- Главная

- Разное

- Дизайн

- Бизнес и предпринимательство

- Аналитика

- Образование

- Развлечения

- Красота и здоровье

- Финансы

- Государство

- Путешествия

- Спорт

- Недвижимость

- Армия

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Application of nickel nanoparticles in diffusion bonding of stainless steel surfaces презентация

Содержание

- 1. Application of nickel nanoparticles in diffusion bonding of stainless steel surfaces

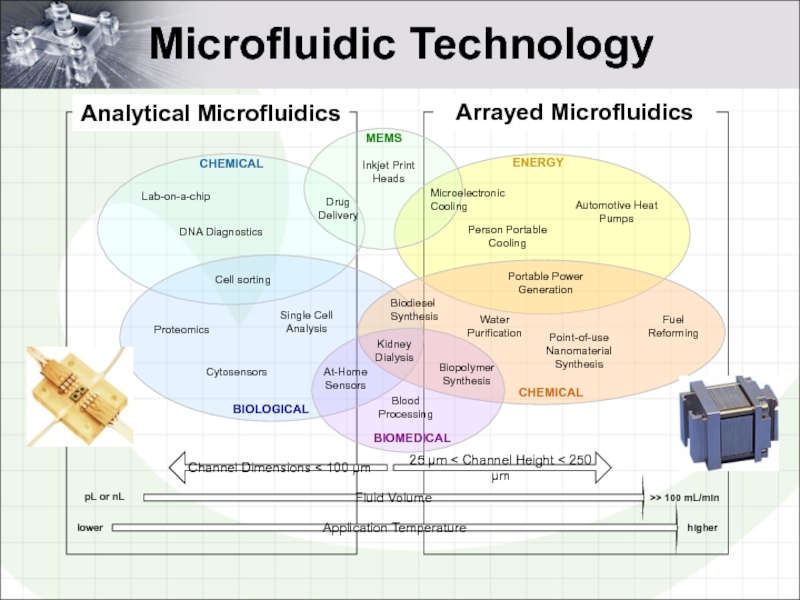

- 2. Microfluidic Technology Analytical Microfluidics Arrayed Microfluidics

- 3. Emerging Industry Fuel Processing Chemical Processing Heating & Cooling Nanomaterial Synthesis Separations

- 4. 200 µm wide channels “Number Up”

