- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Welding презентация

Содержание

- 1. Welding

- 2. 1.Welding 2. Forge or Blacksmith Welding 3.

- 3. Welding is a method of causing fusion

- 4. Forge or Blacksmith Welding Forge welding

- 5. Thermit Welding is not a common process.

- 6. The temperature of

- 7. Electric Welding This type of welding is

- 8. Types of resistance welding are: spot welding;

- 9. Spot Welding This process consists of

- 10. Butt-Welding By this process the parts

- 11. Flash Welding This is another type

- 12. Percussion Welding This process is similar

- 13. Seam Welding This a resistance-welding process

- 14. Resistance – welding process Resistance – welding process

- 15. Seam – welding machine

- 16. Projection Welding This process is similar

- 17. Spot\ Projection Pneumatic Welding machine Projection Welding Electrodes

- 18. Electric Arc Welding This is a

- 20. Gas welding In gas welding, the

Слайд 21.Welding

2. Forge or Blacksmith Welding

3. Thermit Welding

4. Electric Welding

5. Types

of resistance welding:

-Spot Welding;

- Butt Welding;

-Flash Welding;

- Percussion Welding;

-Seam Welding;

-Projection Welding;

- Electric Arc Welding

-Spot Welding;

- Butt Welding;

-Flash Welding;

- Percussion Welding;

-Seam Welding;

-Projection Welding;

- Electric Arc Welding

6. Gas Welding

Contents:

Слайд 3Welding is a method of causing fusion between two like pieces

of metal to form one homogeneous mass of metal.

Fusion of two masses of metal may be brought about four different processes, namely:

Forge or blacksmith welding;

Thermit welding;

3) Electric welding;

4) Gas welding.

Fusion of two masses of metal may be brought about four different processes, namely:

Forge or blacksmith welding;

Thermit welding;

3) Electric welding;

4) Gas welding.

Слайд 4Forge or Blacksmith Welding

Forge welding is a process whereby the

two masses of metal to be welded are heated in a blacksmith’s forge or appropriate furnace until the metal reaches a plastic stage. At that time the two masses are quickly joined and fused together by force from a hand or power hammer. Such a process is limited to fairly low carbon steels of solid plain shape. It is obvious that such welding has a narrow range of application, although there is still a large quantity of forge welding done in railroad shops and country blacksmith shops.

Слайд 5Thermit Welding is not a common process. The process consists of

a chemical reaction obtained by igniting finely divided aluminium and iron oxide.

A mold is formed around the pieces to be welded, and the metal is then preheated to a dull red colour. The aluminium and iron oxide are retained in a funnel-shaped receptacle which can be tapped into the mold when the aluminium and iron oxide have been made molten by the chemical reaction which is started by a fuse.

Thermit Welding

Слайд 6 The temperature of the molten metal is

high enough to fuse the broken sections, thus forming a homogeneous mass of metal.

The equipment for thermit welding is simple and inexpensive but the quality of the weld is not such as to recommend it for extensive use. The process can be used only on low carbon steels and wrought iron.

