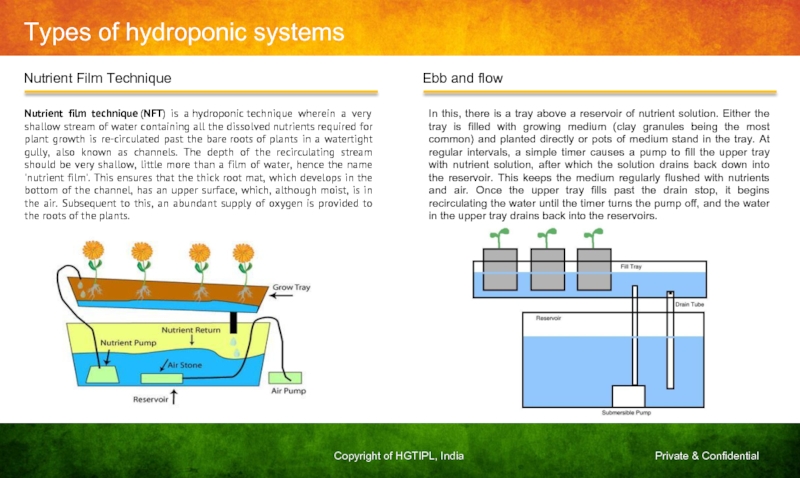

Слайд 14Types of hydroponic systems

Nutrient Film Technique

Ebb and flow

Nutrient film technique (NFT) is

In this, there is a tray above a reservoir of nutrient solution. Either the tray is filled with growing medium (clay granules being the most common) and planted directly or pots of medium stand in the tray. At regular intervals, a simple timer causes a pump to fill the upper tray with nutrient solution, after which the solution drains back down into the reservoir. This keeps the medium regularly flushed with nutrients and air. Once the upper tray fills past the drain stop, it begins recirculating the water until the timer turns the pump off, and the water in the upper tray drains back into the reservoirs.

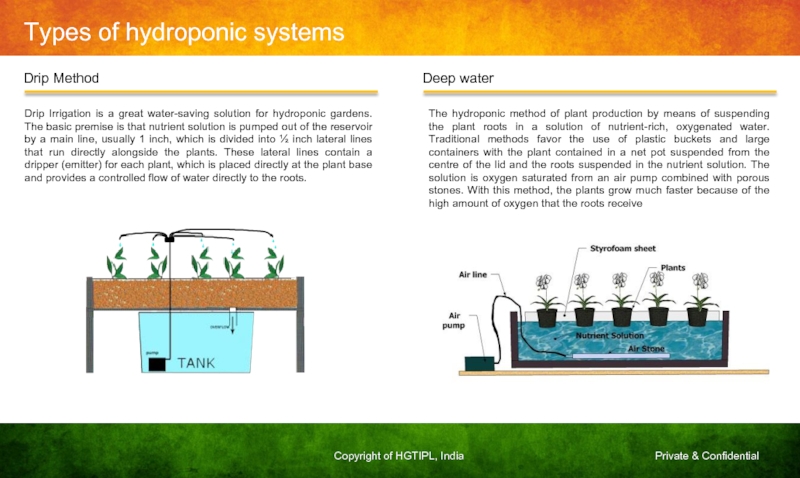

Слайд 15Types of hydroponic systems

Drip Method

Deep water

Drip Irrigation is a great water-saving

The hydroponic method of plant production by means of suspending the plant roots in a solution of nutrient-rich, oxygenated water. Traditional methods favor the use of plastic buckets and large containers with the plant contained in a net pot suspended from the centre of the lid and the roots suspended in the nutrient solution. The solution is oxygen saturated from an air pump combined with porous stones. With this method, the plants grow much faster because of the high amount of oxygen that the roots receive