- 5. “Number Up” Laminae Device

- 6. Outline Motivation and Objective Approach Results Summary

- 7. Diffusion Bonding: Concept Initial 'point' contact

- 8. Diffusion Brazing of SS 316L Filler materials

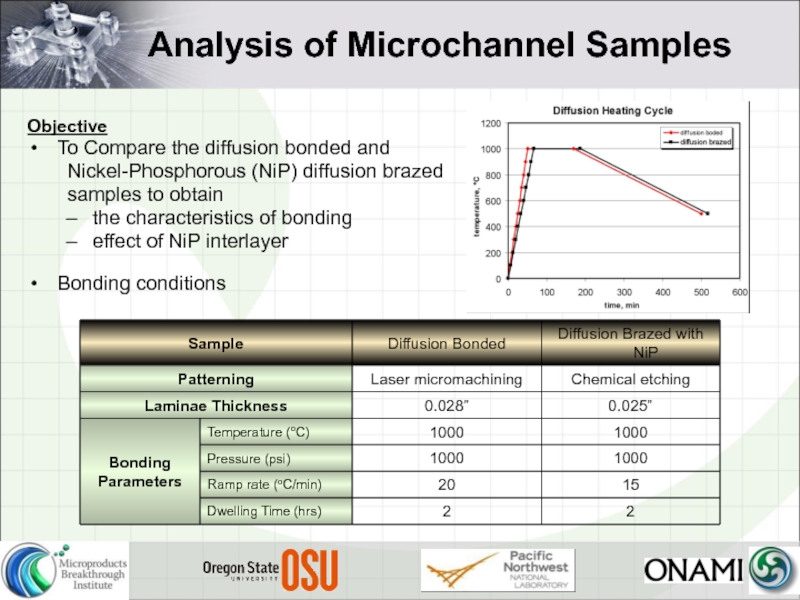

- 9. Analysis of Microchannel Samples Objective To Compare

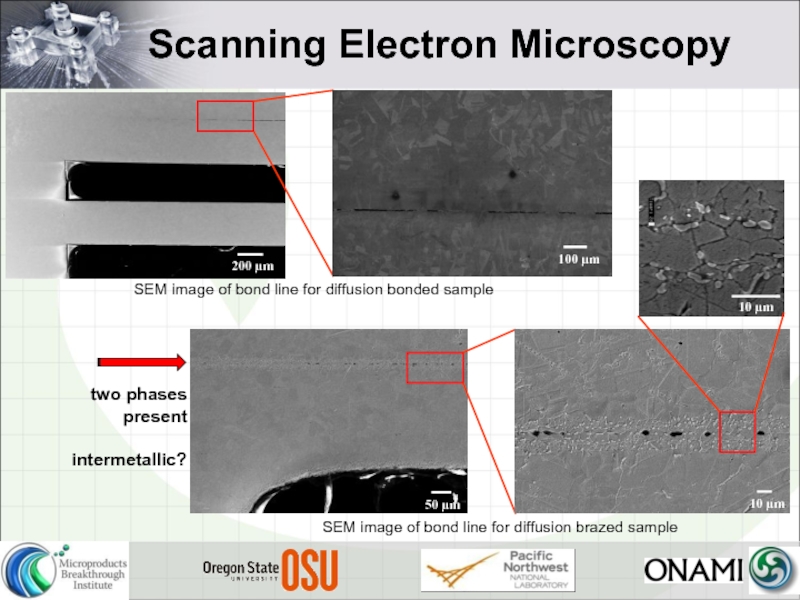

- 10. Scanning Electron Microscopy SEM image of bond

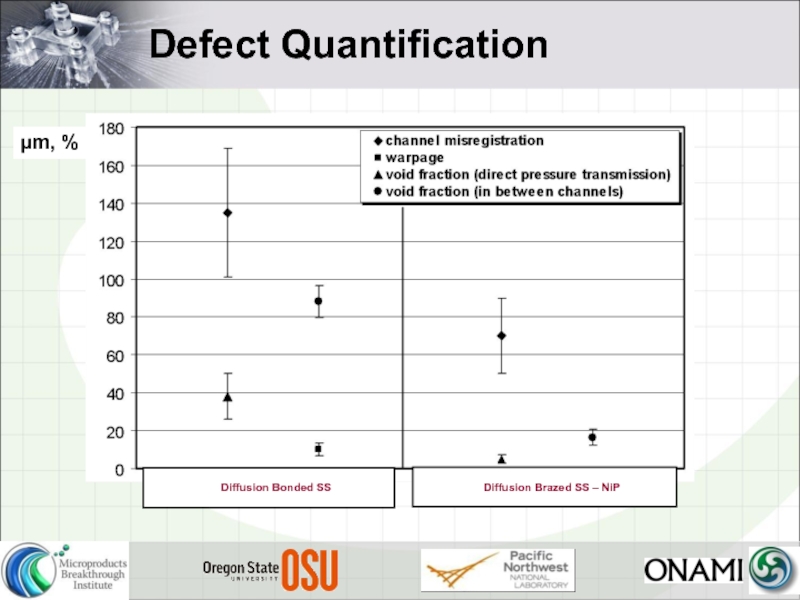

- 11. Defect Quantification µm, %

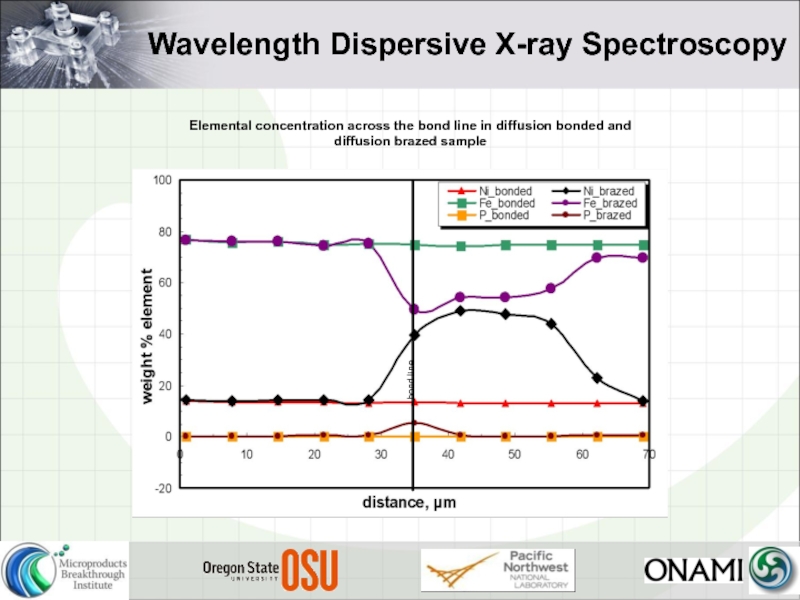

- 12. Wavelength Dispersive X-ray Spectroscopy

- 13. Nanoscale Materials in Chemistry, Wiley, 2001 Q

- 14. Role of Nanoparticles Nano-sized particles exhibit