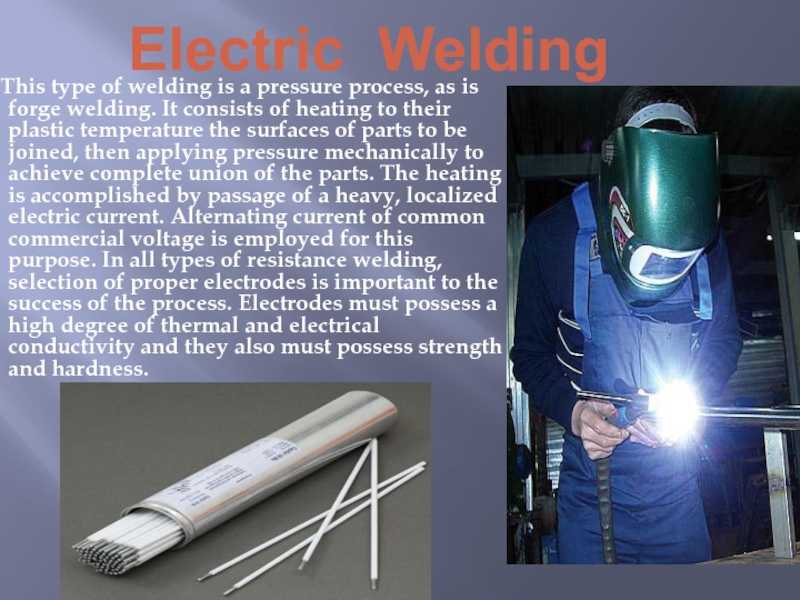

Слайд 7Electric Welding

This type of welding is a pressure process, as is

forge welding. It consists of heating to their plastic temperature the surfaces of parts to be joined, then applying pressure mechanically to achieve complete union of the parts. The heating is accomplished by passage of a heavy, localized electric current. Alternating current of common commercial voltage is employed for this purpose. In all types of resistance welding, selection of proper electrodes is important to the success of the process. Electrodes must possess a high degree of thermal and electrical conductivity and they also must possess strength and hardness.

Слайд 8Types of resistance welding are: spot welding; butt welding; flash welding;

percussion welding; seam welding; projection welding.

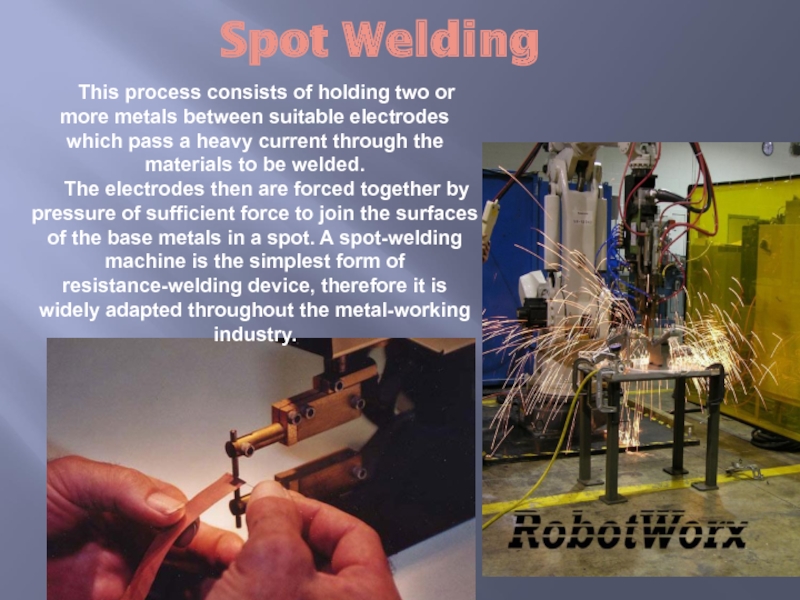

Слайд 9Spot Welding

This process consists of holding two or more metals

between suitable electrodes which pass a heavy current through the materials to be welded.

The electrodes then are forced together by pressure of sufficient force to join the surfaces of the base metals in a spot. A spot-welding machine is the simplest form of resistance-welding device, therefore it is widely adapted throughout the metal-working industry.

The electrodes then are forced together by pressure of sufficient force to join the surfaces of the base metals in a spot. A spot-welding machine is the simplest form of resistance-welding device, therefore it is widely adapted throughout the metal-working industry.

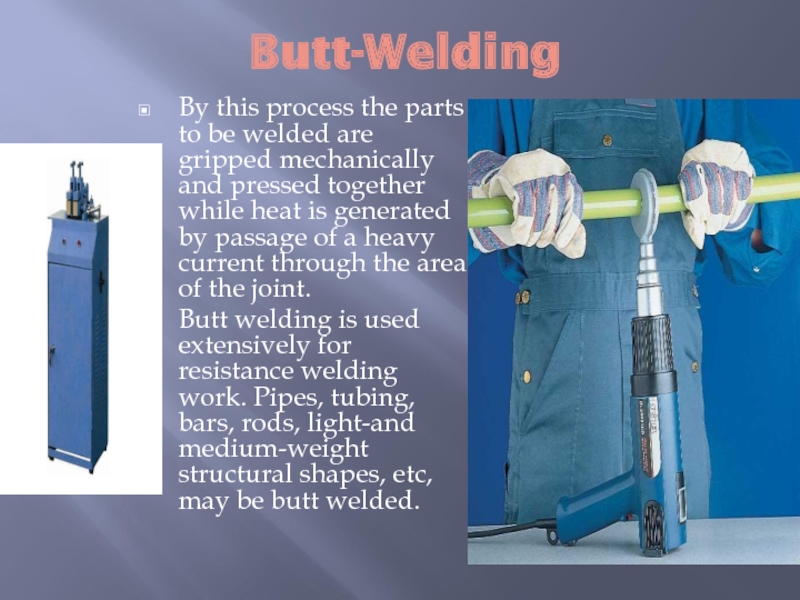

Слайд 10Butt-Welding

By this process the parts to be welded are gripped

mechanically and pressed together while heat is generated by passage of a heavy current through the area of the joint.