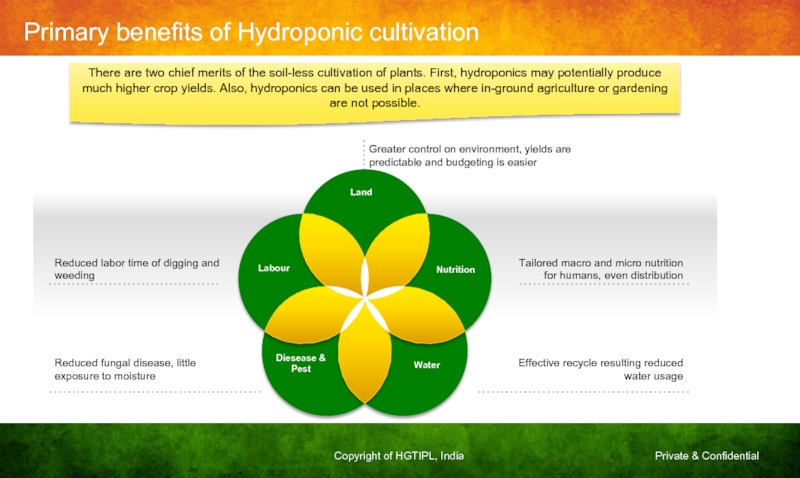

Слайд 16Primary benefits of Hydroponic cultivation

Reduced labor time of digging and weeding

Reduced

Greater control on environment, yields are predictable and budgeting is easier

Tailored macro and micro nutrition for humans, even distribution

Effective recycle resulting reduced water usage

Land

Labour

Nutrition

Diesease &

Pest

Water

There are two chief merits of the soil-less cultivation of plants. First, hydroponics may potentially produce much higher crop yields. Also, hydroponics can be used in places where in-ground agriculture or gardening are not possible.

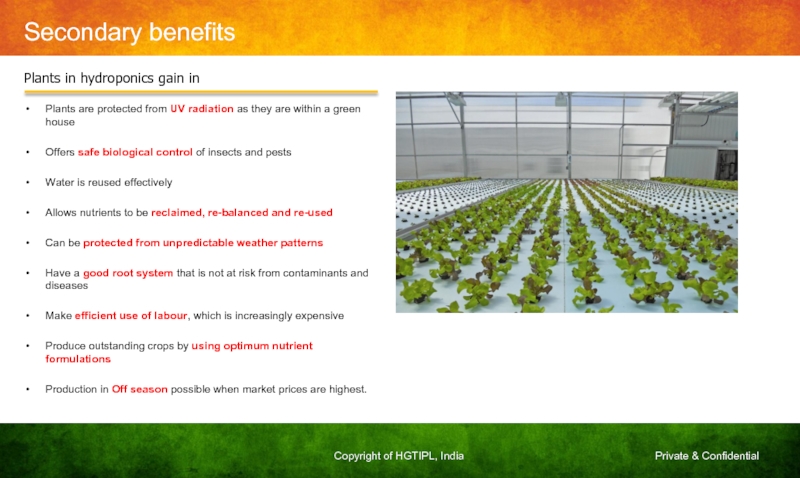

Слайд 17Secondary benefits

Plants in hydroponics gain in

Plants are protected from UV

Offers safe biological control of insects and pests

Water is reused effectively

Allows nutrients to be reclaimed, re-balanced and re-used

Can be protected from unpredictable weather patterns

Have a good root system that is not at risk from contaminants and diseases

Make efficient use of labour, which is increasingly expensive

Produce outstanding crops by using optimum nutrient formulations

Production in Off season possible when market prices are highest.