- 15. Outline Motivation and Objective Approach Results Summary

- 16. Objective and Protocol Objectives to compare NiNP-brazed

- 17. Deposition from NP suspension Spin Coating

- 18. Nicrobraz Binder A commercially available water based

- 19. Film Characterization Continuous and uniform film Nanoparticle

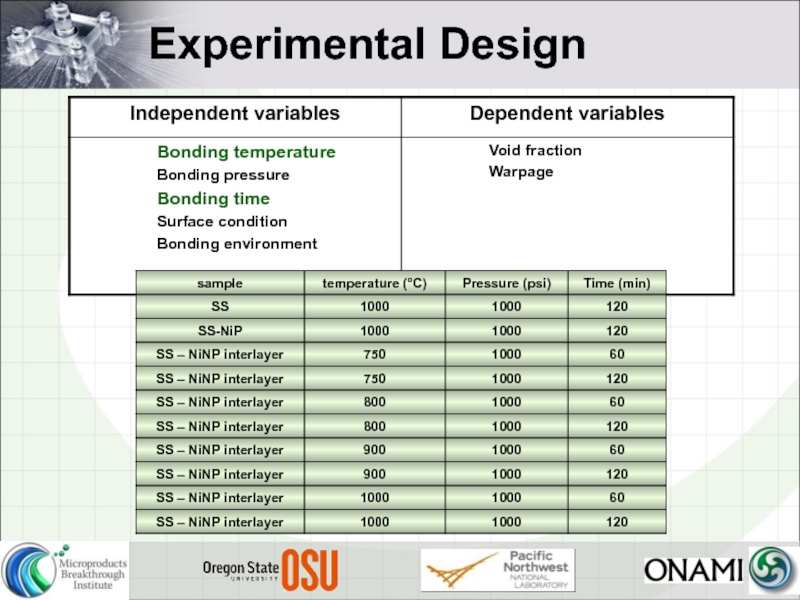

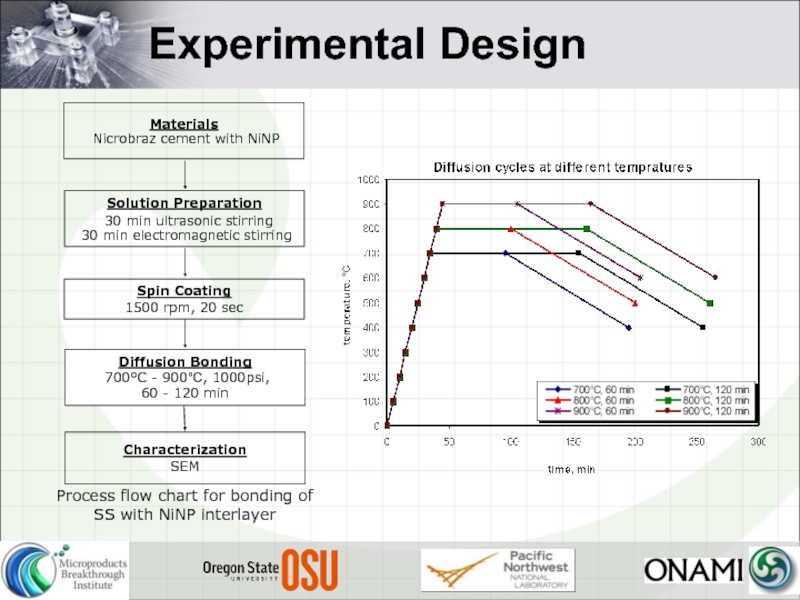

- 20. Experimental Design

- 21. Outline Motivation and Objective Approach Results Summary

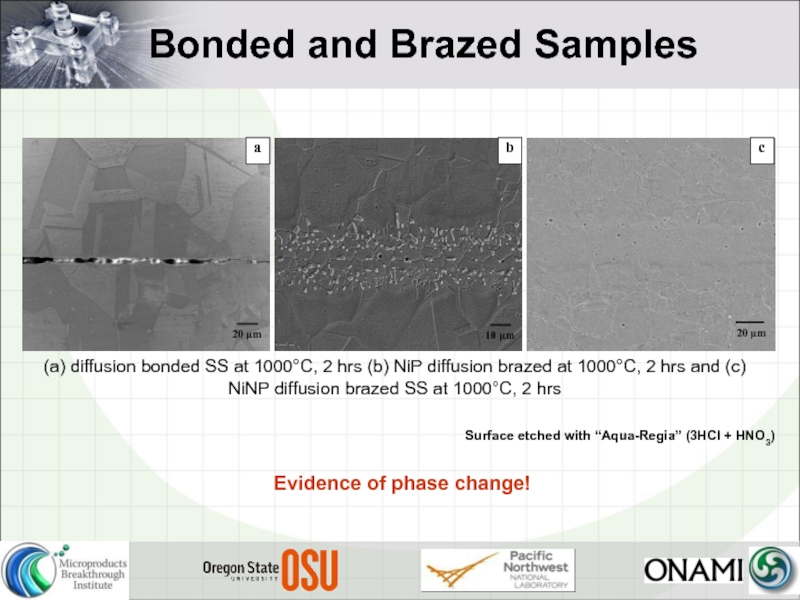

- 22. Bonded and Brazed Samples Surface etched with

- 23. Experimental Design Process flow chart for bonding of SS with NiNP interlayer