Butt welding is used extensively for resistance welding work. Pipes, tubing, bars, rods, light-and medium-weight structural shapes, etc, may be butt welded.

Butt welding is used extensively for resistance welding work. Pipes, tubing, bars, rods, light-and medium-weight structural shapes, etc, may be butt welded.

Слайд 11Flash Welding

This is another type of butt welding, the difference

consisting in the method of heating the base metals. The electrodes are clamped to the parts to be joined, and a heavy current is passed through them. The movable electrode brings the surface of the metal it holds into contact with the surface of the metal held in the stationary electrode. Just before the two pieces meet, an arc developed in the short gap causes sufficient heat to make the surface to be joined plastic.

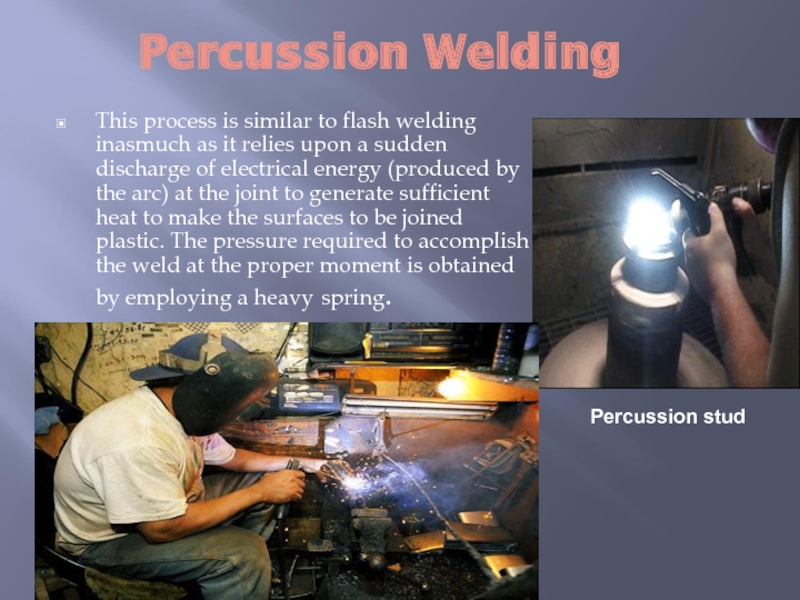

Слайд 12Percussion Welding

This process is similar to flash welding inasmuch as

it relies upon a sudden discharge of electrical energy (produced by the arc) at the joint to generate sufficient heat to make the surfaces to be joined plastic. The pressure required to accomplish the weld at the proper moment is obtained by employing a heavy spring.