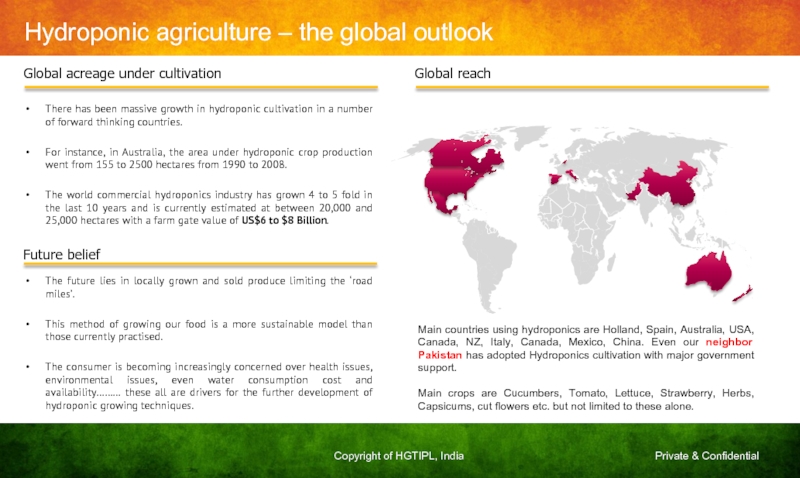

Слайд 20Hydroponic agriculture – the global outlook

Global acreage under cultivation

There has been

For instance, in Australia, the area under hydroponic crop production went from 155 to 2500 hectares from 1990 to 2008.

The world commercial hydroponics industry has grown 4 to 5 fold in the last 10 years and is currently estimated at between 20,000 and 25,000 hectares with a farm gate value of US$6 to $8 Billion.

Future belief

The future lies in locally grown and sold produce limiting the ‘road miles’.

This method of growing our food is a more sustainable model than those currently practised.

The consumer is becoming increasingly concerned over health issues, environmental issues, even water consumption cost and availability……… these all are drivers for the further development of hydroponic growing techniques.

Global reach

Main countries using hydroponics are Holland, Spain, Australia, USA, Canada, NZ, Italy, Canada, Mexico, China. Even our neighbor Pakistan has adopted Hydroponics cultivation with major government support.

Main crops are Cucumbers, Tomato, Lettuce, Strawberry, Herbs, Capsicums, cut flowers etc. but not limited to these alone.

Слайд 22Standards

Laws

Water

Source

Container

System with

Air pump

Seedlings

Customers

People

Land

Nutrients

Green House

The resource universe for a hydroponic system

Resource universe of commercial hydroponic agriculture

Слайд 23Plants grown in hydroponic systems

Tomato's

Lettuce

Bell Pepper

Cucumber

Strawberries

Water Lemon

Potato

Onion

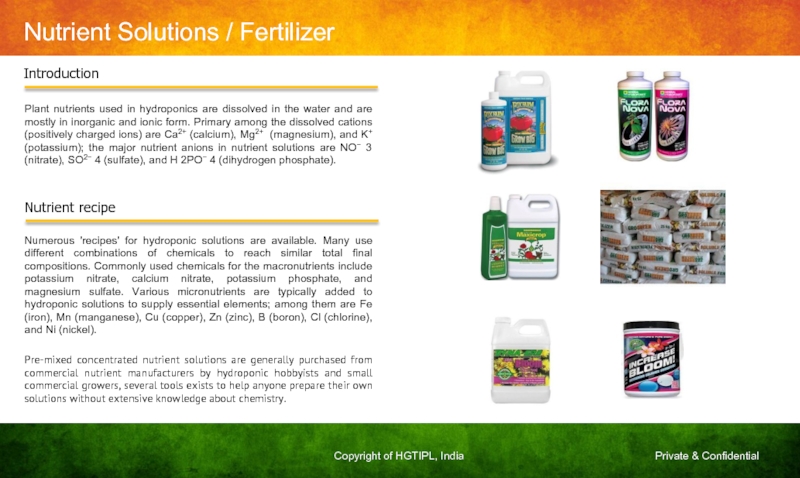

Слайд 24Nutrient Solutions / Fertilizer

Introduction

Plant nutrients used in hydroponics are dissolved in

Nutrient recipe

Numerous 'recipes' for hydroponic solutions are available. Many use different combinations of chemicals to reach similar total final compositions. Commonly used chemicals for the macronutrients include potassium nitrate, calcium nitrate, potassium phosphate, and magnesium sulfate. Various micronutrients are typically added to hydroponic solutions to supply essential elements; among them are Fe (iron), Mn (manganese), Cu (copper), Zn (zinc), B (boron), Cl (chlorine), and Ni (nickel).

Pre-mixed concentrated nutrient solutions are generally purchased from commercial nutrient manufacturers by hydroponic hobbyists and small commercial growers, several tools exists to help anyone prepare their own solutions without extensive knowledge about chemistry.