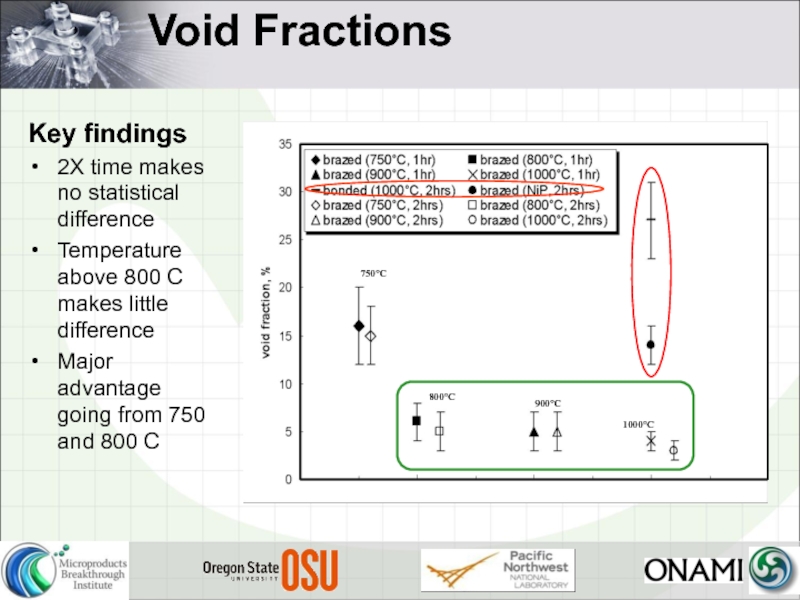

- 24. Void Fractions Key findings 2X time makes

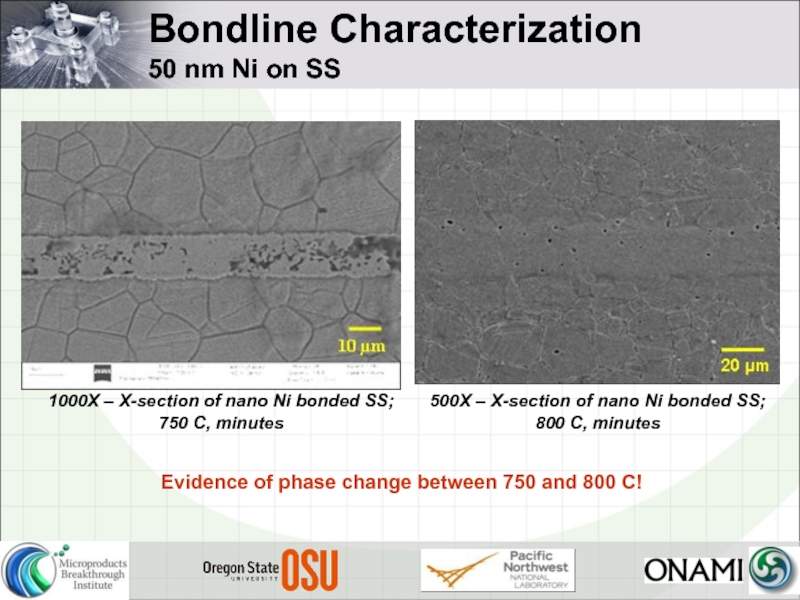

- 25. Bondline Characterization 50 nm Ni on

- 26. Summary A 50 nm+ dia. nickel nanoparticle

- 27. Acknowledgments This research is sponsored by the National Science Foundation CTS.

Слайд 1Application of Nickel Nanoparticles in Diffusion Bonding of Stainless Steel Surfaces