Percussion stud

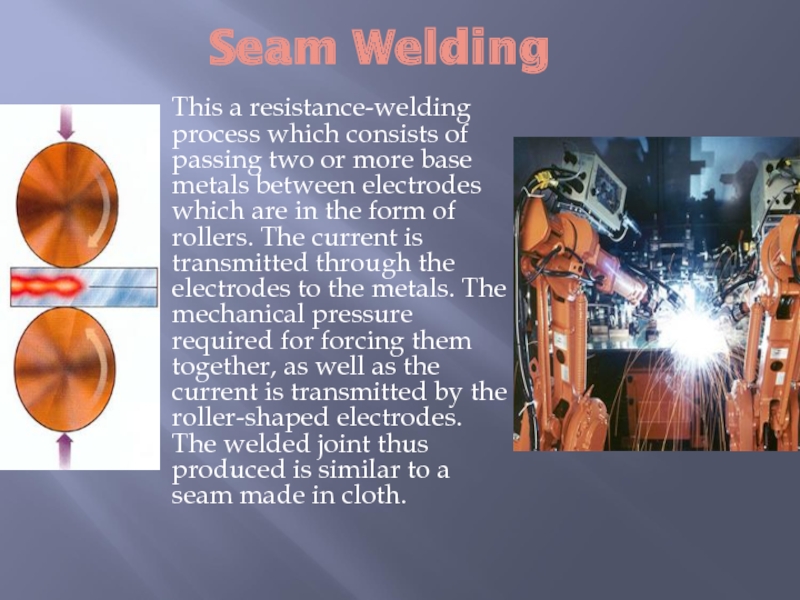

Слайд 13Seam Welding

This a resistance-welding process which consists of passing two

or more base metals between electrodes which are in the form of rollers. The current is transmitted through the electrodes to the metals. The mechanical pressure required for forcing them together, as well as the current is transmitted by the roller-shaped electrodes. The welded joint thus produced is similar to a seam made in cloth.

Слайд 15Seam – welding machine

Refrigerators, metal containers

, gasoline tanks, automobile mufflers, aircraft fabrications, pipes for furnaces and stoves, and other products requiring pressure-tight seams and rapidly produced by seam welding.

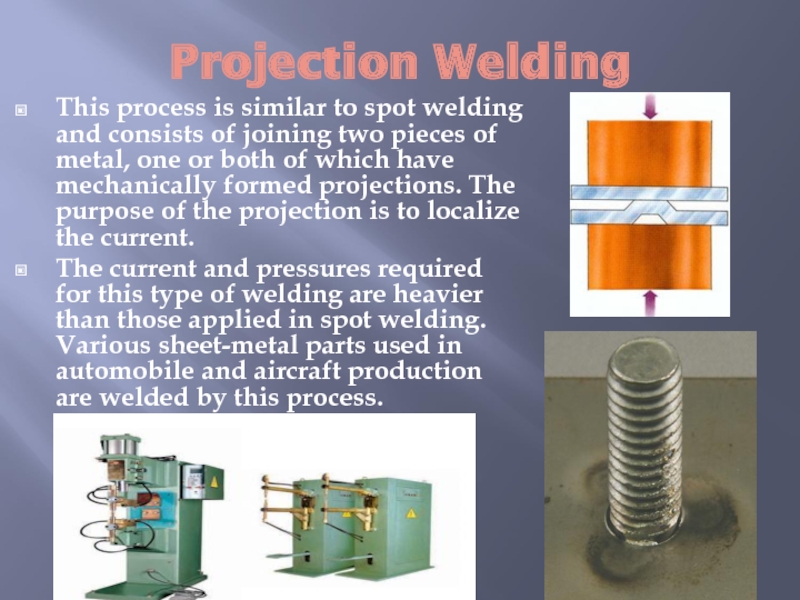

Слайд 16Projection Welding

This process is similar to spot welding and consists

of joining two pieces of metal, one or both of which have mechanically formed projections. The purpose of the projection is to localize the current.

The current and pressures required for this type of welding are heavier than those applied in spot welding. Various sheet-metal parts used in automobile and aircraft production are welded by this process.

The current and pressures required for this type of welding are heavier than those applied in spot welding. Various sheet-metal parts used in automobile and aircraft production are welded by this process.