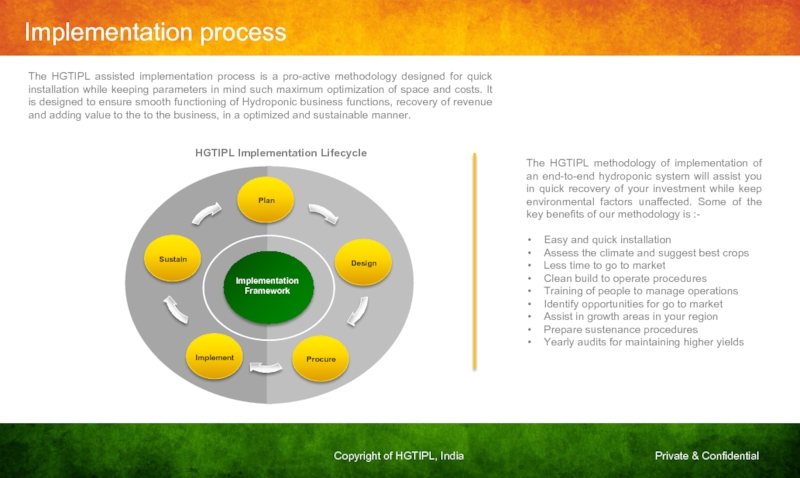

Слайд 25Implementation process

The HGTIPL assisted implementation process is a pro-active methodology designed

Sustain

Implement

Procure

Design

Plan

Implementation

Framework

HGTIPL Implementation Lifecycle

The HGTIPL methodology of implementation of an end-to-end hydroponic system will assist you in quick recovery of your investment while keep environmental factors unaffected. Some of the key benefits of our methodology is :-

Easy and quick installation

Assess the climate and suggest best crops

Less time to go to market

Clean build to operate procedures

Training of people to manage operations

Identify opportunities for go to market

Assist in growth areas in your region

Prepare sustenance procedures

Yearly audits for maintaining higher yields

Слайд 28Opportunity in India

Production and labor costs in developed countries are increasing

India has rich climatic conditions positioning us favorably to market such produce.

Labor costs in India as well as inputs makes India an ideal destination for food outsourcing.

Indian producers can address both domestic as well as International markets such as ME/EU/USA/Far East.

Has intelligent manpower. Can learn fast the operating protocols.

Usually gets a better price based on looks, texture, taste, consistency on daily basis, high nutrition value, reliable supply year round etc.

A country that can produce super-computers, satellites can definitely adopt Hydroponics easily in the author’s view.

Development in India

Marketing channels in India

Wholesale Channels

Retail Channels

Supermarket chains/Export markets.

Cooperatives to help sell their produce.

Producers specialize in one or two types of produce mainly and have full control over their produce.

Outside India

Sales opportunities abound from Indian producers due to better production costing achievable.

Markets are in USA, EU, Far and Middle East.

India has excellent connectivity to above by land, sea and air.

Freight costs from India are high at this time and with better governmental support can be alleviated.