Santosh

School of Mechanical, Industrial and Manufacturing Engineering

Oregon State University

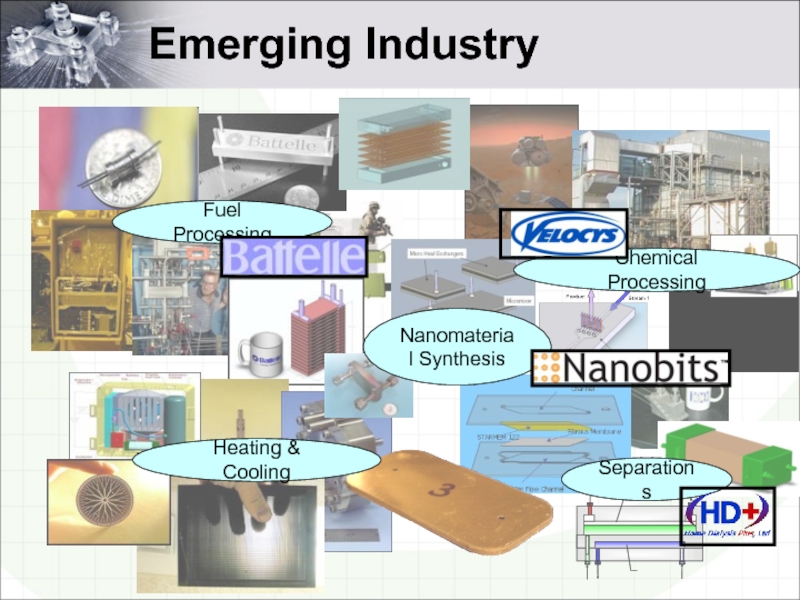

Слайд 3Emerging Industry

Fuel Processing

Chemical Processing

Heating & Cooling

Nanomaterial Synthesis

Separations

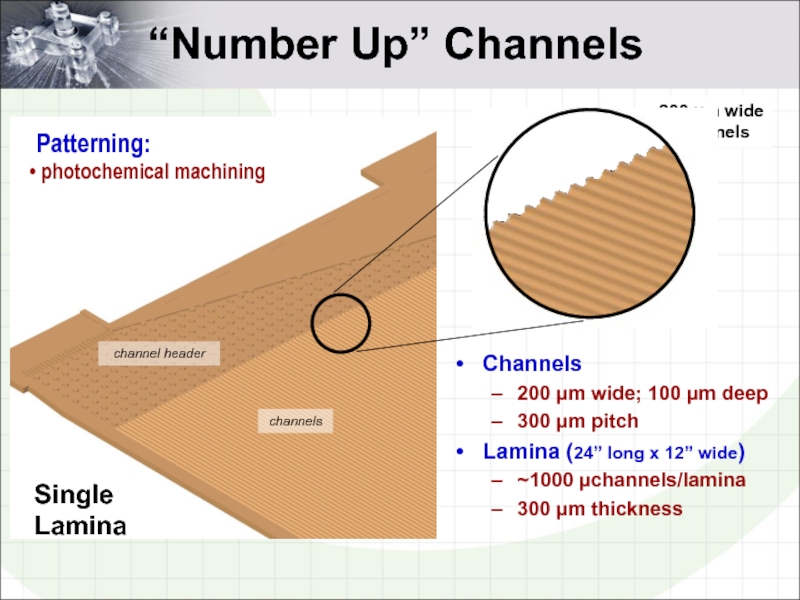

Слайд 4200 µm wide channels

“Number Up” Channels

channel header

channels

Single Lamina

Channels

200 µm wide;

300 µm pitch

Lamina (24” long x 12” wide)

~1000 µchannels/lamina

300 µm thickness

Patterning:

photochemical machining

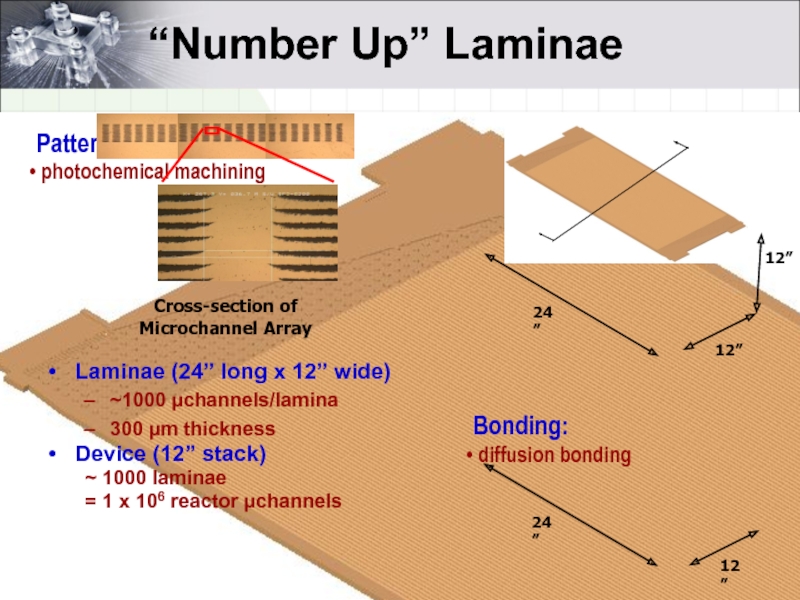

Слайд 5“Number Up” Laminae

Device (12” stack)

~ 1000 laminae

= 1 x 106 reactor

Laminae (24” long x 12” wide)

~1000 µchannels/lamina

300 µm thickness

Bonding:

diffusion bonding

Patterning:

photochemical machining

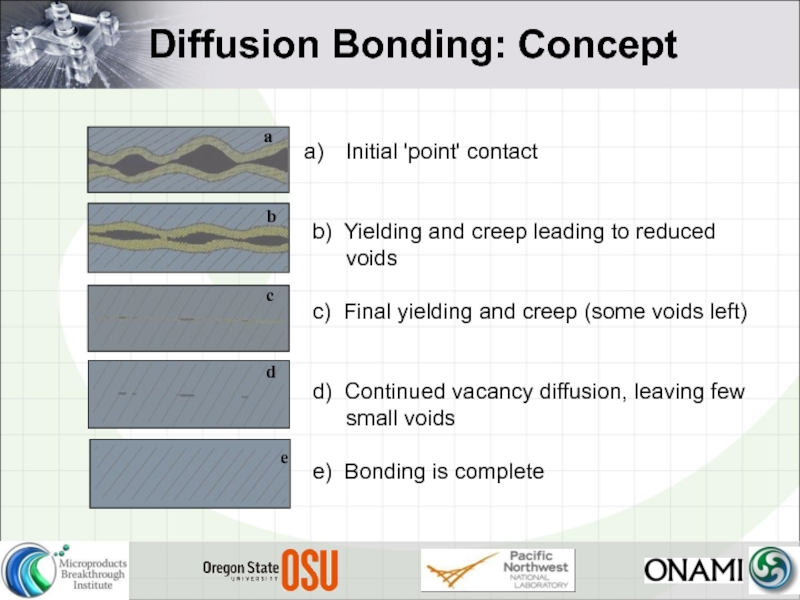

Слайд 7Diffusion Bonding: Concept

Initial 'point' contact

b) Yielding and creep leading to

c) Final yielding and creep (some voids left)

d) Continued vacancy diffusion, leaving few small voids

e) Bonding is complete

Слайд 8Diffusion Brazing of SS 316L

Filler materials such as Ni, Cu, Au

Nickel

Almost 100 % solid solubility in Fe

Good corrosion and wear resistance

Compatible with stainless steel

Temperature depressant materials (TDMs) like Si, B, P etc. added to reduce the melting temperature