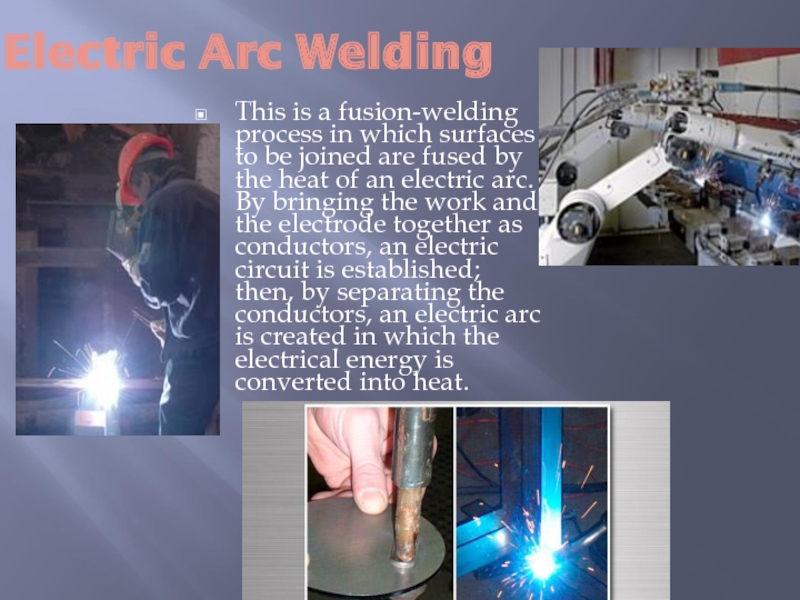

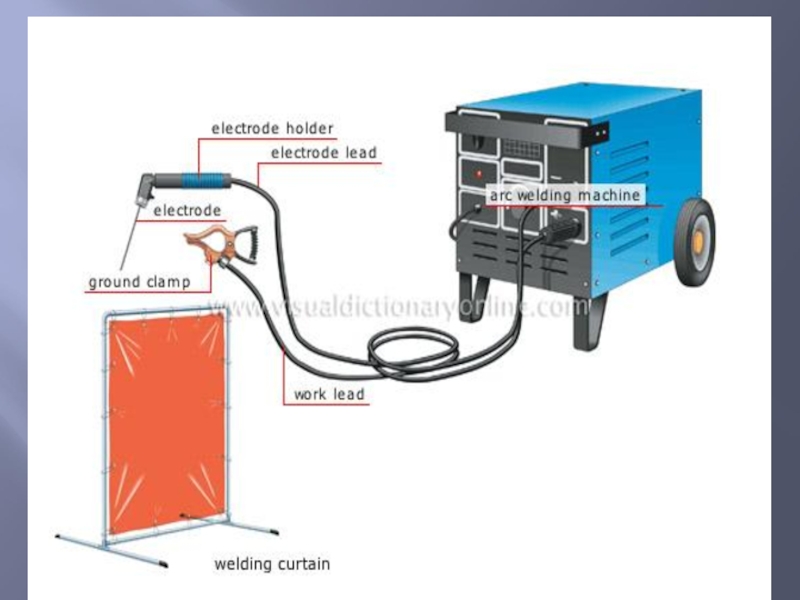

Слайд 18Electric Arc Welding

This is a fusion-welding process in which surfaces

to be joined are fused by the heat of an electric arc. By bringing the work and the electrode together as conductors, an electric circuit is established; then, by separating the conductors, an electric arc is created in which the electrical energy is converted into heat.

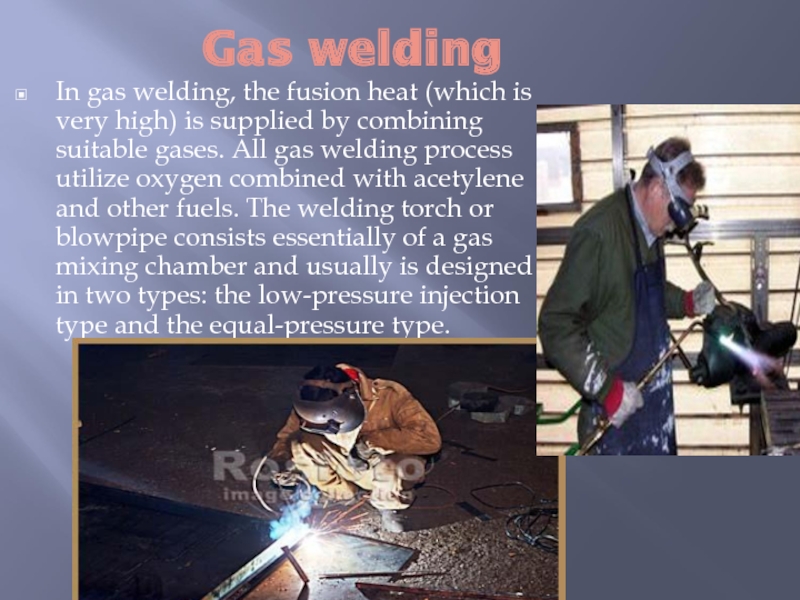

Слайд 20Gas welding

In gas welding, the fusion heat (which is very

high) is supplied by combining suitable gases. All gas welding process utilize oxygen combined with acetylene and other fuels. The welding torch or blowpipe consists essentially of a gas mixing chamber and usually is designed in two types: the low-pressure injection type and the equal-pressure type.