Слайд 29Catalyst for hydroponic farming in India

1

2

3

4

Big growth markets

High population mean higher

Trend moving towards quality of food rather than price / quantity

Organic and clean foods getting preference

Low cost of labor

Manual labor is easily accessible

Low cost to setting up and maintaining operations

Easy communication and teaching arenas

Access to technology

Easy access to green-house and hydroponic technologies

Access to water pumps and HVAC systems

Easy access to fertilizers and IPM technologies

Knowledge

Good knowledge of hydroponic methodologies

Knowledge of markets and customers

Understanding of crops cycles and related diseases & pests

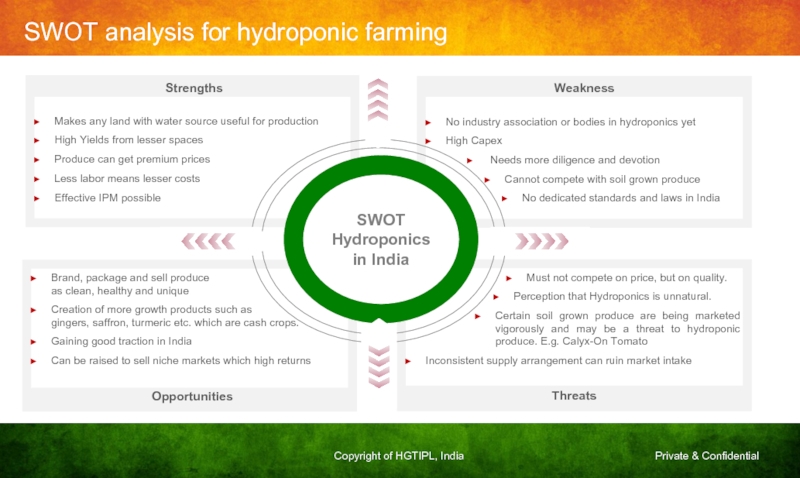

Слайд 30SWOT analysis for hydroponic farming

Makes any land with water source useful

High Yields from lesser spaces

Produce can get premium prices

Less labor means lesser costs

Effective IPM possible

Brand, package and sell produce

as clean, healthy and unique

Creation of more growth products such as

gingers, saffron, turmeric etc. which are cash crops.

Gaining good traction in India

Can be raised to sell niche markets which high returns

No industry association or bodies in hydroponics yet

High Capex

Needs more diligence and devotion

Cannot compete with soil grown produce

No dedicated standards and laws in India

Must not compete on price, but on quality.

Perception that Hydroponics is unnatural.

Certain soil grown produce are being marketed vigorously and may be a threat to hydroponic produce. E.g. Calyx-On Tomato

Inconsistent supply arrangement can ruin market intake

SWOT

Hydroponics in India

Weakness

Threats

Strengths

Opportunities

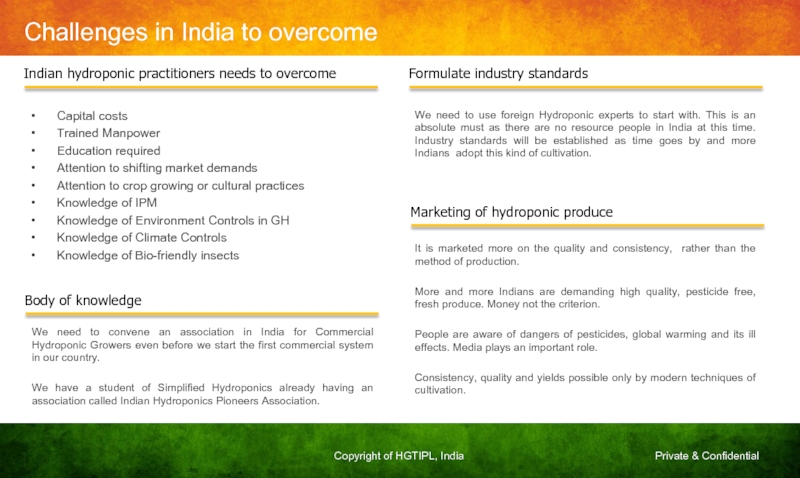

Слайд 31Challenges in India to overcome

Capital costs

Trained Manpower

Education required

Attention to shifting market

Attention to crop growing or cultural practices

Knowledge of IPM

Knowledge of Environment Controls in GH

Knowledge of Climate Controls

Knowledge of Bio-friendly insects

Indian hydroponic practitioners needs to overcome

Body of knowledge

We need to convene an association in India for Commercial Hydroponic Growers even before we start the first commercial system in our country.

We have a student of Simplified Hydroponics already having an association called Indian Hydroponics Pioneers Association.

Formulate industry standards

We need to use foreign Hydroponic experts to start with. This is an absolute must as there are no resource people in India at this time. Industry standards will be established as time goes by and more Indians adopt this kind of cultivation.

Marketing of hydroponic produce

It is marketed more on the quality and consistency, rather than the method of production.

More and more Indians are demanding high quality, pesticide free, fresh produce. Money not the criterion.

People are aware of dangers of pesticides, global warming and its ill effects. Media plays an important role.

Consistency, quality and yields possible only by modern techniques of cultivation.