Transient liquid phase bonding

Adverse effect of TDMs

Formation of secondary phases

Bond strength and ductility ▼

Additional heat treatment cycle ~ up to 24 hrs

Time and Cost ▲

Слайд 9Analysis of Microchannel Samples

Objective

To Compare the diffusion bonded and

Nickel-Phosphorous (NiP)

samples to obtain

the characteristics of bonding

effect of NiP interlayer

Bonding conditions

Слайд 10Scanning Electron Microscopy

SEM image of bond line for diffusion bonded sample

SEM

two phases present

intermetallic?

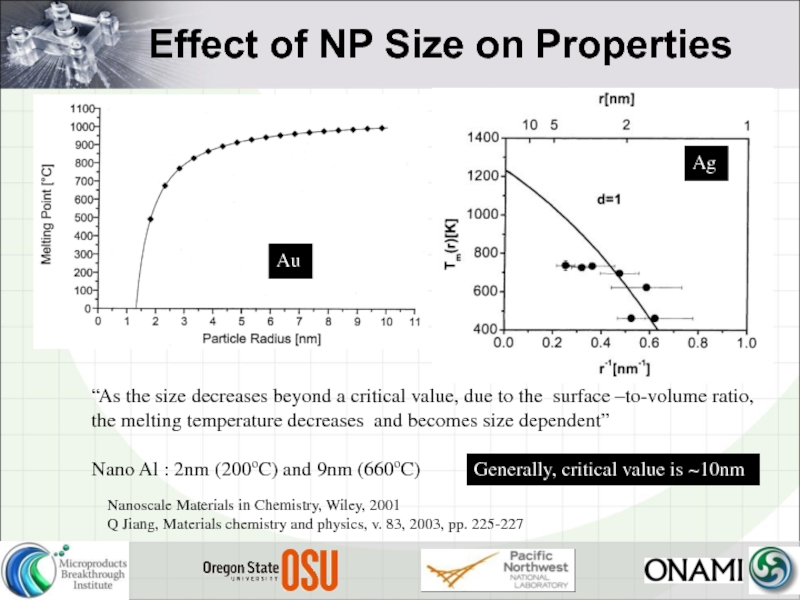

Слайд 13Nanoscale Materials in Chemistry, Wiley, 2001

Q Jiang, Materials chemistry and physics,

Au

Ag

“As the size decreases beyond a critical value, due to the surface –to-volume ratio, the melting temperature decreases and becomes size dependent”

Nano Al : 2nm (200oC) and 9nm (660oC)