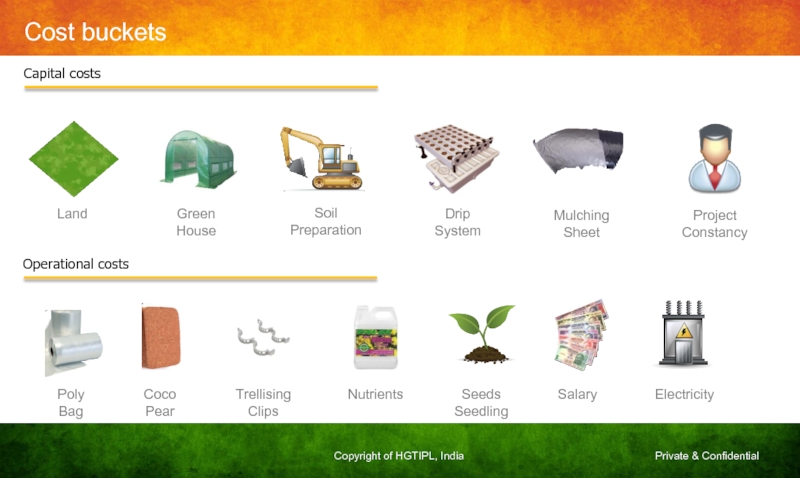

Слайд 33Cost buckets

Capital costs

Operational costs

Drip

System

Land

Green

House

Soil

Preparation

Mulching

Sheet

Project

Constancy

Poly

Bag

Coco

Pear

Trellising

Clips

Nutrients

Seeds

Seedling

Salary

Electricity

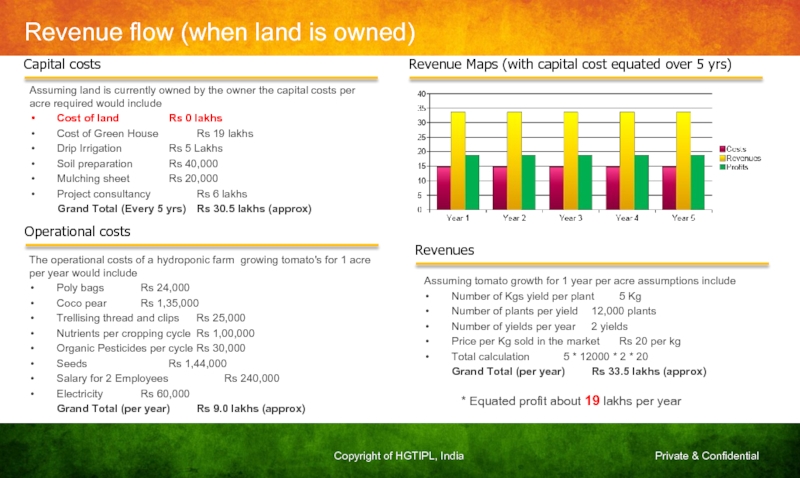

Слайд 34Revenue flow (when land is owned)

Revenue Maps (with capital cost equated

Capital costs

Assuming land is currently owned by the owner the capital costs per acre required would include

Cost of land Rs 0 lakhs

Cost of Green House Rs 19 lakhs

Drip Irrigation Rs 5 Lakhs

Soil preparation Rs 40,000

Mulching sheet Rs 20,000

Project consultancy Rs 6 lakhs

Grand Total (Every 5 yrs) Rs 30.5 lakhs (approx)

Operational costs

The operational costs of a hydroponic farm growing tomato's for 1 acre per year would include

Poly bags Rs 24,000

Coco pear Rs 1,35,000

Trellising thread and clips Rs 25,000

Nutrients per cropping cycle Rs 1,00,000

Organic Pesticides per cycle Rs 30,000

Seeds Rs 1,44,000

Salary for 2 Employees Rs 240,000

Electricity Rs 60,000

Grand Total (per year) Rs 9.0 lakhs (approx)

Revenues

Assuming tomato growth for 1 year per acre assumptions include

Number of Kgs yield per plant 5 Kg

Number of plants per yield 12,000 plants

Number of yields per year 2 yields

Price per Kg sold in the market Rs 20 per kg

Total calculation 5 * 12000 * 2 * 20

Grand Total (per year) Rs 33.5 lakhs (approx)

* Equated profit about 19 lakhs per year

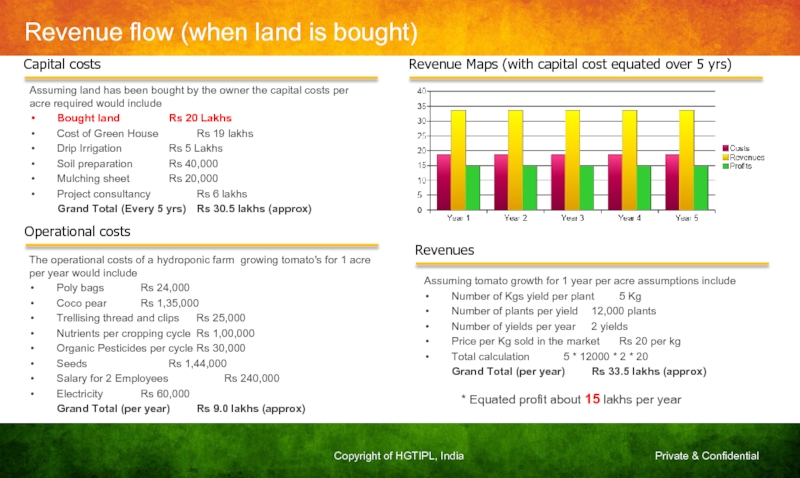

Слайд 35Revenue flow (when land is bought)

Revenue Maps (with capital cost equated

Capital costs

Assuming land has been bought by the owner the capital costs per acre required would include

Bought land Rs 20 Lakhs

Cost of Green House Rs 19 lakhs

Drip Irrigation Rs 5 Lakhs

Soil preparation Rs 40,000

Mulching sheet Rs 20,000

Project consultancy Rs 6 lakhs

Grand Total (Every 5 yrs) Rs 30.5 lakhs (approx)

Operational costs

The operational costs of a hydroponic farm growing tomato's for 1 acre per year would include

Poly bags Rs 24,000

Coco pear Rs 1,35,000

Trellising thread and clips Rs 25,000

Nutrients per cropping cycle Rs 1,00,000

Organic Pesticides per cycle Rs 30,000

Seeds Rs 1,44,000

Salary for 2 Employees Rs 240,000

Electricity Rs 60,000

Grand Total (per year) Rs 9.0 lakhs (approx)

Revenues

Assuming tomato growth for 1 year per acre assumptions include

Number of Kgs yield per plant 5 Kg

Number of plants per yield 12,000 plants

Number of yields per year 2 yields

Price per Kg sold in the market Rs 20 per kg

Total calculation 5 * 12000 * 2 * 20

Grand Total (per year) Rs 33.5 lakhs (approx)

* Equated profit about 15 lakhs per year

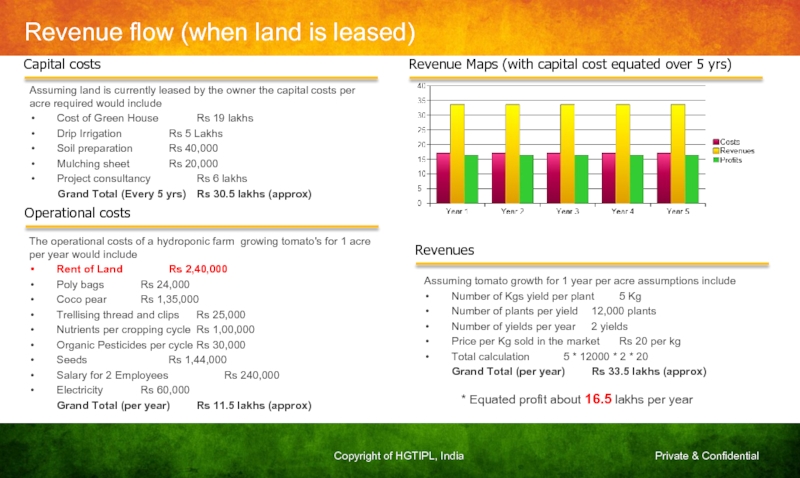

Слайд 36Revenue flow (when land is leased)