Generally, critical value is ~10nm

Effect of NP Size on Properties

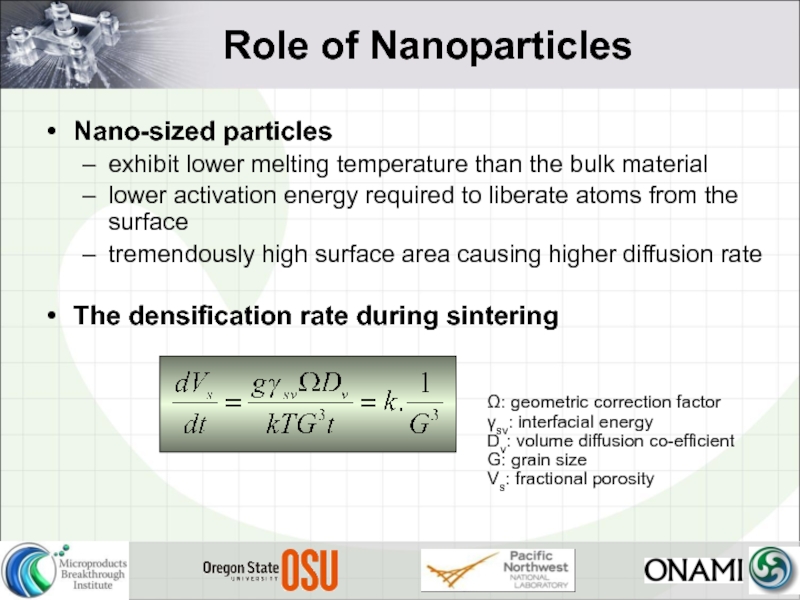

Слайд 14Role of Nanoparticles

Nano-sized particles

exhibit lower melting temperature than the bulk

lower activation energy required to liberate atoms from the surface

tremendously high surface area causing higher diffusion rate

The densification rate during sintering

Ω: geometric correction factor

γsv: interfacial energy

Dv: volume diffusion co-efficient

G: grain size

Vs: fractional porosity

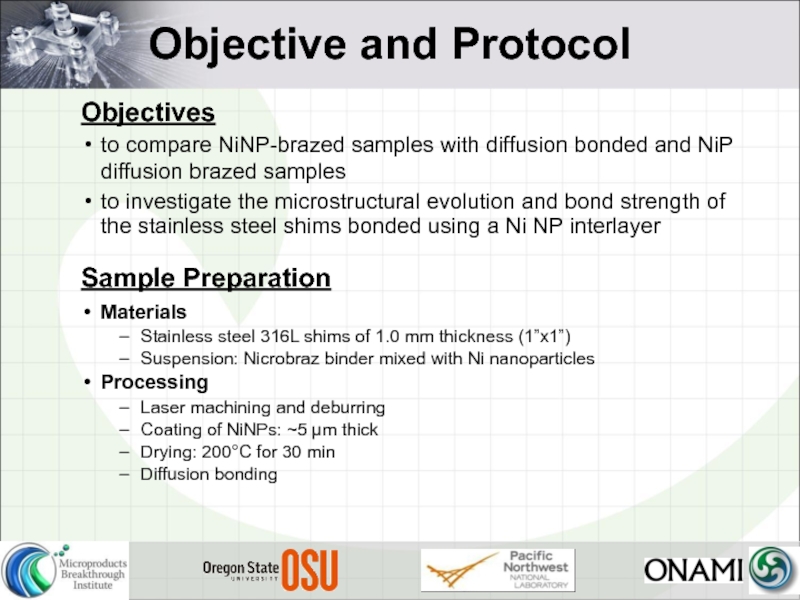

Слайд 16Objective and Protocol

Objectives

to compare NiNP-brazed samples with diffusion bonded and NiP

to investigate the microstructural evolution and bond strength of the stainless steel shims bonded using a Ni NP interlayer

Sample Preparation

Materials

Stainless steel 316L shims of 1.0 mm thickness (1”x1”)

Suspension: Nicrobraz binder mixed with Ni nanoparticles

Processing

Laser machining and deburring

Coating of NiNPs: ~5 µm thick

Drying: 200°C for 30 min

Diffusion bonding

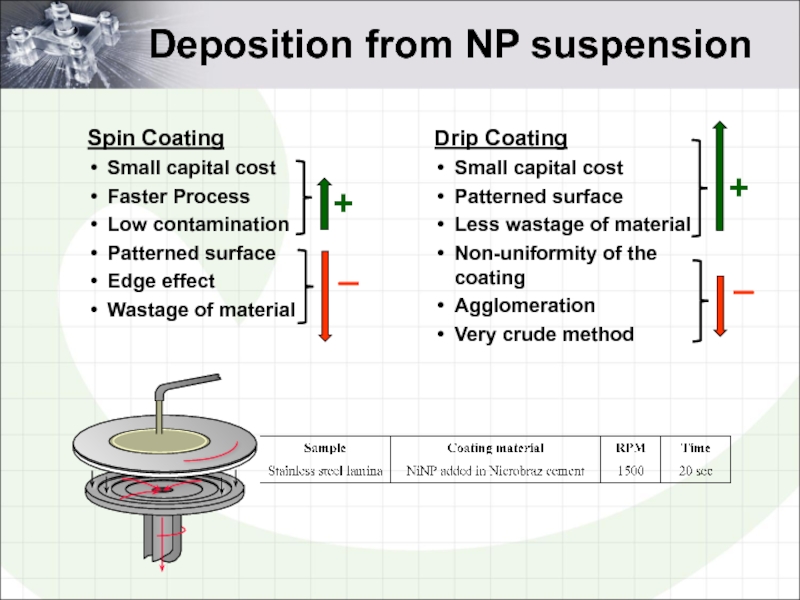

Слайд 17Deposition from NP suspension

Spin Coating

Small capital cost

Faster Process

Low contamination

Patterned

Edge effect

Wastage of material

Drip Coating

Small capital cost

Patterned surface

Less wastage of material

Non-uniformity of the coating

Agglomeration

Very crude method

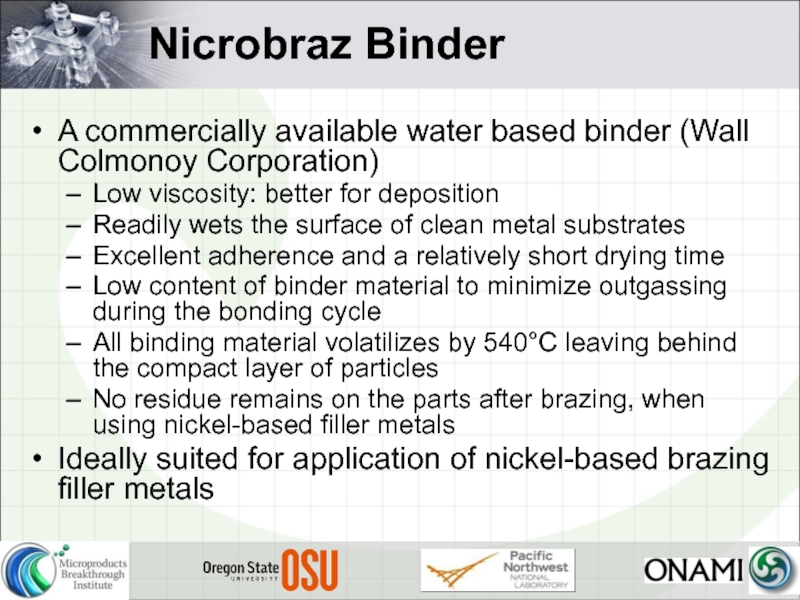

Слайд 18Nicrobraz Binder

A commercially available water based binder (Wall Colmonoy Corporation)