Revenue Maps (with capital cost equated

Capital costs

Assuming land is currently leased by the owner the capital costs per acre required would include

Cost of Green House Rs 19 lakhs

Drip Irrigation Rs 5 Lakhs

Soil preparation Rs 40,000

Mulching sheet Rs 20,000

Project consultancy Rs 6 lakhs

Grand Total (Every 5 yrs) Rs 30.5 lakhs (approx)

Operational costs

The operational costs of a hydroponic farm growing tomato's for 1 acre per year would include

Rent of Land Rs 2,40,000

Poly bags Rs 24,000

Coco pear Rs 1,35,000

Trellising thread and clips Rs 25,000

Nutrients per cropping cycle Rs 1,00,000

Organic Pesticides per cycle Rs 30,000

Seeds Rs 1,44,000

Salary for 2 Employees Rs 240,000

Electricity Rs 60,000

Grand Total (per year) Rs 11.5 lakhs (approx)

Revenues

Assuming tomato growth for 1 year per acre assumptions include

Number of Kgs yield per plant 5 Kg

Number of plants per yield 12,000 plants

Number of yields per year 2 yields

Price per Kg sold in the market Rs 20 per kg

Total calculation 5 * 12000 * 2 * 20

Grand Total (per year) Rs 33.5 lakhs (approx)

* Equated profit about 16.5 lakhs per year

Слайд 37Reasons for failure

Venture not established in a realistic economic framework like

Selection of system/crop/markets/correct management not done

Crop production management inadequate

Yield and quality did not meet budget projections

Lack of diligence on part of the crew

Non adherence to growing protocols

Insufficient attention to marketing

Lack of necessary labour

Incorrect pricing of produce

Product not tailored as per demand

Critical matters to be addressed

Profitability is linked to

Production scale, increasing returns to increasing size.

Ability to supply promised amount with quality and consistency

Capacity to Value add and/or

Find and exploit a unique and high return/value market niche

Слайд 39Who we are

CV Prakash

The Farmer In Chief

Mrs.Sangeeta Bojappa Moorthy

Chief of Operations

Hydroponic

Today, we, at HGT, are leaders in this field in India and our hard earned name has transcended international borders.

The “Pet Bharo” Project, meaning in Hindi, ‘Fill Your Tummy’ project and as we fondly christened it so, is a strong brand name, so much so that, when people call us they ask “Is this Pet Bharo? It’s a word synonymous with Indian Hydroponics.

This achievement has been no mean task. It has been nurtured by persistence, hard work, focus, integrity and above all, a strong sense of personality, character and ethos.

When you approach us you will see for yourself how we make it a point to serve you with humility and a very deep urge to help you.

Слайд 41How can we help

Setting up of Turnkey Commercial Hydroponics/Soil-less Greenhouse systems

Consultancy for Hydroponics/Soil-less Cultivation, Feasibility studies and Project Reports.

Training in Basics of Commercial Hydroponics

Setting up broad acre Hydroponics/Soil-less Food Parks with all facilities.

Supplies of Backyard Greenhouse systems Supply of Hydroponic nutrients and soil-less substrates like Coir Peat/Perlite etc.

Conducts seminars with foreign experts on Hydroponics/Soil-less cultivation from time to time.

Water testing facilities and reports rendered.

Supply of testing equipment's for pH/TDS/EC/Temperature probes etc.

Our key activities

Слайд 43Some successful commercial installations

Hydroponic Strawberry System

The Institute of Simplified Hydroponics

Hydroponics Lettuce/Herbs System

ISH bagged on 23rd March 2011, its second Commercial Hydroponics Lettuce/Herbs order" from a client in Coimbatore. This within three months of its first commercial hydroponics greenhouse order to set up a strawberry greenhouse at Bangalore. The state of the art Lettuce/Herbs Greenhouse will initially start with a one acre pilot expanding to 4 acres in next one year.