Low viscosity:

Readily wets the surface of clean metal substrates

Excellent adherence and a relatively short drying time

Low content of binder material to minimize outgassing during the bonding cycle

All binding material volatilizes by 540°C leaving behind the compact layer of particles

No residue remains on the parts after brazing, when using nickel-based filler metals

Ideally suited for application of nickel-based brazing filler metals

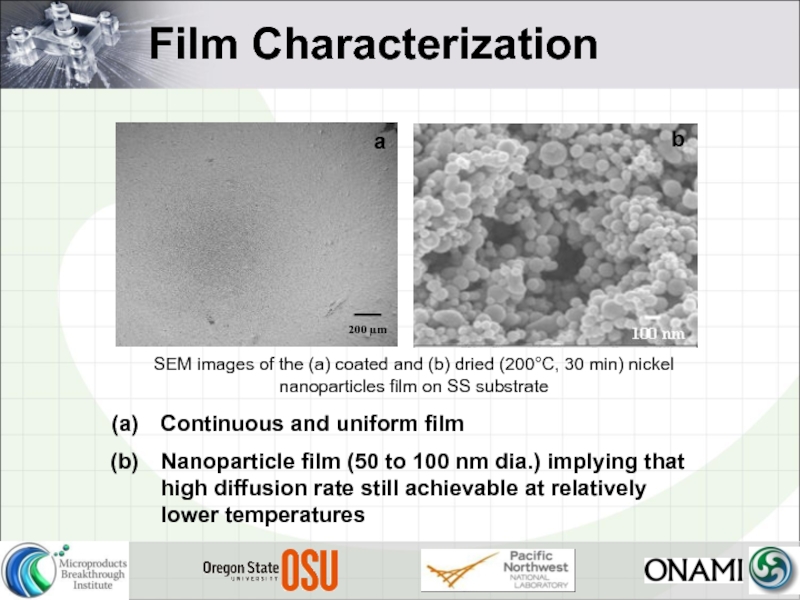

Слайд 19Film Characterization

Continuous and uniform film

Nanoparticle film (50 to 100 nm dia.)

SEM images of the (a) coated and (b) dried (200°C, 30 min) nickel nanoparticles film on SS substrate

a

b

Слайд 22Bonded and Brazed Samples

Surface etched with “Aqua-Regia” (3HCl + HNO3)

Evidence

Слайд 24Void Fractions

Key findings

2X time makes no statistical difference

Temperature above 800 C

Major advantage going from 750 and 800 C

Слайд 25Bondline Characterization

50 nm Ni on SS

1000X – X-section of nano

500X – X-section of nano Ni bonded SS; 800 C, minutes

Evidence of phase change between 750 and 800 C!

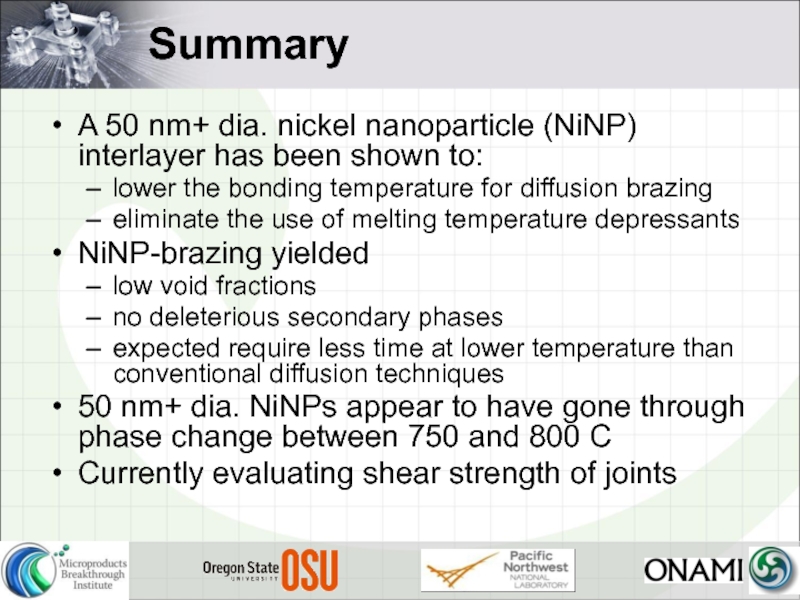

Слайд 26Summary

A 50 nm+ dia. nickel nanoparticle (NiNP) interlayer has been shown

lower the bonding temperature for diffusion brazing

eliminate the use of melting temperature depressants

NiNP-brazing yielded

low void fractions

no deleterious secondary phases

expected require less time at lower temperature than conventional diffusion techniques

50 nm+ dia. NiNPs appear to have gone through phase change between 750 and 800 C

Currently evaluating shear strength of joints